Professional Documents

Culture Documents

Text With EEA Relevance

Text With EEA Relevance

Uploaded by

ΑΝΤΩΝΗΣ ΠΑΝΤΑΖΟΠΟΥΛΟΣOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Text With EEA Relevance

Text With EEA Relevance

Uploaded by

ΑΝΤΩΝΗΣ ΠΑΝΤΑΖΟΠΟΥΛΟΣCopyright:

Available Formats

23.7.

2009

EN

Official Journal of the European Union

L 191/35

COMMISSION REGULATION (EC) No 641/2009

of 22 July 2009

implementing Directive 2005/32/EC of the European Parliament and of the Council with regard to

ecodesign requirements for glandless standalone circulators and glandless circulators integrated in

products

(Text with EEA relevance)

THE COMMISSION OF THE EUROPEAN COMMUNITIES,

(5)

The environmental aspect of circulators that is identified

as significant for the purposes of this Regulation is elec

tricity consumption in the use phase.

(6)

The preparatory study shows that approximately 14

million circulators are placed on the Community

market annually and that their most significant environ

mental impact out of all life-cycle phases is the use phase

energy consumption amounting to 50 TWh in 2005,

corresponding to 23 million tonnes of CO2 emissions.

If no specific measures are taken, electricity consumption

is predicted to increase to 55 TWh by 2020. The

preparatory study shows that use phase electricity

consumption can be significantly improved.

(7)

The preparatory study shows that requirements regarding

other ecodesign parameters referred to in Annex I, Part 1,

of Directive 2005/32/EC are not necessary as power

consumption of circulators in use phase is by far the

most important environmental aspect.

(8)

Circulators should be made more efficient by applying

existing non-proprietary cost-effective technologies that

can reduce the total combined costs of purchasing and

operating circulators.

(9)

Ecodesign requirements should harmonise electricity

consumption requirements for circulators throughout

the Community, thus contributing to the functioning of

the internal market and to improving the environmental

performance of these products.

(10)

To increase the re-use and recycling of circulators, manu

facturers should provide information on the assembly

and dismantling of circulators.

(11)

The ecodesign requirements should not have a negative

impact on the functionality of circulators and should not

negatively affect health, safety or the environment. In

particular, the benefits of reducing electricity

consumption during the use phase should more than

offset any additional environmental impacts during the

production phase.

Having regard to the Treaty establishing the European

Community,

Having regard to Directive 2005/32/EC of the European

Parliament and of the Council of 6 July 2005 establishing a

framework for the setting of ecodesign requirements for energyusing products and amending Council Directive 92/42/EEC and

Directives 96/57/EC and 2000/55/EC of the European

Parliament and of the Council (1), and in particular

Article 15(1) thereof,

After consulting the Ecodesign Consultation Forum,

Whereas:

(1)

(2)

(3)

(4)

Under Directive 2005/32/EC ecodesign requirements

should be set by the Commission for energy-using

products representing significant volumes of sales and

trade, having a significant environmental impact and

presenting significant potential for improvement in

terms of their environmental impact without entailing

excessive costs.

Article 16(2), first indent, of Directive 2005/32/EC

provides that, in accordance with the procedure

referred to in Article 19(3) and the criteria set out in

Article 15(2) of that Directive, and after consulting the

Ecodesign Consultation Forum, the Commission will, as

appropriate, introduce an implementing measure for

appliances in electric motor systems and heating

equipment, such as for circulators.

The Commission has carried out a preparatory study to

analyse the technical, environmental and economic

aspects of circulators typically used in buildings. The

study has been developed together with stakeholders

and interested parties from the Community and third

countries, and the results have been made publicly

available.

Circulators consume much of the energy used in heating

systems in buildings. Furthermore, most standard circu

lators operate continuously, regardless of heating needs.

Circulators are therefore one of the priority products for

which ecodesign requirements should be established.

(1) OJ L 191, 22.7.2005, p. 29.

L 191/36

(12)

EN

Official Journal of the European Union

The ecodesign requirements should be introduced

gradually in order to provide a sufficient timeframe for

manufacturers to re-design products subject to this Regu

lation as appropriate. The timing for the introduction of

these requirements should be such as to avoid negative

impacts on the functionalities of circulators on the

market, and to take into account cost impacts for manu

facturers, in particular small and medium-sized enter

prises, while ensuring timely achievement of the

objectives of the Regulation.

