Professional Documents

Culture Documents

63 & RT 50 New

Uploaded by

rohaiza1979Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

63 & RT 50 New

Uploaded by

rohaiza1979Copyright:

Available Formats

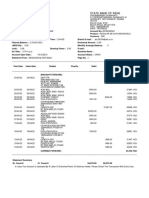

PRICE COMPARISON

SUPPLIER

MADETILL

TNM

MADETILL

TNM

MASASINAR

TNM

MASASINAR

TNM

PART NAME.

63CD

63CD

63CS

63CS

RT 50 STD

RT 50 STD

RT 50 H/P

RT 50 H/P

SUS 409

SUS 409

SUS 409

SUS 409

SUS 409

SUS 409

1.2

1.2

1.2

1.2

1.0

1.0

MATERIAL

SIZE (MM)

AVERAGE MONTHLY QTY (PCS)

NO

ITEM

1 Purchased Parts Price

SACD 60/60

1.2

5,000

(RM)

SACD 60/60

1.2

5,000

(RM)

3,000

(RM)

3,000

(RM)

15,000

(RM)

15,000

(RM)

35,000

(RM)

35,000

(RM)

0.696

0.802

1.056

1.259

0.291

0.840

0.679

0.666

2 Material Price

0.396

0.292

0.726

0.535

0.000

0.479

0.435

0.399

3 Stamping Cost

0.310

0.542

0.330

0.765

0.291

0.398

0.244

0.297

4 Discount

0.010

0.000

0.000

0.000

0.000

0.000

0.000

0.000

5 Net Stamping Cost

0.300

0.542

0.330

0.765

0.291

0.398

0.244

0.297

6 Scrap Recovery

0.000

0.032

0.000

0.041

0.071

0.036

0.045

0.030

C33:

no scrap recovery

E33:

fix scrap price

G15:

depend on market price

G33:

fix scrap price since the base price is RM 5.70 per kg and purchase by Zamria

J15:

depend on market price

J33:

depend on market price

SJM FLEX PART COSTING

ESTIMATE (Cost breakdown list)

Part No.

Part Name .

63CD

CAP

SUMMARY

ITEM

(1) Material Cost

(2) Purchased Part / Finishing Cost

(3) Manufacturing Cost

(4) Sub total = (1)+(2)+(3)

(5) Packaging Charge

(6) Transportation Charges

(7) Administration Charge

(8) Profit

(9) Checking Cost/Holding Cost

(10) Maintenance Cost

(11) Amortize Cost

Total = (4)+(5)+(6)+(7)+(8)+(9)+(10)

Scrap

Total

MADETILL

0.396

0.000

0.140

0.536

0.050

0.030

0.030

0.060

0.000

0.000

0.000

0.706

0.000

0.706

BREAKDOWN

(i) MATERIAL COST

ITEM

Material SACD 60/60

Consumption (kg or m')

Unit Cost (kg or m')

Amount (RM)

Total (RM)

(1.2 X 104)

0.1100

3.600

0.40

0.40

(ii) SCRAP

ITEM

Consumption (kg or m')

Unit Cost (kg or m')

Total (RM)

TOOLING COST

TOOL

Total (RM)

Amortisation Quantity

Total / pc

TNM COST BREAKDOWN SHEET

Ref QUOTATION :

CUSTOMER

SJM FLEX

Category:

Sub Category:

Your contact:

George jacob Sam

PART NUMBER

Item Description

Product group

SFM-12-FB0011

CAP

Date of quotation:

Revision number

30/10/2012

0

Fax:

Currency

Ringgit Malaysia

Address:

