Professional Documents

Culture Documents

Lean Six Sigma Case 2 PDF

Lean Six Sigma Case 2 PDF

Uploaded by

Farhan TariqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lean Six Sigma Case 2 PDF

Lean Six Sigma Case 2 PDF

Uploaded by

Farhan TariqCopyright:

Available Formats

LEAN

Lean Six Sigma Leads Xerox

SINCE 2003,

XEROX HAS

FOCUSED ON

INTEGRATING

LEAN SIX SIGMA

CORPORATEWIDE.

By Arthur Fornari,

Xerox Lean Six

Sigma, and George

Maszle, Xerox Lean

Six Sigma and

Business Support

he origin of Xerox Corp.s lean Six Sigma program can be traced

back to the companys initial leadership through quality initiative in the early 80s. Improvement processes, tools and techniques were deployed across the corporation and centered on improving

business processes to create higher levels of customer satisfaction, quality

and productivity.

As improvement processes evolved through the 80s and 90s, Xerox

explored various approaches to improving its business results. In the late

90s, Six Sigma and lean concepts were adopted locally by Xerox manufacturing and supply chain operations. While these efforts improved

the overall efficiency and effectiveness of specific processes, they were

very focused and limited in scope.

In mid-2002, Xerox leaders

decided to integrate lean and Six

Sigma across the corporation by

committing the resources required

to enable a robust deployment.

They agreed to identify projects

based on value creation and economic profit impact and engage

every function and value chain. Key

deployment management positions

were staffed in every major organization, full-time Black Belt (BB)

candidates were identified based

on the individuals performance

records and leadership potential,

Anne Mulcahy, chairman and CEO,

and intense training began in

visits with Teamwork Day particiJanuary 2003.

pants. Xeroxs annual Teamwork

Since then, Xerox Lean Six

Day celebrates the accomplishSigma, as it is called, has gained

ments of teams in a science fair

increasing momentum. More than

atmosphere.

400 BBs have been trained, more

than 700 high business impact projects have been executed, and significant financial benefits have been delivered. Additionally, 2,000 leaders

have participated in two-day workshops, another 2,500 employees are in

some phase of the Green Belt (GB) certification process, and more than

10,000 employees have been through Yellow Belt (YB) awareness training.

Leaders at all levels are working to integrate lean and Six Sigma

principles into all business processes, including product design and

development, integrated supply chain, marketing and sales, customer

service, infrastructure, governance and strategy deployment. Plans are

S I X

S I G M A

F O R U M

M A G A Z I N E

A U G U S T

2 0 0 4

11

Lean Six Sigma Leads Xerox

in place to continue this momentum into 2005 to

drive even higher levels of customer value and

financial benefits across Xerox.

Selecting Xerox Lean Six Sigma Projects

The management teams identify Xerox Lean Six

Sigma projects based on customer experience

improvement opportunities, alignment of strategic

plans, ability to close business gaps and key areas for

process improvement. As shown in Figure 1, Xerox

views the lean Six Sigma process in two distinctly different stages:

1. The first phase focuses on project selection and

prioritization. Potential projects are assessed

based on their potential business impact and estimated effort. The business unit deployment manager works with the leadership team to identify

the next best opportunity based on various business factors. To ensure alignment with Xerox

goals, the leader of the operation is held accountable for the projects selected.

2. Once the project is selected and the appropriate

sponsor confirmed, the project is queued up for

assignment to the next available BB. The BB uses

the define, measure, analyze, improve and control (DMAIC) improvement process or one of the

design for lean Six Sigma processes to identify

and deploy the best solution for the defined business problem.

Lean Six Sigma projects at Xerox address every leg

of the value lever tree (see Figure 2), and the results

of these projects directly support the Xerox business

goals.

Management Stirs Up Lean Six Sigma Success

Dedicated and committed leaders have been critical

to the success of lean Six Sigma at Xerox. The worldwide deployment was the direct result of Xerox chairman and CEO Anne Mulcahy, who believed in the

approach and asked her leadership team, Is it time

Xerox got serious about deploying Six Sigma worldwide?

