Professional Documents

Culture Documents

Exp6 - Remarks & Sources

Uploaded by

Angeline PinonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp6 - Remarks & Sources

Uploaded by

Angeline PinonCopyright:

Available Formats

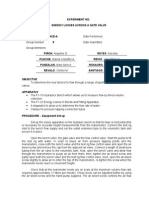

SOURCES OF ERROR

From the time the equipment was set up, a few errors could have

already been made such as not properly calibrating the

equipment and not fully getting rid of the air in the manometers.

Air inside the system may have a great effect on the data

obtained. It was possible that the gate valve was not accurately

adjusted to 75%, 100% and 125% of a turn as desired in the

procedure. Since this experiment, like the previous ones

performed, deals with obtaining the flow rate, a minor source of

error is the inaccuracy in measuring the time. Human and

parallax errors could also have been encountered while taking the

volume readings.

REMARKS

Energy losses in pipe flows are the result of friction between the

fluid and the pipe walls and internal friction between fluid

particles. Minor (secondary) head losses occur at any location in a

pipe system where streamlines are not straight, such as at pipe

junctions, bends, valves, contractions, expansions, and reservoir

inlets and outlets. In this experiment, a minor head loss through a

pipe section that has a gate valve was measured. On opening the

gate valve, the flow path is enlarged in proportion with respect to

the percent of the opening. When fully open, the typical gate

valve has no obstruction in the flow path, resulting in very low or

even negligible friction loss. Moreover, a gate valve was used in

performing this experiment and a pressure gage to measure the

difference in heads. As there were two different types of valves, a

gate valve and a globe valve, the group suggests that future

experiments may involve other types of valves so respective loss

coefficients can be compared as to which type is more efficient to

use in certain circumstances.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Materials Engineer Examination No.5Document14 pagesMaterials Engineer Examination No.5Kulyt G. Bolanio67% (6)

- Personal data collection formDocument1 pagePersonal data collection formRuel Ferreras ReyesNo ratings yet

- Materials Engineer REVIEWERDocument27 pagesMaterials Engineer REVIEWERrekcah eht94% (110)

- 5th Year Ist Sem SchedDocument9 pages5th Year Ist Sem SchedAngeline PinonNo ratings yet

- Logo ScratchDocument2 pagesLogo ScratchAngeline PinonNo ratings yet

- Diamond Grinding of PavementDocument6 pagesDiamond Grinding of PavementAngeline PinonNo ratings yet

- Experiment No.6Document2 pagesExperiment No.6Angeline PinonNo ratings yet

- Soil Mech II - Plate No. 4Document8 pagesSoil Mech II - Plate No. 4Angeline PinonNo ratings yet

- Ojt ExperienceDocument20 pagesOjt ExperienceAngeline PinonNo ratings yet

- Exp6 - Data and Results (Gate)Document1 pageExp6 - Data and Results (Gate)Angeline PinonNo ratings yet

- Postlab Report - Exp No. 6Document5 pagesPostlab Report - Exp No. 6Angeline PinonNo ratings yet

- EXP6 - Computations Factor For Gate ValvesDocument2 pagesEXP6 - Computations Factor For Gate ValvesAngeline PinonNo ratings yet

- 6Document40 pages6Angeline PinonNo ratings yet

- Materials EngineerDocument6 pagesMaterials EngineerAbu Aaqilah AmpasoNo ratings yet

- Back CoverDocument1 pageBack CoverAngeline PinonNo ratings yet

- ME ReviewerDocument16 pagesME ReviewerNil DGNo ratings yet

- 511 (Front)Document1 page511 (Front)Angeline PinonNo ratings yet