Professional Documents

Culture Documents

Scharffen Berger Chocolate Maker

Scharffen Berger Chocolate Maker

Uploaded by

GanesanDurairajCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scharffen Berger Chocolate Maker

Scharffen Berger Chocolate Maker

Uploaded by

GanesanDurairajCopyright:

Available Formats

Scharffen Berger Chocolate Maker

Company Overview

Scharffen Berger was founded in 1996 by Robert Steinberg and John Scharffenberger.

The chocolate maker in US market competing for $1.2 billion premium quality chocolate

segment.

Company had 60 employees and operated from a 27,000 sqft facility with 20,000 sqft

production area, office space of 5,000 sqft and retail space of 2,000 sqft

* Facing high market demand which is outstripping production. High growth in demand is

expected for its premium chocolate products and hence planning capacity expansion

Business Overview

Primary products at Scharffen Berger were

Unsweetened (99% cacao) , Extra Dark (82% cacao) , Bitter sweet (70% cacao), Semisweet , Mocha, Mint (all have 62% cacao), Milk Chocolate (41% cacao)

Others: chocolate sauce, drinking chocolate, cocoa powder and chocolate covered figs

Pricing

Retail: $0.50 for 5 gm, $2.00 for 1 ounce, $4.00 for 3 ounce, $10.00 for 10

ounce. Wholesale: approximately $0.35 per ounce

Sales

$0.6 million in 1998,

$10 million in 2004,

Over $15 million estimated revenues for 2005

Production Process At Scharffen Berger

Current Capacity and expansion

Monthly production capacity of 40,000 kgs i.e. around 29 chonc of chocolate (each

approximately worth $ 30,000 in sales)

Expansion options being considered

Purchasing more of same machines already being used

Adding a new ball mill at $ 300,000 (assuming quality remains same). Expected time

reduction to 15 hrs from avg. 60 hrs of choncing.

When ball mill is installed, Mixer will be next bottleneck. Additional mixer could be

purchased & refurbished at $ 50,000.

Outsourcing the tempering and molding process to co-packers and remove duplication.

However, transporting liquid chocolate was risky and expensive proposition.

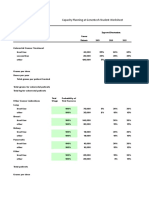

Analysis: Current Situation

Current analysis of the plant shows production capacity of 40000 Kgs

Cleaner Roaster Winnower Mixer

Available Capacity

Input: batch size (Kgs)

Conches

(2)

Temper

450

100

250

250

Mold

200

115

1400

140

140

Output

96

250

185

115

1400

140

140

Quantity of Machine

8 hour Shifts

Cycle Time (mins)

15

75

15

75

1800

60

20

Output in Kgs Per Minute

6.40

3.33

12.33

1.53

0.78

2.33

7.00

Output in Kgs Per hour

384.00

200.00

740.00

92.00

46.67

140.00

420.00

Output in Kgs Per Day

3072.00 1600.00 5920.00

2240.00

6720.00

1472.00 1120.00

Current Capacity Per Month

(Kgs)

40000

Analysis: Adding Ball Mill

Adding ball mill will reduce the average conch time from 60 hrs to 15 hours and hence

increase capacity by around 10%. Mixer will be next bottleneck.

Cleaner Roaster Winnower Mixer

Conches

& Ball Mill Temper

450

Available Capacity

Mold

200

Input: batch size (Kgs)

100

250

250

115

1400

140

140

Output

96

250

185

115

1400

140

140

Quantity of Machine

8 hour Shifts

Cycle Time (mins)

15

75

15

75

450

60

20

Output in Kgs Per Minute 6.40

3.33

12.33

1.53

3.11

2.33

7.00

Output in Kgs Per hour

384.00

200.00

740.00

92.00

186.67

140.00

420.00

Output in Kgs Per Day

3072.00 1600.00 5920.00

1472.00 4480.00

2240.00 6720.00

Capacity Per Month with

Ball Mill (Kgs)

44160

Increase in production

from As Is (%)

10

Analysis: Ball Mill and Shift Adjustments

Addition of ball mill when also supported by increasing shifts achieves an increase in

capacity by almost 66%.