After conducting preliminary presentations addressing that question, the team participated in a leadership workshop to better understand the concepts,

experience the approach and agree on a recommend-

Figure 1. Lean Six Sigma Processes at Xerox

Customer issues and opportunities.

Business strategy.

Goals and objectives.

Priorities.

Project

candidates

Prioritized by

management

team.

Assign project

to belt and

sponsor.

Sponsor

inspects

progress.

Results are

captured and

sustained.

Structured approach to project selection.

Benefit

Low Medium High

DMAIC is the project management framework.

Define

Effort

Low Medium High

12

A U G U S T

2 0 0 4

Sponsor

inspects

deliverables and

checkpoints for

each phase.

Measure

Analyze

Control

Define project purpose and scope.

Measure current per formance.

Analyze causes and confirm with data.

Improve by removing variation and nonvalue added activities.

Control gains by standardizing.

W W W . A S Q . O R G

Improve

Lean Six Sigma Leads Xerox

ed deployment recipe. The workshop enabled the

decisions required to aggressively launch Xerox Lean

Six Sigma across all organizations worldwide in 2003.

Lean Six Sigma Communication Channels

Starting with Mulcahy, Xerox Lean Six Sigma is a

key part of nearly every employee communication. It

is communicated as a key enabler in the quest to

improve Xerox. During the first leadership workshop,

Mulcahy stated, What I worry most about is how to

Several of the showcased projects at Teamwork Day

in June 2003 involved lean Six Sigma.

Figure 2. Xeroxs Value Lever Tree

Price

Revenue

Project goals:

Volume

Revenue

Labor

Cost of

goods sold

Assets

Material

Projects support all value levers and customer facing processes.

Expenses

Fixed cost

Operating

profit

Labor

R&D

Nonlabor

Sales and

manufacturing

Sales,

administrative

and general

expenses

Net operating

profit after tax

General and

administrative

expenses

Economic

profit

Operating

profit

Economic

profit is the

income

generated

relative to all

resources

required,

including

capital costs

from the

balance sheet.

Income tax

Cash

Tax rate

Receivables

Total assets

Inventory

Invested

capital

Land, building

and equipment

Cash

Capital

charge

Other assets

Payables

Weight average

cost of capital

Current

liabilities

Current debt

Other current

liabilities

S I X

S I G M A

F O R U M

M A G A Z I N E

A U G U S T

2 0 0 4

13

Lean Six Sigma Leads Xerox

return Xerox to greatness. Lean Six Sigma is not the

only answer, but its a significant part of the equation.

Lean Six Sigma is incredibly different.

In addition to having leaders communicate via

speeches, meetings and newsletters, Xerox established

an extensive intranet site that provides reference

information, deployment details, project successes

and answers to frequently asked questions. Formal

curriculum also plays a key role in communicating

Xerox Lean Six Sigma to all employees.

To supplement the standard BB and GB courses, an

online YB awareness program was launched in 2003. It

is accessible to all employees and provides a basic

understanding of core processes, tools and expectations.

Customer focus is at the heart of Xerox Lean Six

Sigma (see Figure 3). The outer ring represents Xerox

people providing value to the customer, as defined by

the voice of the customer, leading to improved business results. The cycle is never-ending because continuous improvement is never-ending. The tools and

processes for sustaining this perpetual, customer centric cycle are contained within each of the four components that surround the customer focus circle. They

include the performance excellence process, the

DMAIC improvement process, market trends and

benchmarking, and behaviors and leadership.

The performance excellence process supports the

alignment of strategies and performance objectives,

while the DMAIC improvement process provides the

basic principles and tools for process improvement.

Benchmarking and market trends provide the reference points and best practices for setting aggressive

performance targets and finding better ways to

From the Top: Xeroxs Leadership Commitment

By A. Blanton Godfrey, editor

Recently I interviewed the authors

of this article, both key members of

the Xerox executive team, about

their involvement in Six Sigma. Art

Fornari and George Maszle expanded on their companys implementation of the methodology and its integration with lean principles.

Six Sigma Forum Magazine

(SSFM): What are the key differences in todays Six Sigma at Xerox

and the well-known approach to

business management you had

before, Xeroxs leadership through

quality?

