Professional Documents

Culture Documents

Pump Engineering DataLubosa

Uploaded by

Luis Marsh0 ratings0% found this document useful (0 votes)

59 views22 pagesPumps engineering manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPumps engineering manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

59 views22 pagesPump Engineering DataLubosa

Uploaded by

Luis MarshPumps engineering manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

Pump / Engineering Data

fax

Pump Group

VISCOSITY

] Dynamic Viscosity = u. Rleyns and Poise are common English The reliable pump people

_{and metic uns, respectively

E Kinematic Viscosity = v. Saybolt Seconds Universal (SSU) and | Imo Pump

| Stokes aro comimion Engish and meric uns, respectively 4710 Airport Road (28110)

Kinematic Viscosty (¥) = Dynamic Viscosity (y) / Density (2) PO Box 5020

| Venlo P/SG Monroe, NC

|TeP = 1 contPoise TmPas [dynamic] 28111-5020 USA

hs a 1 cSt= 1 centiStoke imm*/s_ {kinematic} tel (704)-289-6511

a NEWTONIAN vs. NON-NEWTONIAN FLUIDS | «&X_—(704)-280-9273

Je | 124 |In Newtonian fids, viscosity is affected only by temperature | al Imo.Pump @ColfaxCorp.cor

80 15.7 {and slightly by pressure). In Non-Newtonian fluids, viscosity

90} 181 _|is also affected by shear.

100) 205 TYPES OF NON-NEWTONIAN FLUIDS

110} 229 | poghamPuste ts have an exact shea Sin that, once

ra | exceeded, viscosity decreases significantly (e.g, some sluries,

30 | 27-4 ol paints, diiling muds, toothpaste, sewage sludge, catsup)

140) 297 | pssudo-Pascfuids do not ave an exact shear pot But,

150) 31-2 instead, viscosty decreases as the shear rate magritude

t70| S23 _|rereane (e9,some srs, payer, clon ceva,

480/383 [emulsions

j90| 40,7 _|Dilatant fluids increase in viscosity as the shear rate magnitude

200} 43.0 _increases (eg, high solid concentration suspensions, highly-

220| 47:3 _| saturated polymer solutions, printing ink, candy compounds). |

240) 51.7 _ | Thixotropicfulds decrease in viscosty based on both the shear | Internal

ehh hrc Gear

280 60.3 n its previous shear history (¢.g., gypsum pastes, some slurries, Purnps

300 847 some suspensions of solids in liquids, starches, paint).

$20, 68.0 _| Rheopectic fluids increase in viscosity based on both the shear Peristaltic

340) 73.3 |rate magnitude and period of time thay are being sheared (e.g., Comes

360 |__77.7___'gypsum pastes, some slurries, some suspensions of solids in

>360 = 85U+4.633)fquids, greases)

