Professional Documents

Culture Documents

Tesla - Reciprocating Engine

Tesla - Reciprocating Engine

Uploaded by

IonTerinte0 ratings0% found this document useful (0 votes)

10 views4 pagesOriginal Title

0514169 Tesla_Reciprocating Engine

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views4 pagesTesla - Reciprocating Engine

Tesla - Reciprocating Engine

Uploaded by

IonTerinteCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

x

y

2

3

3

40 been utiliz

45 Telatively gr-

5

UniTeD States

Patent OFFICE.

NIKOLA TESLA, OF NEW YORE, N, Y.

RECIPROCATING ENGINE.

SPECIFICATION forming part of Letters Patent No. 614,269, dated February 6, 1894.

Applicntion led August 19,1803, Serial No. 498,689, fo model)

To all whorn it may concern:

Boit known that I, NroLa TEsLa,a citizen

of the United States, residing at New York,

in the county and State of New York, have in-

5 vented cortain new and useful Improvements

in Reciprocating Engines, of which tho fol-

lowing is a speoifioation, reference being bad

to the drawing accompanying and forming a

‘part of the same.

‘0. In the invention which forms the subject of

my present application, tiny object has been,

primarily to provide an engine, which under

the influence of an applied force such as the

elastic tension of steam or gas under pressure

5 will yiéld an oscillatory movement: which,

within very wide limits, will be of constant

Period, irrespective of variations of load, fric-

tional losses and other factors which in all

ordinary engines produce change in the rate

of reciprocation,

‘The farther objects of the invention are to

provide a mechanism, capable of converting

the energy of steam or-gas under prassure

into mechanical power more economically

than the forms of engine heretofore used,

chiefly by overcoming the losses which result

in these by the combination with rotating

parts possessing great inertia of a reciprocat-

ing system; which also, is better adapted for

use at higher temperatures and pressures, and.

which is capable of useful and practical ap-

plication to general industrial purposes, par-

ticularly in,amall nits, .

The invention is based upon certain well

5 known mechanical principles.4 statoment of

which will assist in a better understanding

of the nature and purposes of the objects

sought and results obtained. Heretofore,

where the Bressare of steam or any gas hag

‘and applied for the production

of mechanical motion it has been customary

to connect with the reciprocating. or moving

parts of the engine a fiy-wheel or some rotary

system equivr. nt in ifs effect and possessing

‘mechanical inertia, upon

whieh depenc:..ee was mainly placed for the

maintenance 12 sonstant speed.. This, while

securing in a measure this object, renders im-.

possible the attainmentof the result at which

0 i have arrived, and is attended by disadvan-

tages which br my invention are-entirely ob-

viated. On t.u other hand, in certain cases,

1

3

to maintain in oscillati

whore reciprocating engines or tools have been

used without a rotating system of great iner-

tia, no attempt, so far as I kaow, has been

made to secure conditions which would nec-

oseatily yield such results as I have reached.

It-is swell known principle that if aspring

possessing # sensible inertia be brought un-

der tension, as by being stretched, and then

freed it will perform vibrations which are

isochronous and, as to period, in the main de-

pendent upon the rigidity of the spring, and

its own inertia or that of the system of which

it may form an immediate part. This is

53

a

io

known to be true in all cases where the force -

| which tends to bring the spring or’ movable

system into a given position is proportionate

to the displacement. “

In carrying out my invention and forsecar-

ing the objects in general terms stated above,

I employ tho energy of steam or gas, under

pressure, acting through proper mechanism,

fone piston, and, tak-

ing advantage of the law above stated, I con-

neet with said piston, or cause to act upon it,

a spring, under such ‘conditions as to auto-

matically regulate the period of the vibra-

tion, so that the alternate impulses of the

power impelled piston, and the natural vibra-

tions of the spring shall always correspond

in direction and’ coincide in time.