Xerox: The primary differences in

our approach now are dedicated

resources, pinpointed projects

aligned with strategic goals, an economic profit, bottom-line focus and

a standard set of methods and

processes.

SSFM: What training do the senior leaders receive? What do you

14

A U G U S T

2 0 0 4

actually cover in the two-day training

you mention?

Xerox: In the first four hours, senior leaders receive an introduction to

Xerox Lean Six Sigma and the benefits of lean and Six Sigma. Then we

do an eight-hour simulation working

with customers called Sigma

Station in which the trainees process

advertising requests. When they

start it takes more than 20 minutes

to book a request. After two or three

iterations they can do it in 30 to 45

seconds. This simulation gives them

a way to experience the real world

and use the tools of lean and Six

Sigma. This really hits home since it

is a nonmanufacturing example.

We are finding the leadership by

senior management is making all

the difference. Before, we never

made a business out of business

improvement. People are now

accountable for the economic benefits of their projects. We are also

focusing more than before on the

W W W . A S Q . O R G

customer experience with Xerox.

SSFM: You mentioned 10,000

Yellow Belts (YBs) have been

through awareness training. What

does that consist of?

Xerox: The YB training is a 16hour online training experience. It

comprises the first three modules of

our Green Belt (GB) training. We

have partnered with MoreSteam for

this training.1 We have been using

this approach for four years and

offer the training in five languages.

SSFM: Are all Black Belts (BBs)

trained in design for Six Sigma

(DFSS) as well as in design, measure, analyze, improve and control

(DMAIC)?

Xerox: No, all BBs are trained in

DMAIC, and 10% are also trained in

design for lean Six Sigma (the

define, measure, explore, develop

and implement process). We have

Lean Six Sigma Leads Xerox

improve processes. The behaviors and leadership component is critical in supporting

all components of the framework.

Management processes, at all levels, are

being modified to inspect project progress

and ensure projects focus on the key business gaps and strategies critical to the business success of each operation. From a services and solutions perspective, many customer offerings are now based on sound

lean Six Sigma principles. Additionally,

many of the projects completed or in

process address key customer issues or pain

points. Many other projects provide opportunities to partner with customers and help

them achieve higher levels of performance.

Helping customers find better ways to do

Figure 3. Xerox Lean Six Sigma Framework

Customer

valu

e

Deploying

direction

Setting

direction

eop

X er ox p

Market trends

and benchmarking

results

Customer

focus

Control

Define

Customer

Improve

value Measure

Analyze

le

DMAIC

ul

ts

Behaviors and

leadership

B us

separate courses for design (R&D)

and transactional DFSS. These

courses are two-week add-ons to

the basic five-week BB course.

SSFM: What do you think is

unique about Xeroxs approach? If

someone came to study you now,

what would they learn?

SSFM: General Electric (GE),

Motorola, Honeywell, 3M, Samsung

and others have been frequently

cited as the creators of todays Six

Sigma. Is your approach more similar to one of these companies than

the others?

Xerox: We believe we have made

an excellent integration of Six Sigma

and lean. We have used economic

profit for project selection and built

a value based solid infrastructure.

We are using Six Sigma and lean to

develop our people and train them

for future leadership positions. We

expect to pick our future leaders in

all aspects of the business from

people trained as BBs or at least as

GBs. Most of our people stay

two years as a BB. To be certified

they must complete two or three

projects, create an additional

$500,000 in economic profit and

have leadership endorsement.

Xerox: No, we are not similar to

GE, and we believe Honeywell

keeps lean and Six Sigma separate.

We believe we are more like

Caterpillar and ITT. We see four evolutions of Six Sigma:

1. Motorola was the creator.

2. GE brought the philosophy of

dedicated resources and a

strong business focus.

3. ITT added a value based

approach.

4. Caterpillar has done a good integration of lean and Six Sigma.

Performance

Delivering

excellence

and inspecting

process

SSFM: What has been most difficult in the past 18 months of implementation?

in

s

es

re

Xerox: Getting managers to give

up their best people, getting projects aligned with business needs,

understanding our gaps and opportunities for project selection and trying to break these projects down

into smaller bites than world

hunger.

