Professional Documents

Culture Documents

Nonlinear Finite Element Analysis of Glass Panels: Andrew Kwok Wai So and Chan

Nonlinear Finite Element Analysis of Glass Panels: Andrew Kwok Wai So and Chan

Uploaded by

Luis MartinsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nonlinear Finite Element Analysis of Glass Panels: Andrew Kwok Wai So and Chan

Nonlinear Finite Element Analysis of Glass Panels: Andrew Kwok Wai So and Chan

Uploaded by

Luis MartinsCopyright:

Available Formats

EngineeringStructures,Vol.

ELSEVIER

0141-0296(95)00199-9

18, No. 8, pp. 645~52, 1996

Copyright 1996 Elsevier Science Ltd

Printed in Great Britain. All rights reserved

0141-0296/96 $15.00 + 0.00

Nonlinear finite element analysis

of glass panels

Andrew Kwok Wai So and Siu L a i Chan

Department of Civil and Structural Engineering, Hong Kong Polytechnic University, Hung

Horn, Kowloon, Hong Kong

(Received August 1993; revised version accepted March 1995)

Glass panels which are widely used in curtain wall systems, behave

nonlinearly under high wind load when their deflections exceed

about 3/4 of their thickness. The American and the Canadian design

codes for curtain wall and window systems have made it mandatory to include the effect of large deflection in the design and analysis of glass panels. This paper presents a versatile finite shell

element method for nonlinear analysis of glass panels subjected

to high wind loads. The accuracy of the proposed method is demonstrated via comparison with the results of previous studies and

experiments. The advantage of the present method is its versatility

in handling complex loading and boundary conditions whilst its

longer computational time has been effectively offset by the adoption of the efficient incremental-iterative minimum residual displacement method of analysis and the availability of fast personal

computers. Using the examples studied in this paper, it was found

that the nonlinearity in glass may violate the linear assumption in

the practical loading range, resulting in unexpected glass behaviour if the linear theory is used. More interestingly, the use of

higher strength glass, the tempered or the heat-strengthened glass,

will not increase the load resistance of the panel when it is under

in-plane loads causing instability. Copyright 1996 Elsevier

Science Ltd.

Keywords:glass panels, wind loads, finite element analysis

1.

it reduces the visibility through the glass: the surface wave

of tempered glass distorts the reflected image and the

reflections multiple surfaces of laminated glass also distort

vision. The major reason for special care in the design of

glass is that it has no ductility to allow a moment or force

redistribution like steel and concrete frames. Further, their

over-design is costly. In Hong Kong, the facade system normally takes 15-20% of the total construction cost in a commercial building.

The curtain wall system is directly under the attack of

strong wind during its normal life. The basic design wind

pressure in Hong Kong can be up to 6 kPa for buildings

with a level higher than 250 m, which is not uncommon,

as many buildings are constructed along the hillside. Under

the strong wind action, glass panels deflect considerably so

that the linear theory does not suffice. In fact, in a number

of full-scale mock-up tests by the second author, nearly

all glass panels deflected by more than several times their

thickness during their strength and performance tests. This

high nonlinearity implies that a nonlinear theory should be

used to predict their structural behaviour.

Introduction

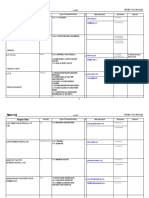

Glass panels are widely used in curtain wall systems to

separate the interior from the exterior of a building. They

have a distinct advantage of providing a clear view of the

outside environment for the occupants. Large glass panels

of size in excess of 1.5 m z are nowadays commonly used

in commercial buildings. In practice, they are structurally

glazed by structural sezlant on the four sides or two sides

with the other two edges clamped along the transoms (see

Figure 1). Aesthetically speaking, their appearance generally is more appealing ~Lhanother finishes.

In spite of the wide use of glass, its behaviour and

properties are not very well known to the engineer when

compared to other materials like steel and concrete. Its

structural importance cannot be overlooked. Its failure will

lead directly to glass debris falling onto the street level and

this is commonly encountered in many buildings. Due to

their brittleness, there is normally no warning of a breakage. Although laminated and tempered glass lowers the

chance of harmful damage, its use may not be preferred as

645

646

Nonlinear finite element analysis of glass panels: A. K. W. So and S. L. Chan

1

v2

Glass

Mullion

I

3

Plead

Spnge"-~ wadga

WeatherinSeal

g ant

Structural

Se~ngBlock~SII

Rod

I Can

Section 1-1

Section 2

A Typical two-sided structural glazing design

We~hering 8eakmt

GIIUll

~,~ ~ : /

WeatheringSeallnt

J.-

1.1. Element formulation and numerical procedure

SttucturldS.lden~t

~=--~

.o IL-JI

iliar with the finite element method which has a stronger

physical perception, the proposed method should be more

readily accepted by the profession.