HAS ADOPTED THE FOLLOWING REGULATION:

Article 1

Subject matter and scope

1.

This Regulation establishes ecodesign requirements for the

placing on the market of glandless standalone circulators and

glandless circulators integrated in products.

2.

(13)

Conformity assessment and measurements of the relevant

product parameters should be performed using reliable,

accurate and reproducible measurement methods, which

take into account the generally recognised state of the art

measurement methods including, where available,

harmonised standards adopted by the European standard

isation bodies, as listed in Annex I to Directive 98/34/EC

of the European Parliament and of the Council of

22 June 1998 laying down a procedure for the

provision of information in the field of technical

standards and regulations and of rules on Information

Society services (1).

23.7.2009

This Regulation shall not apply to:

(a) drinking water circulators, except as regards information

requirements of Annex I, point 2(4);

(b) circulators integrated in products and placed on the market

not later than 1 January 2020 as replacement for identical

circulators integrated in products and placed on the market

no later than 1 August 2015. The replacement product or

its packaging must clearly indicate the product(s) for which

it is intended.

Article 2

(14)

(15)

(16)

This Regulation should quickly ensure the placing on the

market of technologies that reduce the life-cycle environ

mental impact of circulators, leading to estimated elec

tricity savings of 23 TWh by 2020, corresponding to 11

Mt of CO2 equivalent, compared with the situation,

where no action is taken.

In accordance with Article 8 of Directive 2005/32/EC,

this Regulation should specify the applicable conformity

assessment procedures.

In order to facilitate compliance checks, manufacturers

should provide information in the technical documen

tation referred to in Annexes IV and V to Directive

2005/32/EC.

Definitions

In addition to the definitions set out in Article 2 of Directive

2005/32/EC, the following definitions shall apply:

1. circulator means an impeller pump which has the rated

hydraulic output power of between 1 W and 2 500 W

and is designed for use in heating systems or in secondary

circuits of cooling distribution systems;

2. glandless circulator means a circulator with the shaft of the

motor directly coupled to the impeller and the motor

immersed in the pumped medium;

3. standalone circulator means a circulator designed to operate

independently from the product;

4. product means an appliance that generates and/or transfers

heat;

(17)

In addition to the legally binding requirements laid down

in this Regulation, indicative benchmarks for best

available technologies should be identified to ensure

wide availability and easy accessibility of information

on the life-cycle environmental performance of circu

lators.

5. drinking water circulator means a circulator specifically

designed to be used in the recirculation of drinking water

as defined in Council Directive 98/83/EC (2).

Article 3

(18)

The measures provided for in this Regulation are in

accordance with the opinion of the Committee estab

lished by Article 19(1) of Directive 2005/32/EC,

(1) OJ L 204, 21.7.1998, p. 37.

Ecodesign requirements

The ecodesign requirements for circulators are set out in

Annex I.

(2) OJ L 330, 5.12.1998, p. 32.

23.7.2009

EN

Official Journal of the European Union

L 191/37

Compliance with ecodesign requirements shall be measured in

accordance with requirements set out in Annex II, point 1.

The calculation method for the energy efficiency index of circu

lators is set out in Annex II, point 2.

Article 4

Conformity assessment

The procedure for assessing conformity referred to in Article 8

of Directive 2005/32/EC shall be the internal design control

system set out in Annex IV to that Directive or the management

system for assessing conformity set out in Annex V to that

Directive.

Article 7

Revision

The Commission shall review the methodology for calculating

the energy efficiency index, set out in Annex II, point 2 to this

Regulation, for glandless circulators integrated in products

before 1 January 2012.

It shall review this Regulation before 1 January 2017, in the

light of technological progress. The review will include the

assessment of design options that can facilitate re-use and

recycling.

The results of the reviews shall be presented to the Ecodesign

Consultation Forum.

Article 8

Article 5

Entry into force

Verification procedure for market surveillance purposes

This Regulation shall enter into force on the twentieth day

following that of its publication in the Official Journal of the

European Union.

When performing the market surveillance checks referred to in

Article 3(2) of Directive 2005/32/EC, for the requirements set

out in Annex I to this Regulation, the authorities of the Member

States shall apply the verification procedure described in Annex

III to this Regulation.