While, in- the practice of the invention I

may omploy any kind of spring or elastic body

of which the law or principle of operation

above defined holds true, I prefer to use.an

air apring, or generally apeaking a confined

body or cushion of an elistic fluid, as the me-

chanical difficulties in the use of ordinary or

metallic springs are serious, owing mainly, to

their tendency to break. Moreover, instead

‘of permitting the piston to impinge directly

upon such cnshious within its own cylinder,

I prefer, in order to avoid the influence of the

varying pressure of the steam or gas that acts

upon the piston and which might distarb the

relations necessary for the maintenance of

isochronons vibration, and also to better util-

ize the heat oneratod ‘by the compression, to

einploy an independent plunger ‘connected

with the main piston, and a.chamber or cyl-

inder therefor, containing air which is nor-

mally, at the same pressure as the external

‘atmosphere, for thus ® spring of practically.

70

Ps

jo

2

5

2

constant rigidity is obtained, but the air or

gas within the cylinder may be maintained

at any pressure.

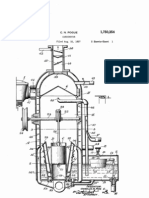

In order to describe the best manner of

which I am aware in which the invention is

or may be carried into effect, I refer now to

theaccompanying drawing which represents

in central cross-section an engine embodying

my improvements.

Aisthe main cylinder in which works a

piston B. Inlet ports CC pass through the

sides of tho cylinder, opening at the middle

Portion thereof and ‘on opposite sides. Ex:

ust ports D D extond through the walls of

the cylinder and are formed with branches

that open into the interior of the cylinder on

each side of the inlet ports and on opposite

sides of the cylinder. .

The piston B is formed with two circumfer-

ential grooves E F, which communicate

through openings Gin the piston with the

cylinder on opposite sides of said piston re-

spectively.

Ido not consider as of special importance

the particular constrnotion and arrangement

of the eylinder, the piston and the ports for

controlling it, except that it is desirable that

all the ports, and more especially, the ox-

haust ports should be made very much lar;

than is usually the case, so that no force due

to the action of tho steam or compressed air

will tend to retard or affect the return of the

piston in either direction.

‘The piston B is secured to a piston rod H,

which works in suitable stuffing boxes in the

heads of the cylinder A. This rod. is pro-

longad on one side and extends through bear-

ings V in a cylinder I suitably mounted or

supported in line with tho first, and within

which is a disk or plunger J carried by the

rod H,

‘the oylindor I is without ports of any kind

and is air-tight except as a small leakage may

occur through the bearings V, which experl-

enze has shown need not be fitted with any

very considerable aecuracy., The cylinder I

4s surrounded by a jacket IK which leaves an

open space or chamber around it. Thd bear-

ings V in the cylinder J, extend through the

jacket K to the outside airand the chamber

between the gylinder aud jacket is mado

steam or air tight as by suitable packing.

‘The main supply pipe L for steam or com-

pressed air leads into this chamber, and the

two pipes that lead to the cylinder A run.

from the said chamber, oil cups M being con-

veniently arranged to deliver oil into thesaid

pipes for lubricating the piston.

In tho particular form of engine shown, the

jacket K which contains the cylinder I is pro-

vided with a flange N by which it is serewod

to the end of the cylinder A. Aswallcham-

ber O is thus formed which has air vents P

in its sides and drip pipes Q leading out from

it through which the oil which collects in it

is carried off. ©

3

a

a

3

3

35

40

814,169

To explain now the operation of the device

above described. In the position of the parts

shown, or when the piston is at the middle

point of its stroke, the plunger J is at the

center of the cylinder I and the air on both

To

sides of the same is at the normal pressure.

of the outside atmosphere. If a source of

steam or compressed air be then connected

to the inlet ports C C of the oylinder A and

@ movement be imparted to the piston asby

a sudden blow, the latter is éaused to recip-

rocate in # manner well understood. The

movement of the piston in either direction

ceases when the force tending toimpel it and

the momentum which it has acquired are

counterbalanced by the increasing pressure

of the steam or compressed airin that end of

the cylinder toward which it is moving aud

as in its movement the piston has shut off at

@ given point, the pressure that impelled it

and established the prossnre that tends to re-

turn it, itis then impelled in the opposite di-

rection, and this action is continued as long

as the requisite pressure is applied. The

movements of the piston compress and rarity

the air in the cylinder I at opposite ends of

the same alternately. A forward stroke com-

presses the air abead of the plunger J which

acts as a spring to return it. Similarly on

the back stroke the air is compressed on the

opposite side of the plunger J and tonds to

drive it forward. This action of the plunger

upou the air contaitiod in the opposite. ends

of the cylinder is exactly the same in princi-

plo as though the piston rod were connected

to the middle point of a coiled spring, tho

ends of which are connected tofixed supports.

