Professional Documents

Culture Documents

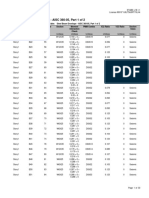

General Tolerance - IsO 2768-MH (DIN 7168) (JIS B 0419)

General Tolerance - IsO 2768-MH (DIN 7168) (JIS B 0419)

Uploaded by

mfahad120Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Tolerance - IsO 2768-MH (DIN 7168) (JIS B 0419)

General Tolerance - IsO 2768-MH (DIN 7168) (JIS B 0419)

Uploaded by

mfahad120Copyright:

Available Formats

Table 1.

Permissible deviations for linear dimensions except chamfered parts

(external radii and chamfer heights, see Table 2.)

Unit : mm

Tolerance class

Designation

Division of basic dimension

0.5 (1)

Over 3

Over 6

Over

Over

Over

Over

Over

up to 3

up to 6

up to

30 up

120 up

400 up

1000

2000

30

to 120

to 400

to

up to

up to

1000

2000

4000

Description

Permissible deviations

f

fine

0.05

0.05

0.1

0.15

0.2

0.3

0.5

medium

0.1

0.1

0.2

0.3

0.5

0.8

1.2

coarse

0.2

0.3

0.5

0.8

1.2

very coarse

0.5

1.5

2.5

Note (1) :

For basic dimensions below 0.5 mm, the deviations shall be indicated adjacent to the

relevant basic dimension(s).

Table 2. Permissible deviations for linear dimensions of chamfered parts

(Rounding of corner and chamfered dimension)

Unit : mm

Tolerance class

Division of basic

dimension

Designation

Description

0.5 (1)

Over 3

up to 3

up to 6

Over 6

Permissible deviations

Note (1) :

fine

medium

coarse

very coarse

0.2

0.5

0.4

For basic dimensions below 0.5 mm, the deviations shall

be indicated adjacent to the relevant basic dimension(s).

Table 3. Permissible deviations for angular deviations

Tolerance class

Deviation of length (unit : mm) of the shorter side of the angle concerned

Up to 10

Designation

Description

Over 10

Over 50

Over 120

up to 50

up to 120

up to 400

Over 400

Permissible deviations

f

fine

medium

c

v

30c

20c

10c

5c

coarse

130c

30c

15c

10c

very coarse

30c

20c

Table 4. General tolerances on straightness and flatness

Unit : mm

Straightness and flatness tolerances for ranges of nominal lengths

Tolerance

Up to 10

class

Over 10

Over 30

Over 100

Over 300

Over 1000

up to 30

up to 100

up to 300

up to 1000

up to 3000

General tolerances on straightness and flatness

H

0.02

0.05

0.1

0.2

0.3

0.4

0.05

0.1

0.2

0.4

0.6

0.8

0.1

0.2

0.4

0.8

1.2

1.6

Table 5. General tolerances on perpendicularity

Unit : mm

Perpendicularity tolerances for ranges of

nominal lengths of the shorter side

Tolerance

class

Up to 100

Over 100

Over 300

Over 1000

up to 300

up to 1000

up to 3000

General tolerances on perpendicularity

H

0.2

0.3

0.4

0.5

0.4

0.6

0.8

0.6

1.5

Table 6. General tolerances on symmetry

Unit : mm

Symmetry tolerances for ranges of nominal length

Tolerance

Up to 100

class

Over 100

Over 300

Over 1000

up to 300

up to 1000

up to 3000

General tolerances on symmetry

H

0.5

K

L

0.6

0.6

0.8

1.5

Table 7. General tolerances on circular run-out

Unit : mm

Tolerance class

Circular run-out tolerance

0.1

0.2

0.5

You might also like

- Din332 PDFDocument4 pagesDin332 PDFmateo100% (2)

- DIN 6930-2 Stamped Steel Parts Part 2 General TolerancesDocument17 pagesDIN 6930-2 Stamped Steel Parts Part 2 General TolerancespopoNo ratings yet

- Assignment 1: Create A Document With The Text Given Below and Save It As FirstDocument12 pagesAssignment 1: Create A Document With The Text Given Below and Save It As FirstVishal100% (9)

- DIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFDocument5 pagesDIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFnoraafshin100% (2)

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov79% (24)