Tel

60122835161

03-90754722

MATERIAL COST

1 Material Name

2 Specification

SACD 60/60

SACD 60/60

3 SHEET THICKNESS

4 STRIP WIDTH

1.20

95.00

5 PITCH

5 INPUT WEIGHT PER UNIT IN GRAMS

90.00

81.05

6 OUTPUT WIGHT PER UNIT

7 SCRAP WEIGHT PER UNIT

8 RAW MATERIAL PRICE

40.53

40.53

3.60

9 INPUT MATERIAL PRICE PER UNIT

10 SCRAP RATE/KG

0.29

1.00

11 SCRAP RECOVERY COST

0.03

12 FINAL MATERIAL PRICE

0.26

A - RAW MATERIAL COST

0.259

MOULD COST

TYPE OF PROCESS

1 CUT AND DRAW

2 TRIMMING AND PIERCING

3 FINAL DRAW

4

TYPE OF MOULD

LIFE OF MOULD IN

SHOTS

Total Cost

10000

8000

4000

300,000

300,000

300,000

10000

8000

4000

B-MOULD COST IN RM

MACHING COST

Operation

Machine Description

1 CUT AND DRAW

2 TRIMMING AND PIERCING

3 FINAL DRAW

22000

No. of

Cycles IN

SEC

Cost per

SEC

110 TON STAMPING MACHINE

63 TON STAMPING MACHINE

100 TON STAMPING MACHINE

C- PROCESSING COST

PROCESS

COST

0.08

0.06

0.06

0.20

SURFACE TREATMENT COST

Specification of Surface Treatment

Operation Rate (per surface unit)

Total Surface area per Item

D- SURFACE TREATMENT COST

Total Manufacturing Cost (per item) (B+C+D)

0.20

E =MATERIAL+MANUFACTURING COST

0.459

D OTHER COSTS

1

2

3

4

Cost

Packing (3%OF E)

MOULD AMORTISATION

Overhead & Margin

Other

Remarks

IN PLASTIC BAGS AND PLACED IN LABELLED CARTON BOX

MOULD AMORTISED ON 72,000 PCS (12 MONTHS)

5% of E

Total Cost

0.014

0.306

0.023

F= TOTAL OTHERS COSTS

0.342

FINAL SELLING PRICE (E+F)

0.802

SJM FLEX PART COSTING

ESTIMATE (Cost breakdown list)

Part No.

Part Name .

63CS

CAP

SUMMARY

ITEM

(1) Material Cost

(2) Purchased Part / Finishing Cost

(3) Manufacturing Cost

(4) Sub total = (1)+(2)+(3)

(5) Packaging Charge

(6) Transportation Charges

(7) Administration Charge

(8) Profit

(9) Checking Cost/Holding Cost

(10) Maintenance Cost

(11) Amortize Cost

Total = (4)+(5)+(6)+(7)+(8)+(9)+(10)

Scrap

Total

MADETILL

0.726

0.000

0.160

0.886

0.050

0.030

0.030

0.060

0.000

0.000

0.000

1.056

0.000

1.056

NICHI

0.650

0.000

0.220

0.870

0.000

0.020

0.040

0.070

0.000

0.010

0.000

1.010

0.030

0.980

ZAMRIA

0.718

0.000

0.091

0.809

0.005

0.008

0.024

0.024

0.008

0.010

0.074

0.962

0.037

0.925

MASASINAR

1.034

0.000

0.136

1.170

0.050

0.050

(1.2 X 104)

0.1100

6.600

0.73

0.73

(1.2 X 104)

0.1000

6.500

0.65

0.65

(1.2 X 104)

0.1260

5.700

0.72

0.72

(1.2 X 104)

0.1590

6.500

1.03

1.03

0.0740

0.500

0.037

0.1080

1.300

0.140

0.024

0.000

0.000

0.148

1.441

0.140

1.301

BREAKDOWN

(i) MATERIAL COST

ITEM

Material SUS 409

Consumption (kg or m')

Unit Cost (kg or m')

Amount (RM)

Total (RM)

(ii) SCRAP

ITEM

Consumption (kg or m')

Unit Cost (kg or m')

Total (RM)

TOOLING COST

TOOL

Total (RM)

Amortisation Quantity

Total / pc

11,025.00

150,000.00

0.0735

31,860.00

216,000.00

0.1475

TNM COST BREAKDOWN SHEET

Ref QUOTATION :

CUSTOMER

SJM FLEX

Category:

Sub Category:

Your contact:

George jacob Sam

PART NUMBER

Item Description

Product group

SFM-10-CP-63001

CAP

Date of quotation:

Revision number

30/10/2012

0

Fax:

Currency

Ringgit Malaysia

Address:

Tel

60122835161

03-90754722

MATERIAL COST

1 Material Name

2 Specification

SUS 409

SUS 409

3 SHEET THICKNESS

4 STRIP WIDTH

1.20

95.00

5 PITCH

5 INPUT WEIGHT PER UNIT IN GRAMS

90.00

81.05

6 OUTPUT WIGHT PER UNIT

7 SCRAP WEIGHT PER UNIT

8 RAW MATERIAL PRICE

40.53

40.53

6.60

9 INPUT MATERIAL PRICE PER UNIT

10 SCRAP RATE/KG

0.53

1.25

11 SCRAP RECOVERY COST

0.04

12 FINAL MATERIAL PRICE

0.49

A - RAW MATERIAL COST

0.494

MOULD COST

TYPE OF PROCESS

1 CUT AND DRAW

2 TRIMMING AND PIERCING

3 FINAL DRAW

4

TYPE OF MOULD

LIFE OF MOULD IN

SHOTS

Total Cost

10000

8000

4000

300,000

300,000

300,000

10000

8000

4000

B-MOULD COST IN RM

MACHING COST

Operation

Machine Description

1 CUT AND DRAW

2 TRIMMING AND PIERCING

3 FINAL DRAW

22000

No. of

Cycles IN

SEC

Cost per

SEC

110 TON STAMPING MACHINE

63 TON STAMPING MACHINE

100 TON STAMPING MACHINE

C- PROCESSING COST

PROCESS

COST

0.08

0.06

0.06

0.20

SURFACE TREATMENT COST

Specification of Surface Treatment

Operation Rate (per surface unit)

Total Surface area per Item

D- SURFACE TREATMENT COST

Total Manufacturing Cost (per item) (B+C+D)

0.20

E =MATERIAL+MANUFACTURING COST

0.694

D OTHER COSTS

1

2

3

4

Cost

Packing (3%OF E)

MOULD AMORTISATION

Overhead & Margin

Other

Remarks

IN PLASTIC BAGS AND PLACED IN LABELLED CARTON BOX

MOULD AMORTISED ON 43200(12 MONTHS)

5% of E

Total Cost

0.021

0.509

0.035

F= TOTAL OTHERS COSTS

0.565

FINAL SELLING PRICE (E+F)

1.259

SJM FLEX PART COSTING

ESTIMATE (Cost breakdown list)

Part No.

Part Name .

CAP

RT 50 STANDARD

SUMMARY

ITEM

(1) Material Cost

(2) Purchased Part / Finishing Cost

(3) Manufacturing Cost

(4) Sub total = (1)+(2)+(3)

(5) Packaging Charge

(6) Transportation Charges

(7) Administration Charge

(8) Profit

(9) Checking Cost

(10) Amortisation Cost

(11) Maintenance Cost

Total = (4)+(5)+(6)+(7)+(8)+(9)+(10)+(11)

(12) Tooling Cost

(13) Total Cost

(14) Discount

(15) Price after discount

(16) Scrap

Total

MASASINAR

0.000

0.000

0.075

0.075

0.050

0.060

0.054

0.054

0.000

0.048

0.000

0.341

0.000

0.341

0.050

0.291

0.071

0.220

BREAKDOWN

(i) MATERIAL COST

ITEM

Consumption (kg or m')

Unit Cost (kg or m')

Amount (RM)

Total (RM)

Actual weight

104 X 106mm

0.1070

0.036

(ii) SCRAP

ITEM

Consumption (kg or m')

Unit Cost (kg or m')

Total (RM)

0.0710

1.000

0.071

TOOLING COST

TOOL

Total (RM)

Amortisation Quantity

Total / pc

52,080.000

1,080,000.000

0.0482

TNM COST BREAKDOWN SHEET

Ref QUOTATION :

CUSTOMER

SJM FLEX

Category:

Sub Category:

Your contact:

George jacob Sam

PART NUMBER

Item Description

Product group

SFM-09-PD-RT002-R1

RT 50 (STANDARD)

Date of quotation:

Revision number

30/10/2012

0

Fax:

Currency

Ringgit Malaysia

Address:

Tel

60122835161

03-90754722

MATERIAL COST

1 Material Name

2 Specification

SUS

SUS 409

3 SHEET THICKNESS

4 STRIP WIDTH

1.20

90.00

5 PITCH

5 INPUT WEIGHT PER UNIT IN GRAMS

85.00

72.52

6 OUTPUT WIGHT PER UNIT

7 SCRAP WEIGHT PER UNIT

8 RAW MATERIAL PRICE

36.26

36.26

6.60

9 INPUT MATERIAL PRICE PER UNIT

10 SCRAP RATE/KG

0.48

1.25

11 SCRAP RECOVERY COST

0.04

12 FINAL MATERIAL PRICE

0.44

A - RAW MATERIAL COST

0.442

MOULD COST

TYPE OF PROCESS

1 CUT AND DRAW

2 TRIMMING AND PIERCING

3 FINAL DRAW

4

TYPE OF MOULD

LIFE OF MOULD IN

SHOTS

Total Cost

10000

8000

4000

300,000

300,000

300,000

10000

8000

4000

B-MOULD COST IN RM

MACHING COST

Operation

Machine Description

1 CUT AND DRAW

2 TRIMMING AND PIERCING

3 FINAL DRAW

22000

No. of

Cycles IN

SEC

Cost per

SEC

110 TON STAMPING MACHINE

63 TON STAMPING MACHINE

100 TON STAMPING MACHINE

C- PROCESSING COST

PROCESS

COST

0.08

0.06

0.06

0.20

SURFACE TREATMENT COST

Specification of Surface Treatment

Operation Rate (per surface unit)

Total Surface area per Item

D- SURFACE TREATMENT COST

Total Manufacturing Cost (per item) (B+C+D)

0.20

E =MATERIAL+MANUFACTURING COST

0.642

D OTHER COSTS

1

2

3

4

Cost

Packing (3%OF E)

MOULD AMORTISATION

Overhead & Margin

Other

Remarks

IN PLASTIC BAGS AND PLACED IN LABELLED CARTON BOX

MOULD AMORTISED ON 150,000 PCS ( 6 MONTHS)

5% of E

Total Cost

0.019

0.147

0.032

F= TOTAL OTHERS COSTS

0.198

FINAL SELLING PRICE (E+F)

0.840

SJM FLEX PART COSTING

ESTIMATE (Cost breakdown list)

Part No.

Part Name .

CAP

RT 50 HIGH POWER

SUMMARY

ITEM

(1) Material Cost

(2) Purchased Part / Finishing Cost

(3) Manufacturing Cost

(4) Sub total = (1)+(2)+(3)

(5) Packaging Charge

(6) Transportation Charges

(7) Administration Charge

(8) Profit

(9) Checking Cost

(10) Amortisation Cost

(11) Maintenance Cost

Total = (4)+(5)+(6)+(7)+(8)+(9)+(10)+(11)

(12) Tooling Cost

(13) Total Cost

(14) Discount

(15) Price after discount

(16) Scrap

Total

MASASINAR

0.435

0.000

0.075

0.510

0.050

0.060

0.036

0.036

0.000

0.037

0.000

0.729

0.000

0.729

0.050

0.679

0.045

0.634

BREAKDOWN

(i) MATERIAL COST

ITEM

Consumption (kg or m')

Unit Cost (kg or m')

Amount (RM)

Total (RM)

Actual weight

90 X 92mm

0.0669

6.500

0.435

0.435

0.022

(ii) SCRAP

ITEM

Consumption (kg or m')

Unit Cost (kg or m')

Total (RM)

0.0449

1.000

0.045

TOOLING COST

TOOL

Total (RM)

Amortisation Quantity

Total / pc

39,680.000

1,080,000.000

0.0367

10/25/2012 Target price for RC Metal (New Samping)

