Professional Documents

Culture Documents

A Knowledege Desisión Support System For Mining Methods Selection For Ore Deposits

A Knowledege Desisión Support System For Mining Methods Selection For Ore Deposits

Uploaded by

TherionhenryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Knowledege Desisión Support System For Mining Methods Selection For Ore Deposits

A Knowledege Desisión Support System For Mining Methods Selection For Ore Deposits

Uploaded by

TherionhenryCopyright:

Available Formats

90 198

A Knowledge-based Decision Support System for

Mining Method SeleCtlon for

Ore Deposits

Sukumar Bandopadhyay, University of Alaska Fairbanks

and

P. Venkatasubramanian, Temple University, Philadelphia

INTRODUCTION

In recent years, research in the field of artificial intelligence (AI) has had many

important successes. Among the most significant of these has been the development of

powerful new computer software known as the "expert systems".

Expert system programs designed to provide expert-level consultative advice in

mineral exploration (Duda et aI, 1981), scientific (Feigenbaum, Buchanan and Lederburg,

1971) and medical (Shortliffe, 1976) problem solving are generally acknowledged

to

be

among the forerunners of this research.

As the decision makers virtually in all fields face a more complex and involved

world within which to operate, the need for some decision support is also becoming

urgent. Thus applications of expert systems continue to spread out reaching problems

that, because of their dimensions or particular aspects, set more demand on the decision

methodologies. To meet these new requirements, many activities which were performed

in the past by the domain expert or engineer must become automated. Furthermore,

previous research (Dawes and Corrigan, 1974; Dawes, 1979) has shown that automating an

expert's decision rules often provide better decision than the expert does. For large

systems it would be very useful (or even necessary) to have formal tools, allowing one for

example, to automatically discover inconsistencies, contradictions or redundancies, or to

identify the possibilities of wrong lines of reasoning in the decision process.

90-0126.KNO

Page 2

Although computers and simulation models have become indispensable tools in

many mine planning endeavors, there is continued reliance on the human expert's ability

to identify and synthesize diverse factors, to form judgments, to evaluate alternatives and

to aid decisions.

Traditionally simulation methods and other analytical techniques have been used to

aid decision making process in mine planning problems. In some sense all these programs

and techniques try to behave expertly in their attempt to perform some well defined set of

tasks. However, some domains are more highly constrained, not easily amenable to

precise scientific formulations, i.e., domains in which experience and subjective judgment

plays an important role.

While the domain of decision-aid is of immense practical value, it is also of

considerable interest in terms of its AI research content. In its most general form, it

involves representing the structure and functions of complex systems, along with some

knowledge about the problems the system is intended to deal with. Inference mechanisms

are needed which can perform completely, even expertly, in domains where system

variables are ill-defined and fuzzy.

Many variables associated with geological, geotechnical, environmental, and other

conditions influence the selection of a mining method for a given mineral deposit. Each of

these variables in turn depends upon other characteristics, for example, geological

variables depend upon the thickness of are body, the grade, etc.; and geotechnical

variables depend on the rock strength, the presence of fractures, etc. Each set of variables

has significant influence on the selection of a method to mine a deposit. In reality, mine

conditions are so varied that an acceptable decision rule cannot be easily written that

covers the selection of a specific mining system or method for all mines or mineral

deposits. The combination of conditions that affect the analysis for one mine cannot

90-0126.KNO

Page 3

necessarily be applied

to

another mine. By changing just only one variable or condition, a

permutation is created that is not applicable to another mining locale.

The selection of mining method for a mineral deposit is thus a decision problem of

the most general sort, where solution is considered to be a highly skilled art. It is

complicated enough to justify development and use of an expert system. Even the best

geological conditions are difficult to cope with if anything less than the most efficient

mining method is used. In addition, subjective judgments are applied to information about

many geological parameters which are inherently descriptive. Impreciseness arises from

the use of descriptive and some-what ill-defined terms. For example, a decision variable

such as ore body thickness is often expressed as "moderately thick". Similarly, the strength

of the hanging wall of an ore body, expressed as "weak". These qualitative expressions of

important variables in the decision process leads to complexity. Human judgment, based

on experience with mineral seams, and geologic conditions, remains the single most

important input of the decision-making technique in the mining method selection.