PRESSURE FLOW RATE

atm (atmospheres) x 2992 = inof Hg Laan mone ue gaimin

im 700 Pa (barrels) x. 0.700 US. gamin

ca ised fotH,O sm (eubie he) X_0.125 US. galimin

aa Rian ca Sinaia ‘emia x 7.481 U.S. gavimin

am AOS pe oti) indi x 000433 = U.S. galimin

bar x 1450 = psi Unr (itersitie) x 0.004403 = U.S. gal/min

Head in ft of Liquid x 8G4231 = psi Umin (litersimin) x 0.264 U.S. galimin

Head in tt of H0 SAT] see (tere/sec) x 1585 = U.S. galimin

Head in m of HO x 142 mith (cubic metersihe) x 4.408 U.S. galfmin

inot Hg finches of Merc.) x 0.491 soteetn ee eee

glen? x 14se8 UK. gal/min x 1.201 U.S. gavin

= US. galimin x 0833 U.K. gatimin

Wa (kloPascal) x 0.145 psi US. gain x 3785 = Umin

mPa (megaPascal) x 145 = psi US. gatimin x 0.207 mr

psi (letin?) x 231 = tof HO USS. galimin x 343 bold

psi X291+SG_= tof Liquid US. gavinin x_0196 = f%min

www.imo-pump.com

lamaten on ti shat reorece on, Vly pire

Pump / Engineering Data

lfax

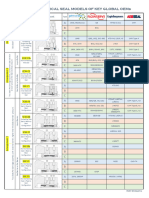

TORGUEE POWER | [ATMOSPHERIC PRESSURE | [ FILTER SOREN MESH SUE

TR x1 250 = Na | Aude Abave | mosphere] [S14 Square Mesh] Size of Opeing

tbein a Sealavel | Prosare | | (wiresn) _[ineh Gn] micron Gi Pump Group

zor = nm || er ‘ou

fe : [sx Joon) 5

x0738 = wee | | 7 ‘ipa i 1600 0.0005} 13. 7

Nm xe051 | ao | see |] “too jooois| 7 The reliable pump people

t» 550 | xo | tes || 2s [eaoir) ae

lb R xelmin + 5252 | 500 1443 | 250 |o.oce| st Imo Pump

{fin x rimin + 63025 Too | 1488 eee ea 1710 Airport Road (28110)

kW xtaet = ho sooo | var |] 132 foams) 108 | pO Box 5020

relents 028 sso | 1382 || jo Joooss) 140 | Monroe, NC

zo | 1308 ‘20 [00070] ive | 28111-5020 USA

Centrifugal smo] rar |] ae focote) 24 | irony 2n0-4st1

a || ae ooo] sex | x _ (704)-289-9273

3 joss sa | ema ImoPump@CotfaxCorp.com

as00 | 1011

qo | ta i |ooee ere

‘ 2 |oooa

zoom | ars 2 |eooes| seo 2-Serew Pumps

zoo | ssa te Joos) s120

30,000 | 4.964 14 0.0510| 1204

aso | 3458 12 [oosno| sea

oe 2720 8 |o0s6a) za62

45,000 ae 6 01318) 3360

sooo | 1682 4 jogaze| sis2

sooo | 1.323 2 [ager] i001 zs

Progressing | 6.000 1.040 Tye micron = 107 meters [Scecine GRANT oa

cavity Pumps | e500 | ost8 ‘fils Baxi" inehes [cean weer (weronco) 1.00

= All Values Typical Tor 67 to 100°F

Pur POWER & EFRCIENGY [ wOTORS Wo ons

ip = Piaraute np ape | | ence 00 osea9e

ip = gules tou np TBR of Torque perme @ 2550 min | | Dower & 197

Postiepecone Pures | LratenatTorue perm @ 2550 min || Ethanol oat

MESO | Sotmet torque perm @ 1750rmn | | Ethylane Giyco 142

Dalhatednhp -Delvered US. gemsDiterensales!| | eo.rnotTorue par ne @ 14500min || Fubar Dose Os osoo9s

‘bhp Thiperetical hnp + Mechanical Loss np | 4.87 lott of Torque per hp @ 1150 rimin Gasol! 083-085

IL 5.53 lott of Torque per hp @ 950 t/min_ Gasoline 0.66-0.74

| "ACB uotr Po ee | dota AI Fue arrose

| | ‘Number of Poles = He x 120/ Sync. rimin Kerosene 076085

Dalvered hip» Delvered gomx DH x80 /3960 | | Exams: Ligeti & Lube Os oasoas

bhp = Delvored US gom x TOHx SG || 5) Stpates tora so He, 1200 unin ACmetor= | | Merry 138

3860 x Puro Overu Ey _| 60x 120/ 1200~ 8 Matty Meche! 80

Apa |] 2#atrteora se e009 rn AC mee= || M7048 0 Tp Catrt oz

vara Pum ety = Delve np soni20/8000= 2 eam oseoas

Sarees = Dehrse | emma Sem wane tergorize Ra] | So nerand Aawaearots D804

= insal ODF & TEFC Max Tomp.Fise 6 Hox. | | Sex Water “025

= pe (Cass 1.15SF & Max40°C (104°F) Amb Temp. | | synthetic Fire Resistant Fiuids 1,081.28

‘Veoaty U.S. gebrin 0.21 x cme ‘Trystyiene Glycol 113

® Phe coarse ara init 8 wo | WEF

peeires eros 5 i Wate 40%)-Giyel Fre Res. Fd 1.08

|" SalRipatiarg aerstarredioas Wad vere F wor BNF | wate (40%)-

Gallons Per Minute

M

Pipe Velocity Ft Fi. Per Sec.

-

|1" Steel Pipe (1.049° I. D.)

