Professional Documents

Culture Documents

Oee 4

Uploaded by

hasan_waqar2004Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oee 4

Uploaded by

hasan_waqar2004Copyright:

Available Formats

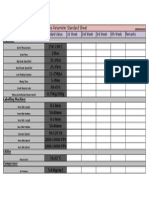

Operating pattern

and machine data:

Process 1

A.

Shifts/day

B.

Hours/shift

C.

Minutes/shift

D.

Planned downtime: lunch,breaks (minutes/shift)

Note: If tag

2

10

=B x 60

600

45

relief is used, enter 0

E.

Total planned production time/shift (minutes)

=C - D

555

F.

Total planned production time/day (minutes)

=A x E

1110

G.

Days/week

H.

Total planned production time/week (minutes)

=F x G

5550

Actual production

run data:

Process 1

I.

Total minutes run

5550

J.

Total breakdown time + changeover and setup time

(minutes)

400

K.

Total number of parts made (good + bad)

45985

L.

Total good parts (first time through only- do not

include parts that were

44345

re-processed or reworked)

M.

Total bad parts

=K - L

1640

N.

Actual cycle time (sec/part)

=((I - J)*60) / K

6.72

Other data:

Process 1

O.

Planned cycle time-the one used for capacity

planning (seconds/part)

P.

Average time per changeover (minutes)

Q.

Average changeovers per shift

R.

Average downtime: changeover time/shift (minutes)

S.

Average downtime: (breakdown time+time for minor

setups and

0

=P x Q

0

40

adjustments)/shift (minutes)

T.

Total projected unplanned downtime/day (minutes)

= (R + S) x A

OEE

calculation

80

Process 1

U.

Equipment Availability:

=(F-T)/F

92.79%

V.

Performance Efficiency

=O / N

74.41%

W.

Quality Rate:

=L / K

96.43%

X.

OEE:

=U x V x W

66.58%

Y.

Planned uptime (hours/day)

= F/60

Z.

Planned uptime (days/week)

=G

AA.

Planned rate of production (parts/minute)

= 60/O

12

AB.

Theoretical production capacity per day

= Y x 60 x AA

Capacity analysis

Process 1

18.50

13320

AC.

Theoretical production capacity per week

= AB x Z

66600

AD.

Weekly Demand

From 830

Release

44200

AE.

Weekly Facilitized Volume

From

Purchasing

45000

AF.

Weekly Parts Available for Shipment

= AC x X

AG.

Daily Demand (Actual-830)

= AD/Z

8840.00

AH.

Daily Demand (Facilitized)

= AE/Z

9000

AI.

Daily Parts Available for Shipment

= AB x X

AJ.

Percent above/below DPV

= (AI-AH)/AH

-1.46%

AK.

Percent above/below Facilitized Volume

= (AG-AF)/AF

-80.07%

AL.

Percent above/below DPV for bottleneck operation

(Minimum value of AJ)

0.33%

AM.

Percent above/below facilitized DPV for bottleneck

operation (Minimum value of AK)

-1.46%

44345

8869

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Cyclic Schedules Powers-Of-Two Policies: 4 Coordinated ReplenishmentsDocument108 pagesCyclic Schedules Powers-Of-Two Policies: 4 Coordinated Replenishmentshasan_waqar2004No ratings yet

- Case StudyDocument10 pagesCase Studyhasan_waqar2004No ratings yet

- Decision Year: Age Revenue (R) Cost (C) Salvage (S)Document1 pageDecision Year: Age Revenue (R) Cost (C) Salvage (S)hasan_waqar2004No ratings yet

- KelloggsDocument4 pagesKelloggshasan_waqar2004No ratings yet

- Simplex MethodDocument16 pagesSimplex MethodShantanu Dutta100% (1)

- Overall Equipment EffectivenessDocument32 pagesOverall Equipment Effectivenesshasan_waqar2004No ratings yet

- Machine Parameter Standard Sheet: Equipments Standard Value 1st Week 2nd Week 3rd Week 4th Week RemarksDocument1 pageMachine Parameter Standard Sheet: Equipments Standard Value 1st Week 2nd Week 3rd Week 4th Week Remarkshasan_waqar2004No ratings yet

- 6s AuditchecklistDocument14 pages6s Auditchecklisthasan_waqar20040% (1)

- 6S Audit FormDocument5 pages6S Audit Formhasan_waqar2004No ratings yet

- Outline of Feasibility ReportDocument1 pageOutline of Feasibility Reporthasan_waqar2004No ratings yet

- Calculating Oee Worksheet: Line / Cell: Process: Machine: DateDocument2 pagesCalculating Oee Worksheet: Line / Cell: Process: Machine: Datehasan_waqar2004No ratings yet

- Yamazumi FHcom Kaizen FormsDocument14 pagesYamazumi FHcom Kaizen Formshasan_waqar2004No ratings yet

- Extraction of Iron: Designed byDocument30 pagesExtraction of Iron: Designed byAlpesh PanchalNo ratings yet

- Improve Your Writing skill-IELTSDocument21 pagesImprove Your Writing skill-IELTSfgousiosNo ratings yet

- Total Productive Maintenance WorksheetDocument2 pagesTotal Productive Maintenance Worksheethasan_waqar2004No ratings yet

- A White Paper On The Benefits of Utilizing OEE in A Job ShopDocument6 pagesA White Paper On The Benefits of Utilizing OEE in A Job Shophasan_waqar2004No ratings yet

- Receding Head Sheet Type Auto Cutting Machine: Cutting Force Cutting Speed Up Speed Down SpeedDocument1 pageReceding Head Sheet Type Auto Cutting Machine: Cutting Force Cutting Speed Up Speed Down Speedhasan_waqar2004No ratings yet

- Level 5 LeadershipDocument15 pagesLevel 5 Leadershiphasan_waqar2004No ratings yet

- CNC Report1Document55 pagesCNC Report1coolguy02088775% (4)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)