Professional Documents

Culture Documents

Bitumen Is Coad

Bitumen Is Coad

Uploaded by

End End0 ratings0% found this document useful (0 votes)

7 views13 pagesasphalt

Original Title

Bitumen is Coad

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentasphalt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views13 pagesBitumen Is Coad

Bitumen Is Coad

Uploaded by

End Endasphalt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

we

ad

1S: 1205-1978

Indian Standard

METHODS FOR TESTING

TAR AND BITUMINOUS MATERIALS:

DETERMINATION OF SOFTENING POINT

( First Revision )

1. SCOPE

LA This standard covers the method for the determination of softening

point of asphaltic bitumen and fuxcd native asphalt, road tar, coal tar

piteh and blown type bitumen.

2. TERMINOLOGY

is standard, the following definition and those

2,0 For the purpose of

i) apply.

given in 18 :334-1965*

2.1 Softening

particular degr

it — ‘Tlic temperature at which the substance attains &

2 of softening under specified conilition of tess,

3. APPARATUS

3. Ring and Ball Apparatus —A =

illustrated in Fig. |

form of apparatus ix

BAL Sted Balls — two; cach 95 mm fiameter and weighing

350 +005 g.

3.1.2 Brass Rinys — twe

shall conform to the follo’

the rings shall be tapered { see Fig, 2) and

dimensions:

Depth 4 £01 mm

Inside diameter at bottom Olmm

Inside diameter at top OL mm

Outside diameter Olmm

*Glomary of terms relating to bituiiea aad tr (resiued).

33

TS: 1205-1978

Fig 1 ASEMMLY oF Apparatus FoR DETERMINATION OF

‘Sortesrxo Post ( Rung axp Batt —Two Ruxos)

For convenience iA mauriting the ngs in a support of the type shown

in Fig. 1 10 4 the ouside diameter of the ring at the Bortam may be

smaller, but shall be not less than 19:0 mm.

31.3 Bell Guide — A convenient form of ball centering guide, 4 recom

mended form of ball guide is illustrated in Fig. 3.

BAA Support — 4

ed the following con

4s) The sings shall be supporied in a horizuntal position with the upper

The one The rings 30 mm below the surface of the bath liquid.

bb) There shall be a distance of exactly 25, mm between the bottom

dtehe rings and the fop susface of the bustom plate of the support,

if any, or the bottom of the bath.

means of supporting the rings may be used provid

ions are observed:

3+

i

1S: 1205 - 1978

new Ommetta 1 BL

SUCHTLT (APPROX O-De=)

Lag Gka Than 95 TO

ALLOW PLACING AMD

CEM TERMe 9-8 STEEL MALL

ed waLe HTH bk BLOESS

FOR MOLOIMG 8ING

LQuALLY seaceD

A mOLeS permet

we

wsttow KL

20-1204 —+

All dimensions in millimetres. ‘All dimensions in millimetres.

Fro, 2 Tarerep Ruxo Fio. 3 Batt Cuntensee Gute

All dimensions in millimetres.

Fis. 4 Runc Hower

@) The thermometer shall be suspended so thar the bottom of the

bulb ie level with the bomem of the rings, and within 10 mm of

the rings, but not souching them.

3.1.5 Thermometer Tc shall be of the mercurysineglass type, nitroges

filed, with the stem made of lead glcss or other suitable glass. It shall ‘be

engraved and enamelled at the bach and provided with an expansion

one ver and glass ring atthe top. The bulb aball be cylindrical, made of

38

ES; 1205 - 1978.

suitable thermonietrie glass, The dimensions. colerances and graduations

of the thermometer shall be as follows!

Range

Graduation at cach

Longer lines at each

Figured at cach

Immenion, mm

Overall length

Length of graduated

portion

Length of bulb, Mas

Stem diameter

Distance from bottom of

bulb to 0°G

Seale error, Max

3.1.6 Bath — a heat resists

1190 mm in depth

3.4.7 Stirer — manual oF mechanical, which 0}

per:

operation.

