Professional Documents

Culture Documents

Pipe Specifications ASTM A-120: Markings

Uploaded by

somewhat0 ratings0% found this document useful (0 votes)

29 views1 pagedfdsf

Original Title

Selective Welcome

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdfdsf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views1 pagePipe Specifications ASTM A-120: Markings

Uploaded by

somewhatdfdsf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

through a furnace where it is heated to 2,600~ and then

bent into an oval by form rollers. It then proceeds

through a welding stand where the heat in the skelp and

pressure exerted by the rolls forms the weld. The pipe is

stretched to a desired OD and ID, and cut to lengths.

(Couplings if ordered for any size pipe will be hand tight

only.)

Pipe Specifications

ASTM A-120

Sizes V8-in. to 16-ins., standard weight, extra strong,

and double extra strong (Std. Wt., XS, XXS). The specification covers black and hot-dipped galvanized welded

and seamless average wall pipe for use in steam, gas,

and air lines.

Markings. Rolled, stamped or stenciled on each length of

pipe: the brand name, ASTM A-120, and the length of the

pipe. In case of bundled pipe, markings will appear on a

tag attached to each bundle. Table 3-2 shows a bundling

schedule.

ASTM A-53

Sizes V8-in. to 26-ins., standard weight, extra strong,

and double extra strong, ANSI schedules 10 through 160

(see Table 3-1 for ANSI pipe schedules). The specification covers seamless and welded black and hot-dipped

76

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Codes Standards For YANBU ProjectDocument7 pagesCodes Standards For YANBU ProjectBehçet Serdal CanbazNo ratings yet

- Piping-Mechanical Design DrawingsDocument4 pagesPiping-Mechanical Design Drawingsamnoorulaman50% (2)

- 9-Csc Asme SpecificationsDocument5 pages9-Csc Asme SpecificationsDany FerdianNo ratings yet

- Pipe SpecificationDocument5 pagesPipe SpecificationDhanielNo ratings yet

- Standards Scope PDFDocument6 pagesStandards Scope PDFaravindhcamNo ratings yet

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423Venkat Dora100% (1)

- Learn Basic of Piping EngineeringDocument43 pagesLearn Basic of Piping Engineeringkaruna100% (1)

- ASTM Specifications GuideDocument7 pagesASTM Specifications GuideSherif AdelNo ratings yet

- 112.09 Heat Exchangers BrochureDocument4 pages112.09 Heat Exchangers BrochureAlexandru DinaNo ratings yet

- Anvil Branch OutletsDocument9 pagesAnvil Branch OutletsRaduNo ratings yet

- PipingDocument13 pagesPipingrudiwoworNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Swagelok Tubing SpecificationsDocument8 pagesSwagelok Tubing SpecificationsAugustine Owo UkpongNo ratings yet

- Swagelok A2333 Data SheetDocument1 pageSwagelok A2333 Data SheetvanpupsNo ratings yet

- A106 Pipe SpecificationsDocument3 pagesA106 Pipe Specificationspundir_vineet100% (1)

- MS 01 181Document4 pagesMS 01 181Mauricio Escobar LabraNo ratings yet

- Technical Data Chart G16667 (Pressure Rating For ASTM A53-40 ERW Type E)Document2 pagesTechnical Data Chart G16667 (Pressure Rating For ASTM A53-40 ERW Type E)polysourceNo ratings yet

- Astm B221 5052 6063 6061Document3 pagesAstm B221 5052 6063 6061Son-Tuan PhamNo ratings yet

- ASTM A192 Boiler Tubes SpecificationDocument3 pagesASTM A192 Boiler Tubes SpecificationSon-Tuan PhamNo ratings yet

- Astm A192 Asme Sa192Document4 pagesAstm A192 Asme Sa192Mingo EvaNo ratings yet

- Socket Weld Fitting GuideDocument7 pagesSocket Weld Fitting GuideMehman NasibovNo ratings yet

- Copper Tube Federal and Astm SpecificationsDocument4 pagesCopper Tube Federal and Astm SpecificationsSai PrasathNo ratings yet

