Professional Documents

Culture Documents

Hardness Vs UTS

Hardness Vs UTS

Uploaded by

Anuj VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hardness Vs UTS

Hardness Vs UTS

Uploaded by

Anuj VermaCopyright:

Available Formats

M. Gako, G.

Rosenberg: Correlation between hardness and tensile properties

in ultra-high strength dual phase steels short communication

155

CORRELATION BETWEEN HARDNESS AND

TENSILE PROPERTIES IN ULTRA-HIGH STRENGTH

DUAL PHASE STEELS SHORT COMMUNICATION

Martin Gako1,*, Gejza Rosenberg1

1

*

Institute of materials research, Slovak Academy of Sciences, Watsonova 47, 040 01 Koice - Slovakia

corresponding author: Tel.: +421 55 729 2473, e-mail: mgasko@imr.saske.sk

Resume

The possibility to predict yield strength, strength limit, fatigue live

estimation as well as other mechanical properties depending on values of

materials hardness is commonly known and it is often used in practice.

The main aim of this contribution is to review the possibilities of

application of correlation relationships between hardness and ultimate

tensile strength of steel sheets in various structural states. The

experiments were performed on advanced steels with structure which is

composed from ferrite and martensite (dual phase steels).

Available online: http://fstroj.uniza.sk/PDF/2011/27-2011.pdf

1. Introduction

Although, basically the hardness test of

the metal materials evaluates only surface

resistance of the material against the plastic

deformation, the hardness test is frequently used

because it represents cheap non-destructive and

simple method for assessment of various

material properties like yield strength, tensile

strength, fatigue limit, but also distribution of

residual strains and, in a case of brittle materials,

fracture toughness [2-4]. In order to determine

the relationship between the ultimate tensile

strength (UTS) and hardness (H) a number of

relations were established [2-4]. In practice, the

simplest equation is most often used:

UTS = H .k

(1)

where k is coefficient. In contribution [1], the

coefficient was in range from 3.38 to 3.55 for

steel, from 3.48 to 3.21 for brass and from 2.86

to 3.63 for nodular iron (the hardness was

measured according to Brinell, HB). Fig. 1

shows the progress of UTS in dependence on

Article info

Article history:

Received 27 May 2011

Accepted 28 July 2011

Online 3 November 2011

Keywords:

Dual phase steel

Vickers hardness

Mechanical properties

ISSN 1335-0803

HB for different materials [1-3]. For aluminium

alloys, in comparison with steels, generally the

smaller values of coefficient k are observed

(Fig.1). This can be well seen from results

mentioned in Fig. 1 based on work [3]. In this

contribution the fact that the value of coefficient

k, in dependence on microstructure state (SDAS

secondary dendrite arm spacing), is in the range

from 2.63 to 2.88 was found. At the steels, the

coefficient k ranges the most frequently in the

interval from 3.0 to 3.6.

According to standard SN 420379,

which is replaced now by STN EN ISO 18265, in

dependence on applied heat treatment or heat

mechanical treatment, the influence of

microstructure on correlation of TS-HB is

reflected by the ratio of yield strength and

tensile strength of steel. By this standard [2], for

the ratio YS/TS in range from 0.5 to 0.9 the

coefficient k in the range from 3.54 to 3.21 (with

increase the ratio YS/TS low value of k is

recommended to use) is recommended to use. In

present, there exist a number of correlation

Materials Engineering - Materilov ininierstvo 18 (2011) 155-159

M. Gako, G. Rosenberg: Correlation between hardness and tensile properties

in ultra-high strength dual phase steels short communication

156

UTS - HB

1400

UT S [M Pa]

1200

Al-Si-Mg (A356)

fine SDAS

1000

Steel [2]

Brass

Steel[1]

800

Cast iron

(nodular)

600

Al-Si-Mg

large SDAS

400

200

90

140

190

240

290

340

HB

Fig. 1. Plot of ultimate tensile strength of various materials as a function of hardness [1-3]

relationships HB UTS a HB YS type, where

besides the empirical coefficients, many other

material characteristics are involved. For

example, the equations by Cahoon et al. are

among the most known which include the strain

hardening exponent [3].

