Professional Documents

Culture Documents

Zetor Service7520-10540 GB

Zetor Service7520-10540 GB

Uploaded by

mink4u0 ratings0% found this document useful (0 votes)

580 views236 pageszetor

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentzetor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

580 views236 pagesZetor Service7520-10540 GB

Zetor Service7520-10540 GB

Uploaded by

mink4uzetor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 236

ZETOR

piel

pty)

eee (Neg E

Cee Ummm UTM

el at mmm

eee Dmg ASU

reir RU RO

MNMEREOOMER

porter Dee UU

CERCOOTE

OPERATOR'S MANUAL

ek

‘The Instruction Manual ve are putting forvard to you will make you faniliar with

the operation and naintenance of your nev tractor.

Though nany of you have auch experience in operation of other tractors, ve would

Like to ask you to nate yourselves as fanilizr vith the contents of this nanual

as possible.

You will find here many itens of nev information and get the perfect view on how

to make the best use of tractor in carrying out various tasks,

If you follov the entioned principles of operation, maintenance and safe

operation, the nev tractor vill be your reliable assistant for nany years.

‘he manufacturer of your tractor wishes you thousands of conveniently acconplished

engine hours.

Yours sincerely

ZETOR

This operating Instruction Manual

contains descriptions, operation and

saintenance instructions of standard

tractor nodel and accessories the

tractor can be equipped vith,

CONTENTS

Serial Number Locations.

Tnportant safety instructions for user...

Preventative maintenance daily.

Getting faniliar vith the tractor.

PHOENIX electronic dash panel...

Operating the tractor.

Utilization for transport.

Pover drive of agricultural machines.

Hydraulic systen

IR 4 BOSCH electronic hydraulies

‘three - point lirkage

Changing front viel track,

Double ~ nounted rear vbeels.....

Ballast weights,

Filling the tires with liquid...

wintenance of tractor.

waintenance instructions

Adjustuent......

Blectrical installation.

Technical data.......

lubrication chart of tractor.

101

105

us

Mo

153

167

a5

TETOR

TBTOR

TETOR

2aTOR

1520

8520 TURBO

9520 TURBO

10520 TURBO INTERCOOLER

SERIAL UKBER LOCATION

‘Tractor Serial Nurber ROPS Cab Serial Nunber ‘Engine Serial Number

SERIAL NUMBER LOCATIONS

finen ordering spare parts or in any other contact, please, use the tractor data titled belov and note the appropriate data

of your tractor in the windows.

Tractor type Tractor Serial Nunber Engine Serial Number

‘TeTOR 7520.0, TENOR 7540.0

BBTOR 7520.1, 2ETOR 7540.1

TBTOR 8520.0, 2ET0R 8540.0

TETOR 8520.1, 2ET0R 8540.1

TETOR 9520.0, ZETOR 9540.0

TETOR 9520.1, ZETOR 9540.1

‘BTOR 10520.0, ZETOR 10540.0

TETOR 10520.1, ZENOR 10540.1

Indications "right", *left®, "in the

front" and "at. the back" relate to

the tractor's driving direction,

‘he manufacturer reserves his right

to make changes to the tractor design

and equipnent resulting in technical

inprovenent.

You vill find this safety alert syzbol

with all safety nessages concerning

the safety of tractor operation,

Observe these warnings and behave

yourself carefully in these cases

Warn your co-workers and other per~

sons.

SAFETY INSTRUCTION FOR USER'S REFERENCE

GENERAL SAPETY REGULATIONS

Only a trained operator having a valid

driving License and acquainted vell

with the operating and safety princip-

Jes is allowed to operate the tractor.

In addition to the warnings contained

in the operating instructions you are

obliged to follow the general safety

and traffic regulations being in force

in the country of tractor utilization,

PROPER CLOTHING

Do not wear loose garnents nor long

hair.

‘Take suitable (prescrised) personal

safety precautions while working,

(Ware vorking boots gloves, etc.)

ANGINE STARTING

‘he engine should never be started by

running the tractor down a slope.

‘fo tow the tractor in order to start

the engine by another tractor or

vehicle, a tov bar must be used,

‘The Key must be in its "I" position on

tthe ignition switch,

While heating engine by an electrical

heater, plug the cable plug in the

heater socket and only then connect

tthe cable to the mains. After heating

isconnect the cable fron the mains

first.

WARNING!

Danger of injury by electric current.

RIDING OPERATION

Fuel systen hoses should be checked

and replaced if any indication of da-

nage is revealed. The indications of

hose danage could be: cracks on

hose surface , slackening of hose

connection pre-stressing viich can be

verified by sliding the hose down vith

an ease, mechanical damage of hoses,

‘The condition of brakes. and steering

mst be permanently perfect. The

brake pedals mist be coupled vith

one another using the latch prior to

driving on roads with trailers. or im-

Plexents. Driving downhill vith

no speed-gear engaged is forbidden, Pay

special attention to driving on slopes

and muddy, sandy, icy or uneven surfa-

ces. Do not exceed the saximun slope

incline specified for the tractor.

(11°as paximua)

Be respectful of total pernissible

weight of tractor-trailer unit as nen-

‘tioned on the tractor rating plate or

(on the warning label attached to the

Tear wheel fender.

SAFETY INSTRUCTION FOR USER'S REFERENCE

‘Do not use the differential interlock

while driving in a bend .It is

forbidden to climb on and off the

noving tractor . hen driving the

tractor with agricultural machines

hinged in the front three-point

Linkage the driving speed of the

tractor should not be above 20 kn/hour

TRANSPORT OF PERSONS, DRIVING

Nunber of persons transported on trac

tor mist not exceed the data mentioned

in the H.0.f.certificate. Inexperienced

‘operators should rot use tractor auxi-

Liary equipment ard must Keep clear,

and not stand betveen the tractor and

any attached implements.

efore driving tte tractor make sure

that passengers or any other obstacle

do not inpede driving,

The naximm persissible velocity of

road train (tracteritrailer or seui-

trailer) vith single-hose air brakes

is 25 kn/hour.

Follow the specified accessibility

as slope angle is concerned, which

for the individual tractors are:

17520

27540 12

18520 19

28540 122

29520 1°

19540 12

110520 1°

1 10540 12°

SALVAGE, PUSHING

‘To free a *bogged-down" tractor use @

tow bar or rope. Never use chains,

Tt is dangerous to stand near the tov

rope when the tractor is being freed,

‘he tractor frane is equipped vith a

front hook serving only for toving the

tractor itself, i.e. without any

trailer or other attachnent.

When pushing other vehicles, trailers,

carriers or sinilar vhile naking use

the tractor never use loose planks or

bars inserted betveen the tractor and

‘the object being pushed.

LEAVING THE TRACTOR

Use the left side of the cab for

getting out of the tractor. Lift off

‘the passenger seat,look if any vehicle

causing danger isn t near and open the

door.tse the running board and hand

tails for entry and exit to and from

driver's cab. When getting out on the

right side, special care should be

taken in the area of the control

levers.

SAFETY INSTRUCTION FOR USER'S REFERENCE

Shift the gear lever in the direction

toward the driver s seat and if the

engine is still , engage the hand-

operated throttle control to its"MAX"

position.Do not park the tractor with

inplenents lifted. Do mt forget to

resove the key fron the ignition

switch and to lock the cab.

ONLY WITH THE ENGINE STOPPED

‘MLL the jobs connected vith re-

fueling, cleaning, lubrication and ad-

justuent to tractor or atzached inple-

tents may be carried out only vith the

engine stopped or other moving parts

at rest except when checking the break

function , hydraulics or battery

charging. Start and operate the engine

ina vell ventilated are only.Bbaust

gas is harnful to health

10

FIRE PREVENTION PRINCIPLES

Refueling should preferably be

carried out with the engine stopped

at the end of vorking day. In case of

a leakage of fuel fron the fuel hose

systen close the fuel cock on the

Tight side of the reservoir, on trac-

tors with an additional reservoir on

‘the top reservoir on the left side,

Do not refill the fuel tank complete-

ly in the sumer season. Wipe off

spilled fuel innediately.

Do not refill the tank near an open

flane and do not snoke,

‘ake special care and follow the fire

safety instructions in environsents

with increased danger of fire

(naylofts,strav stacks and sinilar).

It the tractor is equipped vith

a fire extinguisher it should always

be to hand.

HEALTH AND ENVIRONMENT PROTECTION

‘WHEN HANDLING OTL, PRODUCTS

‘Tractors are not equipped vith special

cab intake air filters. They are

‘therefore not intended for vorking

vith aerosols and other substances

harmful to health. erosene, Diesel

oil, nineral oil and other oil pro-

ducts used during tractor operation

and maintenance of may cause skin

disease, eye irritation or injury,

stomach upsets and nasal irritations.