Gallons Per Minute

fag SHS a AR AND AA BENS

sielalatal sPteteterertst ep Sfalefat eyo

2 2PE Ta

Le’ x sninpow = pinbrq jo 2e4—ss07

Aynery

joadg x Snjnpoy = “UI "bg Jeg “sq]—880}

edi JO 3994 OOL 10} sn|npo|; sso UO

36

Ge

Pipe Velocity Ft. Per Sec.

ST in gE geen

14" Steel Pipe (1.380" I. D.)

SOLA ANIA LON AND

AR AA ODN ARATE PNA

16°2 x sninpow — pinbr 40 18e4—8807

Aynesg 2

ads x sninpo; — “uy "bs seq “sq7—8807

adid JO J99-j OOL 140} SN|NPo| SSO] UONOL-

Gallons Per Minute

36

a

3

z

‘

Pipe Velocity Ft. Per Sec.

PBOCIOCEIIACES

Lez X sninpoy = pinbr7 jo 32e4—ss07

Aynetp oytoads x sninpoy — uy “bg 48d “sq7—s507

adid JO 199-4 OO! 40) snjnpoy| sso7 UOHOL

Gallons Per Minute

37

Pipe Velocity Ft. Per Sec.

2 Steel Pipe (2.067" 1. D

Le'e x sninpow = pinbry jo yae4—ss07

Ayneip oyjoedg x sninpow — “uy -bg Jeg ‘sq}—880]

did JO 1294 OOL 40} snjnpoy sso7 UONOI4

Gallons Per Minute

38

Pipe Velocity Ft. Per Sec.

t

a

cs

3

Sy

Le? X sninpow = pinbl7 Jo }e4—ss07

Aynesg oytoeds x sninpowy = “uy “bg 4oq ‘sq}—8807

adid JO 19944 OO} 10} snjnpo; sso] uOHOL4

Gallons Per Minute

39

aoe

' 8 8

3° Steel Pipe (3.068 I. D.)

Tht

=

Gallons Per Minute

Pipe Velocity Ft. Per Sec.

SPA ALL OLS

Hitter

Eg SS a ATK UA AR

aot

4e°2 x sninpow = pinbry jo 38e4—Ss07

Aynesg oyjoadg x sninpow — “ul ‘bg seg “*Sq]—8807

adid JO 3984 OO! 10} sNninpo|, Sso7 UOHOI

40

Pipe Velocity Ft. Per Sec.

Ca Mt A

RON iS ASS AL SCT ah ap

Le2 x sninpow = pinbrq jo 2eg—ss07

Ayes oyjoeds x sninpow =.uj “bs Jaq “sq7—ss07

adid JO 1994 OO} 10} sninpoy sso7] uOHoU4

Gallons Per Minute

at

Pipe Velocity Ft. Per Sec,

++

|

rit

perry)

sar

|

a

£

é

z

a

SJ

NN] ORL Sa RR Wot BARRY AALS

oe | :

|

Le% x sninpow = pinblq jo 9e4—ss07

‘Ayner ay!98dg x sninpoW — “ul ‘bg 4aq “sq7—Ss07

Sdid 30 38284 OO}. 404 sninpoy sso] uOHoU-4

Gallons Per Minute

Pipe Velocity Ft. Per Sec.

a

: é

a 5 f=

- SSP aN eNOS ORNS 7 rc

. fake SS AES NS ia

4£°2 x sninpoW = Pinbr7 Jo yee4—ss07,

Ayneap oyjoedg x sninpow — "ul “bg Jed “sq7—880]

@did JO 1894 OO} 40) sninpo; sso7 uoNoH4

Gallons Per Minute

43

¢

o

a

6

a

ic

2

3

2

o

FE

@

a

a

Oo

10° Steel Pipe (10.020° I. D.)

CROEXNDENIISDS ts SATA OLS

Beene ee SBCA RRA RS

aleltet et af lal La

Lez x sninpoW = pinbl] jo 2e4—ss07

Ayweay oyjoedg x sninpow — “ul “bg seq *sq7—ss07

@did JO 1994 OO} 10) snjnpoy sso7 uonoH

Gallons Per Minute

“4

4

port TI

aL

te

8

=

z

Pipe Velocity Ft. Per Sec.