The utilizing of the high strength steels

constantly increases in the entire area of

industry. The high demands on strength and

plastic properties of the steel sheets for

automotive industry intended for the autobody

are placed. Among all advanced high strength

steels the dual phase steels (DP) are most often

used for automotiv industry. By comparison to

conventional steels, DP steels have significantly

better combination values of strength versus

ductility and a very good compressibility. The

high plasticity of DP steels is given by

microstructure consisting of soft ferrite and hard

martensite. In consequence of this, these steels

are also known by low value of YS/TS ratio

(mostly YS/TS = 0.6 to 0.7, valid even for steels

with strength over the 1000 MPa) [5,6].

The main aim of this work was to find out

how

the

individual

composition

of

microstructure and low ratio YS/TS results in

value of coefficient k and, at the same time, with

which accuracy it is possible to predict YS and

TS of these steels, by the Vickers hardness

testing.

2. Experimental material

For experiments five low carbon steels

with carbon content C = 0.07 - 0.15 % and

manganese content Mn = 1.0 - 1.8 % were used.

All steels were processed with two modes of

intercritical annealing consisting of heating on

750 C or 800 C (10 minutes hold) and

consequential quenching in water. The volume

fraction of martensite was in range from 20 to 60

%.

The tensile properties was measured on

specimens, which were 120 mm long, and

10 mm wide, with starting measured length

L0 = 50 mm (thickness of specimens was in

range from s = 1.0 to s = 1.2 mm). In this study

the correlation of relationship in form TS - HV,

YS - HV, YS/TS - HV5 as well as the

correlation between strain hardening exponent

and hardness: n - HV was examined.

3. Results and discussion

Among the all studied correlations, as

expected, the highest coefficient of correlation

was found between hardness and strength.

However, also in this case, the correlation

coefficient did not attain the value R2 = 0.9,

therefore the interdependence between strength

and hardness is relatively low. The results show

that the prediction of UTS value based on the

measurement of values of HV5 could be loaded

Materials Engineering - Materilov ininierstvo 18 (2011) 155-159

M. Gako, G. Rosenberg: Correlation between hardness and tensile properties

in ultra-high strength dual phase steels short communication

by considerable error. The biggest scatter of data

is observed in the range from 270 to 325 HV5.

The anticipated strength (UTS calculated from

equation on Fig. 2) is in comparison with the

strength based on tensile test measurement in the

range UTS 125 MPa.

157

The slope in the established equations

reaches more than three times higher values

(Fig. 3). It is likely that for the YS - HV5

correlation using the equation in exponential

form would be more suitable.

Also in the relation YS / UTS = f (HV5),

for the same hardness, it is possible to observe

the break. From the set of correlation

equations it is clear that, for the hardness of

about 330 units HV5, the relation shows a

minimum (Fig. 4). In practical terms we

cannot speak about correlation of YS / UTS HV5, because correlation coefficient is low.

The data in Fig. 4 show that in the range from

210 to 330 units of HV5 the values of ratio

YS / UTS are in the range from 0.5 to 0.7, and

the hardness from 370 to 430 units

of HV5 results in the ratio YS / UTS = 0.7 to

0.85.

When we take into account all measured

values mentioned in Fig.1, and the shape of

correlation equation (1) then we detect that the

coefficient k is in the range from 2.8 to 3.6. The

correlation coefficient for the relation YS = f

(HV5) is less than R2 = 0.8.

This result clearly shows that the

prediction of the yield stress of steel through the

measured values of hardness is loaded with

larger error as it was in the case of strength

prediction. Measured results in Fig. 3 indicate

that the relation YS = f (HV5) at hardness over

the 325 units HV5 is steeper.

UTS - HV5

1400

1300

y = 2,77x + 92,754

1100

R2 = 0,8786

UTS

1200

1000

900

800

700

600

200

250

300

350

400

450

HV5

Fig. 2. Ultimate tensile strength as a function of hardness HV5

YS - HV5

1200

1000

y = 1,5703x + 76,165

R = 0,5694

YS

800

y = 2,5009x - 181,44

R = 0,7695

600

y = 5,4035x - 1312,5

R = 0,736

400

200

200

250

300

350

400

450

HV5

Fig. 3. Yield strength as a function of hardness HV5

Materials Engineering - Materilov ininierstvo 18 (2011) 155-159

M. Gako, G. Rosenberg: Correlation between hardness and tensile properties

in ultra-high strength dual phase steels short communication

158

YS/UTS - HV5

0,9

0,8

y = -0,0003x + 0,6852

R2 = 0,0562

y = 0,0006x + 0,417

R2 = 0,2303

Y S /U T S

0,7

0,6

y = 0,0027x - 0,3592

R2 = 0,5422

0,5

0,4

200

250

300

350

400

450

HV5

Fig. 4. The yield strength to tensile strength ratio, as a function of hardness (HV5)

n - HV5

0,2

0,18

0,16

0,14

0,12

0,1

0,08

0,06

0,04

200

y = -0,0003x + 0,2344

R = 0,5518

250

300

350

400

450

HV5

Fig. 5. The strain hardening exponent as a function of hardness (HV5)