Sone of] products vhen inhaled as

Vapour or when take internally can be

fatal.

The persons in contact with oil pro-

ducts should constantly observe safety

‘and hygiene precautions, use suitable

protective clothing and apparatus and

work only in vell ventilated areas.

SAFETY INSTRUCTION FOR USER'S REFERENCE

Having finished the vork or before

pea] it's essential the operator vashes

off all traces of an oil product using

a non-irritant washing agent and

applying suitable ointment ftand crean

on his bands,

With disconnecting or reconnecting the

hydraulic circuit quick-couplers use

a textile aaterial or cloth to renove

‘the residual ofl vhich remains inside

the socket or on the plug of quick

coupler.

u

‘PREVENTATIVE MAINTENANCE DAILY

Should be carried out daily or every 10 engine hours, no later

PREVENTATIVE MAINTENANCE DAILY

CCHBCK ON FUEL, SYSTEM FOR LEAKS ENGINE OTL, LEVEL, (COOLANT SYSTEM

Check the fuel system for leaks inclu- check the oil level in engine and the check the engine coolant systea for

ding the fuel tank placed above the engine lubrication systen for leaks, leaks and the coolant level in the

engine, Fix any leaks. ‘op up oi] to the specified level. expansion tank, Top up to "AAX" mark,

‘Tractors with a non see-through ex

pansion tank should have the level

about 20 mn under the seat of expan-

sion tank, The aininun coolant level

is approximately 40m under the tank

seat.

PREVENTATIVE MAINTENANCE DAILY

: an

1 a

Ir 4 \

i s yp \

% nr ~

of as Ni ytd wi

‘HYDRAULIC BRAKES PNEUMATIC BRAKES ‘STEERING

Check the hydraulic brakes and the

hydraulic systen of clutch control for

leaks.

Check the brake fluid level in the

expansion tank located under the

steering wheel bracket. Also check the

‘trailer hydraulic brakes,

Check the air brake systen for leaks

leaks and the tractor sraking effi-

ciency including trailer (see "Check

of pneumatic brakes for Leaks"),

u

Check the oil level within the hydro-

static steering reservoir. check the

steering tie-rods and amas for torque

of bolts and nuts.

PREVENTATIVE MAINTENANCE DAILY

‘TIRES AND WHEELS

Check the inflation pressure both in

front. and rear tires. Adjust to the

recommended values depending on the

type of work, check the thread on

front and rear heels - check all the

bolts.

Never ride vith bolts not tight.

‘AIR CLEANER CAB ATR FILTER

Inspect the engine air precleaner and Inspect and clean cab ventilation air

clean it, if necessary. the dry air filters located under the front panel.

cleaner contains a sensor that lights

‘an indicator on the dash panel vhen

too dirty,

5

PREVENTATIVE HAINTENANCE DAILY

‘TRAILING ATTACHMENTS

Inspect the trailing and towing

attachaents including the trailer.

APTER OPERATION WITH FRORT TAPLEMENTS

Clean the front vall of engine redia~

tor using pressure air in the direc

tion avay fron the engine. this hovever

should be done after renoving the

front grill in order to blow the dirt

outside the tractor. Remove the

reraining dirt under the bonnet to

avoid repeated obstruction,

Check the external hydraulic circuitry

fittings of the three-point Linkage

for leaks,

6

SHORT FUNCTIONAL TEST

After starting the engine check

the engane lubrication indicator lanp

is off, ches the accumilator charging

function (the indicator lanp should be

off), and check the hydraulic steering

circuits for function and leaks.

A

‘The tractor user is obliged to nake

himself faniliar with the recomended

procedures and instructions concer-

ning safety operation of the tractor.

It is too late to do so during

operation!

GETTING ACQUALBTED WITH TRACTOR

Page

Driver's sea B

Passenger's seat. 9

Cab features... 2

Cab doors and windows. a

Windscreen vasher. a

Adjustable steering vhee a

Dash panel... 2B

Indicator warning lights...... %

PHORNIX electronic dash panel. n

a

2

26

29

Yarning and information plates 40

nv

DRIVER'S SEAT

WEIGHT ADJUSTAENT

The spring loaded seat is adjustable

to operator's veight vithin the range

of 50 to 120 kgs, Adjustoent can be

carried out by turning the square

handle, The weight adjusteent indi-

cator is placed on the “rear cover of

seat.

‘he total seat springing is 120 m,

Do not adjust the seat vhile

/\ driving

Danger of accident!

Use the left-hand side lever to slide

the seat forvards or backvards within

the range of £ 75.n (11 positions).

VERTICAL, ADJUSTHENT

Use the right-hand side lever to ad-

just the seat to height within the

range of + 30 mn (3 positions).

B

t

N20]

CRAMMER" SEAT - FORE/APT ADJUSTAENT

Adjustuent is nade by a lever on right

hand side of seat within the range of

+75 mm, steps of 15mm,

Height adjustuent is made by Lifting

the seat.the height adjustuent is in

three positions within the range of

+ 30mm,

DRIVER'S WEIGHT ADJUSTMENT

Adjustuent is nade by a control loca~

ted on front bottom section of seat

together vith driver's weight indica~

tion.

PASSENGER'S SEAT

PASSENGER'S SEAT LOCATION PASSENGER "TRANSPORT PASSENGER TRANSPORT

locking lever vhen transpor- ger don't use the arrestnent

ting a passenger. strut on his side for venti-

lation.

‘The passengers's seat is tilting and ‘Always lock the door by When transporting a passen-

is located on the rear fender. A A

(CAB FEATURES

®)

®)

fd

Oy

SHITCHES ON THE RIGHT-HAND SIDE CAB

cova

1, Inner cab lamp, including switch

2, Front two-speed vindshield wiper

and washer switch

3, Rear wiper switch

4, Independently controlled front

Pto switch (tractors vith front

PTO only)

5. Independently controlled back PTO

shaft switch (tractors with front

PQ only)

6, Electro - pneumatic control of

hydraulic system.

‘HEATER CONTROL, PANEL

1, Four-position fan speed selector

2, Heating cock control lever. the LH

position shuts off the cock.

3, Control lever of flap-valve for cab

air circulation, Used for quick

heating of cab at the beginning of

heating. the lever positioned to

the right -the flap-valve is closed

and air is taken in only fron

outside of cab.

4, Rotatable outlets of air supplied

‘to cab.

2»

IN26

FIRST - AID BOX, GLOVE COMPARTMENT

‘AND TOOL KI? BOX

1, First-aid box

Check and complete the contents of

first-aid box regularly.

2, The glove compartuent in the hand

brake panel.

3, Tool-kit bor,

(CAB DOOR AXD WINDOWS

ROLL-OVER PROTECTION STRUCTURE (ROPS) 10 OPEN THE DOOR FROM THE OUTSIDE ‘0 OPEN THE DOOR FROM THE INSIDE

‘The cab doors are all-glass, equipped The cab door can be locked from the 1, lever for opening the door. froa

vith inner handrails and telescopic outside. Depress the lock button after the inside

struts. The front windscreen is unlocking and. use the handle to open

equipped with an up-and-down sun visor the door. 2, door-securing lever preventing

vhile the rear vindow is tilting. spontaneous opening both fron the

The inside of cab is sound-insulated, inside and outside . shift the

‘The cab roof can be equipped vith a lever to horizontal position to

tilting top. Jock the door.

Use the running board and hand

A rail for entry and exit to and

fron the driver's cab.

a

DOOR ARRESTAENT

‘partially opened door can be locket The rear vindov is equipped vith

in position by neans of the arresting a handle.It's open position can be ar~

strut to vent the cab while driving, rested by neans of telescopic stabili-

Release the strut from the door lock ‘ters.

using the lever for door opening,

Shift the arresting strut back to its

initial position,

A

Do not use the arresting strut

‘on the "passenger's" side vhen

transporting hin.

n

‘REAR-VIEW MIRRORS

Adjust the rear-view mirrors before

driving to get good view all over the

driving Lane or vorking site.

WINDSCREEN WIPER/WASHER

f

/

=e

SHITCHING ON THE WASHER WASHER RESERVOIR WASHER NORZLE

‘the front windscreen vasher can be put The washer reservoir including the ‘he nozzle is installed in the upper

into operation by depressing the upper pup unit is attached to the bonnet and can be directed by a need-

‘toggle svitch of two-speed viper loca- left tilting cover of the steering Le or vire of maxinun 0.8 nn in diane-

ted on the right-band coluan. The ma- bracket. ter.

xima tine of uninterrupted operation

of washer punp is 20 seconds.