-15.78%

-5%

-10%

-15%

(0.10)

(0.032)

(0.063)

(0.095)

0.534

0.602

0.570

0.539

TNM COST BREAKDOWN SHEET

Ref QUOTATION :

CUSTOMER

SJM FLEX

Category:

Sub Category:

Your contact:

George jacob Sam

PART NUMBER

Item Description

Product group

SFM-09-PD-RT001-R1

RT 50 HIGH POWER

Date of quotation:

Revision number

30/10/2012

0

Fax:

Currency

Ringgit Malaysia

Address:

Tel

60122835161

03-90754722

MATERIAL COST

1 Material Name

2 Specification

SUS 409

SUS 409

3 SHEET THICKNESS

4 STRIP WIDTH

1.00

90.00

5 PITCH

5 INPUT WEIGHT PER UNIT IN GRAMS

85.00

60.44

6 OUTPUT WIGHT PER UNIT

7 SCRAP WEIGHT PER UNIT

8 RAW MATERIAL PRICE

30.22

30.22

6.60

9 INPUT MATERIAL PRICE PER UNIT

10 SCRAP RATE/KG

0.40

1.25

11 SCRAP RECOVERY COST

0.03

12 FINAL MATERIAL PRICE

0.37

A - RAW MATERIAL COST

0.369

MOULD COST

TYPE OF PROCESS

1 PROGRESSIVE TOOL

2

3

4

TYPE OF MOULD

LIFE OF MOULD IN

SHOTS

Total Cost

24000

300,000

24000

B-MOULD COST IN RM

MACHING COST

Operation

Machine Description

1 PROGRESSIVE TOOL

2

3

24000

No. of

Cycles IN

SEC

Cost per

SEC

110 TON STAMPING MACHINE

C- PROCESSING COST

PROCESS

COST

0.1

0.10

SURFACE TREATMENT COST

Specification of Surface Treatment

Operation Rate (per surface unit)

Total Surface area per Item

D- SURFACE TREATMENT COST

Total Manufacturing Cost (per item) (B+C+D)

0.10

E =MATERIAL+MANUFACTURING COST

0.469

D OTHER COSTS

1

2

3

4

Cost

Packing (3%OF E)

MOULD AMORTISATION

Overhead & Margin

Other

Remarks

IN PLASTIC BAGS AND PLACED IN LABELLED CARTON BOX

MOULD AMORTISED ON 150,000(5 MONTHS)

5% of E

Total Cost

0.014

0.160

0.023

F= TOTAL OTHERS COSTS

0.197

FINAL SELLING PRICE (E+F)

0.666

CALCULATION OF SCRAP RECOVERY : MASASINAR

ITEM

RT 50 STD

RT 50 HP

Gross Weight (kgs)

0.1070

0.0669

Net Weight (kgs)

0.0360

0.0220

Scrap (kgs)

0.0710

0.0449

REMARKS

as per quotation

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- (D) PPT On Arb ProceedingsDocument36 pages(D) PPT On Arb ProceedingsChandraket KumarNo ratings yet

- Productivity and Quality ManagementDocument35 pagesProductivity and Quality Managementniraliparekh27No ratings yet

- Cebu Country Club v. ElizagaqueDocument1 pageCebu Country Club v. ElizagaqueMarie ChieloNo ratings yet

- Procurement PolicyDocument5 pagesProcurement PolicyarjunkaushikNo ratings yet

- Fraud Detection in The Financial Services IndustryDocument24 pagesFraud Detection in The Financial Services Industrychiragjuneja234100% (3)

- Cadbury Committee ReportDocument7 pagesCadbury Committee ReportzeeshanmastimNo ratings yet

- DissertationDocument95 pagesDissertationsriramsanjeev2sNo ratings yet

- Assignment Relationship MarketingDocument17 pagesAssignment Relationship Marketingrohaiza197975% (4)

- GRI - English Lets Report TemplateDocument17 pagesGRI - English Lets Report TemplateXavier BaudequinNo ratings yet