This paper is addressed to the application of a refined

finite element technique to the geometrically nonlinear

analysis of glass panels. The application of the finite

element method to the nonlinear analysis of glass panels

appears to be limited and the recently developed powerful

numerical techniques have not been fully utilized. The triangular element is selected as a basic element for idealization of the plated structure since its shape can be easily

adapted to various complicated boundary conditions.

Numerical examples on the analysis of the snap-through

behaviour of a shallow shell, the stress distribution of a

tested glass panel and the predicted failure load of a series

of glass plates are given to verify the proposed method.

The objective of this paper is to demonstrate the application of this versatile finite element method to the analysis

of glass panels of complex geometry undergoing large

deflections. Most of the finite element procedures used for

the analysis of glass structures are rather obsolete and the

sophisticated and recently developed techniques for the

finite element method have not been used for the analysis

of glass structures. The accuracy of the proposed finite

element method will be compared against a number of

problems for which solutions by other methods or test

results are available. In fact, the nonlinearity of glass panels

in the working load range has provided a very important

chance to apply the nonlinear finite element method to

realistic engineering structures.

GluIplate

Section 2

/U

Section 3

A Typical four-sided structural glazing design

Figure I Typical structural glazed system

There are several methods to tackle the large deflection

problems of plates. Early works in the area include the

finite difference method by Kaiser 1 and Vallabhan and

Wang 2, the closed-form solution by Levy3, the Galerkin

method by Beason 4 and the finite element method by AITayyib5. The close-formed solutions can only be obtained

for some idealized boundary conditions and initial plate

geometry, which may not accurately reflect the actual condition of the glass panels. The Galerkin and the finite difference methods, in general, involve less computational work

than the finite element method but may be limited to standard or simple plate geometry. For glass panels of curved

surface and under complicated boundary conditions such as

the edges not being completely restrained along their sides,

these methods may be too complex. The finite element

method is generally considered to be most versatile in terms

of flexibility. The modification of an existing finite element

program for glass analysis is also believed to be a simpler

task than the coding of a complete finite difference program. Its disadvantage of heavy computational time is

reduced by the powerful incremental iterative nonlinear

numerical methods developed and also the low-priced and

fast microcomputers. Further, as the engineer is more ram-

Whilst the objective of this paper is to demonstrate the

application of the nonlinear finite element method to the

design and analysis of glass panels, the detailed formulation

of the finite element used in the present studies will not be

given. However, a brief description of the method used in

the analysis is necessary in order to provide a reference for

the readers in selecting an element for the analysis of this

type of structures. A complete and detailed discussion on

the element formulation is given in Reference 6.

In general, a thin shell structure has a thickness much

smaller than its lateral dimensions and resists the external

forces by the combined membrane and the bending actions.

To model the behaviour of such a structure, the bending and

the membrane stiffness must be considered in an analysis.

Due to the thinness of glass panels used in practice, the

shear strain energy is minimal and thus the facet element in

conjunction with the Kirchhoff thin shell theory is adopted

herein. To be consistent with the general engineering analysis, each element node is formulated to have six degrees

of freedom which are the three translational and the three

rotational displacements in and about the three mutually

perpendicular axes. The bending and membrane stiffnesses

are uncoupled at element level and each possesses three

degrees of freedom.

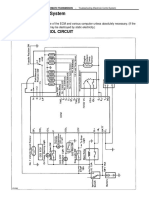

The in-plane stiffness of the present element is chosen

from the one by Allman 7. The advantage of using the

element is due to the adoption of the drilling degree of

freedom, with which an additional fictitious degree of freedom to prevent zero in-plane rotational stiffness when all

elements lie on the same plane, is not required. Each inplane stiffness component possesses three degrees of freedom at each node (i.e. the two translations and the one

rotation as shown in Figure 2) and it is formed from a strain

Nonlinear finite element analysis of glass panels: A. K. W. So and S. L. Chan

z

y

/~lobel

X

Axle

3

X

""3

u3

MembraneStiffness

Figure2

2

x

~ ~y3

0

BendingStiffness

Shell element

field which can be assumed to be constant because the

direct strain variation across the elements is not large.