Fig. 5 shows the dependence of strain

hardening exponent for hardness HV5. Unlike

Fig. 3 and Fig. 4 it is possible to describe the

measured data by one equation, but with low

correlation coefficient R2 = 0.55. The practical

use of correlation equation n - HV5, referred in

Fig. 5, is limited. It is proved by the fact that for

the steels with n = 0.14 hardness from 225 up to

320 units HV5 was measured.

From the measured results in this work it

is evident that the possibility to predict

mechanical properties of dual phase steels by

means of the measured values of hardness is

very limited, if not impossible.

As seen in the Table 1, from known

hardness of steels, also in this case it is possible

to predict the strength of steel with the accuracy

about 10 % UTS. Also we can see the correlation

coefficients and relationships among the hardness

and other mechanical properties which suggest the

possibility of using the hardness measurements. On

the other hand, it should be noted that the

measured data (in the case of relationship

between hardness and ultimate tensile strength)

are not very different from the results measured

for different steels and different structural states

observed by other authors [4, 7].

Table 1

Table of regression analysis for all data sets

Relationship

Best fit equation

Coefficient of

determination

UTS= f (HB)

y = 2.77x + 92.754

R2 = 0.8786

YS = f (HB)

y = 2.5009x 181.44

R = 0.7695

YS/UTS=f(HB) y = 0.0006x + 0.417

R2 = 0.2303

n = f(HB)

y = -0.0003x + 0.2344

R = 0.5518

Materials Engineering - Materilov ininierstvo 18 (2011) 155-159

M. Gako, G. Rosenberg: Correlation between hardness and tensile properties

in ultra-high strength dual phase steels short communication

159

UTS - HB

1400

U T S [M Pa]

1200

Al-Si-Mg (A356)

fine SDAS

1000

Steel [2]

Brass

Steel[1]

800

Cast iron

(nodular)

600

Al-Si-Mg

large SDAS

400

DP

200

90

140

190

240

290

340

HB

Fig. 6. Dependence of ultimate tensile strength of various materials as a function of hardness [1-3]

Evidence of this is Fig. 6 that is identical to

Fig. 1, but complemented with the data

measured in this work (values of HV5 were

converted using the table of values for HB).

Acknowledgements

The authors are thankful to grant agency

VEGA of SR for financial support of this work, which

was realized within the frame of project with No.

2/0195/09.

4. Conclusions

In this work the possibility of prediction

of selected mechanical properties of dual phase

steels by means of Vickers hardness tests was

verified. It was shown that from all correlation

relations established in the work it is practically

applicable only the correlation between hardness

HV5 and UTS (on the basis of known values

HV5 it is possible to predict the strength with an

accuracy of 10%). Results of work clearly

shows that for the prediction of mechanical

properties of dual phase steels with higher

accuracy the influence of the microstructural

parameters in the correlation equations is

necessary to include. That is the aim of our

further research.

References

[1] http://www.calce.umd.edu/TSFA/Hardness_ad_.

htm#6 [1 November 2011].

[2] SN 42 0379 (in Slovak)

[3] L. Ceschini, A. Morri, A. Morri, G. Pivetti:

Mater Des 32 (2011) 1367-1375.

[4] E.J. Pavlina and C.J. Van Type: J. Mater. Eng.

Perform, 17 (2008) 6 888-893.

[5] G. Rosenberg, K. Burkov, . Juhr: Manufact.

Eng. 3 (2009) 49-52.

[6] Xin-sheng Liao, Xiao-dong Wang, Xu-fei Li,

Yheng-hong Guo, Yong-hua Rong: Adv. Mater.

Res. 97-101 (2010) 728-732.

[7] J. Pavlina, C.J. Van Tyne: J. Mater. Eng.

