Professional Documents

Culture Documents

Hondara168eengine Paper Sae

Hondara168eengine Paper Sae

Uploaded by

Diego Drumond0 ratings0% found this document useful (0 votes)

137 views10 pagespapper sae

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpapper sae

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

137 views10 pagesHondara168eengine Paper Sae

Hondara168eengine Paper Sae

Uploaded by

Diego Drumondpapper sae

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

For Advancing Mobility

Land Sea Air and Space, 400 commonweattH ORIVE WARRENDALE, PA 15096

a A Ez The Engineering Society

SAE Technical

Paper Series

890877

Honda Formula One Turbo-charged

V-6 1.5L Engine

Yutaka Otobe, Osamu Goto, Hideyo Miyano, Michio Kawamoto

Akio Aoki and Tohru Ogawa

Honda R&D Co. Lid

International Congress

and Exposition

Detroit, Michigan

February 27-March 3, 1989

Ww 3A

‘The appearance of the code at the bottom of the first page of this paper indicates

‘SAE's consent that copies of the paper may be made for persone! orinteine! use, o¢

{or the personal or intexnal use of speciic cients. This consent is given on the com:

dition. however, that the copier pay the stated per article copy tee rough the

Copyright Clearance Center, Inc, Operations Center, P.O. Bor 765, Schenectady,

N.Y. 12301, for copying beyond that permitted by Sections 107 or 108 of the US

Copyright Law. This consent doos not extend t0 other kinds of copying such as

copying for general distribution, for advertising or promotional purposes, for

ereating new collective works, oF for resale.

Papers published prior to 1978 may also be copied at a per paper fee of $250

Under the above stated conditions

‘SAE routinely stocks printed papers for a period of three years folloning date of

publication Direct your orders to SAE Order Gepartment

To obtain quantity reprint rates. permission to reprint a technical paver or per-

mmission to use copyrighled SAE publications in ciher works, contact the SAE

Publications Division.

No part of this publication may be reproduced in any form, in

an electronic retrieval system or utherwise. without the prior

written permission of the publisher

{SSN 0148-7191

Copyrignt © 1989 Society of Automotive Engineers.inc.

Positions ang opinions advanced n this papar are those of

the author(s) and nat necessary those of SAE. The

's solely responsible for the content ofthe paper. A

“ussions will be printed

ape ifit is published in SAE Transactions, For permiasion

{fo publish this paper in ful or in part, contact the SAE

Publications Division.

Persons wishing 10 submit papers to be considered for

resentation or publication threugh SAE should send the

‘manuscript ora 300 word abstract of # proposed manus.

‘rpt to: Secretary, Engineering Activity Boars, SAE”

Printed in USA,

890877

Honda Formula One Turbo-charged

V-6 1.5L Engine

Yutaka Otobe, Osamu Goto, Hideyo Miyano, Michio Kawamoto

Akio AokI and Tohru Ogawa

Honda R&D Co.

ABSTRACT

‘The "RAL6BE", a curbo-charged V-6 1.5-Liter

engine, vas developed by Honda Motor Co., Led.

for the 1988 Formula One Championship Race

Despite boost restrictions (2.5bar), the

engine boasts @ maximum power of 504 kw (685

ps), which ts equivalent to 136 ku/t (457 ps/ 2)

The’ development of improvenents on the fuel

consumption of this engine allowed the

achtevezent of a sinimum brake specific fuel

consumption of 272 g/kwh (200 g/Psh).

‘This paper introduces major specifications,

along vith power output and fuel consumption

characteristics of the RAI68E racing engine.

In addition, the effects of intake air tempera

ture, boost, atr-fuel ratio, fuel cemperature

and ‘fuel ingredients on fuel efficiency and

Power output are presented

SINCE 1983, HONDA has been supplying leading

Formula One racing teams with dual turbo-charged

Vos L.S-liter engine. Although the engines were

all identical in overall configuration, they

were modified each year as the regulations were

revised; therefore, respective engine code names

were used for each aodification, ag shown in

Table 1

Honda engines have won 40 Grand Prixs in

the last five years. As a result of these

victories, | Honda has been awarded the

Constructac's Championship for the last three

consecutive years. In accordance with the new

regulations, beginning in 1989 only naturally-

aspirated 315-Liter engines will be alloved, and

curbo-charged 1.5-liter engines are eliminated

from participating in the Grand Prix races.

