Professional Documents

Culture Documents

Stud Out 1500

Uploaded by

Nguyen Thanh NguyenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stud Out 1500

Uploaded by

Nguyen Thanh NguyenCopyright:

Available Formats

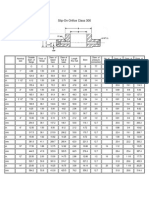

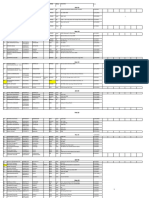

CLASS 1500 STUDDING OUTLET

FLAT BOTTOM

SHELL/HEAD MOUNT

Outside

Dia.

Thick.

RF

O.D.

Stud

Holes

Hole

Depth

Stud

Circle

Tap

Depth

Stud

Length

T

2.00

R

1.38

1/2

0

4.75

21/32

U

1.31

C

3.25

10

V

0.88

3/4

5.12

2.00

1.69

3/4

21/32

1.31

3.50

3/4

4.25

10

0.88

4.38

5.88

2 12

2.00

49/64

1 44

4.00

7/8

1 00

4.88

1 1/4

6.25

2.12

2.50

49/64

1.44

4.38

7/8

1.00

4.88

1 1/2

7.00

2.25

2.88

7/8

156

4.88

1.12

5.38

8.50

2.12

3.62

49/64

1.44

6.50

7/8

1.00

5.25

9.62

2.25

4.12

7/8

1.56

7.50

1.12

5.75

10.50

2.50

5.00

12.25

2.75

6.19

1.81

8.00

1 1/8

1.25

6.38

1 1/8

2.12

9.50

1 1/4

1.44

7.00

14.75

3.12

7.31

1 3/8

2.38

11.50

1 1/2

1.69

8.50

15.50

3.00

8.50

12

1 1/4

2.25

12.50

1 3/8

1 56

8.50

19.00

3.50

10.62

12

1 1/2

2.56

15.50

1 5/8

1.88

9.62

10

23.00

3.88

12.75

12

1 3/4

3.00

19.00

1 7/8

2.12

11.12

12

26.50

4.12

15.00

16

1 7/8

3.31

22.50

2.25

12.12

14

29.50

4.25

16.25

16

2 1/8

3.56

25.00

2 1/4

2.56

13.25

16

32.50

5.00

18.50

16

2 3/8

4.00

27.75

2 1/2

2.81

14.62

18

36.00

5.50

21.00

16

2 5/8

4.38

30.50

2 3/4

3.12

16.00

20

38.75

5.88

23.00

16

2 7/8

4.62

32.75

3.44

17.62

24

46.00

6.75

27.25

16

3 3/8

5.38

39.00

3 1/2

4.00

20.12

Size

2

2 1/2

Hole

Size

TANGENTIAL MOUNT

Tap

Size

T.P.I.

Material:

Studding Outlets are most commonly provided in SA-105. They can also be made from a full

range of stainless and alloy materials.

Thickness:

The standard thickness shown in charts for all studding outlets is the minimum required per

ASME Section VIII Division I Paragraph UG-43(d) for thread engagement and an ID. mount. It is important to

note that each individual application should be analyzed for proper thickness. See general notes for more details.

Facing:

The studding outlet minimum thickness T includes proper raised face per ANSI B16.5. Outlets

can be supplied with any special facing as needed upon request.

Drilling and Tapping: Studding outlets are furnished to ANSI B16.5 specifications unless otherwise specified.

Thread depth is in accordance with ASME Section VIII Division I Para. UG-43(g) for a design temperature not to

exceed 650F, a base metal stress of 17,500 psi, and a stud stress of 25,000 psi. All other materials exceeding

these stresses should be checked for UG-43 compliance.

Bore:

Bore sizes shown above are standard, other sizes can be furnished upon request.

Curving:

All connections can be furnished contoured to fit any shell, head or cone at an additional cost.