2

‘ADIUSTABLE STEERING WHEEL

pat

las

5 g

pate \

hea

N36 Py a 37

STEERING WHEEL POSITIONS

‘The tilting steering vheel can be set

up in one of four positions possible :

1, 0,1, 1.

‘STEERING WHEEL, ARRESTAEN? LEVER

Tf the steering vheel pisition is to

be changed the arrestuent lever has to

be used. This lever is attached to the

immer side of right conscle door,

‘The steering wheel can be fitted vith or without a lock.

a4

Having unlocked the nut by neans of

the arrestuent lever and loosened by

hand, set up the steering vheel posi~

ttion required. Tighten the nut by hand

again and use the force of about 300

on the above-nentioned lever to arrest

the steering vheel in this position,

DASH PANEL

1, Air pressure gauge including nini-

mun pressure indicator (380 kPa)

2, Tachometer vith engine-hour coun-

ter

3, Thermoseter

4. Fuel gauge vith minimun fuel level

indicator. Tractor vith additional

fuel tank contains sensors in both

of these tanks. The fuel gauge

first indicates the level in the

top tank and vhen it's empty,

tthe otto tank level is sensored.

When the varning light lights up,

it indicates there are 8.5 Litres

left in the top tank and renains

Lit during the tine the fuel fron

bottom tank is being drain. Also,

hen the varning ight Lights up,

‘the gaue is svitched for the

‘bottom tank.

Slow beam headlisht switch:

grill lights/cab lights

6.Front wheel drive switch

‘T.Rear work/fog light switch

8.Grill headlight svitch

S.Narning Light seitch

‘10, (not used)

U.turn signal/horn/ Light lever

svitch (high/lov bean light, tum

signal indicators , flasher and

horn).

%

2

B.

Th

16

16.

n

18.

Tey sviteh (could include elec-

tro magnetic locking and steering

lock).

Hand operated throttle

PTO engagenent lever

‘Torque wultiplier lever switch

varning indicator Lights

Stopping device used for inmedi-

ate engine stopping.When the con-

trol is pulled up, the engine

‘stops (2 10520 ~ 2 10540),

‘Thermostarter button

INDICATOR WARNING LIGHTS

5 6 7 8 9 10

/

4112 «13 «14

‘(08

[ea]

=0|

4)

leelleollea||A

N41

Front vheel drive (green)

Rear fog Light (orange)

Cab Lights (green)

Air intake filter clogged up(red)

Front vork Light (yellow)

6, Battery charge (red)

1, Engine oil pressure (red)

8, High bean Lights (bie)

5, Parking brake applied (red)

0, Tractor directional signal

(green)

u.

2

Bb

4M

. Ist trailer directional signal

(green)

. Ind trailer directional signal

(green)

. Warning Lights (red)

|. Not used

‘PHORNEX ELECTRONIC DASH PANEL

N43

DASH PANEL LOCATION

Phoenix electronic dash panel is

optional and substitutes the regular

dash panel. the dash panel is vired

to the electric installation by

2 cable with special connectors. the

dash panel is velcro fitted to the

control panel.

DASH PANEL, DESCRIPTION

1, Warning indicator Lights

2, The Line display nonitors heel

slip (if tractor actual speed sen-

sot is fitted),

4, Display aonitors exgine hours (vhen

entry test is on), tractor travel

speed or PIO revolutions.

4, Travel speed indication button,

a

- PTO revolytions indicator button.

(540 nin"

6, FBO revolutions indicator button,

(1000 nin")

1. Air pressure gauge

8, Fuel gauge - tractors vith two

tanks have the sane conection as

with the standard dash panel.

5, Coolant thernoneter

10, Engine revolutions indicator

PROBNIX ELECTRONIC DASH PANEL

5 6 7

i 9 10 11 12 13 14 15 16 17

Naa

WARNING WTeATOR LIGHTS

1, Rear axle differential lock 7. Charging 13, Parking brake

2, Cab Lights

3, Tractor turn signal indicator

4, Ist trailer turn signal indicator

5, 2nd trailer turn signal indicator

6, High bean Lights

8, Pront vbeel drive

9, Rear fog Light

10, Working Light

11, Overbeated coolant indicator

12, Engine oil pressure

2

MM. Fuel reserve

15. Air filter indicator

16. Minimum air pressure

17, Warning Lights

PHOENIX ELECTRONIC DASH BOARD

DASH BOARD OPERATION

‘the electronic dash board contains preprogramed invariables

stored in nenory vhich are preserved even after disconnec-

ting. The. invariables are stored by the producer and ope-

rator’s interference is impossible, The dash panel is made

to match a certain type of tractor ,it’s properly tested

and special service during operation is not needed.After

inserting Key into ignition svitch and turing to"

sition, the dash panel goes through a n entry test. All

warning indicator Lights (1) and monitor (2) Light up and

‘the installed buzzer goes off for 1-2 seconds.This buzzer is

also used for varnings of exceeding the maxinun coolant tea

»

perature and driving vith applied parking brake. When

the entry test is finished,the engine oil pressure and char-

ging indicators (possibly others, depending on nunber of,

comected appliances) renain lit. The sonitor (2) displays

integer nunber of engine hours. When button (3) is pressed,

the monitor (2) displays decimal values of engine hours.

Your tractor can be equipped vith a radar sensor for actual

traveling speed on request. In that case,the line nonitor(4)

‘splays the percentage of vheel slip.

‘PHORNIX ELECTRONIC DASH BOARD

‘The tractor can now be stared in the regular way. After

riding off, the monitor (2) displays tractor_fraveling speeg

automaticly. It is possible to select 540 nirtor id aie

PTO revolutions nonitoring by buttons (5) and (6). Tractor

traveling speed can be nonitored again by pressing button

(3). The monitor (2) displays the engine hours value only

after turning on the dash panel and going through the entry

test. There is no other vay to nonitor this value. It is

forbidden to turn the dash panel off vhile the engine is

ming by turning the Key in the key svitch to "0"

position.

0

DASH PANEL MAINTENANCE

‘other than changing blown LEDs, the dash panel doesn t need

any other maintenance, If needed, the invariables could be

checked or calibrated.

‘TRAVELING SPEED CALTBRATTON

‘The PHOENIX dash panel is calibrated after fitted on the

tractor in the producing factory. Repeat calibration vben

tires are vorn off or after fitting nev tires or different

inersion tires. calibration is done on 2 narked 100n dis~

tance.

Place the tractor vith recommended inflation of tires and

engine running on the start of the marked 100m track. Press

button (3) for 5-10 seconds until "CAL" appears on the 30-

nitor. Press shortly button (5) subsequently, sign "CAL

starts to flash. Ride off with the tractor in a constant

speed of approximately 10 kn.bod”'.stop the tractor at the

ark after reaching the 100 distance and press button (6).

The monitor displays the nev value of the *X9" invariable

for about tvo seconds, the dash panel goes through the entry

test and is then ready for operation,

KEE SWITCH - ELECTRIC CIRCUIT CoNMECTIONS

ror

‘STOP.

5)

EY REMOVED OR IN "STOP" POSITION

1, EL SWITCH WITH STEERING WHEEL LOCK

AND ELECTROMAGNETIC BLOCKING

1 the key is not inserted in the

starter svitch, the steering vheel is

locked. To unlock the steering vheel

insert the key in the Key svitch and

tum it to the "0" position, If key is

not inserted or in "STOP" position,

the sane electrical circuits as vith

key in "0 position are connected.

TI. KEY SWITCH WITHOUT STEERING WHEEL

‘LOCK AND ELECTROMAGNETIC BLOCKING

Steering vbee] canbe turned in any

‘key position even if not inserted.

KEY IN: "0" POsTTION

‘he live electrical circuits: brake

Lights, cab light, horn and flasher,

tractor Lights, work Light and rear fog

Light, electrical control of hydraulic

aras,varning Lights incl. turn signals

fans. for heating, cooling and air

conditioning,

nu

KEY IN "I" POSITION

In addition to appliances conected

in S102" or *0* position: instruments

and indicator Lights on dash panel,

front drive switch, “turn signals,

rear windscreen viper , hand-lanp

socket. The Key in Key svitch with

steering vheel lock and electronagne-

tic blocking is locked in this posi-

tion vith engine running.

‘STOP

REY IN "II" POsTrTON

The starter circuit is connected.

The position "II" of key is spring-

loaded and the key is returned back to

the "I" position after release. If

starting is repeated,the key should be

‘turned back to its "0" position and

‘then trough "I" to its "II" position,

KEL SWITCH - ELECTRICAL CIRCITT CONNECTIONS

TAPORTANT

A

1

2,

1

2

5.