Perform. 17(6) (2008) 888-893.

Materials Engineering - Materilov ininierstvo 18 (2011) 155-159

You might also like

- Practical AntennasDocument59 pagesPractical AntennasCarlos A. Gallardo100% (6)

- DIAGRAM RAYMOND 4150-4250 - 30000-Up - SC - 1124958CDocument10 pagesDIAGRAM RAYMOND 4150-4250 - 30000-Up - SC - 1124958CRicardo Javier Lopez GarciaNo ratings yet

- Saturn I SA-7 Rocket Countdown ManualDocument152 pagesSaturn I SA-7 Rocket Countdown ManualAviation/Space History Library100% (2)

- Engineering ControlsDocument13 pagesEngineering Controlsmakmak9100% (1)

- Alf CTDocument9 pagesAlf CTadityahivalkar4141No ratings yet

- ChE461-Course Outline and Teaching ScheduleDocument2 pagesChE461-Course Outline and Teaching ScheduleAl JawadNo ratings yet

- Electronic Structure and the Properties of Solids: The Physics of the Chemical BondFrom EverandElectronic Structure and the Properties of Solids: The Physics of the Chemical BondRating: 2.5 out of 5 stars2.5/5 (3)

- Trends in Design & Layout in Foodservice IndustryDocument84 pagesTrends in Design & Layout in Foodservice IndustryCheyneJoyGallego100% (1)

- O&k Fault CodesDocument2 pagesO&k Fault CodesAlejandro EspinozaNo ratings yet

- Effect of Heat InputDocument9 pagesEffect of Heat InputshrikantajitNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Full-Range Stress-Strain Curves For Stainless SteelDocument15 pagesFull-Range Stress-Strain Curves For Stainless SteelNurul HudaNo ratings yet

- Fender Marine CatalogueDocument24 pagesFender Marine CatalogueAndre BlueNo ratings yet

- 04 Master Production Scheduling 2011springDocument44 pages04 Master Production Scheduling 2011springAndre BlueNo ratings yet

- DC System DesignDocument6 pagesDC System DesignTukaram Pawar100% (1)

- Shaft Alignment Using Strain Gauges - Case StudiesDocument16 pagesShaft Alignment Using Strain Gauges - Case StudiesAndre BlueNo ratings yet

- Chapter-1-2, EMC DSA NotesDocument8 pagesChapter-1-2, EMC DSA NotesakragnarockNo ratings yet

- Uae Contractors' Association Members List: Company Name Tel. No. Fax. No. P.O.Box Emirate WebsiteDocument16 pagesUae Contractors' Association Members List: Company Name Tel. No. Fax. No. P.O.Box Emirate WebsiteModular Design TeamNo ratings yet

- Strain Aging TestDocument6 pagesStrain Aging TestPalani KarthiNo ratings yet

- Properties of ElectrodepositsDocument27 pagesProperties of Electrodepositsjvo917No ratings yet

- General Relation Between Tensile Strength and Fatigue Strength of Metallic Materials - J.C. PangDocument11 pagesGeneral Relation Between Tensile Strength and Fatigue Strength of Metallic Materials - J.C. PangMarco Angel Gabriel Polo100% (2)

- Hubungan Kekerasan Dan Kekuatan Tarik Bahan 27-2011Document5 pagesHubungan Kekerasan Dan Kekuatan Tarik Bahan 27-2011Ibnu FajarNo ratings yet

- On The Correlation Between Hardness and Tensile Strength in Particle Reinforced Metal Matrix CompositesDocument4 pagesOn The Correlation Between Hardness and Tensile Strength in Particle Reinforced Metal Matrix CompositesJigar M. UpadhyayNo ratings yet

- Correlation Between Hardness and Tensile PropertieDocument6 pagesCorrelation Between Hardness and Tensile PropertieCaduCasteloBrancoNo ratings yet

- Materials 10 01401 PDFDocument9 pagesMaterials 10 01401 PDFmanjunath k sNo ratings yet

- S690 - S355 Fatigue PropertiesDocument11 pagesS690 - S355 Fatigue PropertiesIstvan WunderlichNo ratings yet

- Increased Resistance To Buckling of Piston Rods Through Induction HardeningDocument6 pagesIncreased Resistance To Buckling of Piston Rods Through Induction HardeningEustahije BrzicNo ratings yet