In this paper, a knowledge-based decision support expert system model for mining

method selection is presented. The expert systems model not only helps select the correct

mining method, it also helps ensure that all important variables have been examined. It

should serve as a check list to be certain that nothing is forgotten. The best of these

systems enable company specialist to maintain knowledge bases that provide mine

planners with valuable engineering support. The knowledge base can be constantly added

to and edited, becoming, in the longer term, a central part in company's information

resources.

An Expert System for Mining Method Selection for Ore Deposits.

Ore deposits are often characterized by extreme complexity, therefore the number

of methods and their variants used in the practice of mining ore deposits is quite

90-0126.KNO

Page

t1

considerable. The diversity of mining conditions and the great number of existing systems

complicate the elaboration of a simple classification of methods for mining ore deposits.

Many researchers believe that the following ten basic mining methods, not including

hydraulic or solution mining, reflect the essence of the methods to be considered in any

selection process.

1.

Open Pit

6.

Room and Pillar

2.

Block Caving

7.

Shrinkage Stoping

3.

Sublevel stoping

8.

Cut and Fill

4.

Sublevel caving

9.

Top Slicing

5.

Longwall

10.

Square-Set Stoping

The major factor in determining the mining method classification is ground

support, which, in turn, depends largely on the geologic characteristics and mechanical

properties of the ore deposits and its host rock. Boshkov and Wright (1973), Morrison

(1976), Tymshare, Inc. (1981), Nicholas (1981) and others have presented schemes for

selecting mining methods. Boshkow and Wright (1,973) listed the mining methods possible

for certain combinations of ore width, plunge of ore, and strength of ore. Morrison (1976)

classified the mining methods into three basic groups, rigid pillar support, controlled

subsidence, and caving; he then used general definitions of ore width, support type, and

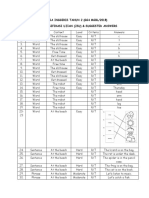

strain energy accumulation as the characteristics for determining mining method (Figure

1). Laubscher (1977), on the other hand, developed a detailed rock mechanics

classification from which cavability, feasibility of open stoping or room and pillar mining,

slope angles, and general support requirements could be determined. Tymshare, Inc.

(1981) developed a numerical analysis that determines one of five mining methods, (1)

open pit, (2) natural caving, (3) induced caving, (4) self-supporting, and (5) artificially

supporting, and calculates the tonnage and grade for the type of deposit described. This

(

90-0126.KNO

Page 5

method is meant to be used as a pre-feasibility tool for geologists.

The decision-making process can be treated as the selection of a particular

alternative from a given set of alternatives so as to best satisfy some given goals or

objectives. The problem to be solved is to evaluate alternatives, e.g., to calculate their

utilities. An expert system for decision-making has to establish an appropriate knowledge

base and use it for utility calculation. In addition to this, it has to explain the way the

utility was calculated.

0-3Om (O-100ft)

Room

Pillar

ShrinkoQ.

'0

'0

. S10cinQ

.!

'0

~ e

80

0

'0

...

::l

:I

0

i-

.=Ic

'0

II)

L

.J

II)

+3Om(+100ft)

Figure 1: A Method Selection Scheme (after Morrison, 1976)

90-0126.KNO

Page 6

The explanation of utility calculation is especially interesting because decision

making knowledge is subjectively defined and often imprecise. It offers different

interpretations and has some degree of uncertainty. This kind of knowledge is usually

referred to as "imprecise knowledge" or soft knowledge. The prevalence of imprecision

increases when the domains are socio-economic in nature. Such domains often have to

contend with nebulous terms and reasoning rules.