Stricter fuel restrictions have | been

gradually adopted, as shown in Table 1. In

1988, the restriction became particularly

noticeable, with the boost limit being lowered

to 2.5 ber and the maximum fuel capacity being.

restricted co 150 liters for the turbo-charged

cars. Fuel restrictions lead to a reduction in

total energy avatlable diring a race: therefore,

indirectly limiting the maxium power of the

engines, This descrip:ion characterizes the

1988 Grand Prix racing season.

Honda's 1988 engine, the RAISE, was

developed to simultaneously’ realize higher pover

and better fuel efficiency. The highest

possible achlevesent of these two conflicting

objectives resulted in an unprecedented 15

victories in 16 events in the 1968 World

Championship races.

Few research papers have mentioned high-

speed, high-boost engines(1-3)*; and there has

been no research reported concerning the fuel

effictency of those engines. This paper in-

troduces the major specifications and power

characteristics, and presents study results

relating co the fuel efficiency of the RAL6BE.

RALGSE ENGINE SPECIFICATIONS

A highly rigid and compact cylinder block

and bearing caps are cast: from strong and stiff

ductile cast fron. For reducing its wetght,

cylinder block thicknesses range between 293.5

mm, vhich also satisfies stiffness requirenents.

Aluminum alloy (Al-Siscus) was adopted as the

saterial for the cylinder head, while almost all

remaining parts being cast from magnesia alloy

(e.g., otl-sump and heid cover). All this

resulted in a compact, light-weight engine: only

146 kg fully-dressed ‘with all equipment. | This

Light-weight coupled vith excellent power

characteristics and relia>ility, made the RAISE

Table 1 Restrictions on turbo-charged cars

and reapective angine code names

Year 1985 1986 1987 1988

Boost pressure(ber abs) — | — 40.

Fuel Capacity(@) 220 195 195 150 |

Enghe code name RAI6EE RMESE ANE7E RAIEBE

-Rumbar Ih BATEMIRESES designate references at end of paper,

0148-7191/89/0227-0877$02.50

Copyright 1989 Society of Automotive Engineers, Inc.

2 890877

2 Aighly competitive engine. The major engine 9-4 to realize high rover output and good fuel

specifications are given in Table 2, Figures | efficiency.

and 2 show the ercss section and the external The cans! re driven by the crankshaft

appearance of the RALGSE, respectively, via two idler gears. The valve operating

The RAL6SE feacures a stroke Of 30.8 mm and wechanism, using rocksr arns, allows high-load

of 79 ma, (a stroke-bore ratio of 0.643), valve springs in the Limited space between che

Providing it with somewhat of a longer stroke valves. Through using this type of configura-

hen compared with ordinary racing engines, The tion, the reduction in the equivalent inertia

valve angle is relacively narrow (32"), with the weight of the mechanism has improved. the

heads of the pistons set almost flat, This revolution limit to an engine speed of more than

configuration allows a compact combustion 13,500 rpa.

chamber and a fair=y high compression ratio of

Table 2. RALOBE engine specifications

[Engine Coce nam= 168 |

| Layout 80°V6

Bore a) 79

Stroke (mm) 50.8

Displacement (cc) 1494

| Compression Ratio 94

Weignt, (ke) 146

Fuel System HONDA PGM FI

Ignition System HONDA PGM IG(COD]

Sa

Fig. | RAL6BE cross ection

890877

A dry-sump Ibrication system was adopted products of Iehikavajina-Hacima Heavy Industries

for the RAIGBE. | Four independent scavenging Co.,Ltd. (INI). They feature ceramic. tarbine

usps draw ‘the Lubricant through strainers at heel and ball ‘beariagss drastically uperavane

the ‘corners of the oil-sump, and then feed it the translent propertios by reducing the teerele

into an oft tank. With “this layout, the moment and friction of cevelving pasts,

scavenging punps effectively circulate the

lubricanc, which tends to gather in the oll-sunp ENGINE PERFORMANCE

due to longitudinal and taveral Geforces during

acceleration, deceleration and cornering respect POWER OUTPUT AND TORQUE - For comparative