4, PROCEDURE

4.1 Prey

TS Sieve 30 (see 1S; 460-

temperature approximating to

ich has been coated wi

plate w

ce glass ves:

he bath

when testing material

Gnd pure glycerine for materials having so}

that of th

th a mixture of cqual parts 0

Low

Temperature

=PC 1 80°C

oC

rG

“Co

‘Total

378 10 384 mm

243 to 279 mm

Sto I+

Not larger than

stem diameter

6070 mm

73 to 0 nm

+o

tion of Test Sample — Heat the materi

bebween 73°C and 100°C abpee its soitening point, stir

Bond and free from air bubbles and water, and filter, if necesiary,

). Place the rings, previously heated to a

es

‘*Speeification for test sieves ( revit)

%

High

Temperature

30 to 200°C

o-5tG

re

s*G

Total

378 to 384 mm

243 to 279 mm

$to 4mm

Not larger than

stem diameter

7510 90 mm

203°C

sel not less than $5 mm in diame-

quid shall be freshly boiled wich

ly having softeniag points below

fening points above 60°C.

ates smoothly to ensure

uniform heat distribution at all ames throughout the bath. The stirrers

shall be so placed that the moulds are not disturbed when the stirrer is in

¢ molten material, on a metal

{glycerine and

alto a temperature

ntl it is completely

through

1811205 - 1978

the level oi

dextrine, ith sufficient melt to give an excess abo

the rug when ennled, Aller cooling for 30 minutes in a

oat ee. ang by femoving the excess with a warmed, sharp knife.

4.2. Materials of Softening Point Below 80°C — Assemble the appararus

sa the fing thermometer and ball guides in position, and All the bath

Te eight ef 50 mm above the upper surface «f the ring! with freshly

boiled distilled water at a temperature of Maintain the bath at a

temperature of 5°C for 15 minutes alter which place 9 ball, previously

ee ys temperature of °C; by means of forceps in each ball guide.

Apply heat to the hath and stir the liquid sn thar the teinperaiure rites at

a runtlorm rate af SO + OSC per minute uncil

seas the ball a paw through the ting. The rate of tem

aw te averaged over the: pericd of te test, and any test in which the

sia temperature rise does not fall within the specified [imits after the

rate oe ae cknutes shall be rejected, Make the determination in duplicate,

4.3 Materials of Softening Point Above 80°C — The procedure for

to cerials, of softening point above 80°C is similar to. thas described

rieitr 4.2 with the differcnce that glycerine is wed in, place of water

wreet oth and the ssarting temperature of the teat is 33°C. Make the

determination in duplicate.

5, REPORT

$5.1 Record for enc ring and ball, the temperarure shown by the thermo”

or grat the instant the sample surrounding the ball touches the Bortose

plate of the suppor, if any, oF the bottom of the bath.

§.2 Rept to the nearest 03°C the nican uf she semperature recorded. in

duplicate determisations, without correctinn for the emergent stem of she

thermometer, as the softeuing point.

6. PRECISION

mean ly mere than the

Gd Test results shall not differ from th

following?

Softening Point Repeatability Repradueibility

es “2 “c

40 to 60 1-0

6lte 8D rs

81 to 100 20

101 to 120 25

121 to 140 30

37

TS: 1205 - 1978

7. PREGAUTIONS

Tal Only freshly boiled distilled water shall be used ia the test, as other

wise air bubbles may focm on the specimen and affect the accuracy of the

results

7.2 The prescribed rate of heating shall be rigidly adhered to for ensuring

accuracy of remults.