Article 6

Benchmarks

The indicative benchmarks for best-performing circulators

available on the market at the time of entry into force of this

Regulation are set out in Annex IV.

It shall apply in accordance with the following timetable:

1. from 1 January 2013, glandless standalone circulators shall

meet the efficiency level defined in Annex I, point 1(1), with

the exception of those specifically designed for primary

circuits of thermal solar systems and of heat pumps;

2. from 1 August 2015, glandless standalone circulators and

glandless circulators integrated in products shall meet the

efficiency level defined in Annex I, point 1(2).

This Regulation shall be binding in its entirety and directly applicable in all Member States.

Done at Brussels, 22 July 2009.

For the Commission

Andris PIEBALGS

Member of the Commission

L 191/38

EN

Official Journal of the European Union

ANNEX I

ECODESIGN REQUIREMENTS

1. ENERGY EFFICIENCY REQUIREMENTS

1. From 1 January 2013, glandless standalone circulators, with the exception of those specifically designed for primary

circuits of thermal solar systems and of heat pumps, shall have an energy efficiency index (EEI) of not more than

0,27, calculated in accordance with Annex II, point 2.

2. From 1 August 2015, glandless standalone circulators and glandless circulators integrated in products shall have an

energy efficiency index (EEI) of not more than 0,23, calculated in accordance with Annex II, point 2.

2. PRODUCT INFORMATION REQUIREMENTS

From 1 January 2013:

1. the energy efficiency index of circulators, calculated in accordance with Annex II, shall be indicated on the name

plate and packaging of the product and in the technical documentation as follows: EEI 0,[xx];

2. the following information shall be provided: The benchmark for most efficient circulators is EEI 0,20.;

3. information concerning disassembly, recycling, or disposal at end-of-life of components and materials, shall be

made available for treatment facilities;

4. the following information shall be provided on the packaging and in the technical documentation of drinking water

circulators: This circulator is suitable for drinking water only..

Manufacturers shall provide information on how to install, use and maintain the circulator in order to minimise its

impact on the environment.

The information listed above shall be visibly displayed on freely accessible websites of the circulator manufacturers.

23.7.2009

23.7.2009

EN

Official Journal of the European Union

ANNEX II

MEASUREMENT METHODS AND METHODOLOGY FOR CALCULATING THE ENERGY EFFICIENCY INDEX

1. MEASUREMENT METHODS

For the purposes of compliance and verification of compliance with the requirements of this Regulation,

measurements shall be made using a reliable, accurate and reproducible measurement procedure that takes into

account the generally recognised state of the art measurement methods, including methods set out in documents

the reference numbers of which have been published for that purpose in the Official Journal of the European Union.

2. METHODOLOGY FOR CALCULATING THE ENERGY EFFICIENCY INDEX

The methodology for calculating the energy efficiency index (EEI) for circulators is as follows:

1. Where a circulator has more than one setting of head and flow, measure the circulator at the maximum setting.

Head (H) means head (in metres) produced by the circulator at the specified point of operation.

Flow (Q) means the volume flow rate of water through the circulator (m3/h).

2. Find the point where

Q H

is maximum and define the flow and head at this point as: Q100 % and H100 %.

3. Calculate the hydraulic power Phyd at this point.

Hydraulic power means an expression of the arithmetic product of the flow (Q), Head (H) and a conversion factor

that aligns the units used in the calculation.

Phyd means hydraulic power delivered by the circulator to the fluid being pumped at the specified point of

operation (in watts).

4. Calculate the reference power as:

Pref = 1,7 Phyd + 17 (1 e0,3

Phyd),

1 W Phyd 2 500 W

Reference power means a relation between hydraulic power and power consumption of a circulator, taking into

account the dependency between circulator efficiency and size.

Pref means the reference power consumption (in watts) of the circulator.

5. Define the reference control curve as the straight line between the points:

(Q100 %, H100 %) and (Q0 %,

H100 %

2 )

L 191/39

L 191/40

EN

Official Journal of the European Union

6. Select a setting of the circulator ensuring that the circulator on the selected curve reaches

23.7.2009

Q H

= max point.

7. Measure P1 and H at the flows:

Q100 %, 0,75 Q100 %, 0,5 Q100 %, 0,25 Q100 %.

P1 means the electrical power (in watts) consumed by the circulator at the specified point of operation.

