Professional Documents

Culture Documents

RP For Direct Manufacture

RP For Direct Manufacture

Uploaded by

FrancisTien0 ratings0% found this document useful (0 votes)

10 views1 pageThe document summarizes a student paper on using rapid prototyping (RP) for direct manufacture instead of injection molding. It discusses that RP has lower costs for smaller production quantities as it can build more parts faster than injection molding. However, the actual crossover point where RP becomes cheaper is higher than expected. The conclusion is that while RP is suitable now for low volume production, its costs are expected to decrease further as the technology improves.

Original Description:

A writing

Original Title

RP for Direct Manufacture

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes a student paper on using rapid prototyping (RP) for direct manufacture instead of injection molding. It discusses that RP has lower costs for smaller production quantities as it can build more parts faster than injection molding. However, the actual crossover point where RP becomes cheaper is higher than expected. The conclusion is that while RP is suitable now for low volume production, its costs are expected to decrease further as the technology improves.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageRP For Direct Manufacture

RP For Direct Manufacture

Uploaded by

FrancisTienThe document summarizes a student paper on using rapid prototyping (RP) for direct manufacture instead of injection molding. It discusses that RP has lower costs for smaller production quantities as it can build more parts faster than injection molding. However, the actual crossover point where RP becomes cheaper is higher than expected. The conclusion is that while RP is suitable now for low volume production, its costs are expected to decrease further as the technology improves.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

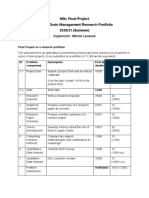

Rapid Prototyping for direct Manufacture

Student: Francis Tien

Class: GCP 12

Date: 3/4

Background: To use rapid prototyping (RP) as a way to

manufacture end products, replacing the current injection

molding method. Costs, use of materials, quality control, and

suitable applications are covered in the paper.

Method: Internet based conference from November 2000

January 2001

Compare and contrast the difference on how rapid prototyping

and injection molding manufacture products with the same

function. Data and information are gathered from Boeings

Rocketdyne propulsion and power section and NASAs Jet

Propulsion lab.

Results: The cost of RP when compared to the cost of injection

molding is lower when manufacturing products in smaller

quantities because RP can build up more parts in less time.

However, the actual number which the two crosses are much

higher than what is expected.

Conclusion: RP may be a suitable way of manufacturing for small

quantities for now, but it is expected to reach a lower cost per

part in the future as the machines for RP will improve and be

more common in industries.

References:

Hopkinson, N., & Dickens, P. (n.d.). Rapid Prototyping for direct

Manufacture. Loughborough Universitys Institutional Repository.

You might also like

- PHD Thesis in Industrial Engineering PDFDocument7 pagesPHD Thesis in Industrial Engineering PDFcyndiruppelspringfield100% (2)

- Mulligan CJ - Wilson M - Bryant G - Vaughan B - Zhou X - Belcher WJ - Dastoor PC. A Projection of Commercial-Scale Organic Photovoltaic Module Costs - Solenergymat and SCs 2014Document9 pagesMulligan CJ - Wilson M - Bryant G - Vaughan B - Zhou X - Belcher WJ - Dastoor PC. A Projection of Commercial-Scale Organic Photovoltaic Module Costs - Solenergymat and SCs 2014Daniel Maldonado ForinNo ratings yet

- Applsci 11 11805 v2Document20 pagesApplsci 11 11805 v2vaNo ratings yet

- Fyp Thesis FormatDocument7 pagesFyp Thesis Formatmariesmithwilmington100% (2)

- Dama 2017Document39 pagesDama 2017binyu2500No ratings yet

- Electronic Doctoral ThesisDocument7 pagesElectronic Doctoral Thesisjuliasolembellevue100% (2)

- Chapter 8 Homework SolutionsDocument8 pagesChapter 8 Homework Solutionsercwyekg100% (1)

- Research Paper On RPCDocument7 pagesResearch Paper On RPCefh4m77nNo ratings yet

- Sample SOPDocument3 pagesSample SOPMark LucasNo ratings yet

- Review of MicroarchitectureDocument1 pageReview of Microarchitecturejzjherd1537No ratings yet

- Final Year Thesis ExampleDocument7 pagesFinal Year Thesis Examplelaurajohnsonphoenix100% (2)

- Research Paper Energy EfficiencyDocument7 pagesResearch Paper Energy Efficiencycwzobjbkf100% (1)

- Application of Rapid Prototyping in AeroDocument11 pagesApplication of Rapid Prototyping in AeronareshNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument19 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsampjesus12No ratings yet

- Six Tenth RuleDocument8 pagesSix Tenth Ruleusman_hafeez86No ratings yet

- 06 Application Form 6 WithCMDocument23 pages06 Application Form 6 WithCMFilip JurićNo ratings yet

- PHD Thesis KTHDocument4 pagesPHD Thesis KTHkimberlybrooksmilwaukee100% (2)

- Research Paper On CFD AnalysisDocument5 pagesResearch Paper On CFD Analysislyn0l1gamop2100% (1)

- Cost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle SystemsDocument19 pagesCost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle Systemskanbur.191No ratings yet

- Energies: Fischer-Tropsch Synthesis As The Key For Decentralized Sustainable Kerosene ProductionDocument21 pagesEnergies: Fischer-Tropsch Synthesis As The Key For Decentralized Sustainable Kerosene ProductionDr-Asad IslamNo ratings yet

- Project Report Format - DiplomaDocument24 pagesProject Report Format - DiplomaMohd YusufNo ratings yet

- GS65543 Taskwk9Document5 pagesGS65543 Taskwk9NURUL HIDAYAH BT IBRAHIM / UPMNo ratings yet