PL Os

ICSENS ale aL ata Slab

PELL PRA PRP DON BE ALOE AS

aR RS SERS SAAT BRR RPP ORT

a SREREIEPECEECP S| Bethe el

Le'z X sninpow = pinbr7 Jo jee4—ss07,

‘Aynerp aytoeds x sninpoyy = “uy “bg 48d “sq7—8507

odid JO 3994 OOL 410} SN|NPO|W SSO] UO]SL-4

Gallons Per

45

46

IMO® Positive Displacement Rotary Pumps

IMO Pump Division, Imo Industries Inc., is the world's

largest designer and manufacturer of high performance,

positive displacement rotary screw pumps. It produces

three positive displacement designs - GTS} geared

twin screw; CIG® crescent internal gear; and IMO",

three-screw rotary pumps. Backed with more than 50,

years of high performance pumping experience, this

precision engineered product line includes pump

models to handle fiows from one to 8500 gpm, at

pressures from 25 to 5000 psi and fluid viscosities from

0.3 to more than a million SSU.

é

IMO pumps have achieved international recognition ©

for their design simplicity, wide fluid viscosity capabil-

ties, pulsation-fee operation, and unusually high

reliability over extended periods. Today, IMO has more

than one-half milion pumps in operation throughout the

woild, Applications are in a broad range of industries

for non-corrosive chemical processing, fuel oil/fluid

transfer, lube oil service, hydraulic power, hydraulic

sealing and turbine governar use.

GTS™ Geared Twin

Screw Pumps

GTS geared twin screw pumps find wide application

in petroloum production and refining, power genera-

tion, petro-chemical, chemical, and many other

process industries. They are used in applica-

tions wherever large volumes (up to 8500

gpm) of fuels, feeds, intermediates and end

products have to be pumped at pressures up

to about 500 psi. These pumps can handle

liquids with an extremely wide range of

viscosities, vapor pressures and densities at

temperatures up to and in excess of 600°F

(815°C). Because the profile of the pumping

screws results in minimum fluid shear, GTS pumps can

also be used with paints, greases and other materials

exhibiting non-Newtonian rheological behavior

Typical Applications

Loading, Off-Loading, Cargo Handling and

Transfer of:

Crude oil, light, middle and heavy distillates

i Residual oils, asphalts and tars

1 Aromatic, naphthenic and aliphatic intermediates

and products

Fats, cls, waxes and soaps

Mt Molasses, glycerol, glues, paints, resins and

polymers

Design and Operation

The GTS is a geared twin screw positive displace-

ment rotary pump. Externally lubricated timing gears

and bearings combined with no internal metal-to-metal

contact enable the pumping of non-lubricating fluids

as well as aggressive media. This arrangement also

allows dry running for unloading and stripping tanks,

or for evacuating long suction lines.

The basic pump design is double ended (see dia-

gram at right.) The fluid entering the inlet port (A) is

split into two equal portions (B) at the iniet end of each

a

set of screws. As the rotating screws intermesh,

transfer chambers are formed trapping and conveying

the fluid axially to the discharge chamber (C) in the

center of the pump. Its also possible to reverse

direction of flow by reversing the direction of rotation.

GTS pump flow capacity is determined by the lead

angle of the screw set. For a given case size, inter-

changeable screw sets with varying lead angles are

available. This enables the flow capability of any one

pump to be extended to cover a wide range of require-

ments.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Cti Atc 105 2000 PDFDocument76 pagesCti Atc 105 2000 PDFLuis Marsh81% (16)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- API Mechanical Seal Models of Reputed Global OEMs 1644656759Document1 pageAPI Mechanical Seal Models of Reputed Global OEMs 1644656759Luis MarshNo ratings yet

- Centrifugal Pump Health Check Up 1691257011Document35 pagesCentrifugal Pump Health Check Up 1691257011Luis MarshNo ratings yet

- Water: Design Aspects, Energy Consumption Evaluation, and ODocument27 pagesWater: Design Aspects, Energy Consumption Evaluation, and OLuis MarshNo ratings yet

- Excel and MathCadDocument13 pagesExcel and MathCadLuis MarshNo ratings yet

- Previews ASME TDP-1 2013 PreDocument9 pagesPreviews ASME TDP-1 2013 PreLuis MarshNo ratings yet