The bending stiffness of the element (see Figure 2) to

be used for glass analysis is based on the assumption of

zero shear strain energy. The Kirchhoff hypothesis is

imposed on the element comers and midside nodes only,

resulting in the so-called discrete Kirchhoff element. The

variation of the transverse displacement, w, is assumed to

be cubic along the element side. The explicit form of the

element can then be obtained about the axis along one side

of the element using an algorithm by Joseph and Rao 8 and

Batoz9. The formulated bending stiffness excludes the need

to carry out numerical integration and is computationally

efficient, especially when a large number of elements are

used. As the breakage of glass is a brittle type of failure

and is assumed to occur when the maximum stress attains

the fracture tensile strength of glass, the advantage of the

numerical integration technique for modelling gradually

spreading plasticity cannot be used in the present studies

and thus an explicit element is preferred.

To carry out a bifurcation or an incremental-iterative

type of second-order analysis, it is necessary to formulate

the tangent stiffness matrix which is composed of the linear, the large displacement and the geometric stiffness

matrices. The linear stiffness matrix is obtained by adding

the in-plane and bending components of the triangular

element as described. The large displacement matrix can

be considered implicitly by a co-ordinate updating process

and the geometric stiffness matrix is obtained by the product of the Cauchy stre:~s and the second-order strain. The

complete matrix has been given by So6.

647

invisible hairy cracks on its surface. The failure stress of a

piece of glass is more dependent on the density of these

hairy cracks than on the theoretical breakage stress which

can be as high as 14000 MPa ~. Thus, a rational design

failure stress is expresed in terms of the duration of load

(WeibuU's theory ]~ for the failure of brittle material), treatment of glass to reduce surface tensile stress and the area

of glass panel being considered. It also depends on the

moisture on the glass surface. Heat strengthened and tempered glass can be used to reduce the tensile stress on the

surface of the glass panels, but they simultaneously reduce

the visibility through the glass. Also, the presence of

impurities such as nickel sulphide will lead to spontaneous

breakage of this type of glass. In some cases such as glass

fins, this tempering process may become useless since the

bending stress is about the strong axis of the glass plate.

To accurately compute the maximum stress in a panel for

checking of stress against failure, the large deflection theory

allowing for the membrane stress should be used. In the

breakage analysis of annealed glass panels, failure is

assumed to occur when the maximum tensile stress is equal

to the breaking stress of the glass which, unfortunately, can

only be obtained on a statistical basis. In general, a factor

of safety of 2.5 is introduced to control the probability of

failure to 8/1000. For tempered glass, the breakage stress

is normally taken as three to four times that of the

annealed glass.

The Canadian Code has adopted the failure prediction

model developed by Beason and Morgan ~2. A simplified

model for failure of glass panels with the effect of load

duration was also presented by Brown ~3. The resistance to

breakage for a surface flaw can be expressed as follows.

f rl

K:= JIo [o-(T)]" dT

(1)

in which T is the load duration, K/is the resistance to failure

by a surface flaw exposed to tensile stress and water vapour, o-(T) is the normal tensile stress at the flaw, expressed

as a function of time, n is a constant and its best fit value.

From experimental data, n is determined as 16 (See Reference 13) and T/is the duration of loading which causes

failure. The glass plate fails when K/reaches some critical

value which depends on the flaw's characteristics and the

stress rate at the flaw. With equation (1), we can adjust the

strength of glass for different load durations. In a computer

analysis, we can compute constant stress causing glass

breakage and relate this to failure stress with different load

durations as follows.

o-~ = o-: [60(n +

(2)

where o-60is the constant stress causing failure of the panel

in 60 s. o-: is the constant stress causing failure in T: s.