Cleaner Roaster Winnower Mixer

Available Capacity

Conches

& Ball Mill Temper

450

Mold

200

Input: batch size (Kgs)

100

250

250

115

1400

140

140

Output

96

250

185

115

1400

140

140

Quantity of Machine

8 hour Shifts

Cycle Time (mins)

15

75

15

75

450

60

20

Output in Kgs Per Minute

6.40

3.33

12.33

1.53

3.11

2.33

7.00

Output in Kgs Per hour

384.00

Output in Kgs Per Day

3072.00 3200.00

200.00

740.00

92.00

186.67

5920.00

2208.00 4480.00

140.00

420.00

2240.00

6720.00

Capacity Per Month with Ball Mill

(Kgs)

66240

Increase in production from As Is

(%)

66

Analysis: With Ball Mill & 2 Mixers (2 Shifts)

Further capacity can only be increased by adding additional mixer, and lets operate that

also at 3 shifts. Now, Temperer will be next bottleneck.

Cleaner

Roaster Winnower Mixer

Available Capacity

Conches

& Ball Mill

450

Temper

Mold

200

Input: batch size (Kgs)

100

250

250

115

1400

140

140

Output

96

250

185

115

1400

140

140

Quantity of Machine

8 hour Shifts

Cycle Time (mins)

15

75

15

37.5

450

60

20

Output in Kgs Per Minute

6.40

3.33

12.33

3.07

3.11

2.33

7.00

Output in Kgs Per hour

384.00

200.00

740.00

184.00

186.67

140.00

420.00

Output in Kgs Per Day

3072.00

3200.00

5920.00

4416.00

4480.00

2240.00

6720.00

Capcacity Per Month with

Ball Mill (Kgs)

67200

Increase in production from

As Is (%)

68

Analysis: Ball Mill, 2 Mixers & Shift Adjustments

Further capacity can be increased by increasing shifts of Temperer, then increasing shift

of cleaner and then increasing shift of Roaster

Cleaner

Roaster

Available Capacity

Winnower Mixer

Conches

& Ball Mill

450

Temper

Mold

200

Input: batch size (Kgs)

100

250

250

115

1400

140

140

Output

96

250

185

115

1400

140

140

Quantity of Machine

8 hour Shifts

Cycle Time (mins)

15

75

15

37.5

450

60

20

Output in Kgs Per Minute

6.40

3.33

12.33

3.07

3.11

2.33

7.00

Output in Kgs Per hour

384.00

200.00

740.00

184.00

186.67

140.00

420.00

Output in Kgs Per Day

6144.00

4800.00

5920.00

4416.00

4480.00

3360.00

6720.00

Capcacity Per Month with

Ball Mill (Kgs)

100800

Increase in production from

As Is (%)

152

Conclusion

In the current situation conchs are the clear bottleneck.

After addition of ball mill the production capacity will increase by around 10%, however

further capacity can be increased by increasing shifts of mixer up to almost 66%

increase in capacity until mixer becomes bottleneck

Then adding a mixer will increase the production capacity to 68%, which can further be

increased up to almost 150% by increasing shifts of Temperer, cleaner and roaster.

Since the expected increase in demand is around 30% by end of the year. Adding ball

mill and adjusting shifts would be sufficient for now.

You might also like

- United CerealDocument6 pagesUnited CerealSouhardya BanerjeeNo ratings yet

- Austrian Desserts Pastry Dietmar Fercher PDFDocument331 pagesAustrian Desserts Pastry Dietmar Fercher PDFDániel Kovács100% (3)

- American Connector Company - CaseDocument11 pagesAmerican Connector Company - CasevipinsureshNo ratings yet

- Panera Bread Case StudyDocument18 pagesPanera Bread Case StudyAvnchick100% (1)

- Iggy PopDocument15 pagesIggy PopAjey BhangaleNo ratings yet

- Pillsbury Cookie ChallengeDocument9 pagesPillsbury Cookie ChallengeHaaris Mateen100% (2)

- United CerealDocument16 pagesUnited CerealMonilGupta100% (3)

- Scharffen Berger Chocolate Maker CaseDocument8 pagesScharffen Berger Chocolate Maker CaseKelvin WongNo ratings yet

- Benihana of Tokyo Analysis of CaseDocument3 pagesBenihana of Tokyo Analysis of CaseAli KhanNo ratings yet