- General Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalDocument2 pagesGeneral Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalRicardo F.A.100% (3)

- DIN EN 10088-3: Stainless SteelsDocument55 pagesDIN EN 10088-3: Stainless SteelsClaudio Rodrigues100% (1)

- Normes ToyotarcDocument13 pagesNormes Toyotarcerwin_teichmannNo ratings yet

- Knurling Profiles DIN 82Document3 pagesKnurling Profiles DIN 82mirzasinanovic100% (1)

- DIN 82-1973-Eng-Knurls PDFDocument4 pagesDIN 82-1973-Eng-Knurls PDFmrccrmmrc100% (2)

- 6935 2011Document13 pages6935 2011Tufan Ünal100% (4)

- Din 7168Document2 pagesDin 7168Amândio Santos75% (4)

- DIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralDocument24 pagesDIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralFranciscoNo ratings yet

- Standard Machining Tolerance JIS B 0405Document6 pagesStandard Machining Tolerance JIS B 0405fsijestNo ratings yet

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- © Barish Namazov: A Calculator Is Allowed On The Following QuestionsDocument6 pages© Barish Namazov: A Calculator Is Allowed On The Following QuestionsName Surname100% (1)

- Standard Machining ToleranceDocument1 pageStandard Machining ToleranceDenny Ilyas AttamimiNo ratings yet

- General Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)Document1 pageGeneral Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)murali036No ratings yet

- Iso 2768-1Document2 pagesIso 2768-1Jennifer Cossette Manicom100% (2)

- General Tolerances DIN ISO 2768Document4 pagesGeneral Tolerances DIN ISO 2768NaveenRajNo ratings yet

- Din 3961Document12 pagesDin 3961Garapati Murarji100% (2)

- Iso Tolerances For Shafts (Iso 286-2)Document2 pagesIso Tolerances For Shafts (Iso 286-2)saifudin-its40% (5)

- Technical Data GearsDocument171 pagesTechnical Data GearsdesetekNo ratings yet

- BS en ISO 12781-2-2011 - Geometrical Product Specifications (GPS) - Flatness - Part 2 - Specification OperatorsDocument24 pagesBS en ISO 12781-2-2011 - Geometrical Product Specifications (GPS) - Flatness - Part 2 - Specification OperatorsCristiano LigabòNo ratings yet

- Vdocuments - MX Din 405 Universo For Knuckle Thread Din 405Document7 pagesVdocuments - MX Din 405 Universo For Knuckle Thread Din 405wauwio1906No ratings yet

- C45 Chemical and Mechanical Properties PDFDocument2 pagesC45 Chemical and Mechanical Properties PDFabhics67100% (2)

- En 10029 PDFDocument5 pagesEn 10029 PDFmanuela vilas boasNo ratings yet

- Tolerance For Press Work PDFDocument1 pageTolerance For Press Work PDFmr.nguyenk100% (1)

- Iso 7379Document2 pagesIso 7379Ahmed ElsafouryNo ratings yet

- Misumi Technical Data PDFDocument1 pageMisumi Technical Data PDFtnchsg100% (1)

- General Tolerance ISO2768 For CNC MachiningDocument5 pagesGeneral Tolerance ISO2768 For CNC Machiningsogaworks2015No ratings yet

- General Tolerances To DIN ISO 2768 T1 and T2Document2 pagesGeneral Tolerances To DIN ISO 2768 T1 and T2manageieNo ratings yet

- Tolerances FabDocument1 pageTolerances FabAnwarNo ratings yet

- Iso 2768-1Document1 pageIso 2768-1Roberto Mota100% (1)

- Guide To General Tolerance - ISO 2768 1&2 StandardDocument6 pagesGuide To General Tolerance - ISO 2768 1&2 StandardQuality controller100% (1)

- Fundamentals of Limits, Fits & TolerancesDocument24 pagesFundamentals of Limits, Fits & TolerancesrajeshNo ratings yet

- Iso 2768-1 TolerancesDocument2 pagesIso 2768-1 TolerancesTang Bv100% (2)

- Toleràncies Dimensionals Iso 2768-1Document1 pageToleràncies Dimensionals Iso 2768-1carlesiemiNo ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- Symbolism in The Feature Film JOURNALDocument26 pagesSymbolism in The Feature Film JOURNALWijayantiNo ratings yet

