Professional Documents

Culture Documents

Cement Subbase Tech Brief

Cement Subbase Tech Brief

Uploaded by

AnantCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Subbase Tech Brief

Cement Subbase Tech Brief

Uploaded by

AnantCopyright:

Available Formats

Boone County Expo Test Sections

DRAFT

May 2013

TECH BRIEF

Cement Stabilization of Subbase and Subgrade

RESEARCH PROJECT TITLE

Boone County Expo Research

Phase I Granular Road Compaction

and Stabilization

SPONSOR

Iowa Department of Transportation

RESEARCH TEAM

David J. White, PhD

Associate Professor

515-294-1463

djwhite@iastate.edu

Pavana K. R. Vennapusa, PhD

Research Assistant Professor

515-294-2395

pavanv@iastate.edu

Peter Becker

Research Assistant

pbecker@iastate.edu

Christianna White, PhD

Technical Editor

515-294-4928

ciwhite@iastate.edu

RESEARCH PARTNERS

Iowa Department of Transportation

Central Iowa Expo

Boone County Engineer

Foth Engineering Alliance

JB Holland Construction, Inc.

Center for Earthworks Engineering

Research

IOWA DOT CONTACT

Mark Dunn, PE

Operations Research Engineer

Office of Research & Analytics

Iowa Department of Transportation

515-239-1447

mark.dunn@dot.iowa.gov

The Iowa Department of Transportation

(DOT) worked with its research partners

to design comparative pavement

foundation test sections at the Central

Iowa Expo Site in Boone, Iowa. The project

was constructed from May through July

2012. Sixteen 700 ft long test sections were

constructed on 4.8 miles of roadway with

the following goals:

One of the objectives of this study is to

investigate the use of PC stabilization to

optimize pavement foundation design, by

measuring in situ engineering properties

over time with a special focus on freeze/

thaw performance. The performance and

cost of construction of foundation layers

with PC stabilization in subgrade versus

subbase layers are compared in this study.

Construct a test area that will allow longterm performance monitoring

Increase the range of stabilization

technologies to be considered for future

pavement foundation design to optimize

the pavement system

Laboratory mix design procedures for

soil-cement mixtures are well-documented

in the literature (PCA 1995, Terrel et al.

1979). According to PCA (1995), normal

range of cement percentage requirement

(by soil weight) for A-1-A soils is 3%-5%,

and for A-6 soils is 9%-15%. In this study,

A-6 subgrade soil was stabilized with 10%

PC, and A-1-A granular soil was stabilized

with 5% PC.

This tech brief provides an overview of in

situ test results and key findings from two

test sections constructed using portland

cement (PC) stabilization in subgrade and

subbase layers.

Description of Test

Sections and In Situ

Testing

Develop local experience with new

stiffness measurement technologies to

assist with near-term implementation

Background

Potential improvements to strength/

stiffness of foundation layers from PC

stabilization are not currently considered in

Iowa DOT pavement design procedures.

The test sections originally consisted of

a thin chipseal coat and an 8 in. recycled

asphalt subbase at the surface. The subbase

material was excavated down to the

subgrade level (Figure 1). The existing

subgrade material is classified as CL or

A-6(5).

MORE INFORMATION

http://www.ceer.iastate.edu

The sponsors of this research are not responsible for

the accuracy of the information presented herein.

The conclusions expressed in this publication are not

necessarily those of the sponsors.

Figure 1. Prepared subgrade prior to placement of PC on the 11th St. North

Boone County Expo Test Sections

TECH BRIEF

The test section with subgrade PC stabilization was constructed by

mixing a target 10% PC into 12 in. of subgrade on 11th St. North.

The process involved distributing PC onto the subgrade (Figure

2), mixing and moisture-conditioning the material with a soil

reclaimer by injecting water into the mixing drum (Figure 3), and

compacting the stabilized subgrade layer with a vibratory pad drum

roller immediately behind the reclaimer (Figure 3). A maximum 1

hour compaction delay was specified on this project.

The test section with recycled subbase PC stabilization was

constructed by mixing a target 5% PC into 6 in. of recycled

subbase material (reclaimed from the original test sections) placed

over the subgrade on 7th St. North and South. The recycled

subbase material is classified as SM or A-1-a (with 14% fines

content). The stabilization process on the recycled subbase layer was

similar to the process described above for stabilization of subgrade

layer (Figures 4 and 5).

DRAFT

May 2013

Within one to three days of curing, a 6 in. crushed limestonemodified subbase layer was placed over the stabilized layers and

compacted using a vibratory smooth drum roller.

In situ testing included testing the foundation layers prior to

construction (May 2012), and after 1, 2 or 3, 7, 28, and 86 or

107 days after stabilization (July to October 2012) and after 281

or 302 days (April 2013) immediately after the spring thaw. In situ

testing methods used included light weight deflectometer (LWD),

dynamic cone penetrometer (DCP), falling weight deflectometer

(FWD), and roller-integrated compaction monitoring (RICM).