+ If the switch needs Lubrication, it may be lubricated using solely

fine graphite through the key opening (never use oil).

‘The Jey svitch is equipped vith a cover vhich has to be turned to

protect the opening fron dust and water after removing the key.

(Important especially with tractors without a cab.)

BY SWITCH WITH STEERING WEBEL LOCK AND ELECTROMAGNETIC BLOCKING

Never use force to turn the key from its *I* position vhile the en-

gine is running. The built-in electromagnet stops mechanically this

key fron turning,

‘The Key can be turned fron the "I* position to "0" only when the en-

gine is stopged - the charging indicator mst be lit.

. When toving the tractor in emergency (vith the battery connected)

tthe Key ust te in the "I" position,

If the battery is not connected, the Key should be turned fron the

"STOP" positicn to the "0¥ position only.In the *I® position the key

would be blocked and it vould not be possible to turn it to the

"STOP" positicn and reaove it fron the key switch

|. Never renove the Key vhile driving the tractor ~ the steering vould

block.

It is necessary to turn the steering vheel slightly hen unlocking

tthe steering iheel ~ the lock will be released and twisting or

breaking of key prevented,

2

SwTTCHES

N52,

N33

SHITCHES

1, Low beam asymnetric cab or front

grill Light switch

2. Road warning Light svitch

‘LOW BEAM LIGHT swrnca

"O* - Low beam Lights in the front

grill ov

"1"-~ Low bean cab lights oi

ROAD WARNING LIGHTS SWITCH

"0% ~ Warning Lights OFF

"1" = Warning Lights 08

SWITCHES

NE

N36

SwITCHES

1 = Front drive svitch- tractors with

front drive only

2 = Tractor Lighting svitch

3 = Thernostarter svitch

‘FRONT DRIVE SWITCH

"0" - Front drive switched OFF

"1" - Front drive switched ON

Use the front drive to in-

A crease the tractor traction

only vhen the rear wheels

are slipping. Driving with front vbee)

drive on roads and hard surfaces

increases front vheel tire wear. An

exception for continuous driving with

front vheel drive is sben carrying

a front attached agricultural nachine

or inplenent. This case is suggested

in the machine s ‘amma expen speed

of these systens is 15 kn.ht,

x

‘TRACTOR LIGHTS SELECTOR SWITCH

"0" ~ Lights switched OPP

"1" ~ Switched on: Clearance and tail

Lights, registration nunber and

control panel Lighting,

"2" ~ Suitched on- in addition to *I*:

High/low beam Lights depending

‘on the position of turn signal,

Lights and horn switches.

only the front grill Lights can be on

high, irrespective of the low bean

switch position,

N58

SWITCHES

1 = Front vork light and rear fog

Light svitch

2- Tum signal, headlight and born

svitch

FRONT WORK LIGHT AND REAR POG LIGHT

SNITCH

*0 ~ switched off

Rear fog Light on

"2" + Front work light 0

TURN SIGHAL,HEADLIGH? AND HORN SWITCH

a Right tum signal

b= Left turn signal

c+ Horn

4 + Headlight flasher

+ Headlight high bean

PEDALS AND LEVERS

1. Driving clutch pedal

2, Brake pedals coupled together by

a latch,

3. Throttle pedal

4, Park brake lever

5, Rear axle differential lock pedal

6, PTO engagenent lever

The differential lock must

A not be used vhen driving

through a bend.

DRIVER CONTROLS

i§

HAND THROTTLE LEVER

1, Hand throttle lever

STOP ~ stopping the engine

YX - Maxinun fuel supply

2, STOPPING DEVICE lever

By pulling the lever, the engine

will stop autonatically.

(only tractors with two lever in-

jection pusp control.)

6

GEAR SHIFTING

1. Main gearshift lever

2, Speed range selector lever

H~ High range, roading speeds

N~ neutral

L = Low range, reduce speed

‘The shifting can only be done with

engine stopped.

3. PTO. dependent

speeds lever.

‘and independent.

DRIVER CONTROLS

2) (R

(3) \1

NGS N64 NG

GEAR SHIFT PRITERN GEAR SHIFT PATTERN GEAR SHIFT PATTERN

Applicable to the folloving variations Three-speed gearbor vith three-stage Four-speed gearbox with revreser.

a Four-speed gearbox with tvo-stage torque nultiplier.

torque multiplier

b - Four-speed standard gearbor with-

out torque noltiplier

¢ ~ Four-speed gearbox vith creeper

speeds

a

DRIVER COWTROIS

TORQUE MULTIPLIER LEVER

‘wo-stage multiplier

1 = Buyeged, gear ratio of 1,3

2 - Disengeged, gear ratio of 1,0

16 forvard and 4 reverse speeds

available (incl. creeper speeds) in

total,

TORQUE MULTIPLIER LEVER

‘Three-stage multiplier

1 = Engaged, gear ratio 1,38

2 ~ Engaged, gear ratio 1,18

3 = Disengaged ,gear ratio 1,0

The three-speed gearbox is fitted vith

three-stage torque multiptier.

18 forvard and 6 reverse speeds

available (incl. high/lov) in total.

2

FORWARD /REVERSE LEVER

1 ~ Forvard speed

2 = Reverse speed

8 forvard and 8 reverse speeds avail

able (incl. high/low ) in total.

‘the ain gear shift lever has four

positions, no reverse position.

DRIVER CONTROLS

Nog

a b)

2 3

S 2

21 RI

:

N70

IN 71

‘CREEPER SPEED LEVER

1, Disengaged, standard speed

2, Engaged, creeper speed

16 forvard and 4 reverse speeds are

available (incl. high/low) in total.

LABEL IDENTIFICATIONS

‘he folloving is fitted on special re-

quest :

a ~ two-stage torme multiplier

b- three-stage torque multiplier

c = reverser

d= creeper

Only one of these devices can be

installed as they exclude each other.

»

BATTERY DISCONWECTION SWITCH

This svitch is accessible after tilt-

ing avay the front shell of tractor.

‘The battery can be discomected by

turning the disconnecting svitch le-

ver in the arrow direction.

WARNING AND INFORWATION PLATES AND LABELS

4 == i

5 ie if

We renee

5 BLES oe

N72 N74

LABEL LOCATIONS

1, Gear shifting label

2, Yaximua total veight of trailer

label

4, Incline access label

4, Warning label 1

5. Warning label 2

6, Tractor lifting label

‘TRACTOR LIFTING LABEL

Indications of lifting points for

non front vheel drive tractors.

‘Tractor Lifting may only be done by

a hydraulic jack vhich is a part of

‘the tractor equipnent.

rn

‘TRACTOR LIFTING LABEL,

Indications of Lifting points for

front vheel drive tractors.

Tractor lifting may only be done by

a hydraulic jack vhich is a part of

the tractor equipnent.

A

Nake yourself vell acquainted

with the gear-shift pattem

prior to driving the nev trac-

tor and try the individual po-

sitions of the gear shift le-

ver vith the engine stopped.

“OPERATING THE TRACTOR

Starting the engine ... a

Imediately after starting the engine ...

Driving off, gear shifting

Foot brakes...

Pheusatic brakes of trailers and senitrailers

Stopping the tractor ..

Park brake .

Running-in procedure

a

STARTING THE ENGINE

Nvs

Before starting the. engine

check to be sure the tractor

is braked reliably and. the

geax shift lever in NEUTRAL

Position,

The engine cannot be started

if the gear shift lever is in

any other than neutral posi-

tion - because of starting

safety device,

It is recommended to svitch the pump

drive off at lover tenperatures on

tractors vith svitchable pump,

STARTING THE ENGINE WITHOUT AUXELTARY STARTING DEVICES

1 ~ Insert the key in the key witch and turn it to the "0" position.

2 ~ Press down the clutch pedal.

3. Turn the key through "I" to "II* position (start). Let the engine idle tor

about 3 to 5 seconds, then release the ey and return it back to the "0"

position, With higher ambient teaperatures the idling can be onitted.

4 ~ Set the maximum fuel supply position on the hand throttle lever.

5 - Turn the key through "I" to "II* position (start). Release the key after the

engine starts. Do not start the engine longer than 15 seconds,

§- After starting the engine reduce engine revolutions gradually. Running the

engine in high revolutions is not suitable.

2

STARTING TEE ENGINE

(B)

15s

30s

=

15

@

N77

{IP THE ENGINE DOESN'T START

Wait for 30 seconds, return the key

to the "O* position and repeat star~

ting.

Never help 2 stopping engine

by the starter. The starter

can be damaged that vay.