Consider the statement "weak hanging wall and weak footwall characteristics have

highly significant influence on the selection of the square-set method for mining an ore

deposit". This statement is useful in selecting a mining system. Note, however, that the

statement is far from precise. First, there is uncertainty in the proposition. Second,

several terms in the statement are ill-defined. "Good" footwall characteristics and "highly

significant" are examples of types of imprecision, distinct from uncertainty, which

arise frequently, and will be referred to as fuzziness. One indication of their being

different is that one type can arise independently of the other.

EXPERT SYSTEM ARCHITECTURE

According to a definition generally accepted as true, expert systems are

characterized by the independence of the control structure and the knowledge base.

Nevertheless, there are different classes of expert systems, each of them implementing a

certain strategy. The architecture of the expert system presented here is based on the

model developed by Bohanec et aI, (1983). The selection of the above formal model was

motivated due to the fact that a semantic tree is a natural form for representing decision

knowledge and provides a suitable framework for experts for systematically formalizing

their decision expertise (Duda et aI., 1978). The tree structure facilitates a gradual

aggregation of the

basic variable

values

through

aggregate

variables.

r("..

\..;

90-0126.KNO

Page 7

Using a top-down approach, a semantic tree with multiple nodes and several leaf

variables (Figure 2) has been defined. Much of this knowledge is internalized in a

knowledge base as production rules, which are IF-TIIEN relationships. A standardized set

of knowledge-independent predicate functions and a range of knowledge specific

attributes, objects and associated values form the vocabulary of primitives for constructing

x =IX

Xl

7 7

X 10 I

= fl (X 27

X2 =

X3 )

f2 (X57 X6)

X3 = f3 (X 41 X7

X4= f4(XS 7 X9, Xl0)

/i~

Figure 2: A Semantic Tree

90-0126.KNO

Page 8

rules. A rule premise is always a conjunction clause, and the action part indicates one or

C\

more conclusion that can be drawn if the premises are satisfied, making the rule purely

inferential. When a quesiton is asked of the knowledge base, a knowledge three is

generated. The derivation of the knowledge is a forward process, where as evaluation of

the tree is a backward contraction process -- a pull-back in the structure of facts.

The Knowledge Base and User's Interface

The knowledge of an area of expertise is generally of the three types: facts, rules of

good judgement (heuristics), and evaluations. The crucial problem in the mining method

selection process is the interpretation of the knowledge, such as:

1.

depth of the orebody and character of the overlying rock,

2.

size, shape and dip of the ore body,

3.

mechanical characteristics of the ore and surrounding rock,

4.

ore grade and degree of continuity.

The goal of the evaluation process is obtained in terms of a preferred mining

method and a description of the mining method. In order to achieve this task, production

rules have been developed which lend themselves to symbolic reasoning.

Within the expert system the knowledge is represented by 4-uplets of the type:

(PARAMETER, CONTEXT, VALUE, CF)

The CONTEXT is instantiated by the name of a mining method. Each

PARAMETER corresponds to an attribute of this CONTEXT and the VALUE qualifies

the attribute. Finally the certainty factor (CF) defines the plausibility of the context. The

plausibility is a number belonging to the (-10, + 10) range (where -10 means false and the

+ 10 means true) and where all the possibilities between the absolutely true and absolutely

false are represented by a number between -10 and + 10 inclusive. For example:

90-0126.KNO

Page 9

(Gen-shape, BLOCK CAVING, irregular, -1/10)

signifies that the selection of block caving is not at all probable when the general shape of

the ore body is irregular. Whereas, (ore-thickness, BLOCK CAVING, very thick, 4/10)

signifies that the selection of bock caving as mining method is probable if the ore body is

very thick.

Since the rules are usually judgmental, that is, they make inexact inferences on a

confidence scale, the conclusions are therefore evaluated by certainty factors. Standard

statistical measures are rejected in favor of certainty factors because experience with

human experts shows that experts do not use information in a way compatible with

standard statistical methods (Negoita, 1985). Thus for example, if some basic variable

describes the "footwall characteristics of the overburden as weak", we can specify the

"selection of square-set mining as a primary method with a certainty factor 4/10".