Results from only the DCP and FWD tests are presented here. All

test results are presented in the Phase I final report.

Data from six contractor bidder unit prices indicated a median

price of $3.33/yd2 and $6.94/yd2 for 5% PC stabilization of

subbase and 10% PC stabilization of subgrade, respectively. This

cost includes only the stabilization cost and not the cost of placing

the modified subbase layer on the surface.

Temperature profiles in the pavement foundation layers are being

monitored at a nearby site on US Highway 30 near Ames, Iowa.

The maximum and minimum temperatures recorded up to a depth

of about 64 in. below the surface and the number of freeze-thaw

(F/T) cycles observed at various depths are shown in Figure 6 (left).

Figure 6 (right) shows a 2010-2011 winter F/T cycle profile for a

roadway in Plainfield, Iowa from Johnson (2012), which indicates

that the number of F/T cycles can be on the order of 40 to 50 at

the top of the subbase/subgrade foundation layers.

Figure 2. Distribution of PC on 11th St. North

Figure 4. Mixing of subbase with PC on 7th St. North

CBR =

292

PI1.12

Figure 3. Mixing, moisture-conditioning, and compaction process of

PC-stabilized subgrade on 11th St. North

Figure 5. Compaction of a PC-stabilized subbase immediately behind

soil reclaimer using a vibratory padfoot roller on 7th St. North

Boone County Expo Test Sections

TECH BRIEF

Various laboratory tests to characterize the compressive strength

and freeze-thaw durability of the PC-stabilized subgrade and

subbase mixtures are also underway and will be reported

separately.

DRAFT

May 2013

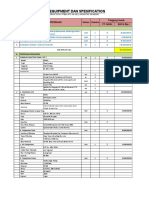

A summary of changes in the average CBRs of the subbase, the

PC-stabilized subbase/subgrade, and the subgrade layers are shown

in Figure 9. Bar charts of average FWD subbase modulus values of

the two test sections are shown in Figure 10.

In Situ Test Results

The field-determined PC content was calculated by dividing the

delivered weight of PC over the roadway area and assuming a

uniform reclamation depth of 6 in. for PC-stabilized subbase and

12 in. for PC-stabilized subgrade. The calculated PC content was

about 11.4% in the 11th St. North section, about 5.2% in the 7th

St. North section, and about 6.2% in the 7th St. South section.

DCP-California bearing ratio (CBR) and cumulative blow profiles

with depths from the PC-stabilized subbase and subgrade sections

before stabilization and after several days of curing up to about

three months after construction and after spring-thaw in April

2013 are shown in Figures 7 and 8, respectively.

Figure 8. DCP-CBR and cumulative DCP blows with depth profiles

from tests conducted on 7th St. South before stabilization and at five

different times after stabilization with 6% PC in recycled subbase

Figure 6. Maximum and minimum temperatures and number of F/T

cycles recorded at various depths in pavement foundation layers from

US Highway 30 near Ames, Iowa (left) and Annual number of F/T cycles

recorded on a roadway near Plainfield, Iowa during 2010-2011 winter

(right)

Figure 7. DCP-CBR and cumulative DCP blows with depth profiles

from tests conducted on 11th St. North before stabilization and at five

different times after stabilization with nominal 11% PC in subgrade

Figure 9. Average CBR of subbase, PC-Stabilized subbase/subgrade,

and subgrade with curing time from 7th St. North/South (with PCSubbase) and 11th St. North (with PC-Subgrade) sections

Boone County Expo Test Sections

TECH BRIEF

CBR and FWD modulus of subbase layers and CBR of the

stabilized layers achieved peak values about three months after

construction. On average, CBR values in the PC-stabilized subbase

layer were higher compared to the PC-stabilized subgrade layer.

However, the average CBR of the subbase layer at the surface was

higher in the PC-stabilized subgrade section compared to the

DRAFT

May 2013

PC-stabilized subbase section (up to about three months after

construction).

Testing during the thawing period yielded the lowest CBR and

FWD modulus values. These results show weakening of the

overlying unstabilized subbase during the spring thaw. The subbase

layers were visibly wet during testing. The underlying stabilized

subbase and subgrade were also weaker, but the CBR values were

still high (> 50) in comparison to other test sections. Additional

monitoring is warranted to investigate the changes in strength with

time.

References

Johnson, Alex. 2012. Freeze-Thaw Performance of Pavement

Foundation Materials, MS thesis, Iowa State University, Ames,

Iowa.

PCA. 1995. Soil-Cement Construction Handbook, Portland Cement

Association (PCA), Skokie, Illinois.