SSFM: What advice do you have

for other companies that have been

leaders in their fields, true quality

leaders, and are now considering

Six Sigma?

Xerox: You have to have a reasona convincing argument from

the top. A burning platform like

Caterpillar had helps. We had made

a significant turnaround at Xerox;

we knew we could be a very good

company. But with Six Sigma we

thought we could be outstanding

we could truly go from good to great.

Reference

1. See www.moresteam.com.

S I X

S I G M A

F O R U M

M A G A Z I N E

A U G U S T

2 0 0 4

15

Lean Six Sigma Leads Xerox

great work and improving their overall experience with Xerox are two important considerations in identifying Xerox Lean Six Sigma

projects.

Continued Progress

The Xerox Lean Six Sigma deployment

has three dimensions:

1. Projects and results.

2. Cultural change.

3. Leadership development.

To continue its progress, Xerox must balance all three dimensions. While the economic benefits from the hundreds of BB

and GB projects are positively impacting

financial results, if Xerox fails to change the

culture or develop the BBs into future leaders, the business results will be short lived.

Xerox also realizes many Six Sigma

deployment efforts do not achieve their full

potential. Leadership believes the key differentiators of success and their ability to continue to make progress in Xerox include:

The ability to achieve full integration

into the business and how Xerox

employees work.

Project selection linked to business

strategies and customer value.

The ability to change culture and leadership behavior.

Engaging the full value chain in all

geographies and operations.

Ability to track results using a robust

project tracking system.

Xerox leadership also believes the basic

elements of the deployment recipe are

sound and are active across the organization

(see sidebar The Path to Transformation).

Even so, it still has a way to go to fully integrate the concepts and establish Xerox Lean

Six Sigma as how we run the business. As

project successes continue to stack up and

gain increased visibility, the momentum will

continue to build. Xerox Lean Six Sigma will

be a significant part of the equation for moving Xerox from a good company to a great

company.

16

A U G U S T

2 0 0 4

W W W . A S Q . O R G

The Path to

Transformation

To enable a successful implementation,

Xerox deployed a proven recipe recommended by the George Group. Even though minor

variations have occurred, this recipe has

clearly guided Xeroxs deployment over the

past 18 months:

1. Select projects based on value creation

opportunity such as return on invested

capital and economic profit, with the

number of projects in process controlled.

2. Use a consistent financial results tracking approach established by the deployment team and financial organization.

3. Consistently deploy and train full-time

BBs, full-time deployment managers,

sponsors and GBs.

4. Assign demonstrated top performers to

the full-time roles.

5. Adopt the defined organizational structure to enable success.

6. Engage operations leadership in the

process and integrate lean Six Sigma

into daily business operations.

7. Achieve critical mass toward the Xerox

transformation of at least 0.5% of the

employee population as BBs in 2003 and

another 0.5% in 2004.

WHAT DO YOU THINK OF THIS ARTICLE? Please share

your comments and thoughts with the editor by e-mailing

godfrey@asq.org.

You might also like

- School Management System Project DocumenDocument67 pagesSchool Management System Project Documenshekharyadaw100% (1)

- Improvement Initiatives in GCR InsuranceDocument20 pagesImprovement Initiatives in GCR InsuranceJoe Wongkar50% (2)

- Dynacorp Case AnalysisDocument4 pagesDynacorp Case AnalysisJyoNo ratings yet

- The Curious Incident of The Dog in The Night TimeDocument5 pagesThe Curious Incident of The Dog in The Night TimeCarmen Luong20% (5)

- Six Sigma Caterpillar (Fix Print)Document10 pagesSix Sigma Caterpillar (Fix Print)AuliaNo ratings yet

- Lean Manufacturing Case Study - Buck KnifesDocument11 pagesLean Manufacturing Case Study - Buck KnifesHarsh Modi100% (2)

- Case Study: Turnround at The Preston PlantDocument3 pagesCase Study: Turnround at The Preston Plantrzr88No ratings yet

- Introducing DMAIC Model With Amazing Examples (Resourceful)Document12 pagesIntroducing DMAIC Model With Amazing Examples (Resourceful)PraveenNo ratings yet