tively’ daca, ue first presen: the performance of our

Application of an appropriate cooling RALG7E engine. "The RALOTE cae cedeetaned cod

system is as important as that of the lubri- Upgraded to che prereqiisives of the 4 tee boore

cation systen for a racing engine. The RAISE restriction." fre aocieue, React we ose

taetae MREAE pumps which supply water Fron each (1910 pa) at 12,000 rye with @ saxiuum torcue

side of the cylinder block. Water galleries are Gf" eu "am (7.7 toca) teen ne ee

located on the outer walls of the cylinder block org ae yet e a nach arg ara ceEsBELES

and the ‘inner walls of the cylinder heads. the folioving operating conditions: (1), Boost

Water travels from the cylinder block galleries, dag a bar. A iportion. of the echauee: gor eae

vassing by the cylinder liners and through the Gaited from the wasie “gute, of the, caause

cylinder Reads, and flows into the cylinder head gantneld. "Turbine speed’ is ‘conteolien ay

galleries. The lateral flow of water through adjusting the opening of the waste gate, this

We engine allows uniform thermal conditions Controlling the boost at 4 bar. (2) Tntake wie

throughout all cylinders. temperature vas 40°C. Hot intake air compressed

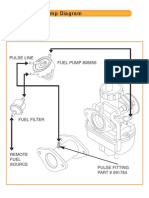

Ye adopted a PGt-FI (Programmed fuel by the turbo-chargecs .# cooled with eir-cooled

Injection Systen), produced in-house, which intercoolers, A portion of the air flowing ato

Sequencially injects fuel into six cylinders. the intercoolers is expelled via by-pass velves

Each cylinder is equipped with exo injectors. A temperature of 40rG 9 maintsined chrough

Whether single- or double-tnjeceion 1s used controlling the valve opening. (3) Equivalence

depends on the amount of fuel required. In ratio was 1.23. (4). Ignition timing was set

addition, the fuel line between the fuel puap at MBT or retarded at the knock Limit, (5)

and the’ injectors has a heat exchanger ‘for Fuel with a toluene ‘content of 86% vas used.

Pre-heating fuel by using water from the cooling As far as this repert 15 concerned, this fuel

syste was generally used during. bench dynanoneter

Dual turbo-chargers, code named “RK6D", are tests and race events (see Table 3)

600) rq woop)

z z

709] 500

400]

2 8

& e é 5

509 00

8 1200 y

g g

220 8 200 8

Sa

200 7 rool |__|,

a7 33 et 678340 W445

ENONE SPEED x10"rom ENONE SPEED <10"rom

Fig. 3 RALOTE power characteristics Fig. 4 RALGBE pover characteristics

Regulations ver? further revised in 1988

restricting the boost limit to 2.5 bar and fuel

tank capacity to 150 liters. In order to

generate higher power output, and improve fuel

efficiency at the same time, the compression

ratio of the RALGSE was increased to 9.4, up

from 7.4 of the RATE. Figure 4 shows the

power characteristics of the RAI6BE, which

produces saximin poser of 506 kw (685. ps) at

12,500 rpm and maxieun toruque of 424 ¥m (43.2

kgla). Running conditions were set ati(1) boost

of 2.5 bar, (2) intake air cenperature of 40°C,

(3) eguivalence ratia of 1.15 and (4) tgnition

timing of MBT or spark retard at the knock

limit, With a rich mixture of the equivalence

ratio. being 1.15 and a low intake air

temperature of 40°C, the engine generates its

saximun power. Houever, the fuel efficiency

Under these conditions was not satisfactory.

under the conditions described above, it

was sometimes obvious that it would” be

fmpossible to compleze an entire race with such

poor fuel efficiency. During a race specified

Tuning conditions were selected to improve fuel

efficiency. Maximus pover conditions vere

realized mainly in qualifying sessions, where

sustained running was not necessary:

fn terns of power par liter, the RAL67E

generated 495 ku/L and the RALGSE produces 336

ke/t. AS Shown in Figure 3, taking boost

csoure {nto consideration, comparison of the

power characteristics shows chat the RAL6SE is

favorable, dve toa higher compression ratio and

lower’ friceion,

CHLINDER PRESSURE DIAGRAM ANALYSIS - The

RALOBE generates $04 kw (685 ps) at 12,500 rps.