STARTING THE ENGINE USING THERKOSTART

‘the thermostart isa device vbich makes it easier to start the engine at

temperatures below.

Starting procedures

1, Follow steps 1 to 4 as described for engine starting without auiliary

devices,

2, Press down the thermostart button, After 20 seconds turn the Key through *I*

to "II" position (start). Do not start longer than 15 seconds. Release the key

imediately after the engine starts but hold the thermostart button pressed

until idle is reglar.

4, If the engine fails to start, release the thermostart button also,

Wait for 30 seconds and repeat starting. Do not start longer than 15 seconds.

“8

STARTING THE ENGINE

220V-4

RE)

N79

COOLANT HEATER

The coolant heater is optional and

is fitted to the engine block

It's output is 1000 W, the voltage

220 Vac.

STARTING THE ENGINE USING COOLANT HEATER

At lov temperatures the heater makes the starting easier by varning up the

coolant. he electrical installation and its protection against dangerous contact

aust be accomplished in accordance with the regulations. Connect the plug to the

heater first and only then to the 220 V mains.

‘After heating disconnect. the device fron the sains first and then the

plug fron the heeater,

Danger of accident |

“

‘DORDIATELY APTER STARTING

[N37]

[N82]

If the engine is turbo

A charged keep the engine

speed at 800 to 1000 r.p.m.

after starting and let it

run without load for about 3

ninutes. During that tine check the

tractor for correct lubrication and

charging (both indicators should

‘turn off) and for other functions

ensuring the correct engine operation.

‘the period of tine for not putting

the engine under pressure has to be

respected, especially in the vinter

season,

Continue to varm up the engine vhile. driving, Warning up the engine by

{dle or sharply increasing engine speed is bad for the engine,

Do not exceed the engine speed above 2000 r.p.m, until the engine

coolant tesperature reaches 45 deg C,

6

DRIVING OFF

Nas

Select the road or lov range speeds

and press down the clutch pedal start

the engine and set its speed to be

within the range of 750 to 800 r.p.2.

Engage the appropriate gear for star~

ting the “machine and increase

‘the engine speed slightly.

Prepare the parking brake for relea-

sing. Release the clutch pedal up to

the point of drive only, then release

the clutch pedal continoously vhile

increasing the engine speed at the

sane tine, Release the parking brake

fully.

Drive off smoothly and slovly. Very

quick start could overload the driving

gear cause excessive fuel consuxption,

excessive vear of tires and damage

the load,

For driving off,use Ist gear only when

driving vith a heavy trailer,up a hill

or in heavy ground conditions.

‘CHANGING TO A HIGHER GEAR

Press doim the clutch pedal, release

‘the throttle pedal at the sane tine

and nove the gear shift lever to neu-

tral. Release the clutch pedal (the

clutch will engage) and push it don

again. Yove the gear shift lever to

the desired gear, release the clutch

pedal slowly (the clutch is engeging)

While increasing the engine speed at

the sane tine,

GEAR SHIFTING

(CHANGING TO A LOWER GEAR

Changing to a lover gear should be done by using 2 double clutching nethod.

Decrease the engine speed by releasing the throttle pedal and

brake the tractor slightly, if necessary. -

1 = Press down the clutch pedal and nove the gear shift lever to neutral. Release

the clutch pede] again and increase the engine speed sinultaneously

(the engine speed level depends on the speed of tractor)

2-~ Press dom the clutch pedal and engage the lover gear. Release the clutch pe~

dal slovly vhile increasing the engine speed at the sane tine.

0

GEAR SHIFTING

N86

CHANGING GEARS DRIVING UP DOW AND

A SLOPE,

When changing to a lover gear vhen

driving uphill, use a short double~

clutching nethod-the speed of tractor

decreases sharply.

‘se longer double ~ clutching nethod

hen driving dombill.

DRIVING DOWNHILL

Tt is prohibited to drive the

A tractor dombill with no gear

engaged.

‘The sharper the slope is, the

lover the engaged gear should

be, If possible, change the

gear before driving downhill.

Repeaber:

‘The gear you use to drive reliably up

‘a hill should be the same for driving

safely dom the hill.

SHIFTING THE HIGH/LOW GEARS

Shifting High/Low gears is the sane

as the shifting of standard gears. The

High/lov lever can be shifted only

when the tractor is still.

ww

YF

RI

[rm

lee

Nag

TORQUE MULTIPLIER SHIFTING

‘he shifting is made vithout pressing

down the clutch pedal by shitting the

lever under the steering vheel and

is automatic even vhen tractor is

under load. There are tvo positions

vith the two-stage torque multiplier

and three positions vith the three

stage multiplier.

REVERSER SHIFTING

The shifting is més by soving the

lever under the steering vbeel. ‘There

are eight reverse gears available

which are about the same ‘speed as the

forvard speeds. Therefore the ‘speed

for driving backvarés for a certain

type of work has to be considered.

‘The reverser shifting is

A done with the clutch pedal

Pressed dom and tractor

still by noting the reverser

lever to position 2, operate

‘the rest cf the levers as

described before.

6

(CREEPER GEAR SHIFTING

For a certain type of work select the

appropriate standard gear, High/Low

and only then shift the creeper gear.

‘he shifting is done vith

A clutch pedal fully pressed

dovn and vith TRACTOR STILL

by moving the creeper lever

to position 2,

‘BRAKES

FOOT BRAKES

‘hese brakes are of two pedal type

that operate vet disc type hydraulic

brakes vith an automatic pressure

equalizer.

‘The two brake pedals must be

A latched together vhen dri-

ving on road, Use the pedals

unlatehed for braking the

left or right heel only

‘hen vorking on ground oF

field.

FRONT DRUM BRAKES

‘These brakes are optional for front

heel driven tractors. If only one

pedal is used to brake the tractor,

the front drun brakes are not in ope-

ration.

50

FRONT CARDAN SHAFT BRAKE

This is optional for front wheel

driven tractors. If only one pedal is

used to brake the tractor, the brake

i not in operation.

BRIKES

‘TRAILER AND SEMI~TRATLER BRAKES

The trailer and seni-trailer air

brakes control is synchronized vith

tractor braking including the brake

effect.the vorking pressure is adjus~

ted by a replator to 710820 kPa. If

the pressure value drops below

450830 KPa, the pressure-relief valve,

iscomects the secondary appliances

(differential lock,front drive svitch,

electro-preusatic Lifting of three-

point Linkage).

WARNING DEVICE

‘A decrease in pressure below 380 kPa

is indicated by the red warning light

located in the pressure gauge vithin

the dash panel.

If the pressure drops below

Ax ia, the tractor vith

braked trailer or seni-

trailer cannot continue in

operation unless pressure

increases.

st

SINGLE- AND OOUBLE-LINE BRAKES

T-- single-Line brake coupler

II = double-Line brake couplers

She air tank volue is 20 liters.

Connection of single-line

AN brakes should be carried out

with the tractor braked by

the park brake or vith the

shut off cock located at the

coupler shut.

‘The coupler should be closed by a

cover when not connected to trailer.

SHUT-OFF COCK

Tf the single- and double-line brakes

are fitted, the single-Line coupler

is equipped with a shut-off cock.

The lengthwise position of cock le-

ver means the cock is open.If double-

line brakes are used, this cock mst

be shut.

‘Tractors with the nev equipment are

not fitted vith a shut-off cock since

the coupler contains a return valve.

SINGLE-LINE BRAKES

The regulator adjusts the vorking

pressure to 590420 kPa, The air tank

volume is 20 liters.

‘the maxim permissible dri-

A“ speed of tractor vith

trailer (seni-trailer) and

single-Line

25 ka/hour.

air brakes is

52

DOUBLE-LINE BRAKES

‘The working pressure is adjusted to

7no#20 kPa. The air tank volune is

20 litres.The left-hand coupler cover

is marked yellov, the right-hand is

red,

‘the maximum speed of trac

Ae with trailer (seni-

trailer) and double-line air

brakes is 40 ka/nour.