- NewellDocument17 pagesNewellNandish GuptaNo ratings yet

- Final Report Group7 Case1 Scharffen Berger Rev02Document18 pagesFinal Report Group7 Case1 Scharffen Berger Rev02Anushree SinghNo ratings yet

- Scharffen Berger Chocolate Maker (A)Document5 pagesScharffen Berger Chocolate Maker (A)CHIMANKAR NISHANT PRAKASH [PGP Mumbai 2016 Batch]No ratings yet

- New Balance Case StudyDocument3 pagesNew Balance Case StudyDimas AdityaNo ratings yet

- Midterm Exam AnswersDocument8 pagesMidterm Exam AnswersJ100% (1)

- Aldi FinalDocument13 pagesAldi FinalRachit Kumar100% (3)

- Chocolate Maker Excercise Case Schatfeen BergerDocument1 pageChocolate Maker Excercise Case Schatfeen BergerpacoNo ratings yet

- Scharffen Berger Chocolate Maker - Robert Paul EllentuckDocument9 pagesScharffen Berger Chocolate Maker - Robert Paul EllentuckRobert Paul Ellentuck100% (4)

- Corporate Gifters Giftex 2019Document9 pagesCorporate Gifters Giftex 2019hsco rdNo ratings yet

- Service Marketing-Pret A Manger - Group 6Document6 pagesService Marketing-Pret A Manger - Group 6Chiku JainNo ratings yet

- Presentation RoshenDocument22 pagesPresentation RoshenDiana Lazari100% (1)

- 2 Weeks Supply: Capacity Analysis On Current Production CapabilityDocument6 pages2 Weeks Supply: Capacity Analysis On Current Production CapabilityPuran NarwaniNo ratings yet

- OM1 Case Analysis Scharffen Berger Chocolate Maker Group1Document5 pagesOM1 Case Analysis Scharffen Berger Chocolate Maker Group1Abhishek Rungta100% (1)

- Case 4 AnalysisDocument3 pagesCase 4 AnalysisKoustubh Khandekar0% (1)

- Chocolate CaseDocument4 pagesChocolate CaseAmol KatkarNo ratings yet

- Salem Analytics Panera Bread Company Final ReportDocument31 pagesSalem Analytics Panera Bread Company Final ReportCecille TaguiamNo ratings yet

- Scharffen Berger Case Study - Team 2Document12 pagesScharffen Berger Case Study - Team 2Andrew Bernier100% (1)

- Benihana of TokyoDocument6 pagesBenihana of TokyoSumit FatewarNo ratings yet

- Genentech Student Worksheet - ResultDocument10 pagesGenentech Student Worksheet - ResultArijit MajiNo ratings yet

- Report On Packaging Industry in IndiaDocument8 pagesReport On Packaging Industry in IndiaAjey BhangaleNo ratings yet

- Scharffen Berger Chocolate Maker (A)Document8 pagesScharffen Berger Chocolate Maker (A)Andy VibgyorNo ratings yet

- Foldrite Furniture Company: CASE StudyDocument4 pagesFoldrite Furniture Company: CASE StudyJapkirat Oberai0% (1)

- Guia Do Açucar 2Document228 pagesGuia Do Açucar 2antonio cristoNo ratings yet

- Schaffen Berger Case AnnalysisDocument7 pagesSchaffen Berger Case AnnalysisTamarai Selvi ArumugamNo ratings yet

- ChocolatierDocument99 pagesChocolatierAyah MaherNo ratings yet

- Scientific Glass - SolutionsDocument29 pagesScientific Glass - SolutionsShirsendu Bikash Das100% (1)

- OM2 LeitaxCase GroupE7Document9 pagesOM2 LeitaxCase GroupE7Ashfaq Shaikh50% (2)

- Foldrite Furniture CaseDocument7 pagesFoldrite Furniture CaseJoe Joy0% (2)

- BUS 101 Term Paper On PRAN-RFL GroupDocument48 pagesBUS 101 Term Paper On PRAN-RFL GroupSanaullah Siddique100% (3)

- Engn9 Final Paper Compass BoxDocument10 pagesEngn9 Final Paper Compass BoxMatthew GorhamNo ratings yet