Certainty factors (CF) are a measure of the association between the premise and

action clauses in each rule and indicate how strongly each clause is believed. When a

production rule succeeds because its premise clauses are true, the certainty factors of the

component clauses are combined. The resulting certainty factor is used to modify the

certainty factor in the action clauses. Thus, if the premise is believed only weakly,

conclusions derived from the rule reflect this weak belief. Also, because conclusions of

one rule may be the premise of another, reasoning from premises with less than complete

certainty factor is common place.

For each rule in the system, a CF is assigned by the domain expert. It is based on

the expert's knowledge and experience. The CF that is included in a rule is a component

certainty factor (CF comp), and it describes the credibility of the conclusion, given only the

evidence represented by the preconditions of the rule. The rules are so structured that any

)

90-0126.KNO

Page 10

given rule either adds to belief in a given conclusion or adds to disbelief. Because there

are many rules that relate to any given conclusion, each of which can add to the overall

belief or disbelief in a conclusion, a cumulative certainty factor is used to express the

certainty of the conclusion, at a given point in execution, in light of all of the evidence that

has been considered up to that point.

Inference rules are defined as situation - action pairs. The left member (i.e., the

situation) describes a constraint on each of the certainity factors associated with several

events. When the constraint is satisfied then the right member (Le., the action) of the rule

is triggered. This "action" modifies the certainty factor associated with all the events

belonging to the right member of the rule, following the certainty factor combination law.

For example:

/* Geometry * /

gen-shape (Open-pit, Massive, 3/10).

gen-shape (Block-caving, Massive, 4/10).

ore-thickness (Open-pit, Narrow, 2/10).

ore-thickness (Block-caving, Narrow, -1/10).

o-rack-strength (Open-pit, Weak, 3/10).

o-rock-strength (Block-caving, Weak, 4/10).

o-fracture-spacing (Open-pit, Close, 3/10).

o-fracture-spacing (Block-caving, close, 4/10).

/* Rule Base * /

Start -7 decision (X,A,B,C,D,K), Write (X,K).

Decision (X,A,B,C,D,K), -

Cl

".J'

j* Ore-zone'" /

geometry (X,A,B,K1),

ore-zone (X,C,D,K2),

K = min (K1,K2).

Geometry (X,A,B,C,K1) -

gen shape (X,A,L)

ore-thickness (X,B,M)

Kl = min (L,M).

Ore-zone (X,C,D,K2) -

o-rock-str (X,C,L1)

o-fracture-spacing (X,D,L2)

K2 - min (L1,L2)

The activation of the rules modifies the certainty factor by combining the individual

certainty factors from each parameter group (Figure 3).

(

90-0126.KNO

Page 11

START

LEVEI:1

WRITE(X ,K)

K= MIt-HK1,K2)

MIN(K1,K2 )

LEVEL-2

GEOMETRY

(X,A,B,K1)

K2= MIN(L1,L2)

MIN (L1, L2)

LEVEL-3

K1=MIN(L,M)

MIN( L,M)

ORE ROCK

ORE-THICKNESS

(X,B,M)

STRENGTH

ORE FRACTURE

SPACING

(X,D,L2)

(X,C,L1 )

Figure 3: A Segment of the Mining Method Selection Semantic Tree

User Interface

The output of the mining method expert system is a characterization of each are

deposit in terms of the stability of the ground (hanging wall, footwall, and are zone) and its

influence on the selected mining method. The strength properties of the hangwall,

footwall and the ore zone are characterized by the ratio of the uniaxial strength of the

material to the overburden pressure, the fracture spacing and the fracture shear strength.

The characteristics of the of the are body are defined by the general shape, the are

thickness, the plunge of the are body, and the grade distribution. Information acquired

from the external environment is qualitative and imprecise -- "narrow", "thick", "uniform",

etc. Based on terms of this type, and the sets of heuristic rules, inferences are developed.