HYDRAULIC TRAILER BRAKES

Nio7]

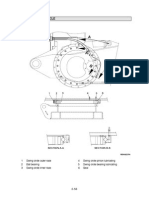

HVORAULIC TRAILER BRAKES 1. Bosch brake valve

2. Pressure coapensator

Hydraulic trailer brake control is synchronized vith braking of tractor including 3, Bleeding screw

brake effect, ‘he hydraulic ofl pum provides the operational pressure. Bosch 4, Foot brake pedal

brake valve 1 is fitted within the independent hydraulic pump in the circuit, 5, Rocksbaft cover

‘the trailer brake valve is controlled by the brake fluid pressure fron the com- 6, Tractor disc brakes

pensator 2 according to the force on the brake pedal. the pressure at the coupler 7, Gearbox oil

should be 12-15 Xa vhen the brake pedal is pressed fully.the brake valve provides - Oil outflow back to gearbor

brake function prior to hydraulic control. Wen bleeding the tractor brake systen - Ol intake to rockshaft cover

do not forget to also bleed the BOSCH brake valve by bleeding srev 3. B - Oil intake to trailer coupler

Y-- Brake fluid intake to pressure

compensator

P - Oil intake from hydraulic puap

3

‘STOPPING THE TRACTOR

Sa we

po

N 103}

STOPPING SHE TRACTOR - PARK BRAKE

Stop the tractor slovly wider normal

conditions. Press dom the clutch

pedal and nove the gear shift lever

to neutral before stopping completely.

Brake the tractor to prevent it's

spontaneous aovesent by applying the

parking brake. It is indicated on the

dash panel if the parking brake is

applied.

ae

STOPPING THE ENGINE

If the engine bas been used under

heavy load, it needs to be cooled down

after vork. ‘Therefore, decrease the

engine speed dovn to 800 to 1000 rpa

for five ninutes vith no load before

stopping. Stop the engine by moving

the hand accelerator lever to STOP

position or if tractor is equipped

vith STOP DEVICE, pull the control.

LEAVING THE TRACTOR

‘the key can be tured fron the "I"

to *0* position only when the engine

is still-the battery charge indicator

has to be lit.

If the tractor is on a slope, its

spontaneous noving must be prevented,

as follows: tractor braked, engine

stopped,a lov gear engaged and vheels

blocked.

Do not forget to remove the

Key fron the key switch

before leaving the cab and

Jock the door,

RUNING IN PROCEDURE

DURING THE PIRST 100 HOURS

During the first 100 hours of ope~

ration

> put engine under norsal

A loads |

~ avoid Light loads

= avoid excessive engine

idling

= check engine

frequently

(excessive engine consuaption during

‘this period is usual)

oil level

= check bolt joints, especially on

parts used for lifting

~ fix any defects to prevent later

danage or even danger in operation

= use the sane procedure after

overhaul

55

FIRST 10 HOURS

The running in should be carried out

in traffic vith hydraulic pump

switched off (control lever in *0*

position).

RUNNING 11 PROCEDURE

IN 103]

APTER 10 HOURS

Drain ware oil fron the gear-box and

Clean through an outside filtration

uit vith filtration ability of 20

nicrons. This can be done using suc-

ttion or sinply by draining.

If the filtration unit is not availa-

ble drain the transnission oil into a

Prepared container.

‘There are five draining holes totally:

(1 = clutch housing, 1 - gearbox,

3 ~ final drive). Let oil set for at

Jeast 2 hours and then pour clean of)

back into gearbox. The total cil vo-

lune is approvinately 40 litres.

ATER 10 HOURS

Renove and clean the magnetic insert

(2) as well as the mash insert (2) of

transnission oi) filter.

ash both parts in petrol, fit then

hack after letting the petrol drip off.

‘id of2, if necessary, until the oi]

level reaches the upper nark on the

dipstick (3). From nov of, you can use

the tractor hydraulic systea vith no

limitations.

APTER 70 HOURS

Drain var oil from the engine and

replace the engine oil cartridge fil-

ter. Fill the engine vith nev oil up

to the specified level (after short

engine idling and letting new oil to

set, up to top mark on dipstick),

RUNNING IN PROCEDURE

N11

APTER 70 HOURS

Check the cylinder Liner head for

torque (the recomended torque vben

‘the engine is cold is 160 to 180 Na)

and valve clearances (0,25 0.05

hen engine is cold).

APTER 70 HOURS ATER 70 HOURS

Renove and clean:

1 = magnetic insert of suction gear-

box filter.

2 mash insert of suction gearbox

filter,

Replat

3 paper insert of paper cartridge

oil filter.

Check the nuts on botton flange of

air regulator for torque.

a

APTER 100 HOURS

‘he tractor can be operated vith no

restrictions after the running in

period.

‘he recomnended engine routine:

~ recoanended operation engine speed:

1400 to 2300 rpa

engine idle:

700 down to 650 rpa

+ operation oi] pressure:

0,2 to 0.5 Ma

~ operation oi] pressure at idle:

0.05 Ma as minimum,

~ coolant temperature: 60 to 95 degc.

RUNING IN PROCEDIRE.

38

A

Before you drive be sure the

tractor's technical condi

tion neets the requirenents

for safe traffic,

If a trailer or a seni-

trailer is connected, check

the coupling and secure load.

Never leave noving tractor

to couple trailer by your-

self. Also keep in nind your

assistant's safety.

UTILIZATION FOR TRANSPORT

Page

Front BOOK «+44: 0

Trailer hitch etagenent . 6

Multistage trailer hitch. 6

Automatic taw jew 6

Swinging drav-bar 6

Automatic pick-ap hitch . 8

Pick-up hitch extension . 8

DraW BAL se evessseeene 6

8

‘UTILIZATION FOR TRANSPORT

FRONT HOOK

It is used for toving tractor without

a trailer or attachzents.

Use a tow bar or rope for

freeing a bogged-dom trac-

tor, never use chains,

‘TRAILER HITCH ETAGEKENT

Tt is used for coupling double-axle

or smaller single-arle trailers.

It can be adjusted vertically into 3

positions with steps of 100 mn, hen

working with various inglenents, the

hitch should be adjusted, tilted or

removed including the carrier if

necessary.

Cy

MULTISTAGE TRAILER HITCH

‘The diameter of the pin is 30 mn, the

saximun vertical static load is 10 kW.

UPTLIZATION FOR TRANSPORT

IN 119

AUTOMATIC TAW JAN

‘The autonatic tav jaw is mounted in

place of the multistage hitch, It en=

ables the driver to couple up a trai-

ler from the driver's seat vithout the

help of an assistant.

‘To attach a trailer simultaneously:

~ pull out the locking device (1)

~ using the lever (2), Lift the main

pin (3) until it resains in the

Upper position,

‘he static load on the hitch must not

exceed 10 ki,

SWINGING DRAW BAR

This bar is used for attaching agri-

cultural machinery and trailers, It

can be adjusted transversely in five

positions with steps of 80 nm and

Vertically in four positions (by tur-

‘ning the whole bar round the longitu-

dinal axis about 16)° and reassembling

‘the lover portion of fork). If the

tractor is equipped vith a multistage

trailer hitch, the swinging bar is

fitted to the bracket on the hitch.

a

‘SWINGING DRAW BAR

en vorking vith driveline, the ne~

cessary space for the work is provi-

ded only vhen the drav bar fork is

set to it's lovest position. The maxi-

mm vertical static load of the fork

is oki.

‘UTILIZATION FOR TRANSPORT

AUTOMATIC PICK-UP HITCH

This hitch is intended for coupling

of single-axle trailers vith the tow

bar eye diameter of 50 mn.

‘he hook on the autonatic pick-up

hitch is attached to the hydraulic

Lifting arns by adjustable telescopic

dravbars. The pick-up hitch can be

raised or lovered by the hydraulics

aking it simple to attach a trailer

to the tractor. the maxim static

load on the hitch should not exceed

15 i.

COUPLING THE TRAILER

The hitch is controlled by the inner

circuit lever (1) with position con-

trol selected (the selection control

lever (2) in *P* position). the hook

on the tractor and the evebolt on the

hitch are hydraulically lifted to the

position where the carry:ng hooks en-

gage. The hydraulic lifting arms must

be lovered slightly so that the pick-

up hitch rests on the carrying hooks.

he telescopic dravbars (3) must not

be stretched.

Oy

‘UNCOUPLING THE TRAILER

‘en disengaging the trailer the pick

up hitch has to be raised slightly

to allow the carrying hooks to un-

Jock by noving the pick-up hitch

lever backwards,

UPTLIZATION FoR TRANSPORT

aN

coy

5 37 OS

IN 126]

PICK-UP HITCH EXTENSION

It is available together vith the

automatic pick-up hitch, It makes it

possible to couple all machines con-

nected to the svinging drav bar. The

pick-up hitch extension substitutes

the swinging draw bar in the middle

position, ‘The maxinun static load

should not exceed 8 ii.

DRAW BAR

‘he drav tar is adjustable by the

hydraulic Listing nechanisn within

‘the whole lifting range. Only those

agricultural machines which load the

draw bar downwards can be coupled to

it. The maxinun static load should not

exceed § KN,

Renove the carrier of the

A trailer hitch etagenent incl.

jaw hen working vith the

draw bar.