8. Calculate at these flows

H

ref

PL Hmeas

P1,meas, if Hmeas Href

PL = P1,meas, if Hmeas > Href

where Href is the head on the reference control curve at the different flows.

9. Using PL and this load profile:

Flow

[%]

Time

[%]

100

75

15

50

35

25

44

Calculate the weighted average power PL,avg as:

PL,avg = 0,06 PL,100 % + 0,15 PL,75 % + 0,35 PL,50 % + 0,44 PL,25 %

Calculate the energy efficiency index (1) as:

EEI

PL;avg

Pref

C20 %, where C20 % = 0,49

(1) CXX % means a scaling factor that ensures that at the time of defining the scaling factor only XX % of circulators of a certain type have

an EEI 0,20.

23.7.2009

EN

Official Journal of the European Union

ANNEX III

VERIFICATION PROCEDURE

For the purposes of checking conformity with the requirements laid down in Annex I, the authorities of the Member

States shall use the measurement and calculation procedure set out in Annex II.

Member States authorities shall test a single circulator. If the energy efficiency index exceeds the values declared by the

manufacturer by more than 7 %, the measurements shall be made on three more circulators. The model shall be

considered to comply if the arithmetical mean of the measured values for the latter three circulators do not exceed

the values declared by the manufacturer by more than 7 %.

Otherwise, the model shall be considered not to comply with the requirements of this Regulation.

In addition to the procedure set out in this Annex, Member States authorities shall use reliable, accurate and reproducible

measurement methods, which take into account the generally recognised state of the art, including methods set out in

documents the reference numbers of which have been published for that purpose in the Official Journal of the European

Union.

ANNEX IV

INDICATIVE BENCHMARKS

At the time of the adoption of this Regulation, the benchmark for the best available technology on the market for

circulators is EEI 0,20.

L 191/41

You might also like

- Casinillo NewsarticelDocument2 pagesCasinillo NewsarticelJaja V100% (1)

- CE Marking Medium Voltage Switchgear and TransformerDocument7 pagesCE Marking Medium Voltage Switchgear and TransformerShailesh ChettyNo ratings yet

- Abhay-Pattnaik Rainforest Capital Profile PDFDocument1 pageAbhay-Pattnaik Rainforest Capital Profile PDFSethra SenNo ratings yet

- CELMA EcoDesign (SM) 263 - Consolidated 245 2009 Regulation As Amended by 347 2010 RegulationDocument36 pagesCELMA EcoDesign (SM) 263 - Consolidated 245 2009 Regulation As Amended by 347 2010 RegulationJairo H Pinzón CastroNo ratings yet

- EU 2015-1189-Eko Dizajn KotloviDocument15 pagesEU 2015-1189-Eko Dizajn KotloviAida DedicNo ratings yet

- Regulation 327-2011 EC 歐盟風機生態設計規範Document14 pagesRegulation 327-2011 EC 歐盟風機生態設計規範muho1No ratings yet

- Commision Regulation (EU) 2019-2020 Ecodesign Requirements For Light Sources PDFDocument32 pagesCommision Regulation (EU) 2019-2020 Ecodesign Requirements For Light Sources PDFThanosEleftheroudisNo ratings yet

- ERP Regulation 2281-2016Document50 pagesERP Regulation 2281-2016Bianca-Elena LupuNo ratings yet

- Non Domestic Building Services Compliance GuideDocument76 pagesNon Domestic Building Services Compliance GuideZoe MarinescuNo ratings yet

- CELEX 32010L0030 enDocument12 pagesCELEX 32010L0030 enMichalisCharalambousNo ratings yet

- Celex 32012R0547 en TXTDocument9 pagesCelex 32012R0547 en TXTDANE80No ratings yet

- Regulation 626 2011 EEDocument78 pagesRegulation 626 2011 EEGiannisNo ratings yet

- EU GPP Criteria For Road Lighting and Traffic Signals EU RecomDocument48 pagesEU GPP Criteria For Road Lighting and Traffic Signals EU RecomipradaNo ratings yet

- Mandato À CENDocument3 pagesMandato À CENmayordomo5625No ratings yet

- EHDOTUS CPD REVISIO CPRproposal Com2008 311Document61 pagesEHDOTUS CPD REVISIO CPRproposal Com2008 311harri.sauvalaNo ratings yet