The use of a design factor of 2.5 has been introduced to

control the probability of failure (POF) to 0.008. The POF

can be expressed in terms of the Weibull distribution as

follows

1.2. Failure criterion

For commercial annealed glass, which is widely used in

curtain wall systems, tbe failure and breakage of glass is,

generally speaking, due to the stress concentrated at the

POF = 1 - e -B

in which,

(3)

648

N o n f i n e a r finite e l e m e n t analysis o f glass panels: A. K. W. So a n d S. L. Chan

P

1.4. Hinged cylindrical shell

E

R

L

(I

E

=2540 mm

=254 mm

=0.1 rad

=3.10275 kN/mrn'

=0.3

Case 1

h

=12.7 mrn

Case 2

h =6.35 mm

Figure3 Hinged cylindrical shell

0,4

- -

Ver~:ll ddection at pobt C

....

Virgil dlglctlon id point E

~

;>

/

A/

10

15

20

25

30

35

Displacement(rnrn)

Figure4 L o a d - d e f l e c t i o n curve f o r cylindrical shell (case 1,

The first example serves to validate the analysis tool for

cylindrical structures in a snap-through problem and the

strength of the structure when it is made of glass material

is then computed.

Figure 3 shows a circular cylindrical shell of thickness

12.7 mm and subjected to a concentrated central load

applied on the convex side. The longitudinal boundaries are

hinged and immovable while the curved edges are free. A

four-by-four mesh for one-quarter of the panel has been

considered. The problem has been used extensively for testing of a new element and the nonlinear solution method

for snap-through and snap-back analysis. The results of

applied load against the central deflections are shown in

Figure 4. In this example, the arc-length '4 solution method

is used for the load-increment and the minimum residual

displacement method 15 for load-iteration. The results agree

very well with those by Surana 16 and Sabir and Lock 17.

In the second example, the thickness of the cylindrical

shell is reduced to 6.35 mm while the geometric and physical data are the same as in the previous example. The structural response of the modified structure is quite different

from the previous example. Snap-back is observed in

addition to snap-through. The load-deflection curves for

the central point and midpoint of the curved edge are plotted in Figure 5. Again, the results compare very well with

those of References 16 and 17.

The accuracy of the NAShell program in analysing the

structures confirms the validity of the suggested element

and its associated numerical procedure in dealing with

problems involving large change of geometry. The program

encounters no divergence in tracing the complete equilibrium path, demonstrating that the proposed method can

handle, not only the nonlinear analysis of glass panels, but

also other types of shell structures which exhibit instability

and snapping behaviour.

thickness = 12.7 ram)

1.5. Curved glass panel

8= Z t- oj

where e is the natural number, Ao and So are the area and

the characteristic strength of the reference glass panel,

respectively, and A and S,,.p.r are the area and characteristic

strength, respectively, of the glass panel. S,,,p.r is a function

of the Weibull parameter, m, p is the pressure and r is the

aspect ratio. From the collected failure data for in-service

glass 13 and fitted to equation (3), the Weibull parameters

m and So were obtained as 7 and 32.1 MPa, respectively,

for a reference area, Ao, of 1 mL These values are used in

the Canadian Code and adopted herein.

In this example, a curved glass panel with base dimensions

of 1500mm x 1500 mm, radius of 1500 ram, Young's

modulus of 70000 MPa, Poisson's ratio of 0.22 and thickness of 8 ram, and under uniform lateral load is analysed

0.8

0.4

A

Z

O.

1.3. Numerical examples

The developed finite element method is used for the checking of stress in several types of glass structures. The method

will first be validated against bench mark large deflection

problems, then the analytical solution for a simply supported plate under uniformly distributed load and finally the

breakage analysis of a series of tested glass panels. These

examples should demonstrate how the finite element

method can be used effectively to predict the strength of

these structures which this type of analysis appears to have

not yet solved.

0'

X

.,

-0.2,

-0,4

&

"

o.

s.... *'

Sabl ~d

,,

~.

Lock

.j7

",

"~

10

15

20

25

30

Displacement (mrn)

Figure 5 L o a d - d e f l e c t i o n curve f o r cylindrical shell (case 2,

thickness = 6.35 mm)

Nonlinear finite element analysis of glass panels: A. K. W. So and S. L. Chan

Posltlveoressure direction

(normal tb surface),

I~legetht9prel~sur~direction

, (normal zo 8unsce)

./

/'/

,oonner

R =

1500mm

L =

E =

1500mm

71000MPa

0.22

=8mm

649

assumed to act perpendicularly to the glass surface. In

Figure 7, we can see the load-deflection path at the plate

centre and the failure loads for annealed glass and tempered

glass under positive and negative pressure acting on the

projected base area. Failure is assumed when the maximum

principle tensile stress reaches the breakage strength

14.25 MPa which is calculated from equations (3) and (4)

with POF = 0.008, Ao = 1 m 2, So = 32.1 MPa and rn -- 7.