In the case of high-speed, Righ-boost engines,

combustion often becomes unstable; in the worst

890877

which constantly generate high power

Concerning the RAL68E, we increased the

compression ratio, and nodified the intake port

configuration and the fuel injection system in

order to stabilize combustion.

There have been fev studies concerning

cycle variations in a high-speed, high-boost

engine. The cycle variation was analyzed by

measuring cylinder pressure during maxinum power

generation.

A pressure transducer (product of Kistler)

connected to a charge amplifier was used to

measure the cylinder pressure. Samples vere

taken at each crank angie degree. A combustion

analyzer (product of Ono Sokki) was adopced for

the analysis.

Figure 6 is an averaged pressure diagram

of 500 consecutive cylinder pressure measure~

ments under the conditions of 12,500 rpm, boost

of 2.5 bar, intake air temperature of 40°C,

equivalence ratio of 115 and ignition timing

of 35° 8.T.0.c.

‘The waxinum combustion pressure was 16.7

ma, crank angle at which maximum pressure

produced was 17° A.T.D.C., and indicated mean

effective pressure (IME.P.), was 3.8 MPa

Figure 7 shows the frequency distribution

of I.ME.P. indicating chat the standard devia~

tion wae 0,20 MPa agairst the average value of

L.M.E.P, of 3.8 MPa, which revealed that fairly

stable combustion was achieved.

Purl eRFICLENCY

The main objectives when developing the

RAL6BE to consune less fuel during a race were

to improve fuel consusp:ton characteristics and

the development of high energy fuel (heavy

fase. leading to istiring. This could pose specific weight fuel)

SPehoton when atcompeing to sasufaccure engines ‘The ‘throtele opening distribution during

20

g

=

- 445

700|

& w

2 5

& 600 B 10

3 £

2 500 ]

2

$ 5

400]

300)

1B 20 85 30 35 40 45 30 780 B75 Bo

00ST PRESSURE bar CRANK ANGLE deg

Fig. 5 Maximum power of RALGSE and RAL6TE

related to boost pressure

Fig. 6 Cylinder pressure diagram of RAIGSE

under condit.on of maximum pover

generation

890877

a race is shown in Figure 8 (1988 San Marino GP,

with driver Alain Prost), Since it was re:

Vealed thet full-throtele and closed-throttle

dominate the throttle conditions during a race,

we concentrated on improving the fuel consump

tion at full-chrotele.

Figure 9 shows the RAL6SE performance when

the aajor factors were set to minimize fuel

consumption, indicating that minimum brake

specific fuel consunption (B-S.F.C.) 43 272

yk (200 g/psh) at 12,000 rpm, and maxieun

Power is 456 kw (620 ps) at 12,500 rpm. The

operating factors of this condition are @ boost

of 2.5 bar, intake air temperature of 70°C,

equivalence ratio of 1.02 and fuel temperature

of 80°C

concerning

straight stretches,

circuits used for GP racing,

number and type of corners

20

FREQUENCY

é

MPe

INDICATED MEAN EFFECTIVE PRESSURE

1g. 7 LMLE.P, frequency distribution

78)

R

50

a]

s |

g be

g 0

25 8)

D

f

be |

is |

oi

= =

0 20° 40 " 60” 80 "100%

Close <——— THROTTLE. ——> PEN

Fig. @ Throttle opening distribution

during a race event

(88 San Marino GP)

and overall racing distances sre not always the

same. Thus, even if the engine's operating

conditions remain the same, fuel consumption

(in/2) differs.

When favorable fuel consumption wi

observed at sone circus! richer mixture setting

and reduction in intake air temperature were

Possible. Though these conditions worsen

B.S.F.C. of the engine itself, they can be

selected as operating fa:tors to generate higher

power.

EFFECT OF INTAKE AIR TEMPERATURE - The

intercooler system makes it possible to cool the

intake air down to a temperature which is only

Isc higher than that of ambient air. This

is achieved by closing the by-pass vaives and

dixecting all the air through intercoolers. As

the intake air temperature increases, B.S-F.C.

becomes better (see Fig. 10). After the intake

air temperature exceeds 70°C, B.S.P.C, improve

ment tends to become sacurated. Despite rela

tively bad volatility of the fuel used, a rise

in the intake air temperature promotes,

vaporization. This B.S.F.C, improvement might

be attributed to the wel” vaporized fuel,

Mowever, as the temperature increases,

there is a tendency to generate knocking, and

the ignition timing must be retarded to avoid

Ae. “When the timing is retarded further from

M.B.T., the results have an undesirable effece

on B.S-F.C.