90-0126.KNO

Page 12

The determination of the ground stability and characteristics of the ore body is used

to determine the mining method. Figure 4 is an example of the user interface with the

system. The expert system contains 13 parameters, and the geological knowledge is

encoded within 514 produciton rules. Using the resources available at the University of

Alaskaz Fairbanks, this expert system was implemented and studied on a VAX 750

computer, using essentially standard Prolog.

$ pro

C-Prolog version 1.5

1 ?- ['methfux.pro].

methfux.pro consulted 27752 bytes 1.90201

yes

1 ?- start.

Questions on geometry and grade dbn of deposit

General shape

m: Massive

tp : Tabular or Platy

i : Irregular

I: i.

Ore thickness

n: Narrow

i : Intermediate

t: Thick

\It : Very thick

Rock mech characteristics for hanging wall

Rock material strength

w: Weak

m: Moderate

s: Strong

I:w.

Fracture spacing

vc : Very close

c: Close

w:Weak

vw : Very weak

I: c.

Fracture strength

w: Weak

m: Moderate

s: Strong

(,

I:w.

Rock mech characteristics for ore zone

I: i.

Ore plunge

f: Flat

i : Intermediate

s : Steep

Rock material strength

w: Weak

m: Moderate

s: Strong

I: s.

Grade distribution

u: Uniform

g : Gradational

e: Erratic

Fracture spacing

vc: Very close

c: Close

w:Weak

vw : Very weak

I: u.

I:vc.

I:w.

(

90-0126.KNO

Page 13

Fracture strength

w:Weak

m: Moderate

s: Strong

I:w.

Rock mech characteristics for foot wall

Rock material strength

w:Weak

m: Moderate

s: Strong

I:w.

Fracture spacing

vc : Very close

c: Close

w: Weak

vw : Very weak

I: c.

Fracture strength

w: Weak

m: Moderate

s: Strong

I:w.

Mining methods and their correspoinding scores

2

o

-1

-1

o

o

2

o

3

Openpit

Block Caving

Sublevel Stoping

Sublevel Caving

Longwall

Room and Pillar

Shrinkage Stoping

Cut and Fill Stoping

Top Slicing

Square Set Stoping

no

I?1 Exit

[ Prolog execution halted 1

Figure 4: An Example of the User-Interace with the Expert System.

90-0126.KNO

Page 14

CONCLUSION

Expert system models are still evolving, both theoretically and in terms of their

practical applications in mining engineering. It is an useful tool for the domain considered

since analytical models are not amenable. Mining integrates the skill of many engineering

disciplines. Within these disciplines lies experience and expertise found in not other

industry. To capture and widely apply this expertise is the challenge to developing

knowledge base systems. This paper shows how the methodology of expert systems may.be

integrated in a mining method selection process. The integration of expert knowledge in

designing an inference process seems to be advantageous for many technical reasons.

REFERENCES

Bohanec, M., Bratko, 1., and Rajkovic, V., 1988, "An Expert System for Decision Making",

Proceedings of the Joint IFIPWG 8.3 lHASA Conference on Processes and Tools

for Decision Support, H.G. Sol, (efd), North-Holland, Amsterdam, 254 p.

Boshkov, S.H., and Wright, F.D., 1973, "Basic and Parametric Criteria in the Selection,

c.

Design and Development of Underground Mining Systems", SME Mining

Engineering Handbook, Chapter 12.1, Vol. 1, SMEI AlME, p 12.2-12.13.

Dawes, R.M., 1979, "The Robust Beauty of Improper Linear Models in Decision Making",

American Psychologists, Vol. 34, pp. 571-582.

Dawes, R.M., and Corrigan, B., 1974, "Linear Models in Decision Making", Psychological

Bulletin, Vol. 81, p. 95-106.