For tempered glass, the failure stress is assumed to be four

times the value for annealed glass 18. In Figures 8 and 9,

we can see the principal stresses on the bottom surface for

negative and positive pressure, respectively, at the instant

of failure pressure.

It can be seen in the analysis that the failure pressure for

annealed and tempered glasses is on the same rates as stress

for the tensile load (positive pressure) case where the geometrical change is not significant. However, for the compressive load (negative pressure) case, the failure pressure

oenter

Figure 6

L a y o u t a n d p r o p e r t i e s o f c u r v e d glass panel

(see Figure 6). The longitudinal boundaries are hinged and

immovable while the curved edges are restrained in the

longitudinal direction. Due to symmetry, only a quarter is

analysed with a grid size of 11 x 11. The wind load is

~, 220

0.

~, 2o0

i

-7

Fa

-3

'~ 180

8=

16o

140

rE

15 5

120

100

60

__~E._ Failure load for Annealed Glass

conner

A) Stress contour at failure load for annealed glass

oenter

20

012

0:4

0'.S

018

1

1.2

Deflection at Centre along the Loading Direction (mm)

A) Positive Pressure

,-,8O

)

I

/o

90

D.

~" 70

Failurepoint

for Annealed Glass

Failurepoint

for Tempered Glass

-10

-10

50

.o

13

Q- 4O

30

20

10

00

Deflection at Cenlre along the Loading Direction (mm)

oonner

B) Stress contour at failure load for tempered glass

B) Negative Pressure

Figure 7

Load-deflection

p a t h at c e n t r e o f c u r v e d glass p a n e l

Figure8

Principal stress on b o t t o m

p r e s s u r e (all stresses in M P a )

surface under negative

Nonlinear finite element analysis of glass panels: A. K. W. So and S. L. Chan

650

center

1.5

W

h

0.5

-I

+ - TImolheniko 18

and W o ~

oonner

A) Stress contour at failure load for annealed glass

100

200

3o0

Figure 10 Load-deflection of a simply supposed square plate

oeriter

12

olo= ~TI0

30

O0

100

200

. ~ 300

Figure 11 Bending stresses and centre and corner

oonner

B) Stress contour at failure load for tempered glass

12

Figure9 Principal stress on bottom surface under positive

pressure (all stresses in MPa)

ratio may not be equal to the ratio for failure pressure on

breakage stresses. This is due to the change in the geometry

of the glass resulting in the nonlinearity between the stress

and the load. In other words, the strength of a glass structure made of tempered and annealed glass is not always in

the same ratio as their breakage stress. As demonstrated in

this example, the tempering process for glass has a very

different response when the structure is under loads in different directions. Care should be taken in allowing for this

discrepancy in glass structure behaviour which is not a consideration in structures made of other materials. Although

concrete is also weak in tension, its design generally

ignores the presence of the portion in tension. For glass

structures, cracks due to tension will lead directly to the

breakage of the complete piece of glass and thus cannot

be allowed. This characteristic of glass as an engineering

material significantly alters the design philosophy and

concept.

Eh'

V CentreA = t ~ n k o

in

X PolnlB ~.Wc~nm~ 18

PointC ~ ! ~

100

200

qb'

Eh'

300

Figure 12 Membrane stresses at centre, centre edge and corner

Nonlinear finite element analysis of glass panels: A. K. W. So and S. L. Chan

1.6. A square simply supported plate under uniform

load

In this example, a 10 in simply supported square plate with

edge displacement fully restrained is analysed. The thickness of the plate is 0.04 in while the Young's modulus is

27.6 x 106 psi and Poisson's ratio is 0.316. The objective

of this problem is to check the accuracy of the stress computed by the developed program.

The deflection, bending and membrane stresses are plotted in Figures 10-12, respectively. The analytical solution

to this problem by Timc,shenko and Woinowsky-Krieger~9

is also plotted in the sarne figures for comparison.