EFFECT OF BOOST PRESSURE - Higher boost has

good effects on both fover and B.S.F.C., as

shown in Fig. Il. Ona of the prominent reasons

4s that, in proportion to the rise in boost,

charging efficiency ircreases and provides

higher indicated horse pover while the engine’

mechanical loss rerains almost the same,

resulting in an improvement of brake. theraai

efficiency.

7 i 7

owen

340

320 &

¢g

soo §

Sree oe ee

ENGNE SPEED x1 Dm

Pig. 9 RAL6SE performance at mininum fuel

consumption

5

Power

°

Fis

30

10

ao 6060708090

INTACE AIR TEMPERATURE =“

Effect of intake air venperature

on power and B.S.F.C.

390877

EFFECT OF AIR FUEL RATIO - Regarding air

fuel ratio, peak power is reached at an

equivalence ratio of 1.15, and power gradually

decreases as the ratic falls below this figure

The leaner the mixture becoues, the better the

B.S.P.C., a8 shown in Fig. 12. However, with

a ‘ratio lover than 1,02, unsatisfactory

transient response may appear, thus soking the

engine becone insufficient. for racing per=

formance.

EFFECT OF PRE-MEATING FUEL ~ B,S.P.C. is

improved through promotion of vaporization with

higher intake air temperature. The sane effect

can be achieved using pre-heated fuel (1.e.,

fuel heated before in:ection). As the distii~

lation characteristics shown tn Table 3 reveal,

the racing fuel for the FALSE is not easily

vaporized at the anblent temperature because it

does not contain low toiling-point ingredients.

For thie reason, the RAL68E was equipped with

2 heat exchanger capable of pre-heating fuel

using the water fron the cooling system. After

being fed by the fuel puap and chen heated, it

is distributed to the injectors. It is possible

to heat the fuel co a temperature 15°C below

that of the water.

43, _ 7

+9]

%

+aH

+2}

POWER

a

Bi 22 23 24 25 26

OOST PRESSURE bar

kffect of boost pressure on power

and B,S.F.C.

OSs 068 102 708 110 11a 148 120

EQUIVALENCE RATIO

Fig. 12 Effect of equivalence ratio on power

and 8.3.F.0

890877

The amount of water which flows into che

exchanger is controlled by @ solenoid valve

which maintains the cesired fuel cenperature.

Figure 13 shows the effect of fuel tempera

tures on the fuel efficiency. It is. act

knowledged that, although the effect is not

Significant, the fuel consumption is reduced as

the fuel temperature rises.

A combination of operating factors to

achieve the best B.3.F.C., while maintaining

Satisfactory performance, is an intake alt

temperature of 70°C, a boost of 2.5 bar, an

equivalence ratio of 1.02 and fuel temperature

of 80°C. With this combination, B.S.F.C. 18 272

g/kesh (200 g/psh) at 12,000 rpm.

EFFECT OF TOLUENE CONTENT - The octane

number of fuel for Formula One racing is limited

to 4 saxicum of RON 102. Adopting a higher con-

pression ratio 1s expected to improve both power

and 3.5.F.C. However, at the sane time, the

possibility of knocking becones higher. There

fore, the knocking properties of fuels determine

naxituz compression ratio. It sometimes ap-

pears chat differences in fuel ingredients

effect knocking properties, even though the RON

of the fuels ts the same. The davelopaent of

a fuel with good knocking properties under high

speed and boost conditions 1s essential for

adopting @ high compression ratio.