Consequently the two chambers may be con-

idered asasingle spring. Thecompressions

of the air in the cylinder I and the conse-

quent loss of energy due mainly to the im-

porfect olasticity of the air, give rise to a very

considerable amount of heat. This heat I

utillze by conducting the steam or compressed

air to the engine oylinder through the cham-

ber formed by the jacket surrounding the air-

spring cylinder. ‘The heat thns taken ap and

used to raise the temperatureof the steam or

air acting upon the piston is availed of to in-

crease the efficiency of the engine, In any

given engine of this kind the normal pross-

ure will produce a stroke of determined

longth, and this will be increased or dimin-

ished according to the increase of pressure

above or the reduction of pressure below the

normal.

Tn constructing the apparatus I allow for a

variation in the Iength of atroke by giving to

the confining eylinder I of the air spring

properly determined dimeusions. The greater

the pressure upon the piston, the higher will

bethe degree of compression of theair-spring,

and the consequent counteracting force npon

the plunger. ‘The rate or period of recipro-

cation of the piston however is no more de-

pendent upon the pressure applied to drive

r

3.

Ss

io

5

T05

3°

814,160 : 8

it, than would be the pariod of osaillation of

8 pendulum permanently maintained in vi-

bration, upon the force which -periodically

impels it, the effect of variations in such force

§ being merely to-produce corresponding vari-

tions in the length of stroke or amplitude of

vibration respectively. The period is mainly.

determined by the rigidity of the air spring

and tho inertia of the moving aystem, and I

xo may therefore: secure any period of oscilla-

tion within very wide limits by properly por-

tioning these factors, as by vatying the di-

mensions of the air chamber which is equiva-

lent to varying the rigidity of the apring, ot

1§ by adjusting the weight of the moving parts.

These conditions aro all readily determina:

le, and an ebgine oonstracted as herein de-

seribed may be made to follow the principle

of operation above stated and maintain a

20 perfectly uniform period through very much

wider limits of pressure than in ordinary use,

it is ever likely to be subjected to and it may

be successfully used as a prime mover wher-

ever & constant rate of oscillation or speed is

a5 required, provided the limits within which

the forces tending to bring the moving sys-

tem'to's given position are proportionate to

the displacements, are not matorially ex-

ceeded. - The pressure of the air confined in

30 the cylinder when the plunger J is in its

central position will always be practically

that of the surrounding atmosphere, for while

the.cylindér is sé constructed as not to per-

mit atch sudden escape of air as to sensibly

35 impair or modify the action of the air spring

thore will atill bea slow leakago of air into or

out of it around the piston rod according to

the preasura therein, g0 that the pressure-of

the air on opposite sides of -the plunger will

4¢ always tend to remain at that of the outside

atmosphere.

*__As an instance of the uses to which this en-

_ gino may be applied I have shown ita piston

‘rod connected with & pawl R the oscillation

45 of which drivesa trainof wheels. Thesé may

‘constitute the train of a clock or of any other

mechanism. The pawl R is pivoted at R’

and its bifurcated end engages with the teeth

of the ratchet wheel alternately on oppo-

50 site sides of the same, one end of the pawl

at éach half oscillation acting to propel the

wheel forward through the space of one tooth

when it is ep; id and ‘locked by the other

-end‘on the last half of the oscillation which

85 brings the fret end into position to. engage

with another tooth. .

Another application of the invention is to

aiove # conductor in a magnetic field for gen-

erating electri¢ currents, and in these and

60 similar uses it is obvious that the character-

jatios of the engiterender it especially adapt-

ed for use in-small sizes or units.