- Project Charter TemplateDocument7 pagesProject Charter TemplateKevin Brennan100% (1)

- SCL - Winning The Deming Prize - Case StudyDocument17 pagesSCL - Winning The Deming Prize - Case StudyspantdurNo ratings yet

- Greiner's Growth Model: BY Moses K. KisubiDocument17 pagesGreiner's Growth Model: BY Moses K. Kisubimoses kisubiNo ratings yet

- Samsung Uses Six Sigma To ChangeDocument4 pagesSamsung Uses Six Sigma To ChangeHarold Dela FuenteNo ratings yet

- Strategic Quality ManagementDocument3 pagesStrategic Quality ManagementArjunSP100% (1)

- Industrial Andon SystemDocument27 pagesIndustrial Andon SystemKavana K Gowda100% (1)

- Bi Scorecard Process SummaryDocument5 pagesBi Scorecard Process SummarySaving ValleyNo ratings yet

- Operational Readiness Review A Complete Guide - 2020 EditionFrom EverandOperational Readiness Review A Complete Guide - 2020 EditionNo ratings yet

- Windowstweaksguide For Windows 10Document73 pagesWindowstweaksguide For Windows 10Zeljko Radakovic100% (1)

- Six Sigma at WiproDocument16 pagesSix Sigma at Wiprosheru101No ratings yet

- Six Sigma in MotorolaDocument9 pagesSix Sigma in MotorolanidhiNo ratings yet

- The Application of Lean Six Sigma To Improve A Business ProcessDocument139 pagesThe Application of Lean Six Sigma To Improve A Business Processkushal pramanickNo ratings yet

- Applying Six Sigma at 3MDocument13 pagesApplying Six Sigma at 3MdchNo ratings yet

- Benchmark Six Sigma DFSS Black Belt CertificationDocument4 pagesBenchmark Six Sigma DFSS Black Belt CertificationKiran SoniNo ratings yet

- Xerox CorporationDocument15 pagesXerox Corporationranjitjosan100% (1)

- Six Sigma ApproachDocument7 pagesSix Sigma Approachdalaalstreet09No ratings yet

- Six Sigma of Motorola, General Electric and SkyMarkDocument23 pagesSix Sigma of Motorola, General Electric and SkyMarkSam Wing HongNo ratings yet

- Chap07 Conclusions and Future ScopeDocument3 pagesChap07 Conclusions and Future ScopeNavneet Mishra100% (1)

- A Review of Six Sigma Approach Methodology Obstacles and BenefitsDocument5 pagesA Review of Six Sigma Approach Methodology Obstacles and Benefitsjustin ambroseNo ratings yet

- Lean & Agile Systems in WiproDocument10 pagesLean & Agile Systems in WiproShreshth Gupta100% (1)

- The Agile Approach: Process ImprovementDocument6 pagesThe Agile Approach: Process ImprovementSazones Perú Gerardo SalazarNo ratings yet

- Pepsico CaseDocument8 pagesPepsico CaseAkshay tyagiNo ratings yet

- The DMAIC Improvement ProcessDocument4 pagesThe DMAIC Improvement ProcessParag SaveNo ratings yet

- Case Analysis Form - Fletcher ElectronicsDocument2 pagesCase Analysis Form - Fletcher ElectronicsAmir YousafNo ratings yet

- 13.SCM - Make Vs BuyDocument2 pages13.SCM - Make Vs BuyWah KhaingNo ratings yet

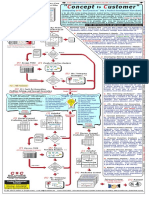

- " Oncept Ustomer": SolutionsDocument1 page" Oncept Ustomer": SolutionsJac DNo ratings yet

- Six Sigma Marketing and ProductivityDocument13 pagesSix Sigma Marketing and ProductivitySayan MitraNo ratings yet

- Ims Policy: XXXXXX Cement Strives To Provide Safe and Healthy Work Environment, For ConductingDocument1 pageIms Policy: XXXXXX Cement Strives To Provide Safe and Healthy Work Environment, For Conductingrsekumar1980No ratings yet