Tho tank capacity regulation Limits fuel

amount to 150 liters, ané refueling during a

race event is forbidden. In order to obtain a

higher Level of fuel energy for a race, a fuel

largely calorific in capacity is needed (i.e.,

a dense fucl). Comparative evaluation” of

various fucls revealed that a fuel with high

toluene content is most favorable to meet the

Foquirenonts, Knocking properties and effects

on B.S.F.C. of the Cast fuels (see Table 3) are

shown (n Figure Lé

Toluene content rattos were 30%, 60% and

Bez for cach test fucl. Appropriate amounts of

normal heptane and isooctane were respectively

nixed with toluene to achieve a RON of 102. Ag

toluone has a heavier density when compared to

6070 80 S0

FUEL TEMPERATURE =

Fig. 13 Effect of fuel temperature on power

B.S.F.C

7

paraffine fuels, a fuel containing much toluene

has a larger’ calorific value in capacity

(Cal/ec). Whether knocking occurred or not wes

observed through analyzing the output signal cf

charge amplifier connacted to a piezo-electric

pressure transducer fixed in the place of the

spark plug washer. Observations were conducted

under ‘the engine operating conditions of

12,000 rpm, 2.5 bar, intake air temperature of

70°C and an equivalence ratio of 1.15. The

knock-limit {gnition timing advances as the

ratio of toluene increases in the fuel in-

Bredients, resulting in better B.S.F.C. In

addition,” since the test fuels differ in

density, “brake specific volumetric fuel con-

sumption (B.S.V.F-C.)" (ce/kuh) was considered,

and studies revealed that a fuel containing

higher ratio of toluene in the fuel ingredients

proved most effective.

R +f

||

© 40]

o

~4

407) '

oe6 BT.0C

2

&

KNOCK LIMIT IGNITION TIMING

e

&

a5

20) b-—4

o 20 43 60 80 400

TOLUENE CONTENT RATIO %

Fig. 14 Effect of colusne content ratio on

Knock limit ignition timing and fuel

consumption

* 8.5.V.F.C "brake spscific volumetric fuel

consumption” (ee /kwa)

8

Table 3. Test fuel specifications

RAGING)

Aa B FUEL *

Toluene ™ 30 60 84

Fuel cone MHeotene on = AS 1B

ingredient ;

Isooctane» 68 = «30.5 0

Research Octane Number 101.6 101.9 101.8

Motor Octane Number 94.2 91.2 90.0

Density (@t15'C) 0.747 0.799 0.840

Net Calorific Value 19300 100159817

| Stoichiometric Ratio 14.5 14.0 13.7

Reid Vapor Pressure 9.154 0.141 0.120

‘astm

Initial Boling Point) 96.0 98.5 100.0

10% > 97.5 100.5 105.0

50% =) 98.8 102.0 108.0

30% 100.0 105.0 108.0

End Point 123.5 108.0 | 116.0 |

‘This fuel 4s jofntly developed by ELF FRANCE

‘and HONDA for the special racing purpose.

suMMaRy

Honda has developed @ Formula One turbo-

charged V-6 1.5-Miter engine, which was very

Successful in the 1988 Grand Prix racing season.

Through the research and development on this

engine, the results can be summarized as

follows

(1) Optimizing operating factors to produce

the best results possible under the 2.5 bar

restriction, the engine successfully produced

f naxtmun power ourput of 506 kw (685 ps), which,

ts equivalent to 336 kw/t (457 ps/D.

(2) & combination of operating factors vas

studied to minimize fuel consumption and the

Rinisua brake specific fuel consumption was

found to be 272 g/kwh (200 g/Psh) when the

engine generated 456 ku (620 Ps).

(3) # high toluene content in fuel had a good

effect on knocking properties and allowed

advanced ignition timing, which resulted in

improvement of brake specific fuel consumption.

Toluene alsa had a good effect on improvenent

of brake volumetric specific fuel consumption

because of the heaviness of its density.

890877

ACKNOWLEDGEMENT

The authors gratefully acknowledge the

contributions of all the meabers of the Formula

One Engine project in the research and

development of the RALSSE, Special thanks are

extended to Professor Tsuyoshi Asanuma of Tokai

University, for the technical advice given when

preparing this paper. The authors are alco

indebted co Shyusuke Akazaki for his

contribution in preparing the manuscript.

REFERENCES

1. cheitian Hoefer, "Renaule Gordini EF

I-erster Formel-I-Motor mit Abgasturbe-

aufladung", Mocortechnische eitsehrift,

45(1984)10, pp. 415-418,

Der BY

Aautonobil-

78(1976)4, PP.