- ISOIEC 25040 - v3 - 0 PDFDocument83 pagesISOIEC 25040 - v3 - 0 PDFSebastian CoddNo ratings yet

- An Analysis of The Business and Financial Performance of Tesco PLCDocument17 pagesAn Analysis of The Business and Financial Performance of Tesco PLCbanardsNo ratings yet

- EbayDocument32 pagesEbayrohaiza1979No ratings yet

- EbayDocument32 pagesEbayrohaiza1979No ratings yet

- Assignment BBMP1103Document11 pagesAssignment BBMP1103rohaiza1979100% (1)

- CBCT2203Document22 pagesCBCT2203rohaiza1979100% (1)

- Assignment Company LawDocument5 pagesAssignment Company Lawrohaiza1979No ratings yet

- Bbaw 2103Document13 pagesBbaw 2103rohaiza1979No ratings yet

- Bbaw 2103Document13 pagesBbaw 2103rohaiza1979No ratings yet

- AU-00314 Auditing A Business Risk ApproachDocument43 pagesAU-00314 Auditing A Business Risk Approachredearth2929No ratings yet

- Standard Costs and Variance Analysis Standard Costs and Variance AnalysisDocument26 pagesStandard Costs and Variance Analysis Standard Costs and Variance Analysischiji chzzzmeowNo ratings yet

- SD Develop em Net ServicesDocument36 pagesSD Develop em Net ServicesGGHMADNo ratings yet

- Soal Temp BingACAKDocument12 pagesSoal Temp BingACAKSyauqi Bay RoesNo ratings yet

- The Flights of Malaysia Airlines Marketing EssayDocument17 pagesThe Flights of Malaysia Airlines Marketing EssayMia KulalNo ratings yet

- How Decoupling Creates Win-Win For Power Companies and CustomersDocument11 pagesHow Decoupling Creates Win-Win For Power Companies and CustomersClutha Mata-Au River Parkway GroupNo ratings yet

- Siemens Proposal For SAP UAcademy at IIBSDocument3 pagesSiemens Proposal For SAP UAcademy at IIBSNag28rajNo ratings yet

- Facilities Management Quality and User Satisfaction in Outsourced ServicesDocument16 pagesFacilities Management Quality and User Satisfaction in Outsourced ServicesAHMEDNABTNo ratings yet

- Print SummaryDocument3 pagesPrint Summarylalit patankarNo ratings yet

- IGL Relocation - BrochureDocument13 pagesIGL Relocation - BrochureIGL RelocationNo ratings yet

- Tracking ReportDocument135 pagesTracking ReportRoel AllosadaNo ratings yet

- All About BSNL: Industry Founded Headquarters Area Served Key PeopleDocument3 pagesAll About BSNL: Industry Founded Headquarters Area Served Key Peopleshweta shettyNo ratings yet

- Labor Code 2810.5 NoticeDocument2 pagesLabor Code 2810.5 NoticejohnlusfNo ratings yet

- Entrepreneurship Concept & DefinitionDocument5 pagesEntrepreneurship Concept & DefinitionanoopguptNo ratings yet

- Analisis Kualitas Layanan Pada Perusahaan Jasa Travel Agent Berbasis E-Commerce Dengan Metode E-Servqual Dan QualityDocument16 pagesAnalisis Kualitas Layanan Pada Perusahaan Jasa Travel Agent Berbasis E-Commerce Dengan Metode E-Servqual Dan QualityPitri HandayaniNo ratings yet

- MNCDocument106 pagesMNCChessking Siew HeeNo ratings yet

- Nitaqat LawDocument7 pagesNitaqat Lawrubella zaidNo ratings yet

- STATEMENT Format SviDocument4 pagesSTATEMENT Format SviSUMIT SAHANo ratings yet

- DKAM-Newsletter January 2014 FinalDocument11 pagesDKAM-Newsletter January 2014 FinalCanadianValueNo ratings yet

- MC1 - Case Study Assessment - Zee GroupDocument4 pagesMC1 - Case Study Assessment - Zee GrouphemakumarbNo ratings yet