- Eu Reg 666Document11 pagesEu Reg 666trsenurNo ratings yet

- ERP EC 1275 2008PublishedRegulation PDFDocument8 pagesERP EC 1275 2008PublishedRegulation PDFlain kaoNo ratings yet

- Discussion Paper: by The Energy Community SecretariatDocument25 pagesDiscussion Paper: by The Energy Community SecretariatEngineerNo ratings yet

- Text With EEA RelevanceDocument21 pagesText With EEA RelevanceAlla Naveen KumarNo ratings yet

- This Document Is Meant Purely As A Documentation Tool and The Institutions Do Not Assume Any Liability For Its ContentsDocument20 pagesThis Document Is Meant Purely As A Documentation Tool and The Institutions Do Not Assume Any Liability For Its ContentsddNo ratings yet

- ISCC EU 205 Greenhouse-Gas-Emissions v4.1 January2024Document67 pagesISCC EU 205 Greenhouse-Gas-Emissions v4.1 January2024imran.teknikkimiaNo ratings yet

- RoHS Detective - 32017L2102 - V2017Document4 pagesRoHS Detective - 32017L2102 - V2017Asia Dragon Capital JSCNo ratings yet

- Eu 2019-2024Document22 pagesEu 2019-2024Vitor Fiorito da SilvaNo ratings yet

- Celex 02009L0125-20121204 en TXTDocument40 pagesCelex 02009L0125-20121204 en TXTsvastaklikNo ratings yet

- Guidance Paper K: European Commission December 2004Document25 pagesGuidance Paper K: European Commission December 2004Dimitris DountsisNo ratings yet

- Mandate To Cen/Cenelecconcerning The Execution of Standardisation Workfor Harmonized Standards OnDocument30 pagesMandate To Cen/Cenelecconcerning The Execution of Standardisation Workfor Harmonized Standards Ondatagap datagapNo ratings yet

- Celex 32019R2013 en TXTDocument28 pagesCelex 32019R2013 en TXTIONUT.SNAKENo ratings yet

- Mandate BioMethane Injection Into G+NG Grid - m475Document4 pagesMandate BioMethane Injection Into G+NG Grid - m475goldanodragonzNo ratings yet

- 2018 2002 EuDocument21 pages2018 2002 EuAritra DasguptaNo ratings yet

- A9RC7ABDocument129 pagesA9RC7ABdongjinencNo ratings yet

- Commission: (Acts Adopted Under The EC Treaty/Euratom Treaty Whose Publication Is Not Obligatory)Document12 pagesCommission: (Acts Adopted Under The EC Treaty/Euratom Treaty Whose Publication Is Not Obligatory)nevenkanikNo ratings yet

- 2023 - EU - Energy Performance of Buildings - UpdatedDocument128 pages2023 - EU - Energy Performance of Buildings - Updatedheerali singhNo ratings yet

- FG For Joint TYNDP ScenariosDocument15 pagesFG For Joint TYNDP ScenariosManohar ReddyNo ratings yet

- III/B-2/EB D (98) : Standardisation, Including Industrial Aspects of Electronic TradingDocument20 pagesIII/B-2/EB D (98) : Standardisation, Including Industrial Aspects of Electronic TradingJoao NovaisNo ratings yet

- 02006L0032 20081211 enDocument28 pages02006L0032 20081211 enbzkizo_sbbNo ratings yet

- Directive 2001 80 ENVDocument27 pagesDirective 2001 80 ENVSergio PereiraNo ratings yet

- Directiva 2004 101 en PDFDocument6 pagesDirectiva 2004 101 en PDFiulian.pocotila5367No ratings yet

- CAN EbenchmarkingppfinalDocument16 pagesCAN Ebenchmarkingppfinalapi-26627973No ratings yet

- YenilenebilirenerjidirektifleriDocument8 pagesYenilenebilirenerjidirektifleriKorkutYigitYigitalpNo ratings yet

- Regulation (EU) 2019/631Document41 pagesRegulation (EU) 2019/631csNo ratings yet

- European Commission: Roof Coverings, Rooflights, Roof Windows and Ancillary ProductsDocument23 pagesEuropean Commission: Roof Coverings, Rooflights, Roof Windows and Ancillary Productsdatagap datagapNo ratings yet

- Technical Booklet K 2012Document81 pagesTechnical Booklet K 2012Ali GurselNo ratings yet