Prof.Dr.-1ng.W.Rixmann, Esslingen,

Formel-2-Rennactor —M12/6

technische Zeizsehrift,

147-149)

3, Dipl.-Ing. Christian Hoefer, Fellbach, “Die

Ferrari-Grand-Prix-Modelle", Autonobil-

technische, Zeitschrifre, 78(1976)7/8, pp.

321-325.

You might also like

- Dellorto Motorcycle Carburetor Tuning GuideDocument20 pagesDellorto Motorcycle Carburetor Tuning GuideButt Hair100% (1)

- Como Quien Pierde Una Estrella VozDocument2 pagesComo Quien Pierde Una Estrella VozGerardo100% (2)

- Ford Intake Ports ReportDocument30 pagesFord Intake Ports ReportgosculptorNo ratings yet

- Suzuki GSX-R1000 2005-2006Document6 pagesSuzuki GSX-R1000 2005-2006Mr. TNo ratings yet

- SU Carb Manual - 90 PagesDocument91 pagesSU Carb Manual - 90 PagesDamian RoweNo ratings yet

- 388 1006 1 PBDocument20 pages388 1006 1 PBGabriel Evangelista dos SantosNo ratings yet

- Kawasaki ZX6R 16Document103 pagesKawasaki ZX6R 16OliverNo ratings yet

- Toyota Motorsport GMBH - The Home of High PerformanceDocument27 pagesToyota Motorsport GMBH - The Home of High PerformanceMarcos SoarNo ratings yet

- Mikunibsr 42Document13 pagesMikunibsr 42José Sousa100% (1)

- 125cc-180cc Aprilia SR Dragster Runner Typhoon Skipper Machines Tuning GuideDocument6 pages125cc-180cc Aprilia SR Dragster Runner Typhoon Skipper Machines Tuning GuideCarlos Barba PNo ratings yet

- Bultaco Alpina 250,350 '77 Parts Book.Document100 pagesBultaco Alpina 250,350 '77 Parts Book.Nikolas Karrer100% (2)

- SOHC Head Flow Data + CarburetorsDocument62 pagesSOHC Head Flow Data + CarburetorsVincenzo SepeNo ratings yet

- Racecar Engineering 2004 10 PDFDocument7 pagesRacecar Engineering 2004 10 PDFfreddyonnimiNo ratings yet

- Yamaha TZR250 3xv SP F3 Sugo ManualDocument73 pagesYamaha TZR250 3xv SP F3 Sugo ManualFernando AzevedoeSilva100% (2)

- English Handheld1 PDFDocument64 pagesEnglish Handheld1 PDFPaul VadasNo ratings yet

- SU Needle Types For Which CarsDocument2 pagesSU Needle Types For Which CarsBennie Barnard100% (1)

- 1980 Yamaha YZ50 Service ManualDocument30 pages1980 Yamaha YZ50 Service Manual5m0k3yNo ratings yet

- The Dellorto PHBG Tuning Textbook?Document11 pagesThe Dellorto PHBG Tuning Textbook?Kjell G HaldorsenNo ratings yet

- Ansmann 21 Motor Tuning GuideDocument2 pagesAnsmann 21 Motor Tuning Guidebaggy trousersNo ratings yet

- Formula Michigan 2018 Event GuideDocument76 pagesFormula Michigan 2018 Event GuideGonzaloNo ratings yet

- Ssp653 WG enDocument88 pagesSsp653 WG enHajirashid26No ratings yet

- Volkswagen FIA World Rally Championship Technology Information Package 2014Document38 pagesVolkswagen FIA World Rally Championship Technology Information Package 2014VWvortexNo ratings yet

- The New 911 GT3 RS and 911 GT3: Extreme TruthDocument52 pagesThe New 911 GT3 RS and 911 GT3: Extreme TruthGonzalo Bautista Gatica100% (2)

- 2015 Audi Sport Fact BookDocument156 pages2015 Audi Sport Fact BookCees RietveldNo ratings yet

- Higher - Compression Gordon JenningsDocument8 pagesHigher - Compression Gordon JenningscarmechanicNo ratings yet

- RA618HDocument5 pagesRA618HFCIUSNo ratings yet

- MotorsportDocument11 pagesMotorsportNuno PiresNo ratings yet

- Volks World Feb 14 Double Man XDocument3 pagesVolks World Feb 14 Double Man X4lexxNo ratings yet