- Modeling of The Yield Strength of A Stainless Maraging SteelDocument4 pagesModeling of The Yield Strength of A Stainless Maraging SteelFernando HenriqueNo ratings yet

- Investigations On Longitudinal Fillet Welded Lap Joints of HSSDocument8 pagesInvestigations On Longitudinal Fillet Welded Lap Joints of HSSzgrouproNo ratings yet

- Heat InputDocument5 pagesHeat InputBhanukiran ParavastuNo ratings yet

- Durability de MST 2014Document19 pagesDurability de MST 2014irfankohaaNo ratings yet

- Austenite Morphology and Distribution Dependence of Impact Toughness in S32101 Duplex Stainless Steel Laser WeldsDocument10 pagesAustenite Morphology and Distribution Dependence of Impact Toughness in S32101 Duplex Stainless Steel Laser WeldsOumaymaNo ratings yet

- Rotational Stiffness Determination of The Semi-Rigid Timber-Steel ConnectionDocument8 pagesRotational Stiffness Determination of The Semi-Rigid Timber-Steel ConnectionmdkmlNo ratings yet

- Correlation Between Process Parameters Grain Size and Hardness of FrictionDocument12 pagesCorrelation Between Process Parameters Grain Size and Hardness of FrictionAhmadNo ratings yet

- Fitting Curves and Impact Toughness Transition Temperature of Quenched and Tempered Steel WeldsDocument9 pagesFitting Curves and Impact Toughness Transition Temperature of Quenched and Tempered Steel WeldsSiangmalamNo ratings yet

- Effect of Post Weld Heat Treatment On The Corrosion Behavior of Resistance Spot Welded Super Duplex StainlessDocument12 pagesEffect of Post Weld Heat Treatment On The Corrosion Behavior of Resistance Spot Welded Super Duplex StainlessWilliam WilkenNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument6 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- Failure Mode of Dissimilar Resistance Spot Welds Between Austenitic Stainless and Low Carbon Steels M. Pouranvari, P. Marashi, M. GoodarziDocument6 pagesFailure Mode of Dissimilar Resistance Spot Welds Between Austenitic Stainless and Low Carbon Steels M. Pouranvari, P. Marashi, M. GoodarziNarayanan SubramanianNo ratings yet

- 18934-Article Text PDF-112287-2-10-20211222Document16 pages18934-Article Text PDF-112287-2-10-20211222jiji wangNo ratings yet

- Le 2016 KitagawaDocument34 pagesLe 2016 KitagawaMajed NesrineNo ratings yet

- Dual Phase Steel FundamentalsDocument15 pagesDual Phase Steel FundamentalsAnshuman RoyNo ratings yet

- Influence of Friction Stir Welding Parameters On Grain Size and Formability in 5083 Aluminum AlloyDocument15 pagesInfluence of Friction Stir Welding Parameters On Grain Size and Formability in 5083 Aluminum AlloySakthi ManokaranNo ratings yet

- Limitations of The Hollomon Strain-Hardening EquationDocument11 pagesLimitations of The Hollomon Strain-Hardening EquationTiago TurcarelliNo ratings yet

- NI Tutorial 3642 enDocument6 pagesNI Tutorial 3642 enronaldxmenNo ratings yet

- Correlation Between Deformation-Induced Microstructures and TGSCC Susceptibility in A Low Carbon Austenitic Stainless SteelDocument9 pagesCorrelation Between Deformation-Induced Microstructures and TGSCC Susceptibility in A Low Carbon Austenitic Stainless SteelMilagros MorantesNo ratings yet

- Residual Stress Effect On Fatigue Strength of Non-Load-Carrying Cruciform Welded Joints of SM570Q Steel For Welded Structures PDFDocument6 pagesResidual Stress Effect On Fatigue Strength of Non-Load-Carrying Cruciform Welded Joints of SM570Q Steel For Welded Structures PDFEmad A.AhmadNo ratings yet

- The Effect of Galvanizing On The Mechanical Resistance and Fatigue Toughness of A Spot Welded Assembly Made of AISI410 MartensiteDocument12 pagesThe Effect of Galvanizing On The Mechanical Resistance and Fatigue Toughness of A Spot Welded Assembly Made of AISI410 Martensitenico0001586No ratings yet