USING TRAILER OR SEMT-TRATLER

Wen a trailer is comected

‘the tractor rear axle static

load should not exceed the

naximun specified value.

‘The maximum veight of the coupled

braked trailer or seni-trailer must

not exceed the naximun value,

A

Prior to connecting an agri~

cultural machine to the Pto

check if the speed of the

PTO and the machine are the

sue. Serious damage and

accidents may result trom

different speeds selected.

‘POWER DRIVE OF AGRICULTURAL MACHINES

Safety precautions vhen using PIO ..

Engagenent/disengagenent of the P10 clutch

Shifting the dependent and independent speeds of P10

Changing the speeds

Front Po

PTO covers

6

POWER DRIVE OF AGRICULTURAL MACHINES

WAILE USING THE. PtO-

Check if all. covers are at~

A tached properly. Do not for-

get to fit the PIO cover

after vork back again.

Coupling / uncoupling of the

driveline mst be carried

out after the PIO has defi-

nitely stopped.

Persons not authorized to work with

the tractor attachments mustn't dvell

between the tractor and the coupled

nachine,

PIO CLUTCH ~ ENCAGEMEWT/DISENGAGEMENT

1 = Cluteh engaged

2 = Clutch disengaged

6

(CHANGING DEPENDENT AND INDEPENDENT

‘PIO SPEEDS

1 = Independent P10 speeds regardless

on the tractor speed (1000 rpa or

540 rpa).

‘he gear shifting should be carried

out at very lov engine speed, the

tractor clutch pedal should be

pressed down at the sane tine.

2 = Neutral

3 Dependent P10 speeds (through the

gearbox).

‘he gear shifting should be carried

out with the PTO shaft clutch disen-

gaged.

POWER DRIVE OF AGRICULTURAL KACHINES

4 5 IN 132]

CHANGING THE PTO SPEEDS Rov PIO P10 COVERS

‘he gear change can be carried out by Engagenent/disengagenent of the shaft 1 ~ metal PTO cover

‘turning the output shaft (1) of 35 me is carried out as follows: Hove the PIO 2 ~ PIO cover

in diameter. After removing the cover clutch lever to the "engaged" position. - 3 ~ 180 PTO cover

and the pluy (2) the output shaft The gear shifting it's self should be 4 - P10 cover

should be pulled out, turned around and done by the electric svitches located 5 ~ PIO cover

fitted back again, The output shaft

for 540 rpu has 6 splines, for 1000

rpm 21 splines. It is also possible

to fit a 6 splines output shaft both

for 540 and 1000 rpa,

in the cab (B). The front PIO is put

into operation by svitch 1,the rear

Pro by the switch 2. If svitches 1 and

2 are both turned on both PIO shafts

are put into operation at once. If the

shafts are not in operation ve recon-

vend to nove the lever on the control

panel to the "off" position because of

losses in performance,

0

‘The PIO should alvays he protected by

eans of a cover of any type.

6

HYDRAULIC SYSTEX

Page

1

n

n

n

2

RB

B

m

%

b

6

UnMer CTCUIE ssesssereseeeessseeeen

Inner circuit control Lever ..s...cssssseesee

Preselector control lever ...

Response control lever .....

Electropneumat:c control of hydraulic system

cab switch ..

Fender button

Outer hydraulic circuit

Rear outer hydraulic circuit outlets .

Outer circuit control lever

Single-acting cylinder control ..

Double-acting cylinder control .++..0 6

Front outer hyéraulic circuit outlets 1

Selecting control valve optional (SCY). 8

ERR BOSCH electrobydraulics a

‘Three point Linkage «sss... 85

8

HYDRAULIC SYSTEM

IN 134

‘HYDRAULIC SYSTEM

‘The systen consists of the inner and

outer circuit (1). The pressure oil

supply is provided by a disengageable

or non-disangageable hydraulic gear

ppunp (2) of tvo optional sizes avail-

able, which pumps oil fron the conaon

fill of the gearbox and differential

housing.

PUMP DISCHARGE RATE

tax. 43 V/ain of oil vith OW 16 puep

~zax. 60 I/nin of ofl vith OW 20 punp

The maxima oil pressure in the

hydraulic systen provided by the

relief valve is 18.5 1a,

DISENGAGEABLE HYDRAULIC HP

switch on the hydraulic punp

drive (1) by means of the

lever (2) only if you use

hydraulic inplenents.

("0 ~switched off, "1" -svitched on)

Engagenent of the hydraulic pump

should be carried out orly vhen the

engine is stopped. When starting the

engine in the winter season, it is

suitable to svitch the pump off.

(Lever in *0* position). & non-disen-

‘ageable punp is optional. If the en-

gine is running the pup is in ope-

ration, This option is used for trac-

tors vith hydraulic trailer brakes,

0

TNWER CIRCUIT

The inner circuit is controlled by

the iner circuit control lever (2),

the preselector lever (2) and the

response control lever (3).

The position of the inner circuit

control lever can be locked by @

control lever stop (4).

HYORAULIZ SYSTEM

-

KE o

Vg Z\ :

a

‘DINER CTRCULT CONTROL LEVER

This lever can be used as follovs:

a= Lifting the inplenents into

transport position

(raised to naxinun)

b= Height adjustuent to. three point

Linkage with inplenents vith po-

sition control and ploughing

depth adjustuent vith draft or

nixed control.

€ - Setting of floating position vhen

vorking vith a vheeled inplenent,

PRESELECTOR CONTROL LEVER

‘This control lever has three positions labeled P, X, D.

P - Position contrel.the inplenents attached to the three-point Linkage are kept

autosatically in a constant height (position) according to the tractor.

X= Mixed control. It is a combination of position and draft control. It is

suitable especially for ploughing on lands vith various ground resistance,

D - Draft control. The inplenents attached to the three points linkage are auto-

natically novel to an appropriate height according to soil resistance.

n

HYDRAULIC SYSTEM

N39]

RESPONSE CONTROL LEVER

This lever operates the cock vhich

controls the anount of oi! floating

to the outer and inner hydraulic cir-

cuits. With the lever in horizontal

position, a ninimm anount of oil is

floving to the inner circuit.the res-

triction of oil flow with draft and

nixed control the response of hydrau-

Lic system is reduced (ven ploughing

under various soil conditions).

ELECTROPNEUMATIC CONTROL OF HYDRAULIC SYSTEM

It is an optional hydraalic control and to Lift the three point Linkage to its

highest position without changing the set position of the main inner circuit

control lever. This device can be operated either by a cab svitch (1) or fron the

outside using the buttons located on the ends of hoth rear fenders (2).

n

HYDRAULIC SYSTEM ~ ELECTROPNEUKATIC CONTROL

IN 140]

cB SHIT

‘It is used to raise implement at the

end of a field vhere the tractor is

+o be turned round.tiben the svitch is

on, the inplenent is raised, vben it

is switched off the implenent is

lowered to the initial position set

by the nain inner circuit control

lever,

FENDER BUTTON

Controlling the lover Link novenents

of the three point Linkage fron the

outside, it enables the driver to

attach the implement easier. the lin~

Yage is raised wile the button is:

pressed, vhen it is released the links

are lovered to the initial position

set by the inner circuit control lever.

a

USING THE BUTTONS

The driver must be standing

A clear of the implenent being

attached to the three point

Linkege when using the but-

‘tons not to be caught by the moving

parts. then the inplenent is raised

to the transport position the imer

circuit lever bas to be noved to the

‘top position. The implenent has to be

lovered vhen the tractor is stopped.

HYDRAULIC SYSTEM ~ ELECTROPNEINATIC CONTROL

IN 144

‘OUTER HYDRAULIC CIRCUIT YAXTMOK OUTER HYDRAULIC OPTLETS SUPPLY

‘his circuit supplies oil to the ‘te naximun outer outlets supply to the inplenent assister cylinders

hydraulic attachnents connected to A is 12 Litres of oil with 40 Litres of gearbox oil volune (to the top

‘the outer hydraulic outlets with ark), unless the tractor is operating ona slope. If the supplied

quick couplers at the ends, The front vvolune is too high the oil level can lover so much it can result in

(B) and rear (A) quick coupler iner damage of pumps, torque multiplier and PI0 clutch caused by air

dianeter is 12.5 ma according to dravn through the gearbox and hydraulic pumps. Special care should

130 5675, Quick couplers RK 12 are be taken vith the oil that remains in the quick couplers vhen con-

optional. necting or discomecting the couplers. This oil should be wiped off

vith a piece of cloth for environsental reasons.