- Machine Design 9 May 2013Document77 pagesMachine Design 9 May 2013M Mirac CicekNo ratings yet

- Technical: Engine Blueprinting 101 - Part OneDocument4 pagesTechnical: Engine Blueprinting 101 - Part OneRussell GouldenNo ratings yet

- AutoVolt July-August 2017Document81 pagesAutoVolt July-August 2017Kaloyan IvanovNo ratings yet

- Puma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsDocument4 pagesPuma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsRobert DennisNo ratings yet

- F1-SP2e AllDocument376 pagesF1-SP2e Alljalm66100% (1)

- SAE Measurement j1287 - 199807Document7 pagesSAE Measurement j1287 - 199807Sport moteurNo ratings yet

- Volvo Learns To Use Modular Function DeploymentDocument7 pagesVolvo Learns To Use Modular Function Deploymentgabig910% (1)

- RET Bellmouth SeptDocument4 pagesRET Bellmouth SeptPravin RajanNo ratings yet

- NISMO - Vehicle Dynamics Simulation of A Racing CarDocument18 pagesNISMO - Vehicle Dynamics Simulation of A Racing Carizadk0% (1)

- Honda x8rs Tuning GuideDocument2 pagesHonda x8rs Tuning GuideCarlos Garrido RegateroNo ratings yet

- Moto Guzzi Robin Workshop ManualDocument15 pagesMoto Guzzi Robin Workshop ManualMichael James WebbNo ratings yet

- Cota 4rt Race ReplicaDocument168 pagesCota 4rt Race ReplicaMatthias BielickiNo ratings yet

- 2006 Sprinter Parts CatalogDocument782 pages2006 Sprinter Parts CataloginterloNo ratings yet

- Puma Race Engines PDFDocument8 pagesPuma Race Engines PDFpichaidvNo ratings yet

- VFR400 Engine Mods-R OliverDocument5 pagesVFR400 Engine Mods-R OliverAndrés Nuñez0% (1)

- GX Series Engines: HEN-P-8219 GX Brochure New 3/18/09 3:57 PM Page 2Document8 pagesGX Series Engines: HEN-P-8219 GX Brochure New 3/18/09 3:57 PM Page 2Felipe HernándezNo ratings yet

- Pistons Catalogue 2009 (V2.2 Compact)Document28 pagesPistons Catalogue 2009 (V2.2 Compact)Mr.JohnNo ratings yet

- Animal Carb TuningDocument5 pagesAnimal Carb TuningRusty100% (1)

- 968 History: 924 Carrera GT 924 Carrera GTS Carrera GTS Club SportDocument24 pages968 History: 924 Carrera GT 924 Carrera GTS Carrera GTS Club SportKeith WarlickNo ratings yet

- CS Info Book Club Sports 3.2LDocument9 pagesCS Info Book Club Sports 3.2LGen ShibayamaNo ratings yet

- Production Process of Honda MoterbikesDocument30 pagesProduction Process of Honda MoterbikesJob KeralaNo ratings yet

- Mix Trompeta ChilombianoDocument1 pageMix Trompeta ChilombianoDenise AlvaradoNo ratings yet

- Enfermeiro Ebsrh 2015Document10 pagesEnfermeiro Ebsrh 2015Neila Reis da SilvaNo ratings yet

- 01 - Lista de Parametros SimplificadaDocument8 pages01 - Lista de Parametros SimplificadaLuis Felipe VidigalNo ratings yet

- Building ActDocument136 pagesBuilding ActVeronika RaušováNo ratings yet

- El Pastor - VihuelaDocument1 pageEl Pastor - VihuelaDamian Guardia SalazarNo ratings yet

- 5756867Document1,027 pages5756867Sách Việt Nam50% (2)

- Los Mareados Arreglo Hernan PossettiDocument2 pagesLos Mareados Arreglo Hernan PossettiteomondejarmusicaNo ratings yet

- 6periostitisDocument10 pages6periostitisAntonioNo ratings yet

- Cicuta Tibia - TubaDocument2 pagesCicuta Tibia - TubaYohan Octavio Vera DelgadoNo ratings yet