It can be seen from Figures 10-12 that the results

obtained by the present program are in very good agreement with the analytical solution. The validity of the

method in this problem confirms its reliable application to

plate analysis involving a large change in geometry. The

accuracy of the analysis results show clearly that the proposed method can be u:~ed for the design of widely used

651

fiat glass under severe wind loads. The analysis results

shows not only the thickness required for a certain probability of failure, but also can be used to calculate the corresponding deflection in a single analysis and to determine

the highest stressed region in the plate. Obviously, cracking

in this highly stressed zone has a more detrimental effect

on the strength of the glass than in other areas. This information is valuable for the safety inspection of glass plates.

1.7. Failure test of in-service glass

In this example, the test results obtained by the Institute for

Research in Construction (IRC) of the National Research

Council of Canada for 47 in-service window glass removed

from the University of Ottawa's Thompson Residence in

1986 were compared.

The breaking stress of glass is determined by assuming

the characteristic strength equals 32.1 MPa as recommended by the Canadian code and the corresponding

breakage stress is then computed from equation (3). It is

Table 1 Test results of in-service glass

No

P6o (kPa)

Thickness (mm)

X (mm)

Y (mm)

NAShell

Ratio

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

2.84

4.57

2.26

5.27

4.47

4.10

5.62

4.12

5.29

5.01

4.47

5.75

3.66

5.39

4.79

5.70

5.73

6.08

4.58

4.77

5.16

2.92

3.38

5.14

5.54

6.18

5.04

5.03

4.04

5.02

2.19

2.46

2.54

3,75

2.73

3.11

3.11

4.64

4.83

2.66

1.86

3.01

3.27

4.27

4.51

3.98

3.08

4.10

4.00

4.10

4.00

4.05

4.00

4.07

3.90

4.00

4.00

3.93

3.95

3.84

3.90

3.95

3.88

4.04

3.93

3.90

4.09

4.01

4.00

3.97

3.86

4.00

3.96

4.00

3.96

3.96

3.91

3.83

3.77

3.69

3.75

4.00

4.05

3.93

4.01

4.81

3.80

3.83

4.05

3.94

4.04

3.86

3.87

3.74

1300

1300

1300

1300

1300

1300

1298

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1340

1340

1340

1342

1357

1356

1356

1358

1358

1374

1374

1300

1300

1300

1300

1300

1300

905

905

905

905

905

905

897

930

929

930

928

925

925

924

925

930

925

900

900

900

895

900

899

930

900

975

975

975

975

975

916

916

916

916

1300

1300

1300

1300

1300

1342

1342

1062

1062

1065

1065

1065

1065

1.73

1.73

1.73

1,73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.73

1.70

1.70

1.70

1.70

1.70

1.66

1.66

1.58

1.66

1.43

1.43

1.36

1.43

1.81

1.21

1.21

1.81

1.66

1.73

1.66

1.66

1.58

1.64

2.64

1.30

3.04

2.58

2.37

3.24

2.38

3.05

2.89

2.58

3.32

2.11

3.11

2.76

3.29

3.31

3,51

2.64

2.75

2.98

1.68

1.95

2.97

3.20

3.65

2.97

2.97

2.38

2.96

1.32

1.48

1.61

2.26

1.91

2.17

2.29

3.24

2.67

2.21

1.54

1.66

1.97

2.46

2.72

2.40

1.95

Mean ratio = 2.51

652

Nonlinear finite element analysis of glass panels: A. K. W. So and S. L. Chan

generally believed that the in-service time reduces the

breakage stress of a glass panel due to the increased density

of hairy cracks on the glass surface.

The equivalent 60 s pressure of the test results and output

by NAShell are tabulated in T a b l e 1. The average ratio of

test failure results to the predicted breaking load by NAShell is 2.51. This ratio is considered to be in a reasonable

range because the failure stress used in NAShell has

included the probability of failure of 8/1000. Not single

sample had a failure load lower than the predicted load,

indicating the reliability of the suggested method for the

design of glass panels.

Conclusions

A finite element model is proposed for nonlinear and breakage analysis of glass panels subjected to lateral wind load.

The simple triangular element used in the present studies

performs very well in the problems studied in this paper.

The nonlinear numerical method together with the presented element is capable of dealing with analysis involving

large geometrical change and snapping instability. The

moderately large deflection behaviour for actual glass

panels is believed to be well within the range of application

of the proposed method.