TEXAS FLANGE 877-610-8924

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Concrete Frame Design Manual: CSA A23.3-04Document82 pagesConcrete Frame Design Manual: CSA A23.3-04Mbayo David GodfreyNo ratings yet

- Awareness Training On CMMI Initiative: Sepg Yash Technologies PVT LTD HyderabadDocument59 pagesAwareness Training On CMMI Initiative: Sepg Yash Technologies PVT LTD HyderabadDeepaliNo ratings yet

- Sultan Saed Al - Zahrani Est ProfileDocument60 pagesSultan Saed Al - Zahrani Est ProfileaayasirNo ratings yet

- NGL Recovery Technologies: Irfan HussainDocument23 pagesNGL Recovery Technologies: Irfan HussainFarhad Ashraghi100% (1)

- Capintec CRC-15W Dose Calibrator PDFDocument238 pagesCapintec CRC-15W Dose Calibrator PDFwesleyNo ratings yet

- Flanges Pn40 Din En1092 1Document2 pagesFlanges Pn40 Din En1092 1Nguyen Thanh NguyenNo ratings yet

- Uputstvo Za Advance Steel 2019Document55 pagesUputstvo Za Advance Steel 2019Zoran SimićNo ratings yet

- Jpep 0 1360 T 4141 PDFDocument44 pagesJpep 0 1360 T 4141 PDFNguyen Thanh NguyenNo ratings yet

- Welding Neck Orifice Class 600Document1 pageWelding Neck Orifice Class 600Nguyen Thanh NguyenNo ratings yet

- Welding Neck Orifice Class 2500Document1 pageWelding Neck Orifice Class 2500Nguyen Thanh NguyenNo ratings yet

- Threaded Orifice Class 300Document1 pageThreaded Orifice Class 300Nguyen Thanh NguyenNo ratings yet

- Welding Neck Orifice Class 900 DimensionsDocument1 pageWelding Neck Orifice Class 900 DimensionsNguyen Thanh NguyenNo ratings yet

- Welding Neck Orifice Class 2500Document1 pageWelding Neck Orifice Class 2500Nguyen Thanh NguyenNo ratings yet

- Slip-On Orifice Class 300 Dimensions and SpecificationsDocument2 pagesSlip-On Orifice Class 300 Dimensions and SpecificationsNguyen Thanh NguyenNo ratings yet

- Welding Neck Orifice Class 1500 Dimensions and SpecificationsDocument1 pageWelding Neck Orifice Class 1500 Dimensions and SpecificationsNguyen Thanh NguyenNo ratings yet

- 900 Spect BlindDocument1 page900 Spect BlindNguyen Thanh NguyenNo ratings yet

- Weld Neck Flange Bore Dimensions ChartDocument1 pageWeld Neck Flange Bore Dimensions ChartNguyen Thanh NguyenNo ratings yet

- 600 Spect Blind PDFDocument1 page600 Spect Blind PDFNguyen Thanh NguyenNo ratings yet

- Welding Neck Orifice Class 400: In. Mm. In. MMDocument1 pageWelding Neck Orifice Class 400: In. Mm. In. MMNguyen Thanh NguyenNo ratings yet

- Welding Neck Orifice Class 300Document1 pageWelding Neck Orifice Class 300Nguyen Thanh NguyenNo ratings yet

- 150 Spect BlindDocument1 page150 Spect BlindNguyen Thanh NguyenNo ratings yet

- RF Flange Dimensions and Weights ChartDocument1 pageRF Flange Dimensions and Weights ChartNguyen Thanh NguyenNo ratings yet

- Class 600 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDocument1 pageClass 600 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenNo ratings yet

- Class 900 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDocument1 pageClass 900 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenNo ratings yet

- Conectores GraylocDocument0 pagesConectores Graylocpablotorresbozzo2686No ratings yet

- U-Bolts Supports PDFDocument4 pagesU-Bolts Supports PDFNguyen Thanh NguyenNo ratings yet

- Class 300 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDocument1 pageClass 300 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenNo ratings yet

- CLASS 2500 STUDDING OUTLET SPECIFICATIONSDocument1 pageCLASS 2500 STUDDING OUTLET SPECIFICATIONSNguyen Thanh NguyenNo ratings yet

- Texas Flange: Dimensions of Ring-Joint FacingsDocument6 pagesTexas Flange: Dimensions of Ring-Joint Facingsmanu_giteNo ratings yet

- Electrical TutorialDocument15 pagesElectrical TutorialNguyen Thanh NguyenNo ratings yet

- Hvac TutorialDocument43 pagesHvac TutorialNguyen Thanh NguyenNo ratings yet

- Cadpipe BS TutorialDocument44 pagesCadpipe BS Tutorialrayzone1No ratings yet

- Class 150 - Standard Connection SpecificationsDocument7 pagesClass 150 - Standard Connection SpecificationsNguyen Thanh NguyenNo ratings yet