Figure 10. Average FWD subbase modulus on 7th St. North/South (with

PC-Subbase) and 11th St. North (with PC-Subgrade) sections

Terrel, R.L., J.A. Epps, E.J. Barenberg, J.K. Mitchell, M.R.

Thompson. 1979. Soil Stabilization in Pavement StructuresA

Users ManualVol. 2: Mixture Design Considerations,

FHWA-IP-80-2, Federal Highway Administration, Washington,

D.C.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 01 Principles and Practices of Maintenance PlanningDocument24 pages01 Principles and Practices of Maintenance PlanningGeorgy Kurien100% (2)

- Business Process Re Engineering MCQ For StudentsDocument5 pagesBusiness Process Re Engineering MCQ For StudentsGujar Dwarkadas100% (4)

- Ussd Money TransferDocument4 pagesUssd Money TransfermadrasNo ratings yet

- VP - 10 - Ball Cement Mill Monitoring, Inspection & EvaluationDocument41 pagesVP - 10 - Ball Cement Mill Monitoring, Inspection & Evaluationrecai92% (13)

- HCIA-Data Center Facility V1.0 Training MaterialDocument422 pagesHCIA-Data Center Facility V1.0 Training MaterialShamsuzzaman FaridNo ratings yet

- 2.3 DEWA Training - Design of A Solar PV System - Part 2Document42 pages2.3 DEWA Training - Design of A Solar PV System - Part 2Ramzan100% (1)

- Chapter 1 La Camiseta T-Shirt Printing BusinessDocument12 pagesChapter 1 La Camiseta T-Shirt Printing BusinessRoxanne Jover Templa100% (3)

- FLSmidth Pneumatic Transport CompressorDocument1,191 pagesFLSmidth Pneumatic Transport CompressorDavid HidalgoNo ratings yet

- V P P0C42 0667 G0 0001 A o 021 R01 C3Document2 pagesV P P0C42 0667 G0 0001 A o 021 R01 C3Veronica HidalgoNo ratings yet

- AutoChief Control PanelDocument2 pagesAutoChief Control PanelSamo SpontanostNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Selection in HRMDocument7 pagesSelection in HRMN C Abhijith100% (5)

- Project Report On Input Power Factor Correction of Ac To DC Converter CircuitDocument57 pagesProject Report On Input Power Factor Correction of Ac To DC Converter CircuitAkshyat Das100% (7)

- D2s 1.LAG PDFDocument30 pagesD2s 1.LAG PDFSiêuThịHoaDalatNo ratings yet

- LTE Layer 2 (MAC, RLC, PDCP) Interview QuestionsDocument2 pagesLTE Layer 2 (MAC, RLC, PDCP) Interview Questionsraghvendra singhNo ratings yet

- Himanshu Sharma: Comparative Analysis of Mens CosmeticsDocument2 pagesHimanshu Sharma: Comparative Analysis of Mens CosmeticsPriya SharmaNo ratings yet

- Openmp For JavaDocument94 pagesOpenmp For Javabogdan.oancea3651No ratings yet

- CUDA8.0 Installation Guide LinuxDocument41 pagesCUDA8.0 Installation Guide LinuxPaul MccarthyNo ratings yet

- Disbursement VoucherDocument1 pageDisbursement VoucherApril SamonteNo ratings yet

- UP NHM ANM Recruitment 2021Document6 pagesUP NHM ANM Recruitment 2021Rajesh K KumarNo ratings yet

- Unit 8 - Week 7: Assignment 7Document4 pagesUnit 8 - Week 7: Assignment 7vennila dhanagiriNo ratings yet

- Break Down IPAL Packed ATS 100.100Document5 pagesBreak Down IPAL Packed ATS 100.100yayanNo ratings yet

- Tapa Leviton Blanca - PJ8-WDocument2 pagesTapa Leviton Blanca - PJ8-WmichaelNo ratings yet

- 4ps Innovation Textbook PDFDocument88 pages4ps Innovation Textbook PDFDiane ChakanzahNo ratings yet

- Cancer Draft 2Document2 pagesCancer Draft 2Ish ramsNo ratings yet

- Vertedores en SifónDocument21 pagesVertedores en SifónEfrenNo ratings yet

- Preparation of Fly Ash and Rice Husk Ash GeopolymerDocument7 pagesPreparation of Fly Ash and Rice Husk Ash GeopolymerMarita M. OrbegosoNo ratings yet

- Formal Verification of An ARM Processor: Vishnu A. Patankar Alok Jain Randal E. BryantDocument14 pagesFormal Verification of An ARM Processor: Vishnu A. Patankar Alok Jain Randal E. BryantManinder SinghNo ratings yet

- Format of DissertationDocument3 pagesFormat of Dissertationameyaiba100% (1)

- Waukesha Gas EngineDocument2 pagesWaukesha Gas Enginepolaris44No ratings yet