- GenentechDocument4 pagesGenentechAchal Goel100% (2)

- Case Study - Tyndall Furniture (B)Document12 pagesCase Study - Tyndall Furniture (B)이현주100% (4)

- Shouldice Hospital Group8Document8 pagesShouldice Hospital Group8Rahul Shankar0% (1)

- Phillips Vs Matsushita Case StudyDocument7 pagesPhillips Vs Matsushita Case StudyDan Ochieng Jr.No ratings yet

- Group - 4 Tetra PakDocument8 pagesGroup - 4 Tetra PakkjhathiNo ratings yet

- Dore Dore CaseDocument6 pagesDore Dore CaseShishir Kumar100% (1)

- OM Scharffen Berger Case FactsDocument13 pagesOM Scharffen Berger Case FactsPratima Rani100% (1)

- Case Analysis: - By: FAS Group A2Document14 pagesCase Analysis: - By: FAS Group A2Alan SamNo ratings yet

- Scharffen Berger Chocolate MakerDocument6 pagesScharffen Berger Chocolate MakerRashmikanta MaharajNo ratings yet

- Final Report Group7 Case1 Scharffen BergerDocument18 pagesFinal Report Group7 Case1 Scharffen BergerJAFZ197750% (2)

- Chocolate CaseDocument17 pagesChocolate CaseRonit RainaNo ratings yet

- Baria Planning Solutions, IncDocument10 pagesBaria Planning Solutions, IncJayant Jordan DùttåNo ratings yet

- Making SMaL Big: SMaL Camera TechnologiesDocument28 pagesMaking SMaL Big: SMaL Camera Technologiesattar11No ratings yet

- R&R CaseDocument14 pagesR&R CaseSyed Mahmudul MuddassirNo ratings yet

- EQAB Day4 ReportDocument13 pagesEQAB Day4 ReportSudeep Krishna Shrestha100% (3)

- Patagonia CaseDocument1 pagePatagonia CaseArmyandre Rossel SanchezNo ratings yet

- Bacchus, Safraz LE1 - NCCDocument6 pagesBacchus, Safraz LE1 - NCCshaf33zaNo ratings yet

- Shouldice Hospital CaseDocument2 pagesShouldice Hospital CasefedardoNo ratings yet

- Pillsbury Cookie Challenge: by Group 9Document7 pagesPillsbury Cookie Challenge: by Group 9Aman UpadhyayNo ratings yet

- B 2 MicrofridgeDocument7 pagesB 2 MicrofridgeSATYANSH BHATNAGARNo ratings yet

- Performance Over The Course of Simulation MarkstratDocument5 pagesPerformance Over The Course of Simulation MarkstratAnkit SutariyaNo ratings yet

- Barilla's Spa Case Study (Group-04)Document18 pagesBarilla's Spa Case Study (Group-04)lokesh_chaudhary_1No ratings yet

- Group 4 - Shouldice HospitalDocument9 pagesGroup 4 - Shouldice HospitalRithwik PrathapNo ratings yet

- BlanchardDocument9 pagesBlanchardtwinkle kumariNo ratings yet

- Operations Management Dr. Rogelio OlivaDocument8 pagesOperations Management Dr. Rogelio OlivaA SNo ratings yet

- Bergerac System - Group 6Document8 pagesBergerac System - Group 6Rahul BurmanNo ratings yet

- Machine Capacity of Woven Dyeing FloorDocument3 pagesMachine Capacity of Woven Dyeing FloorMd. Saidul IslamNo ratings yet

- 2018 Small Soap Machines Sapo-Flakes - EngDocument6 pages2018 Small Soap Machines Sapo-Flakes - EngAgus SudarmaNo ratings yet

- Project Profile-Manufacturing of Rusk CokkiesDocument15 pagesProject Profile-Manufacturing of Rusk CokkiesSannat JainNo ratings yet

- CERAWeek 2016 Agenda at A GlanceDocument13 pagesCERAWeek 2016 Agenda at A GlanceAjey BhangaleNo ratings yet

- Confess Confess Deny 3 Yrs. 1 Yr. 10 YrsDocument3 pagesConfess Confess Deny 3 Yrs. 1 Yr. 10 YrsAjey BhangaleNo ratings yet