73 A shect of filter paper or thin amalgamated sheet, placed on the

hattom of the glass vesel and conveniently weighed would prevent the

material from sticking to the glass vessel, and considerable time and trouble

in cleaning would thereby be saved.

a =

38

_—

18: 1206 ( Part I) - 1°78

Indian Standard 7

METHODS FOR TESTING

TAR AND BITUMINOUS MATERIALS:

DETERMINATION OF VISCOSITY

PART | INDUSTRIAL VISCOSITY

( First Revision )

1, SCOPE

Ll This standard ( Part I) covers the methods for the determination of

viscosity of road tar and cutback bitumens.

2. TERMINOLOGY

2.0 For the purpose of this standard, the following definition and those

given in 1S: 334-1965° shall apply.

2:1 Industrial Viseosity—The property of a fluid by which it resists

few due to internal (eiction, and one of the methods by which it is

ow red, ie by determining the time taken by $0 ce uf the material to

Menem a. cup throuch a specified otifice under standard conditions of

teat and at specified temperature.

3. METHOD A (-VISCOMETER FITTED WITH 10-mm CUP

FOR ROAD TAR)

3.1 Apparatus

3,1 Tar Plscomster — consists cxsencially of a cup having a specificd

ormer and valve: a water bath mounted un three legs having a tuitable

orifice orthe cup, 2 stirrer, a shicld and a receiver (se Fig. L)- The

Iillowing is the detailed description of the different parts and accessorics

of tar viscometer?

a) Cup — known as the 10-mm cup, is conscructed of hard brass tube

fake dimensions shown in Fig. 2 and fitted with an external brass

Collar at the upper (open) end uf the cylinder to support the

ee

Glossary of terms relating to bitumen and tar [ recued

39

ee

1S: 1206 ( Part 1) - 1978

AaLyE SUPPORTED:

Dy MUP POSTION

eo Manout

Fig. 1 Tas VscomeTeR

1811206 ( Part I) - 1978

zi fe

SCREWED +65 PITCH PHOSPHOR BRONTE

i _

vowel METAL

nop

SCREWED

+6 PITCH

fo 5.900028

PA 35

ig

CpMOsPHOR BRONTE

GO/IO CAST

SeosP4OR BRONTE

SPHERE 12:70 7-05 OA

All dimensions in millimetres

Fro. 2 l0smm Tar Cup anp Vau'

pin the aleve of the water bath. The bosom he cup consi

cee arealar phosphar-branae piste served nto the cylinder and

wade conical ti facilitate drainage ar after use. [t

provided centrally with 9 perfectly guindrical. ph?

of

PooTIO cast ) extension of the dimensions firs” inky 2. The

citension is drilled and polished 3 Wemm

olan orifive. “The upper im of 2 perfectly

gular in order t provide a seating for

‘The dimensions of orifice and jet shall be as &

Diameter of the orifice 10000 = 0025 =m

Length of the jet 5-000 = 0025 mat

41

811206 ( Part I) - 1978

b)

a)

e)

3}

hb

Carved shieid — tied to the UPR EE

Valve —shall be of dimensions shown in Fig. 2- Tt serves to close

the orice of the 10-mm cup and is a phosphor-bronze sphere

the Grad ta a mohel metal rod. The rod is provided with a

igvelling peg and at the upper end a hemisphero by whieh the

waive is held in the valve support.

Water batk — made of copper sheet, it cylindrical in shape, about

Veo gum in diameter and 108 mm in depth. It may be heated

Ue nieally, care being taken that local heating ig avoided.

The water bath is mounted on three equidistant legs which

arg riveted to the exlindrical wall of the bat! and are of sufficient

feagth to permit a 100-ml cylinder co be placed below the orifice

of the cup.

Steese — to receive the cup and to bold it in position with an

Sex Tang ft. Tt va stout brass tube, 105 mm in height

se] 42 mm internal diameter, which is bronzed of soldered into

and fal hole cut in the bottom of the bath.