- Acto Delegado Comisión Europea HindrógenoDocument13 pagesActo Delegado Comisión Europea HindrógenoIrene CastroNo ratings yet

- Cellar .0001.02 DOC 1Document130 pagesCellar .0001.02 DOC 1kausihan selvamNo ratings yet

- EU Regulation 2023 - 1542 Concerning Batteries and Waste Batteries (2023!07!28) CELEX - 32023R1542 - EN - TXTDocument117 pagesEU Regulation 2023 - 1542 Concerning Batteries and Waste Batteries (2023!07!28) CELEX - 32023R1542 - EN - TXTPruebas de funcionamientoNo ratings yet

- REDIIDocument55 pagesREDIIMadalina GrigorescuNo ratings yet

- LeafletnewPED0496 02 tcm16-55963 PDFDocument4 pagesLeafletnewPED0496 02 tcm16-55963 PDFwahyu wibowoNo ratings yet

- EN EN: European CommissionDocument123 pagesEN EN: European CommissionWinnie NatchaNo ratings yet

- Official Journal of Machinery (MD) DIRECTIVE (2006/42/EC) : Try It For Free OnDocument10 pagesOfficial Journal of Machinery (MD) DIRECTIVE (2006/42/EC) : Try It For Free OnpmpintoisqNo ratings yet

- Consolidada ENDocument16 pagesConsolidada ENZornitza UrumovaNo ratings yet

- Draft Delegated Act Additionallity RFNBOsDocument7 pagesDraft Delegated Act Additionallity RFNBOsIngenioerenNo ratings yet

- Guideline To Machinery Directive 2006 - 42 - ECDocument457 pagesGuideline To Machinery Directive 2006 - 42 - ECSam JoseNo ratings yet

- Sistem 2+Document25 pagesSistem 2+Elena VelkovskaNo ratings yet

- Passive Houses Legislation - Cons Cons (2010) 05386 (Rev3) enDocument71 pagesPassive Houses Legislation - Cons Cons (2010) 05386 (Rev3) enkaliagraNo ratings yet

- Tsi HSR EngDocument287 pagesTsi HSR EngjamNo ratings yet

- Intertek Guidance Machinery DirectiveDocument24 pagesIntertek Guidance Machinery DirectiveGuglielmo CancelliNo ratings yet

- Building Regulation Part L Possible Future PerformanceDocument25 pagesBuilding Regulation Part L Possible Future PerformancenubazNo ratings yet

- EUROCOD 5 - Design of Timber Structures - General RulesDocument72 pagesEUROCOD 5 - Design of Timber Structures - General RulesAdi Alex100% (1)

- B Council Directive 92/42/eec of 21 May 1992 On Efficiency Requirements For New Hot-Water Boilers Fired With Liquid or Gaseous FuelsDocument16 pagesB Council Directive 92/42/eec of 21 May 1992 On Efficiency Requirements For New Hot-Water Boilers Fired With Liquid or Gaseous Fuelsbzkizo_sbbNo ratings yet

- Comparative Study on Policies for Products’ Energy Efficiency in EU and China: Joint Statement Report Series, #6From EverandComparative Study on Policies for Products’ Energy Efficiency in EU and China: Joint Statement Report Series, #6No ratings yet

- Sustainable Energy Technology, Business Models, and Policies: Theoretical Peripheries and Practical ImplicationsFrom EverandSustainable Energy Technology, Business Models, and Policies: Theoretical Peripheries and Practical ImplicationsNo ratings yet

- EU China Energy Magazine 2022 April Issue: 2022, #3From EverandEU China Energy Magazine 2022 April Issue: 2022, #3No ratings yet

- CB PumpsDocument3 pagesCB PumpsΑΝΤΩΝΗΣ ΠΑΝΤΑΖΟΠΟΥΛΟΣNo ratings yet

- Series CB: Centrifugal Pumps With Two ImpellersDocument2 pagesSeries CB: Centrifugal Pumps With Two ImpellersΑΝΤΩΝΗΣ ΠΑΝΤΑΖΟΠΟΥΛΟΣNo ratings yet

- Grundfos GO BrochureDocument3 pagesGrundfos GO BrochureΑΝΤΩΝΗΣ ΠΑΝΤΑΖΟΠΟΥΛΟΣNo ratings yet

- Datenblatt SX EnglDocument2 pagesDatenblatt SX EnglΑΝΤΩΝΗΣ ΠΑΝΤΑΖΟΠΟΥΛΟΣNo ratings yet