It can be seen that the behaviour of glass is highly nonlinear in many cases when the breaking pressure is

approached. This demonstrates the importance of considering the effect of change in geometry in glass panels when

computing stress and deflection. In many cases, when the

geometry changes significantly, the stress contour differs

very considerably between the linear and the nonlinear

analyses.

An important observation is that, as the stress is not

necessary proportional to the load in the higher nonlinear

range, the ratio between the failure pressure for tempered

glass may not be equal to four times that of the annealed

glass, as is normally assumed for the increase in breaking

stress in an annealed glass caused by the tempering process.

Thus, for glass structures with behaviour controlled by

instability and large deflection, the use of higher strength

glass, the tempered glass, may not result in a corresponding

increase in strength as in the case for flat glass design. Special care should be taken to select an appropriate type of

glass for a particular form of glass structure of different

characteristics. A finite element analysis computer program

such as the one proposed in this paper can be used in the

prediction of the pressure at failure when large geometrical

change is likely.

References

1 Kaiser, R. 'Rcchnerische and experimentelle Ermittlung der Durchbiegungen und Spannungen von quadratischen Platten bei freier Auflagerung anden Randern, gleichmassig verteilter Last und grossen Ausbiegungen', A.fa.M.M. 1936, 16 (2), 73-78

2 Vallabhan, C. V. G., and Wang, B. Y-T. 'Nonlinear analysis of rectangular glass by finite difference method', Institute for Disaster

Research, Texas Technical University, Lubbock, TX, June 1981

3 Levy, S. 'Bending of rectangular plates with large deflections',

NACA Tech. Note 846, 1942

4 Beason, W. L. 'A failure prediction model for windows glass', PhD

thesis, Texas Technical University at Lubbock, TX, 1980

5 A1-Tayyib, A. J. 'Geometrically nonlinear analysis of rectangular

glass panels by finite element method', PhD thesis, Texas Technical

University at Lubbock, TX, 1980

6 So, A. K. W. 'Geometrically nonlinear and breakage analysis of glass

systems by the finite element method', PhD thesis, Department of

Civil and Structural Engineering, Hong Kong Polytechnic University, 1995

7 Allman, D. J. 'A compatible triangular element including vertex

rotations for plane elasticity analysis', Comp. Struct. 1984, 19 (1-

2), 1-8

8 Joseph, L T. and Rao, K. 'A fast algorithm for triangular plate bending element', Int. Y. Num. Meth. Engng 1979, 14, 1100-1104

9 Batoz, J. L. 'An explicit formulation for an efficient triangular platebending element', Int. J. Num. Meth. Engng 1982, 18, 1077-1089

10 Dalgliesh,W. A. and Taylor, D. A. 'The strength and testing of window glass', Can. Z Engng 1990, 17, 752-762

11 Weibull, W. 'A statistical theory of the strength of materials', Royal

Swedish Institute for Engineering Research, Stockholm, Sweden,

No. 151, 1939

12 Beason, W. L. and Morgan, J. R. 'Glass failure prediction model',

J. Struct. Engng, ASCE 1984, 110 (2), 197-212

13 Brown, W. G. 'A practicable formulation for the strength of glass

and its special application to large plates', Publication NRC 14372,

National Research Council of Canada, Ottawa, Ontario, Canada, 1974

14 Crisfield, M. A. 'A faster incremental/iterative solution procedure

that handles snap-through', Comp. Struct. 1981, 13 (1-3), 55-62

15 Chan, S. L. 'Geometric and material nonlinear analysis of beam-columns and frames using the minimum residual displacement method',

Int. J. Num. Meth. Engng 1989, 11, 23-30

16 Surana, K. S. 'Geometrically nonlinear formulation for the curved

shell elements', Int. J. Num. Meth. Engng 1983, 19 (4), 581-615

17 Sabir, A. B. and Lock, A. C., 'The application of finite elements to

the large deflection geometrically nonlinear behaviour of cylindrical

shells', in C. A. Brebbia and H. Tottenham (eds), Variational

methods in engineering, Southampton University Press, Southampton, 1973, pp. 7/66-7/75