- Chemical Engineering Thesis PDFDocument6 pagesChemical Engineering Thesis PDFMonique Carr100% (2)

- Compare Program ParadigmDocument2 pagesCompare Program ParadigmprabhuNo ratings yet

- Engineering Research Project Abstract and Introduction 2016Document4 pagesEngineering Research Project Abstract and Introduction 2016PoncoNo ratings yet

- Uf Submit DissertationDocument6 pagesUf Submit DissertationWriteMyPaperForMeIn3HoursMilwaukee100% (1)

- Accepted Manuscript: Chemical Engineering ScienceDocument23 pagesAccepted Manuscript: Chemical Engineering ScienceluigiNo ratings yet

- Accepted ManuscriptDocument43 pagesAccepted ManuscriptSurulivelrajantNo ratings yet

- SCM Research Portfolio Summer 2021Document10 pagesSCM Research Portfolio Summer 2021Dj KhaledNo ratings yet

- PHD Thesis NtuDocument6 pagesPHD Thesis Ntusaralewisdenver100% (1)

- 5 THDocument10 pages5 THGODWYN MNo ratings yet

- Bachelor Thesis Cover LetterDocument4 pagesBachelor Thesis Cover Letterydpsvbgld100% (2)

- Team 17: Estimation of Environmrntal Impact of Additive Manufacturing MaterialsDocument9 pagesTeam 17: Estimation of Environmrntal Impact of Additive Manufacturing MaterialsjSunayanaNo ratings yet

- Application of Pinch Technology in Refrigerator Condenser Optimization by Using CFDDocument4 pagesApplication of Pinch Technology in Refrigerator Condenser Optimization by Using CFDEditor IJTSRDNo ratings yet

- Material Flow OptimizationDocument11 pagesMaterial Flow OptimizationfilipearnauldNo ratings yet

- Literature Review On Rapid PrototypingDocument7 pagesLiterature Review On Rapid Prototypingea59j0hq100% (1)

- Research Papers On Aerodynamics PDFDocument5 pagesResearch Papers On Aerodynamics PDFtrsrpyznd100% (1)

- Taha 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012057 PDFDocument21 pagesTaha 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012057 PDFShameem KNo ratings yet

- Preliminary Estimation of Natural Gas Pipeline Construction Costs With Regression AnalysisDocument10 pagesPreliminary Estimation of Natural Gas Pipeline Construction Costs With Regression AnalysisAyman FawzyNo ratings yet

- Research Paper On RTSPDocument7 pagesResearch Paper On RTSPvehysad1s1w3100% (1)

- Performance Comparison and Evaluation of Web Development Technologies in PHP, Python and Node - JsDocument9 pagesPerformance Comparison and Evaluation of Web Development Technologies in PHP, Python and Node - JsashokmvanjareNo ratings yet

- Form A: Research Proposal Form Special Program For Research Against Covid-19 (Sprac)Document6 pagesForm A: Research Proposal Form Special Program For Research Against Covid-19 (Sprac)Huzaifa Bin HashimNo ratings yet

- Capital Cost Estimate Rule of ThumbDocument9 pagesCapital Cost Estimate Rule of ThumbParallaxster100% (1)

- 1 s2.0 S0360132318305729 MainDocument11 pages1 s2.0 S0360132318305729 Mainquang tranNo ratings yet

- Optimization of Low Speed Wind Turbine Blade Profile On The Basis of Lift CoefficientDocument9 pagesOptimization of Low Speed Wind Turbine Blade Profile On The Basis of Lift CoefficientKay LimNo ratings yet

- Knowledge Base Vs AIDocument17 pagesKnowledge Base Vs AIDeelipDapkeNo ratings yet

- Matthew J.: Research InterestsDocument7 pagesMatthew J.: Research Interestsharold_73k3388No ratings yet

- Dissertation Aerospace EngineeringDocument7 pagesDissertation Aerospace EngineeringPapersHelpUK100% (1)

- CPSP Dissertation FormatDocument5 pagesCPSP Dissertation FormatIDon'TWantToWriteMyPaperNorthLasVegas100% (1)

- M Tech Thesis Format RGPVDocument5 pagesM Tech Thesis Format RGPVhollyschulzgilbert100% (2)

- Department of Building, National University of Singapore, Singapore 119260 PWD Corporation Pte LTD, Singapore 069110Document11 pagesDepartment of Building, National University of Singapore, Singapore 119260 PWD Corporation Pte LTD, Singapore 069110sonyNo ratings yet

- Full Download Exploring Marketing Research 11th Edition Babin Test BankDocument35 pagesFull Download Exploring Marketing Research 11th Edition Babin Test Bankantimerepoonac.qv6z1t100% (25)

- Grohmann Et Al. - 2015 - Reducing Manufacturing Costs by Direct Roving PlacementDocument6 pagesGrohmann Et Al. - 2015 - Reducing Manufacturing Costs by Direct Roving PlacementJohn MichaelNo ratings yet

- VO AreasOfPractice FinalDocument14 pagesVO AreasOfPractice FinalVictor OkhoyaNo ratings yet

- Wind Power Operating Cost in UsDocument28 pagesWind Power Operating Cost in UsByambaa BattulgaNo ratings yet

- Energies: Cost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle SystemsDocument18 pagesEnergies: Cost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle SystemssilencruzNo ratings yet

- Gmu Thesis ReviewDocument4 pagesGmu Thesis Reviewlyjtpnxff100% (1)

- High Performance Parallelism Pearls Volume Two: Multicore and Many-core Programming ApproachesFrom EverandHigh Performance Parallelism Pearls Volume Two: Multicore and Many-core Programming ApproachesNo ratings yet