- Using Short Hold Times To Mitigate LME Cracking in Electrode Indent of Resistant Spot Welded Third Generation Advanced High Strength SteelDocument20 pagesUsing Short Hold Times To Mitigate LME Cracking in Electrode Indent of Resistant Spot Welded Third Generation Advanced High Strength Steelsongyang hanNo ratings yet

- Residual Stresses and Fatigue at Tubular Welded StructuresDocument12 pagesResidual Stresses and Fatigue at Tubular Welded StructuresElias KapaNo ratings yet

- Minimum Reinforcement in RC BeamsDocument7 pagesMinimum Reinforcement in RC BeamsNguyen KhoiNo ratings yet

- The Modulus of Elasticity of Steel Is It 200 GPaDocument8 pagesThe Modulus of Elasticity of Steel Is It 200 GPaPratik PatelNo ratings yet

- EletrodoDocument8 pagesEletrodoAyrton PabloNo ratings yet

- Influence of Welding Speed On Corrosion Behaviour of Friction Stir Welded AA5086 Aluminium AlloyDocument11 pagesInfluence of Welding Speed On Corrosion Behaviour of Friction Stir Welded AA5086 Aluminium AlloysaifbenNo ratings yet

- The Relationship Between Impact Transition Temperatures SteelDocument6 pagesThe Relationship Between Impact Transition Temperatures SteelUri SterinNo ratings yet

- The Effects of Notch Geometry On Fatigue Life Using Notch Sensitivity FactorDocument6 pagesThe Effects of Notch Geometry On Fatigue Life Using Notch Sensitivity FactorHamza DjeloudNo ratings yet

- Effect Method Young's Modulus Estimation Fatigue LifeDocument15 pagesEffect Method Young's Modulus Estimation Fatigue LifeTeoTyJayNo ratings yet

- Engg - Comparison Study of The Joint Strength Using Welding MethodsDocument6 pagesEngg - Comparison Study of The Joint Strength Using Welding MethodsImpact JournalsNo ratings yet

- Post-Weld Heat Treatment of API 5L X70 High Strength Low Alloy Steel Welds - PMCDocument29 pagesPost-Weld Heat Treatment of API 5L X70 High Strength Low Alloy Steel Welds - PMCMartin UrrizaNo ratings yet

- Tensile-Shear Fracture Behavior Prediction of High-Strength Steel Laser Overlap WeldsDocument15 pagesTensile-Shear Fracture Behavior Prediction of High-Strength Steel Laser Overlap WeldsJavier oNo ratings yet

- Amplitude and Force Profiling: Studies in Ultrasonic Welding of ThermoplasticsDocument9 pagesAmplitude and Force Profiling: Studies in Ultrasonic Welding of ThermoplasticsSangeet Kr SinghNo ratings yet

- Grade On Reliability AnalysisDocument9 pagesGrade On Reliability AnalysisMohd Zain KangdaNo ratings yet

- Wse2013 Paper Deng 3Document4 pagesWse2013 Paper Deng 3Tadeu FelixNo ratings yet

- Manuscript Preparation Instruction For Publishing in Computer Modeling in Engineering and Science (CMES) - 2021Document14 pagesManuscript Preparation Instruction For Publishing in Computer Modeling in Engineering and Science (CMES) - 2021JuanNo ratings yet

- Magnetic Properties and Retained Austenite Quantification in SAE 4340 SteelDocument7 pagesMagnetic Properties and Retained Austenite Quantification in SAE 4340 SteelMonica Sands0% (1)

- Theoretical Study For Bond Between Reinforcement Steel and ConcreteDocument10 pagesTheoretical Study For Bond Between Reinforcement Steel and ConcreteSulaim Al KautsarNo ratings yet

- Parameter Calibration and Application of Fracture Models To High-Performance Steel Seismic DampersDocument6 pagesParameter Calibration and Application of Fracture Models To High-Performance Steel Seismic DampersIhab El AghouryNo ratings yet

- Vibratory Stress Relieving - It's Advantages As An Alternative To Thermal TreatmentDocument5 pagesVibratory Stress Relieving - It's Advantages As An Alternative To Thermal Treatmentsinan alqassabNo ratings yet

- Effect of Strain Rate Upon Plastic Flow of SteelDocument12 pagesEffect of Strain Rate Upon Plastic Flow of SteelLily MaNo ratings yet