- Cardinal Utility, Consumer Surplus and Producer SurplusDocument23 pagesCardinal Utility, Consumer Surplus and Producer SurplusJaiaaditya RaoNo ratings yet

- U Series CatalogueDocument8 pagesU Series CatalogueAristo MNo ratings yet

- Angella Final Corrected Dissertation$$$Document52 pagesAngella Final Corrected Dissertation$$$bstogarepiNo ratings yet

- Tutorial Letter 001/3/2021: Semester 1 and 2Document49 pagesTutorial Letter 001/3/2021: Semester 1 and 2Lerato MnguniNo ratings yet

- 1Document10 pages1shiv infotechNo ratings yet

- Hotel ParagonDocument2 pagesHotel ParagonPrey Nuo CapoCanonieriNo ratings yet

- Acknowledgement: "Miss Sumita Dutta Roy" "Debyani Saha" "Changes of Packaging"Document16 pagesAcknowledgement: "Miss Sumita Dutta Roy" "Debyani Saha" "Changes of Packaging"Ryan XinghaNo ratings yet

- Ultimate Guide For Forklift TrainingDocument20 pagesUltimate Guide For Forklift TrainingFaith ChikeNo ratings yet

- Pearsons Federal Taxation 2019 Comprehensive 32nd Edition Rupert Solutions ManualDocument15 pagesPearsons Federal Taxation 2019 Comprehensive 32nd Edition Rupert Solutions Manualbannerolglycide41uud100% (25)

- 002016-2017 S2S TRAINING PROPOSAL SLAC On THE DEVT OF SCHOOL MRFDocument7 pages002016-2017 S2S TRAINING PROPOSAL SLAC On THE DEVT OF SCHOOL MRFBenjamin MartinezNo ratings yet

- River of Dreams English 9Document3 pagesRiver of Dreams English 9Cresilda BiloyNo ratings yet

- Instructions For USPS Form 1583Document3 pagesInstructions For USPS Form 1583Dan LeeNo ratings yet

- Chapter 2 - Accounting Equation and Double EntryDocument10 pagesChapter 2 - Accounting Equation and Double EntrykundiarshdeepNo ratings yet

- Orlin PetkovDocument2 pagesOrlin PetkovOrlin PetkovNo ratings yet

- Equipment: Chapter 25: PROPERTY, PLANT &Document4 pagesEquipment: Chapter 25: PROPERTY, PLANT &Czar RabayaNo ratings yet

- Downloads Introduction To Microsoft Teams PDFDocument61 pagesDownloads Introduction To Microsoft Teams PDFErika SusiloNo ratings yet

- International Examples of Affordable Housing - Shelter URBED TrustDocument19 pagesInternational Examples of Affordable Housing - Shelter URBED TrustAkshata ChauguleNo ratings yet

- Green MarketingDocument20 pagesGreen MarketingSamuel Bruce RocksonNo ratings yet

- American Business CultureDocument3 pagesAmerican Business CultureNamJin KimNo ratings yet

- Critical ReflectionDocument1 pageCritical ReflectionPatrina SamuelNo ratings yet

- Business Math For Finals NotesDocument8 pagesBusiness Math For Finals NotesPullos, Gillian C.No ratings yet

- All Subjects For B.Com TPP 6th SemDocument3 pagesAll Subjects For B.Com TPP 6th SemBaavaraja.KNo ratings yet

- NazewegukasubedeDocument2 pagesNazewegukasubedeshaft181No ratings yet

- Artificial IntelligenceDocument7 pagesArtificial IntelligencePrarthi BhoirNo ratings yet

- Assignment Contract To SellDocument4 pagesAssignment Contract To SellEloisa TecsonNo ratings yet

- Sample Tax OrdinanceDocument13 pagesSample Tax OrdinanceJohven Centeno RamirezNo ratings yet

- Thomas Cook CRMDocument23 pagesThomas Cook CRMahen123No ratings yet

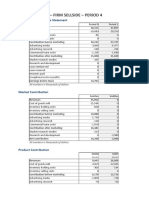

- Financial Report - Firm Sellside - Period 4: Company Profit & Loss StatementDocument73 pagesFinancial Report - Firm Sellside - Period 4: Company Profit & Loss StatementNancy suri100% (1)