Duda, R., Gaschnig, J., and Hart, P., 1981, "Model Design in the Prospector Consultant

System for Mineral Exploration", Expert System in the Micro-Electronic Age, D.

Michie (ed), Cambridge Press, p. 154-167.

Duda, R., Hart, P.E., Nilsson, N.J., and Sutherland, G., 1978, "Semantic Network

Representations in Rule-Based Inference Systems", Pattern Directed Inference

(:.

\

90-0126.KNO

Page 15

System, D.A. Waterman and F. Hayes-Roth (ed), Academic Press, New York.

Feigenbaum, E.A., Buchanan, B.G., and Lederberg, J., 1971, "On Generality and Problem

Solving: A Case Study Using the DENDRAL Program", Machine Intelligence,

Vol. 6, P. 165-190.

Laubacher, D.H., 1977, "Geomechanics Classification of Jointed Rock Masses - Mining

Applications", Transactions of the Institute of Mining and Metallugy of South

Africa, Section A, Vol. 6, p. AI-A7.

Morrison, R.K.G., 1976, A Philosophy of Ground Control, McGill University, Canada, p.

125-159.

Negoita, C.V., 1985, Expert Systems and Fuzzy Systems, Benjamin/Cummings.

Nicholas, D.E., 1981, Method Selection - A Numerical Approach, Design and Operation

of Caving and Sublevel Stoping Mines, D.R. Steward (ed), SME/ AIME, New York,

p.39-53.

Tyrnshere, Inc., 1981, Computer Evaluation of Mining Projects, Mining Journal, Vol. 10,

p.11l.

Shortliffe, E.H., 1976, Computer-based Medical Consultation: MYCIN, American

Elsevier, New York.

90-0126.KNO

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Substance Abuse WorkbookDocument21 pagesSubstance Abuse Workbookpaul macharia61% (18)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Creativity and InnovationDocument326 pagesCreativity and InnovationFred100% (4)

- A Critical Review of Rock Slope Failure Mechanisms The Importance PDFDocument23 pagesA Critical Review of Rock Slope Failure Mechanisms The Importance PDFAlonso Valeriano100% (2)

- Mining Geomechanics - AWestern. AustraliaDocument6 pagesMining Geomechanics - AWestern. AustraliaAlonso ValerianoNo ratings yet

- Korean Mathematics CurriculumDocument23 pagesKorean Mathematics CurriculumcikguhafidzuddinNo ratings yet

- Underground Mapping ExampleDocument2 pagesUnderground Mapping ExampleAlonso ValerianoNo ratings yet

- 1Z0-338 Dumps - Oracle Exadata Database Machine ExamDocument8 pages1Z0-338 Dumps - Oracle Exadata Database Machine ExamThomas William29% (7)

- Homeroom Guidance-Dll-Module-1-Q1Document5 pagesHomeroom Guidance-Dll-Module-1-Q1janecil bonzaNo ratings yet

- Fourth International Symposium On Block and Sublevel CavingDocument2 pagesFourth International Symposium On Block and Sublevel CavingAlonso ValerianoNo ratings yet

- DEM Bloque FlexuralDocument12 pagesDEM Bloque FlexuralAlonso ValerianoNo ratings yet

- In Situ StressDocument47 pagesIn Situ StressAlonso ValerianoNo ratings yet

- Diseño de Minas Subterraneas: Time PeriodDocument1 pageDiseño de Minas Subterraneas: Time PeriodAlonso ValerianoNo ratings yet

- TecnotestDocument12 pagesTecnotestAlonso ValerianoNo ratings yet

- Environmental Impact Assessment of Open Pit Copper Mining in IranDocument12 pagesEnvironmental Impact Assessment of Open Pit Copper Mining in IranAlonso ValerianoNo ratings yet

- Puente Tarucani 25+300: Detalles Test Profundidad Metros #De GolpesDocument2 pagesPuente Tarucani 25+300: Detalles Test Profundidad Metros #De GolpesAlonso ValerianoNo ratings yet