- Chapter 9Document14 pagesChapter 9mayank0999No ratings yet

- Mazda Quality Management SystemDocument6 pagesMazda Quality Management SystemHunter Frasca0% (1)

- DMAIC Case Study-Delivering Record Products Without DelaysDocument7 pagesDMAIC Case Study-Delivering Record Products Without DelaysNabeel RamzanNo ratings yet

- Ford Production SystemDocument4 pagesFord Production Systempravit08No ratings yet

- Improving Bank Call Centre Operations Using Six Sigma: Rahul GautamDocument8 pagesImproving Bank Call Centre Operations Using Six Sigma: Rahul Gautamsajeeby100% (1)

- Toyota Case StudyDocument2 pagesToyota Case StudyJIng JhingNo ratings yet

- Dell Case Study - G02Document3 pagesDell Case Study - G02Miniteca Mega Rumba0% (1)

- QFD PresentationDocument75 pagesQFD PresentationBhushan Verma100% (3)

- CEOs Commitment To Process Improvement Propels IPL To World Class TRACC 3458Document37 pagesCEOs Commitment To Process Improvement Propels IPL To World Class TRACC 3458Ruddy Morales MejiaNo ratings yet

- Insights To Action - New Operating Model Often Needed...Document1 pageInsights To Action - New Operating Model Often Needed...Wilson Perumal & CompanyNo ratings yet

- Dell Manufacturing PracticesDocument10 pagesDell Manufacturing PracticesShilpa UnnikrishnanNo ratings yet

- Lean ImplementationDocument28 pagesLean ImplementationJacob EdwardsNo ratings yet

- Value Stream Mapping Examples For Different IndustriesDocument19 pagesValue Stream Mapping Examples For Different IndustriesShane Mc GillycuddyNo ratings yet

- 1.0 LSS Quality Files Define OpportunitiesDocument113 pages1.0 LSS Quality Files Define OpportunitiesMurrell J RizonNo ratings yet

- Introduction To Six Sigma - EnglishDocument18 pagesIntroduction To Six Sigma - Englishnitin98325100% (3)

- Juran'S Trilogy-Planning, Control, ImprovementDocument18 pagesJuran'S Trilogy-Planning, Control, ImprovementJoannah RiveraNo ratings yet

- MBA Full Project List RM SolutionDocument34 pagesMBA Full Project List RM SolutionKesanam SpNo ratings yet

- Implementing Lean Six Sigma To Overcome The Production Challenges in An Aerospace CompanyDocument22 pagesImplementing Lean Six Sigma To Overcome The Production Challenges in An Aerospace CompanyfennyNo ratings yet

- ADL Digital Lean ManagementDocument4 pagesADL Digital Lean ManagementDuarte CRosaNo ratings yet

- 04 The Six Sigma MethodologyDocument53 pages04 The Six Sigma Methodologychteo1976No ratings yet

- Deming's Principles PDFDocument6 pagesDeming's Principles PDFmeraNo ratings yet

- Quality AwardsDocument3 pagesQuality AwardsAnbarasu KarthikaichamyNo ratings yet

- Quality CouncilDocument12 pagesQuality Councilpoma mehar33% (3)

- Mahindra and Mahindra LimitedDocument8 pagesMahindra and Mahindra LimitedRothin ShawNo ratings yet

- NR XeroxLeanSixSigma 2004mayDocument4 pagesNR XeroxLeanSixSigma 2004maywcm10No ratings yet

- Henry-1473226926-Lean Six Sigma Black BeltDocument8 pagesHenry-1473226926-Lean Six Sigma Black BeltBhagath KrishnanNo ratings yet

- Lean Six Sigma Black Belt - KPMGDocument8 pagesLean Six Sigma Black Belt - KPMGHarischandra Prasad VvnNo ratings yet

- Coulisse Journal 4 PDFDocument52 pagesCoulisse Journal 4 PDFDenis MenaceNo ratings yet

- LamyDocument5 pagesLamyDenis MenaceNo ratings yet

- Bird Nest Brochure SIRIM Oct 2011Document5 pagesBird Nest Brochure SIRIM Oct 2011Denis MenaceNo ratings yet