- Socket WeldDocument7 pagesSocket WeldahmedNo ratings yet

- Pipe SizeDocument3 pagesPipe SizeJimmy EfraimNo ratings yet

- ASME Pipe and Valve Standards GuideDocument4 pagesASME Pipe and Valve Standards GuidecatdoNo ratings yet

- Astm Piping SpecsssssssDocument1 pageAstm Piping SpecsssssssAjithNo ratings yet

- ASME - ANSI B16 Standards PDFDocument8 pagesASME - ANSI B16 Standards PDFgaurav_10683368850% (2)

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Pipe and Tube SizeDocument32 pagesPipe and Tube Sizehothanhdung2002No ratings yet

- Basics of Piping Scribd PDFDocument60 pagesBasics of Piping Scribd PDFmohamed sheerazNo ratings yet

- Standards For Pipe LineDocument57 pagesStandards For Pipe Linegopaltry33% (3)

- Stainless Steel Pipe SpecificationsDocument11 pagesStainless Steel Pipe SpecificationsGonzalo MazaNo ratings yet

- Adjustable Roller HangerDocument1 pageAdjustable Roller HangerSyed Kamal FareedeeNo ratings yet

- Cooling Coil Sample - SpecDocument1 pageCooling Coil Sample - Specpal_stephenNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- Steel Flanges Ansi Stnd1Document36 pagesSteel Flanges Ansi Stnd1Harshvardhan MishraNo ratings yet

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- ASTM A210 Seamless Medium Carbon Steel Tube1 PDFDocument5 pagesASTM A210 Seamless Medium Carbon Steel Tube1 PDFaditya ekaNo ratings yet

- Technical Catalouge PDFDocument41 pagesTechnical Catalouge PDFDhanish KumarNo ratings yet

- Essential Buttweld Pipe Fittings GuideDocument4 pagesEssential Buttweld Pipe Fittings Guidekamal_mdNo ratings yet

- Stainless steel pipe specs for corrosion resistanceDocument3 pagesStainless steel pipe specs for corrosion resistance1trungson1No ratings yet

- Basco Type 500Document12 pagesBasco Type 500Sebastian OviedoNo ratings yet

- ASME StandardsDocument8 pagesASME Standardsanappan100% (1)

- Fittings in Steel PipeDocument2 pagesFittings in Steel Pipekumar sandeepNo ratings yet

- MS 01 107Document12 pagesMS 01 107Floyd AnthonyNo ratings yet

- Valves, Flanges, Fittings, and Gaskets: Asme B16Document14 pagesValves, Flanges, Fittings, and Gaskets: Asme B16mhmd telfah100% (1)

- Manual Victau TubDocument22 pagesManual Victau TubAlex Arma del CarpioNo ratings yet

- ASME Standard List of Piping and FittingsDocument7 pagesASME Standard List of Piping and Fittingsjuantamad02No ratings yet

- Flange Summary Data SheetDocument1 pageFlange Summary Data SheetMJ MagdyNo ratings yet

- Asme Sa 213 Grade t92 TubesDocument1 pageAsme Sa 213 Grade t92 TubesFerroPipENo ratings yet

- OneSteel Steel Pipe Final LoResDocument24 pagesOneSteel Steel Pipe Final LoResAgus Budi PrasetyoNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- System Description Design GuideDocument15 pagesSystem Description Design GuideCivil FriendNo ratings yet

- Figure 4-7. Hubs Used With API Clamp Type Connectors. (Courtesy of American Petroleum Institute.)Document1 pageFigure 4-7. Hubs Used With API Clamp Type Connectors. (Courtesy of American Petroleum Institute.)somewhatNo ratings yet

- Text Continued On Page 70Document1 pageText Continued On Page 70somewhatNo ratings yet

- Got 610Document45 pagesGot 610somewhatNo ratings yet

- Rightful LigamentDocument1 pageRightful LigamentsomewhatNo ratings yet

- Urethane Scraper Cup Specifications and SizesDocument1 pageUrethane Scraper Cup Specifications and SizessomewhatNo ratings yet