- Planning For Operating ExcellenceDocument11 pagesPlanning For Operating ExcellenceAlonso ValerianoNo ratings yet

- RPS EnglishDocument8 pagesRPS EnglishsitisarahsekeriNo ratings yet

- Skills For Pre-Toefl TestDocument2 pagesSkills For Pre-Toefl TestCarlos Mauricio Nin CorralesNo ratings yet

- Performance Task No.2-BASIC AUTOCADDocument1 pagePerformance Task No.2-BASIC AUTOCADVincent LibreaNo ratings yet

- Sarah Diwan Joins Hyde Park Neighborhood Club Staff 10/22/10Document1 pageSarah Diwan Joins Hyde Park Neighborhood Club Staff 10/22/10beth_parker6051No ratings yet

- K To 12 Nail Care Learning ModuleDocument335 pagesK To 12 Nail Care Learning ModuleWilma Arenas MontesNo ratings yet

- AIMA ExcersicesDocument61 pagesAIMA ExcersicesAnas HamdanNo ratings yet

- Bahasa Inggeris Tahun 2 (Gg4 Mgbl/2018) Jadual Spesifikasi Ujian (Jsu) & Suggested AnswersDocument2 pagesBahasa Inggeris Tahun 2 (Gg4 Mgbl/2018) Jadual Spesifikasi Ujian (Jsu) & Suggested AnswersDayangku EffaNo ratings yet

- One Month Study GuideDocument2 pagesOne Month Study GuideAshik Ishtiaque EmonNo ratings yet

- 021220-Brochure-Equity Research and ValuationDocument6 pages021220-Brochure-Equity Research and Valuationdabster7000No ratings yet

- First Day of ClassDocument5 pagesFirst Day of ClassMyatBoneBoNo ratings yet

- PCCloneEX User Guide - ENGDocument14 pagesPCCloneEX User Guide - ENGjeanhertzNo ratings yet

- Chapter 3 Kingdom Plantae (BIOLOGY 11th)Document8 pagesChapter 3 Kingdom Plantae (BIOLOGY 11th)asel.aakashinstitutionNo ratings yet

- Math WHLP q2 RegDocument11 pagesMath WHLP q2 Regkero roy tadeoNo ratings yet

- Brian Josephson ThesisDocument6 pagesBrian Josephson Thesiskarenwashingtonbuffalo100% (1)

- Hema ResumeDocument2 pagesHema Resumen_hemavathi76No ratings yet

- FINAL PPT PR1!11!12 UNIT 2 LESSON 2 Types of Qualitative ResearchDocument26 pagesFINAL PPT PR1!11!12 UNIT 2 LESSON 2 Types of Qualitative ResearchChristian NavarreteNo ratings yet

- 11-PURNEA 11: District Wise Top 3 Candidate List Matric Exam - 2024Document38 pages11-PURNEA 11: District Wise Top 3 Candidate List Matric Exam - 2024vikashara4uNo ratings yet

- Weather Wonders Weekly 2.Document2 pagesWeather Wonders Weekly 2.Sapphire JordaanNo ratings yet

- Reading Report in Reading in Philippine HistoryDocument8 pagesReading Report in Reading in Philippine HistoryChristine Jade MorenoNo ratings yet

- Chapter I.editedDocument20 pagesChapter I.editedGADOR JEEZYLNo ratings yet

- Job StressDocument7 pagesJob StressRemar PabalayNo ratings yet

- ConnectPay UABDocument17 pagesConnectPay UABAhmer HussainNo ratings yet

- ACLP Consignement TrackingDocument4 pagesACLP Consignement TrackingKumar UditNo ratings yet

- Pupil's Orientation 2023-2024 - Grade - 2 - 3Document71 pagesPupil's Orientation 2023-2024 - Grade - 2 - 3Kram Solomon Nogala FullNo ratings yet

- GATE 2018 QuestionsDocument13 pagesGATE 2018 QuestionsNilesh UdmaleNo ratings yet