- FAG BearingDocument51 pagesFAG BearingbayuwiroNo ratings yet

- Math MYP I Summative Assessment Criteria C TessellationsDocument6 pagesMath MYP I Summative Assessment Criteria C TessellationsMich CastillejaNo ratings yet

- 4th QUARTERLY Exams in DIASS 11Document5 pages4th QUARTERLY Exams in DIASS 11Rollie Boy EsguerraNo ratings yet

- Band 9 EssaysDocument24 pagesBand 9 Essaysa1english academyNo ratings yet

- Understanding and Applying Theories of Career DevelopmentDocument48 pagesUnderstanding and Applying Theories of Career DevelopmentKamal ZafarNo ratings yet

- Some Implications of The Okir Motif in Lanao and Sulu ArtDocument40 pagesSome Implications of The Okir Motif in Lanao and Sulu ArtDanielle SalaanNo ratings yet

- Jeff Batten Resume Revised 4-15-2020Document5 pagesJeff Batten Resume Revised 4-15-2020api-419922188No ratings yet

- Aurolab Three PieceDocument1 pageAurolab Three PiecePRADEEP TEKADENo ratings yet

- Politically Incorrect Guide To ScienceDocument274 pagesPolitically Incorrect Guide To ScienceAgnieszka WisniewskaNo ratings yet

- 1.1.3 B. Tech EceDocument873 pages1.1.3 B. Tech EceVishith ReddyNo ratings yet

- انجليزي 0Document4 pagesانجليزي 0Noura AdhamNo ratings yet

- SOP - Control of Quality RecordsDocument11 pagesSOP - Control of Quality Recordshimawan setyarsoNo ratings yet

- STS Reaction PaperDocument3 pagesSTS Reaction PaperRentsu KaruroNo ratings yet

- Biology Grade 9Document232 pagesBiology Grade 9asahel los100% (1)

- Quizzes On Thesis StatementsDocument6 pagesQuizzes On Thesis Statementsfjnsf5yf100% (1)

- Tabla de RatioDocument33 pagesTabla de RatioLuis Antonio GuerraNo ratings yet

- PNS BAFS PAES 228 - 2017 - Design of A Rockfill DamDocument11 pagesPNS BAFS PAES 228 - 2017 - Design of A Rockfill DamJan BakosNo ratings yet

- Week 12Document3 pagesWeek 12linaNo ratings yet

- STS Prelim Chapter 2 Historical Antecedents in The Course of Science and TechnologyDocument30 pagesSTS Prelim Chapter 2 Historical Antecedents in The Course of Science and TechnologyVenice Marie ArroyoNo ratings yet

- C. Truesdell (Auth.) - Six Lectures On Modern Natural Philosophy-Springer-Verlag Berlin Heidelberg (1966)Document130 pagesC. Truesdell (Auth.) - Six Lectures On Modern Natural Philosophy-Springer-Verlag Berlin Heidelberg (1966)Cindy BergamoteNo ratings yet

- Reason and Impartiality As Requirements For EthicsDocument2 pagesReason and Impartiality As Requirements For EthicsJohn Alfred FernandezNo ratings yet

- Maren Clegg Et Al. (Ed.), Water and The Environment in The Anglo-Saxon WorldDocument277 pagesMaren Clegg Et Al. (Ed.), Water and The Environment in The Anglo-Saxon WorldAnonymous hXQMt5No ratings yet

- MDP408a Lecture08Document42 pagesMDP408a Lecture08Hisham Ahmed FouadNo ratings yet

- A Semi-Detailed Lesson Plan in Grade 9 Mathematics: The Six Trigonometric Ratios: Sine, Cosine, Tangent, Cosecant, and TangentDocument3 pagesA Semi-Detailed Lesson Plan in Grade 9 Mathematics: The Six Trigonometric Ratios: Sine, Cosine, Tangent, Cosecant, and TangentHazel LiwanagNo ratings yet

- O Level Physics MagnetismDocument21 pagesO Level Physics MagnetismSaad AhmedNo ratings yet

- HBO PPT Chap 6 8Document60 pagesHBO PPT Chap 6 8Beat Karb0% (1)

- ST All Subjects 6 q4 #2Document22 pagesST All Subjects 6 q4 #2ryan jude delapazNo ratings yet