Having now described my invention, what

I claim is— 7 as

‘L.A reciprocating engine comprising in 65

combination, a cylinder, a piston anda spring

conneoted with cracting upon the reciprocat-

ing element, the said spring and reciprocating

element being related in substantially the

manner described so thatthe forees which tend

to bring the reciprocating parts into a given

position are proportionate to the displace-

ments, whereby an isochronous vibration is

obtained. ting engin ‘sing in 48

. A reciprocating engine comprising in

combination, # cylitetera piston impelled by

steam or gas under pressure, and an airspring

maintained in vibration by the movements of

the piston, the piston and spring being related

in substautially the mauner described so that 80

the forees which tend to bring the recipro-

cating parts into a given position aro pro-

portionate to the displacements whereby an

isochronous vibration is obtained.

3. The combination of a cylinder and pis-

ton adapted to be reoiprocated by steam or

gas under pressure, a cylinder and a plunger

therein reciprocated by the piston aud cousti-

tuting an air aprin; acting upon said piston,

the piston and spring being related in the

manner described so that the forces which

tend to bring the piston into.a given position

are proportionate to the displacement where-

by an isochronous oscillation of the piston is

obtained.

‘4. The combination of a cylinder and a pis-

ton adapted to be reciprocated by steam or

gas under pressure, a cylinder and piston con-

Stituting an sir spring connected. with the

piston, a jacket forming a chamber around

the air spring through which the steam: or

comp! gas is passed on its way to the

cylinder, as and for the purpose set forth.

&. The method of producing isochronons

movement herein described,which consists in

resiprocating a piston by steam or gas under

pressure and controlling the rate or perfod of

reciprocation by the vibration of # spring, as

set forth,

6. The method of operating a reciprocating

engine which consists in reciprocating a pis-

ton, maintaining by the movements of the pis-

o

0

2

| ton, the vibration of an ait spring and apply-

ing'the heat genorated by the compression of

the spring to the steam or gas driving the 125

piston.

Wit NIKOLA TESLA.

itnessos:

Parke W. Pace,

R. F. GAYLORD.

“(Qo Model.)

N. TESLA.

RECIPROOATING ENGINE.

No, 614,169. Patented Fob. 8, 1804.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Franklin B. Mead Jr. (US Pat. 5590031)Document15 pagesFranklin B. Mead Jr. (US Pat. 5590031)GaleriaTechniki.PLNo ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- US Pat. 3693731Document10 pagesUS Pat. 3693731GaleriaTechniki.PLNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- Thomas Galen Hieronymous (US Pat. 2482773)Document6 pagesThomas Galen Hieronymous (US Pat. 2482773)GaleriaTechniki.PL100% (1)

- Canada Patent - 29.537Document24 pagesCanada Patent - 29.537GustavBlitzNo ratings yet

- Canada Patent - 24.033Document12 pagesCanada Patent - 24.033GustavBlitzNo ratings yet

- Canada Patent - 142.352Document18 pagesCanada Patent - 142.352GustavBlitzNo ratings yet

- United Kingdom Patent - 8575Document6 pagesUnited Kingdom Patent - 8575GustavBlitzNo ratings yet

- United Kingdom Patent - 2975Document9 pagesUnited Kingdom Patent - 2975GustavBlitzNo ratings yet

- Canada Patent - 135.174Document12 pagesCanada Patent - 135.174GustavBlitzNo ratings yet

- Canada Patent - 30.142Document10 pagesCanada Patent - 30.142GustavBlitzNo ratings yet

- United Kingdom Patent - 6502Document5 pagesUnited Kingdom Patent - 6502GustavBlitzNo ratings yet

- United Kingdom Patent - 6481Document9 pagesUnited Kingdom Patent - 6481GustavBlitzNo ratings yet

- United Kingdom Patent - 2812Document7 pagesUnited Kingdom Patent - 2812GustavBlitzNo ratings yet

- Nicola Tesla (US Pat. 1655114)Document8 pagesNicola Tesla (US Pat. 1655114)GaleriaTechniki.PL100% (1)

- United Kingdom Patent - 2801Document5 pagesUnited Kingdom Patent - 2801GustavBlitzNo ratings yet

- Nicola Tesla (US Pat. 685955)Document7 pagesNicola Tesla (US Pat. 685955)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (US Pat. 787412)Document6 pagesNicola Tesla (US Pat. 787412)GaleriaTechniki.PLNo ratings yet

- United States Patent - 685.957Document5 pagesUnited States Patent - 685.957GustavBlitzNo ratings yet