- Why CG RequiredDocument2 pagesWhy CG RequiredAjey BhangaleNo ratings yet

- Unfair Trade Practices ActDocument2 pagesUnfair Trade Practices ActAjey BhangaleNo ratings yet

- UTP Project ProposalDocument7 pagesUTP Project ProposalAjey Bhangale0% (1)

- DeSilva & ArmstrongDocument11 pagesDeSilva & ArmstrongAjey BhangaleNo ratings yet

- Tanishq: Positioning To Capture The Indian Woman'S HeartDocument6 pagesTanishq: Positioning To Capture The Indian Woman'S HeartAjey BhangaleNo ratings yet

- Chap 011Document10 pagesChap 011Ajey BhangaleNo ratings yet

- Ec Quiz Fiscal&Monetarypolicyii AnswersDocument4 pagesEc Quiz Fiscal&Monetarypolicyii AnswersAjey BhangaleNo ratings yet

- EDLPDocument37 pagesEDLPAjey BhangaleNo ratings yet

- CCF Script For OnlineDocument20 pagesCCF Script For OnlineSurbhi MadanNo ratings yet

- Dairy Milk Full ProjectyDocument65 pagesDairy Milk Full ProjectyMahesh Kumar0% (1)

- Know Your Chocolates LatestDocument1 pageKnow Your Chocolates Latestkzn_guyNo ratings yet

- Profile of RespondentsDocument36 pagesProfile of RespondentsPratibha SharmaNo ratings yet

- PracticalsDocument3 pagesPracticalsExamination Cell CAEPHTNo ratings yet

- Fruit Roll Ups - Google SearchDocument1 pageFruit Roll Ups - Google Searchrona abrianaNo ratings yet

- Consumer Studies PAT GR 12 2023 (Food Production) EngDocument29 pagesConsumer Studies PAT GR 12 2023 (Food Production) EngJonie du PlooyNo ratings yet

- Iv. Internal EnvironmentDocument4 pagesIv. Internal EnvironmentPatrik Oliver PantiaNo ratings yet

- Recipe ReportDocument79 pagesRecipe ReportMuhd HafeezNo ratings yet

- Natural Essence Company in IndonesiaDocument20 pagesNatural Essence Company in IndonesiaFlo CartNo ratings yet

- Synthetic Food Colorants For Use As Food AdditivesDocument9 pagesSynthetic Food Colorants For Use As Food AdditivesMadhu ShaliniNo ratings yet

- Briessweet™ Tapioca Syrup 42de: (100G As-Is) (Dry Basis)Document1 pageBriessweet™ Tapioca Syrup 42de: (100G As-Is) (Dry Basis)Anonymous Pjbdf4wWNo ratings yet

- 2019 KNGDocument25 pages2019 KNGVivian LeighNo ratings yet

- Charlie and The Chocolate FactDocument2 pagesCharlie and The Chocolate FactSatta 'Sami' FodayNo ratings yet

- Brainstorming: Write As Many Different Jobs As They CanDocument11 pagesBrainstorming: Write As Many Different Jobs As They CankatyaNo ratings yet

- Project On Gourmet IcecreamDocument19 pagesProject On Gourmet IcecreamKhawaja FaizanNo ratings yet

- Willy WonkaDocument3 pagesWilly Wonkaheaven_mariNo ratings yet

- Practical File Questions With AnswersDocument7 pagesPractical File Questions With AnswersPriyanshu KumarNo ratings yet

- Brochure - CAASDocument36 pagesBrochure - CAASLoraineNo ratings yet

- Introduction: Candy Store Anthropometry International Case StudyDocument2 pagesIntroduction: Candy Store Anthropometry International Case StudyNisha LamixaneNo ratings yet

- Lab Exer 10 - Pastillas de LecheDocument4 pagesLab Exer 10 - Pastillas de LecheJack FrostNo ratings yet

- Catalogue Part IIDocument12 pagesCatalogue Part IIBadrinath ChoudhuryNo ratings yet

- Solving Problems With FractionsDocument3 pagesSolving Problems With FractionsDavid KotutNo ratings yet

- Tes Evaluasi - Instruction TextDocument4 pagesTes Evaluasi - Instruction TextAgung PurnamaNo ratings yet