- Passenger Processing and Check-In: 23, 24, 25 MARCH 2010 Brussels, BelgiumDocument4 pagesPassenger Processing and Check-In: 23, 24, 25 MARCH 2010 Brussels, BelgiumDenis MenaceNo ratings yet

- FORM 3 - PEO Survey For Employer PDFDocument3 pagesFORM 3 - PEO Survey For Employer PDFFNo ratings yet

- What Is An MCU? SCM Is Going To Be Out of Date?Document15 pagesWhat Is An MCU? SCM Is Going To Be Out of Date?mengxiangNo ratings yet

- Inject MethanolDocument9 pagesInject MethanolabdounouNo ratings yet

- Ed Plan 3.0 PakistanDocument20 pagesEd Plan 3.0 PakistanSajjadNo ratings yet

- Types of Quantitative Research With SeatworkDocument11 pagesTypes of Quantitative Research With SeatworkIce IoNo ratings yet

- Using History To Teach Mathemat - Victor J. Katz PDFDocument267 pagesUsing History To Teach Mathemat - Victor J. Katz PDFLucius Thales da SilvaNo ratings yet

- Solution ManualDocument3 pagesSolution ManualhajasoftwareNo ratings yet

- ASE 2017 - Programme PreviewDocument51 pagesASE 2017 - Programme PreviewEmma HillNo ratings yet

- A Study On Workforce Diversity Management EssayDocument10 pagesA Study On Workforce Diversity Management EssayHND Assignment HelpNo ratings yet

- OGP Health Performance IndicatorsDocument20 pagesOGP Health Performance IndicatorsdediekosNo ratings yet

- Challan DAVIET ADocument1 pageChallan DAVIET AYashobhit SharmaNo ratings yet

- Course Information Confidential: Universiti Teknologi MaraDocument6 pagesCourse Information Confidential: Universiti Teknologi MaraFaiz BakarNo ratings yet

- Establishing Objectives and Budgeting For The Promotional ProgramDocument41 pagesEstablishing Objectives and Budgeting For The Promotional Programgttrans111No ratings yet

- 4 - 1 - EthnocentrismDocument7 pages4 - 1 - EthnocentrismFrancisco Javier Larraín SánchezNo ratings yet

- Opem 311Document6 pagesOpem 311MARITONI MEDALLANo ratings yet

- ABE International Business College: Republic of The Philippines Department of Education ABE - CaintaDocument2 pagesABE International Business College: Republic of The Philippines Department of Education ABE - CaintalgNo ratings yet

- The Hack Proof Password System WorkbookDocument6 pagesThe Hack Proof Password System Workbookjames007spyNo ratings yet

- Unit Lesson Plan 2Document10 pagesUnit Lesson Plan 2api-547427297No ratings yet

- Work Power and EnergyDocument18 pagesWork Power and EnergyTabada NickyNo ratings yet

- Term Project DetailsDocument4 pagesTerm Project Detailsapi-316152589No ratings yet

- Operations Research & Data Mining: Siggi OlafssonDocument50 pagesOperations Research & Data Mining: Siggi Olafssonepgp09No ratings yet

- Absorption Distance Nomogram Steam HumidifiersDocument1 pageAbsorption Distance Nomogram Steam HumidifiersFELIXDEJNo ratings yet

- Emergency Shutdown Valves - A Functional Safety Approach To SelectionDocument4 pagesEmergency Shutdown Valves - A Functional Safety Approach To SelectionBramJanssen76No ratings yet

- 04 Digital Transformation of Capital Execution With EPC 4.0 Strategy Julien de BeerDocument39 pages04 Digital Transformation of Capital Execution With EPC 4.0 Strategy Julien de BeerMuhammad Saeed100% (2)

- Isabella: Math: Grade 5: Session 6: Multiplying Fractions Using DiagramsDocument17 pagesIsabella: Math: Grade 5: Session 6: Multiplying Fractions Using DiagramslorenzomoloNo ratings yet

- Brown 1980 PoliticalsubjectivityDocument358 pagesBrown 1980 PoliticalsubjectivityGeorge PanNo ratings yet

- New Microsoft Word DocumentDocument30 pagesNew Microsoft Word DocumentRajesh KannaNo ratings yet