“tirer — consists of four vertical vanes, with the upper and lower

etions turned im oppesite directions, mounted on a cylinder

Pehich lips on the sleeve with an easy, sliding fit. The cylinder is

wr peay between the vanes to, facilitate reat transfer from the

water in the bath to the tar cups vertical grooves are provided on

he inner surface of the cylinder to prevent the water in the bath

from being carried into the tar cup, if the stirring system be

raised.

ec ofthe cylindet and extends

Cer ihin about 5 mam of she walls of the Natct bath. ‘This shield

te ean insulated handle for rotaring the stirrer, a support for

405 5 pereent 10 percent of the

uf the mean

mean

45

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AsphaltDocument182 pagesAsphaltEnd EndNo ratings yet

- Flexible Pavement Design ToolDocument13 pagesFlexible Pavement Design ToolRolando LópezNo ratings yet

- RIDOT Highway Design ManualDocument104 pagesRIDOT Highway Design ManualEnd EndNo ratings yet

- 1 (Varaha) (Suh)Document7 pages1 (Varaha) (Suh)End EndNo ratings yet

- FloodDocument5 pagesFloodEnd End100% (1)

- Bentley MicroStation CONNECT Edition v10 00 00 25 x64 Torrent - Kickass TorrentsDocument4 pagesBentley MicroStation CONNECT Edition v10 00 00 25 x64 Torrent - Kickass TorrentsEnd End0% (3)

- BS 598 104 1989 PDFDocument18 pagesBS 598 104 1989 PDFEnd EndNo ratings yet

- DBMDocument29 pagesDBMEnd EndNo ratings yet

- Performance Evaluation of Polymer Modified Asphalt MixDocument39 pagesPerformance Evaluation of Polymer Modified Asphalt MixEnd End100% (1)

- BLENDING of MSS Mix Design TypeDocument3 pagesBLENDING of MSS Mix Design TypeEnd EndNo ratings yet

- BitumenDocument35 pagesBitumenamanbhu1991100% (5)

- Quality Audit - Check Sheet - Carriage WorkshopDocument24 pagesQuality Audit - Check Sheet - Carriage WorkshopEnd End100% (1)

- (CRMB) 60 Bitumen Test Results Nov 10Document26 pages(CRMB) 60 Bitumen Test Results Nov 10End EndNo ratings yet

- Test Method OthersDocument15 pagesTest Method OthersEnd End100% (1)

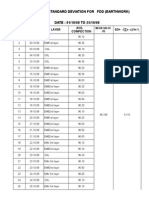

- SD of HighwayDocument8 pagesSD of HighwayEnd EndNo ratings yet

- Calibration of Rapid Moisture Meter No. R-1Document20 pagesCalibration of Rapid Moisture Meter No. R-1End EndNo ratings yet

- Material Specific Gravity Weight (KG) Volume (Cum) : Age Date of Testing Weight Load Strength Average RemarksDocument8 pagesMaterial Specific Gravity Weight (KG) Volume (Cum) : Age Date of Testing Weight Load Strength Average RemarksEnd EndNo ratings yet

- Upgradation of Gurgaon - Faridabad & Ballabgarh - Sohna Roads On BOT BasisDocument2 pagesUpgradation of Gurgaon - Faridabad & Ballabgarh - Sohna Roads On BOT BasisEnd EndNo ratings yet

- StripDocument666 pagesStripEnd EndNo ratings yet

- CBR - 3 - EnergyDocument187 pagesCBR - 3 - EnergyEnd End100% (1)

- WMM Mix DesignDocument23 pagesWMM Mix DesignEnd EndNo ratings yet

- Bituminous MacadamDocument3 pagesBituminous MacadamEnd EndNo ratings yet

- Summary of Concrete Mix Design With Ultratech Cement Opc-53Document6 pagesSummary of Concrete Mix Design With Ultratech Cement Opc-53End EndNo ratings yet

- FNL SRNMP Vol 2 Uppwd r2Document271 pagesFNL SRNMP Vol 2 Uppwd r2End EndNo ratings yet