18 Structuraldesign of glass for buildings, National Standard of Canada,

CAN/CGSB-12.20-M89, Canadian General Standards Board, 1989

19 Timoshenko,S. P. and Woinowsky-Krieger,S. Theory of plates and

shells' (2nd edn) McGraw-Hill, 1959, pp. 396-428

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- 1995 Dakota Service ManualDocument1,430 pages1995 Dakota Service Manuallilfroger100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1998 Mitsubishi Lancer Evo4and5 ManualDocument391 pages1998 Mitsubishi Lancer Evo4and5 Manualjorgedanielpyrih100% (1)

- Bent Plywood BicycleDocument21 pagesBent Plywood BicycleCarol FolhaNo ratings yet

- Hvac NotesDocument9 pagesHvac NotesMegha SinghNo ratings yet

- GC Mrig Utilisation of Coal Washery ReDocument30 pagesGC Mrig Utilisation of Coal Washery Resheth_parag1No ratings yet

- Cable System Technology Review of XLPE EHV Cables, 220 KV To 500 KV PDFDocument361 pagesCable System Technology Review of XLPE EHV Cables, 220 KV To 500 KV PDFCriss T100% (1)

- Ecozero PDFDocument12 pagesEcozero PDFvranceanu.ovidiu-1No ratings yet

- Copy of Walt Disney Factories List in BD - November-2021Document2 pagesCopy of Walt Disney Factories List in BD - November-2021Ferdous Khan RubelNo ratings yet

- Petrotest Product 13-0285 enDocument3 pagesPetrotest Product 13-0285 endchyNo ratings yet

- Product DataDocument2 pagesProduct DataKalaiyazhagan ElangeeranNo ratings yet

- Welding of Tool SteelDocument15 pagesWelding of Tool SteelRonaldo JuniorNo ratings yet

- Glucopon 425 NHH TI enDocument4 pagesGlucopon 425 NHH TI enledude21No ratings yet

- A.v.L Based On Manufacturers - June2000Document490 pagesA.v.L Based On Manufacturers - June2000seetharaman k sNo ratings yet

- DewHughes LTP27 JC HistoryDocument10 pagesDewHughes LTP27 JC Historyikramullah041288No ratings yet

- Electronic Control System: PrecautionDocument13 pagesElectronic Control System: Precaution2791957No ratings yet

- Commercial Bronze Strip For Bullet JacketsDocument7 pagesCommercial Bronze Strip For Bullet Jacketsist93993No ratings yet

- AMTEC Threaded Inserts PDFDocument36 pagesAMTEC Threaded Inserts PDFdlstoneNo ratings yet

- Loctite Stycast 2762Ft: Technical Data SheetDocument3 pagesLoctite Stycast 2762Ft: Technical Data SheetankitaNo ratings yet

- TRB Usucger PHD Workshop Jan 2005Document9 pagesTRB Usucger PHD Workshop Jan 2005CepiNo ratings yet

- BPS Arp - Ss-01aDocument9 pagesBPS Arp - Ss-01asparkCENo ratings yet

- Sika PlasterstikDocument2 pagesSika Plasterstikkobus bekkerNo ratings yet

- Kel 1 Paradigma I Unit Operasi TambahanDocument38 pagesKel 1 Paradigma I Unit Operasi TambahanRomeo gadunganNo ratings yet

- Albond HS CastableDocument2 pagesAlbond HS CastableGurdeep Sungh AroraNo ratings yet

- 449087main NASA White Sands Test Facility PDFDocument2 pages449087main NASA White Sands Test Facility PDFAlejandro Kanito Alvarez SNo ratings yet

- 1 s2.0 S1876610218311561 MainDocument13 pages1 s2.0 S1876610218311561 MainLaraba MohamedNo ratings yet

- D7832D7832M-14 Standard Guide For Performance Attributes of Waterproofing Membranes Applied To Below-Grade Walls - Vertical Surfaces (Enclosing Interior Spaces)Document3 pagesD7832D7832M-14 Standard Guide For Performance Attributes of Waterproofing Membranes Applied To Below-Grade Walls - Vertical Surfaces (Enclosing Interior Spaces)Satya kaliprasad vangara0% (1)

- Ce 2405 Set2Document8 pagesCe 2405 Set2sheikNo ratings yet

- Sloution 5.2 FrictionDocument2 pagesSloution 5.2 FrictionShyamala Manjunath33% (3)

- DPRB Acsce 26Document54 pagesDPRB Acsce 26Pratham M JariwalaNo ratings yet