- 43 4 Polak PDFDocument10 pages43 4 Polak PDFricardomax2No ratings yet

- Chapter 10 - Testing of Welded JointsDocument18 pagesChapter 10 - Testing of Welded JointsFauzan BenraxidNo ratings yet

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- The Route To Signing The IAF or ILAC ArrangementsDocument8 pagesThe Route To Signing The IAF or ILAC ArrangementsAndre BlueNo ratings yet

- A Presentation On Lean ShipbuildingDocument32 pagesA Presentation On Lean ShipbuildingAndre BlueNo ratings yet

- Modsonic CatalogueDocument44 pagesModsonic CatalogueAndre BlueNo ratings yet

- Offshore Structural Steel: Stock ProgramDocument12 pagesOffshore Structural Steel: Stock ProgramAndre BlueNo ratings yet

- Resolution Mepc.197 (62) Green PassportDocument50 pagesResolution Mepc.197 (62) Green PassportAndre BlueNo ratings yet

- Offshore Structural Steel: Stock ProgramDocument12 pagesOffshore Structural Steel: Stock ProgramAndre BlueNo ratings yet

- Half Wave RectifierDocument15 pagesHalf Wave RectifierIshan Kavdia100% (2)

- 1001 Inventions and Awesome Facts From Muslim Civilization PDF, Epub, EbookDocument4 pages1001 Inventions and Awesome Facts From Muslim Civilization PDF, Epub, EbookMe YouNo ratings yet

- Je Est Un Autre Rimbaud DissertationDocument7 pagesJe Est Un Autre Rimbaud DissertationWriteMyEconomicsPaperSpringfield100% (1)

- TBS ModelsDocument18 pagesTBS Modelsajmal_2kNo ratings yet

- ApilogDocument57 pagesApilogSansongNo ratings yet

- 001 G.R. No. 170633 October 17, 2007 MCC Industrial Sales Corp Vs Ssangyong CorpDocument18 pages001 G.R. No. 170633 October 17, 2007 MCC Industrial Sales Corp Vs Ssangyong CorprodolfoverdidajrNo ratings yet

- Ob 11 Organisational - BehaviourDocument22 pagesOb 11 Organisational - BehaviourHarshil JoshiNo ratings yet

- ErosionSedFlyer PDFDocument2 pagesErosionSedFlyer PDFrishiNo ratings yet

- CBV734EW User's ManualDocument32 pagesCBV734EW User's Manualdenisdupeyron100% (1)

- Eq List IEC 60335-2-2 (6.2) 2016-20170412Document2 pagesEq List IEC 60335-2-2 (6.2) 2016-20170412le duc huynhNo ratings yet

- Xercise P S P R: Roducing Ales and Rofit EportsDocument2 pagesXercise P S P R: Roducing Ales and Rofit EportsMichael Bone-crusher PhiriNo ratings yet

- 04 - Sanjana Bhandiwad - PC CladdingDocument16 pages04 - Sanjana Bhandiwad - PC CladdingSanjana BhandiwadNo ratings yet

- Tratado Practico Del Magnetismo - Aubin GauthierDocument415 pagesTratado Practico Del Magnetismo - Aubin Gauthierjuliobispo100% (1)

- Parameter Check 112 ResultDocument29 pagesParameter Check 112 ResultrathoremssssssNo ratings yet

- Rundown Parallel SessionDocument8 pagesRundown Parallel SessionMuhammad HarisNo ratings yet

- PCM As 'External Sensor' For: TSC1 With Asset Surveyor SoftwareDocument6 pagesPCM As 'External Sensor' For: TSC1 With Asset Surveyor SoftwarejaviermvNo ratings yet

- Huawei For Sale From Powerstorm 4SB07041353Document4 pagesHuawei For Sale From Powerstorm 4SB07041353nethouse123No ratings yet

- 5 Ways To Determine If String Has All Unique Characters - Java Code With Example - Java Hungry11 PDFDocument8 pages5 Ways To Determine If String Has All Unique Characters - Java Code With Example - Java Hungry11 PDFNikhil Chandan100% (1)

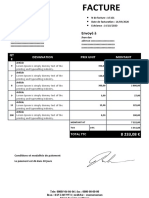

- Nom de Société: Facturé À Envoyé ÀDocument1 pageNom de Société: Facturé À Envoyé ÀSylvestre Charles AmanNo ratings yet