- Figure 4-1. API Threaded Flange. (Courtesy of National Supply Company.)Document1 pageFigure 4-1. API Threaded Flange. (Courtesy of National Supply Company.)somewhatNo ratings yet

- Table 4-5 API Type 6B Flanges For 3000 Psi Maximum Working PressureDocument1 pageTable 4-5 API Type 6B Flanges For 3000 Psi Maximum Working PressuresomewhatNo ratings yet

- Repair DareDocument1 pageRepair DaresomewhatNo ratings yet

- Figure 6-10. Flange Insulation Sets. (Courtesy of Jaqua-Mckee, Inc.) 133Document1 pageFigure 6-10. Flange Insulation Sets. (Courtesy of Jaqua-Mckee, Inc.) 133somewhatNo ratings yet

- Sheets LongtermDocument1 pageSheets LongtermsomewhatNo ratings yet

- Table 3-1 Continued: (Continued On Next Page)Document1 pageTable 3-1 Continued: (Continued On Next Page)somewhatNo ratings yet

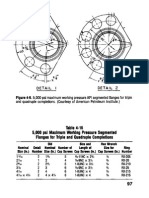

- API segmented flanges for triple and quadruple completionsDocument1 pageAPI segmented flanges for triple and quadruple completionssomewhatNo ratings yet

- Reducers and reducing outlet tees tableDocument1 pageReducers and reducing outlet tees tablesomewhatNo ratings yet

- Dimensions of Stainless Steel Stub Ends: Table 5-3Document1 pageDimensions of Stainless Steel Stub Ends: Table 5-3somewhatNo ratings yet

- Branch & Header Same Weight or ScheduleDocument1 pageBranch & Header Same Weight or SchedulesomewhatNo ratings yet

- Figure 4-1. API Threaded Flange. (Courtesy of National Supply Company.)Document1 pageFigure 4-1. API Threaded Flange. (Courtesy of National Supply Company.)somewhatNo ratings yet

- Tiresome DieDocument1 pageTiresome DiesomewhatNo ratings yet

- Figure 8-1. Pipe Tally Sheet. 150: No. or or or or or or or or or or or orDocument1 pageFigure 8-1. Pipe Tally Sheet. 150: No. or or or or or or or or or or or orsomewhatNo ratings yet

- Table 1-9 Alloy Steel Stud Bolts For ANSI 2500-1b Raised Face Flanges, Each With Two Heavy Hex NutsDocument1 pageTable 1-9 Alloy Steel Stud Bolts For ANSI 2500-1b Raised Face Flanges, Each With Two Heavy Hex NutssomewhatNo ratings yet

- Starveling SleetyDocument1 pageStarveling SleetysomewhatNo ratings yet

- Thy QuarrelDocument1 pageThy QuarrelsomewhatNo ratings yet

- ANSI Steel Stud Bolts TableDocument1 pageANSI Steel Stud Bolts TablesomewhatNo ratings yet

- Dimensions of Stainless Steel Stub Ends: Table 5-3Document1 pageDimensions of Stainless Steel Stub Ends: Table 5-3somewhatNo ratings yet

- Tickle BadgeDocument1 pageTickle BadgesomewhatNo ratings yet

- Shows That An 8-In. Pipe Has An OD of 8.625 Ins. So, Using The Equation,, 322 12 X 3.1416 X T 28.58 Ibs/ftDocument1 pageShows That An 8-In. Pipe Has An OD of 8.625 Ins. So, Using The Equation,, 322 12 X 3.1416 X T 28.58 Ibs/ftsomewhatNo ratings yet

- Branch & Header Same Weight or ScheduleDocument1 pageBranch & Header Same Weight or SchedulesomewhatNo ratings yet

- Tested Ramp All I AnDocument1 pageTested Ramp All I AnsomewhatNo ratings yet

- Taste BalanceDocument1 pageTaste BalancesomewhatNo ratings yet