- 5 DB Arithmetic PDFDocument85 pages5 DB Arithmetic PDFnadia_naaz90No ratings yet

- Create DDL Schema of Particular Table To A FileDocument3 pagesCreate DDL Schema of Particular Table To A FileUpender ThatishettiNo ratings yet

- A615060 PDFDocument49 pagesA615060 PDFAlex BurceaNo ratings yet

- BERDocument12 pagesBERThorNo ratings yet

- Cma B6521 PDFDocument1 pageCma B6521 PDFSurya MantaNo ratings yet

- Ece 8085 Microprocessor PDF ReportDocument19 pagesEce 8085 Microprocessor PDF Reportgourav VermaNo ratings yet

- Service Copy NewDocument86 pagesService Copy NewSKS MOTERS DEVARA HIPPARGINo ratings yet

- Lesson Plan in Aquaculture Ncii (Afa)Document3 pagesLesson Plan in Aquaculture Ncii (Afa)Adam WareNo ratings yet

- C Piscine: Summary: This Document Is The Subject For Day01 of The C Piscine at 42Document15 pagesC Piscine: Summary: This Document Is The Subject For Day01 of The C Piscine at 42NestorNo ratings yet

- Destiny 2: Destiny 2 Is An Online-Only Multiplayer First-Person Shooter Video GameDocument22 pagesDestiny 2: Destiny 2 Is An Online-Only Multiplayer First-Person Shooter Video GameDoktormin106No ratings yet

- Why Is Bandwidth Expressed in 3db and Not in 4db or 5db?: 2 AnswersDocument5 pagesWhy Is Bandwidth Expressed in 3db and Not in 4db or 5db?: 2 AnswersRajeev Mohan VermaNo ratings yet

- What Is A PLCDocument13 pagesWhat Is A PLCsushant_jhawerNo ratings yet

- Peoplesoft System Sizing QuestionnaireDocument14 pagesPeoplesoft System Sizing QuestionnaireaustinfruNo ratings yet

- ASTM D3689 (Prueba de Carga en Traccion)Document11 pagesASTM D3689 (Prueba de Carga en Traccion)Josh ClaureNo ratings yet

- Bme Lab: Belt Drive Vs Chain Drive Vs Gear DriveDocument12 pagesBme Lab: Belt Drive Vs Chain Drive Vs Gear DriveYash SorathiyaNo ratings yet

- ISO13849-1 Cat Je PDFDocument24 pagesISO13849-1 Cat Je PDFDan001500No ratings yet

- Palm Beach County Property Appraiser PTO Balance Report 4-30-2012Document7 pagesPalm Beach County Property Appraiser PTO Balance Report 4-30-2012LynnKWalshNo ratings yet

- Mimaki Engineering Co., LTD.: You Can Also Download The Latest Manual From Our WebsiteDocument142 pagesMimaki Engineering Co., LTD.: You Can Also Download The Latest Manual From Our WebsiteMauricio VillarNo ratings yet

- Origin: by Dan BrownDocument6 pagesOrigin: by Dan BrownDhrithiNo ratings yet

- Indo Farm Company Profile PDFDocument28 pagesIndo Farm Company Profile PDFƎɯox SatíshNo ratings yet

- UC Berkeley Digital Transformation Brochure 16 07 2019 PDFDocument17 pagesUC Berkeley Digital Transformation Brochure 16 07 2019 PDFColean AraujoNo ratings yet

- Tech Mahindra Launches 'mPAC' - Managed Platform For Adaptive Computing (Company Update)Document3 pagesTech Mahindra Launches 'mPAC' - Managed Platform For Adaptive Computing (Company Update)Shyam SunderNo ratings yet

- Spring Biochem Offer LetterDocument3 pagesSpring Biochem Offer LetterRocky RayNo ratings yet

- Whitepaper: Autocad Plant 3D Performance - Maximizing SpeedDocument4 pagesWhitepaper: Autocad Plant 3D Performance - Maximizing SpeedNeel KadakiyaNo ratings yet

- Noise Control Sound Absorption GuideDocument32 pagesNoise Control Sound Absorption GuideRukminiPriyankaNo ratings yet