4

HYDRAULIC SYSTEM

Ha OR

EAR OUTER HYDRAULIC CIRCUIT OUTLETS

In the standard version there are

‘three quick couplers at the end of the

cutlets on the panel (A). The couplers

"I and "2" are pressure couplers. the

pressure in corresponding coupler de-

pends on the outer circuit lever posi-

‘tion, She third coupling "0" is con-

rected to the return line for the

cil of hydraulic implements floving

into the transuission (e.g. rotary

hydronotors).the outer circuit outlets

can be supplied without quick couplers

but with plugs (8).

(OUTER CIRCUIT CONTROL LEVER

This lever bas 4 positions according to the label:

a = Pressure vithin quick coupler *1*, coupling "2* connected to the return line,

‘the lever is mved to it s far back position. tt aust be held in this position

othervise it returns to "b* (neutral} autonatically.

b= Neutral position (locked).the outlets of both "1" and "2" couplers are closed

and the oil is blocked vithin the comected hydraulic inplenent. The spring-

Joaded lever is held in this position autonatically.

© ~ Floating position. the quick couplers "1" and #2" are connected to the return

Line, the ofl can flow through in either direction. the lever in this position

is locked.

4 - Pressure in coupling "2", coupling *1* comected to the return line.the lever

is in it s far forvard position. Tt mst be held in this position othervise it

returns automatically to *c* (floating) position.

B

‘HYDRAULIC SYSTEM

SINGLE-ACTING CYLINDER CONTROL

Cylinder connections should always be

carried out to the quick coupler "!

= lifting, lever in "3" position

(pressure in coupler "1")

~ end of Lifting, the lever noves

to "bY position (neutral),

~ lowering, the lever in #e*

tion (floating),

= end of lowering, the lever is noved

to the *b* position (neutral).

posi-

DOUBLE-ACTING CYLINDER CUTROL

‘The cylinder connectiors should be

carried out to coupler "1" and "2":

= moverent in one direction (the lever

in "a" position ~ preseure to coup-

ler "1"),

end of movenent (the lever in."b"

position ~ neutral),

= novenent in opposite direction

(the lever in "é* position -pressure

to the coupler *2*)

= end of novenent (lever in "b" posi

tion - neutral).

%

DOUBLE-ACTING CYLINDER CONTROL

When operating the double-

Aes cylinder the outer

circuit control lever should

be moved over the "c* posi-

tion as quickly as possible due to

the fact that both sides of the wor-

King cylinder are connected to the

return Line vbich can result in un-

controllable piston rod movenent.

‘HYDRAULIC sysTEM

COUPLING OP MACHINES AND TAPLEMENTS 10 THE OUTER HYDRAULIC CIRCUIT

‘COUPLING OF MACHINES AND IXPLEMENTS CONSISTING OF SEVERAL PARTS

Wen vorking vith agricultural machines and inplenents consisting of several

parts (such as barrovs, scrubbers and combinators) vhere side franes are

attached to the center frane vhich could be raised into vertical position by

using independent hydraulic cylinders operated by the outer nydraulic circuit

of the tractor, it is necessary to alvays control the movenent of the side franes

by noving the outer circuit control lever to the top position. this vay the

coil in quick coupler *1* vill provide the control of the side panels coupler #2"

is return,

CONNECTING A ROTARY HYDROHOTOR

If a rotating hydronotor is comected to the outer hydraulic ottlet, its return

Line should always be connected to the quick coupler "0",

CONMECTING A REVERSIBLE ROTARY HYDROMOTOR

Areversible rotating hydromotor should be comected to the quick couplers

"1" and "2" for functional reasons.tn this case a relief valve mst be fitted

to both lines to reliably eliminate the pressure peaks vhen the machine is

stopping. the return lines of these relief valves should be connected to the

‘coupling *¢

n

‘FRONT OUTER HYDRAULIC CIRCUIT OUTLETS

‘These outlets can be installed in the

panel in the right-hand comer of cab

frane. ‘The installation is related to

the additional SCV. They are intended

for operation of the front three

point linkage or for other front

pounted adapters. the marking of the

outlets aswell as their utilization

are the saue as for the rear outlets.

‘HYDRAULIC SYSTIN

|

\ On 152)

IN 153

OPTIONAL SELECTIVE CONTROL VALVE (SCV)

This block is intended for agricultu-

ral machines vhich require indepen-

dent control of tvo hydraulic appli

ances. It is located on the rockshaft

cover (A) and cen be supplied ina

‘three- or four-position version vith

float position.the control levers for

both sections are located on the

right rear fender in the cab (8)

Front outer (C) outlets or rear outer

outlets are installed with the addi-

tional scv (0).

‘THREE-POSITION VERSION

Control lever positio:

I. The rear end position ~ pressure

oil is supplied to coupling "

IL. Middle position - neutral (block).

IIL. She top end position - pressure

oil is supplied to coupling "5",

‘te lever returns to niéle position

autonatically.

‘tractors vith nechanical hydraulic

systens are equipped vith tvo-section

SCV, each in four-position version,

‘Tractors vith BAR hydraulic system are

equipped vith SCV vith one four-posi-

tion section and one three position

section.

8

OUR-POSTTION VERSION

I. The rear end position ~ pressure

oil is supplied to coupling "4"

or "6",

IT, Middle position ~ neutral (block)

TIL. The top end position - pressure.

‘oil is supplied to coupling "3"

or "5%,

‘the lever returns to widdle position

autonatically. The lever can be noved

forvards through "III" to "IV" po-

sition - floating position, Both coup-

Lings "3% and "4" or "5" and "6" are

connected to the return line, In this

‘option the floating position is at

the end of the control lever novenent.

ELBCTROHYORAULICS EHR 4 - BOSCH

g

22

iwi

87

IN 155

CONTROL PANEL LOCATION CONTROL FUNCTIONS 6 - Response control

7 Control mixing. Snooth setting

‘The pane) (1) is located on the top -1= The lever for Lifting has 4 posi- froa draét control to position

section of the right fender. It sub- tions: control.

stitutes the manual hydraulic con- a) transport, Lifting 4 ~ Indication of lifting.

trol (inner circuit). the outer b) stop position 9 - Indication of lovering.

hydraulic circuit function is provi- ¢) regulation, lovering control

ded by the optional scV controlled 4) free position, quick sinking PUMP DISCHARGE RATE

by two levers located on the top (the spring returns the lever

area of the fender (2), If warning back to *c* position). A tractor with BHR BOSCH is equipped

indicator (3) lights, the oil filter 2 ~ Blocking of transport position. with a UR 20 pump vith naxiun supply

insert has to be renoved, 3 = Lovering rate control 0. max. of 60 1/ain. the naximn pressure in

4 = Selection of three point Linkage a hydraulic systen equipped with EER

position, BOSCH provided by the relief valve is

5 - Limitation top position of the 21 HPa.

three point Linkage.

7

‘ELECTROHYDRAULICS BAR 4 ~ BOSCH

IN 156

USING THE EER 4 ~ BOSCH CONTROL PANEL

A= Wot in function

Me electric installation is switched off by the key in

the Key svitch. the electric circuits are switched off,

the three point Linkage is blocked.

B - Unblocking

After switching on the electric installation by key in

the key svitch the three point Linkage is still blocked.

‘The linkage doesn't lift nor lover. the unblocking is

done vith electric installation svitched on and engine

running by moving the lifting lever (1) to "a" position.

(only & short period of tine is sufficient)

After returning the lever (1) to "c* position the three

point Linkage takes up the position set by the control

elezents,

80

C= Using the fender button controls

‘he button controls only provide coupling and uncoupling

of inplenents. The labels of the buttons on both fenders

correspond to the sovenent of the tree point linkage.

‘he Linitation of the three point Linkage is not provi-

ced by the regulation system vben using the fender but-

ton control. The piston stroke is stopped eechanically.

‘herefore it is not suitable to use the button controls

in the upper area of the three point linkage novezent.

Fach tine the button controls are used the regulation

systen is blocked again and the *UnblockingY procedure

(8) has to be repeated again.

D = Inplenent transport.

Shift the Lifting control lever (1) to "a" position and

secure by locking lever (2).

E = Limitation of the three point Linkage top position.

‘This is done by control lever (5). The linitation

can be carried out in the upper half of the three point

Linkage novenent.

F ~ Field operation

o through the B procedure and set the desired position

of the elenents according to the type of work. Setting

the depth of the inplenent is provided by control (4).

Control (6) is used for response adjustaent.

Yaxinun response symbol. ~~

Yenimun response symbol —\~

ELBCTRORYORAULICS EHR 4 - BOSCH

Use control (7) for preselection and mixing.

Draft control symbol f=

Position control symbol -g=2

The regulation function (lifting and lowering) can be