Professional Documents

Culture Documents

HighTens AISI4340

HighTens AISI4340

Uploaded by

Alois Junior Hernandez SanchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HighTens AISI4340

HighTens AISI4340

Uploaded by

Alois Junior Hernandez SanchezCopyright:

Available Formats

ENGINEERING STEELS

HIGH TENSILE STEEL AISI 4340

AISI 4340 Nickel Chrome - Moly

High Tensile Steel, generally

supplied hardened and tempered

to condition U in sections up to

100mm, with a tensile strength of

930 1080 MPa and aiming for

this strength range in larger

sections. It offers a very good

balance of strength, toughness

and wear-resistance.

Typical Applications:

Heavy-duty axles, shafts, heavy-duty

gears, spindles, pins, studs, collets,

bolts, couplings, sprockets, pinions,

torsion bars, connecting rods, crow

bars, conveyor parts etc.

Typical Chemical Analysis

0.40%

Carbon

0.25%

Silicon

0.70%

Manganese

1.85%

Nickel

0.80%

Chromium

0.25%

Molybdenum

Related specifications:

AS 1444-1996

4340

BS EN10083-1-1991 817M40

BS 970-1955

EN 24

JIS G 4103

SNCM 439

SAE & UNS

4340 & G43400

Werkstoff 1.6565

40NiCrMo6

Surface Treatment:

Will Nitride with a typical surface hardness up to HRC 60.

Will Flame or Induction harden with a typical surface hardness up to HRC 58.

Mechanical Property Requirements in Condition U - to AS 1444-1996

Impact

Section

0.2% Proof

Tensile

Elongation

Izod

Charpy

Stress

Strength

On 5.65So

mm

MPa

MPa

%

J

J

*up to 63

755 min

930 1080

9 min

47 min 42 min

up to 100

740 min

930 1080

12 min

*Applies only to bars bright drawn after hardening and tempering

Hardness

HB

269 331

269 331

Typical Mechanical Properties Hardened and tempered in section size listed.

Section

Yield Strength

Tensile Strength Elongation

Izod

Hardness

in mm

MPa

MPa

%

J

HB

880

1000

17

85

295

50

850

980

17

80

290

100

730

930

17

75

275

200

Typical properties for guidance only

www.tatasteelnz.com

0800 109 999

High Tensile Steel AISI 4340

Welding:

Readily welded in the annealed condition

but avoid when possible if hardened and

tempered due to the effect on the

mechanical properties. Welding in the

nitrided, flame or induction hardened

condition is not recommended.

Welding procedure:

Low hydrogen electrodes are

recommended. Pre-heat at 200C

300C and maintain during welding.

Cool slowly in ashes or sand etc and

stress relieve if this is possible.

Welding details for guidance only

HEAT TREATMENT:

Forging:

Heat to 1150C

Hold till uniform

Minimum forging temperature 850C

Cool slowly in ashes or sand etc.

Annealing:

Heat to 830C 850C

Cool in furnace

Stress Relieving:

Annealed: Heat to 600C 650C

Hardened: Heat to 500C 550C

Cool in still air

Hardening:

Heat to 830C 880C

Quench in oil or polymer

Tempering:

Heat to 450C 660C cool in still air

NB. Tempering within the range 250C

450C will result in temper brittleness

and should be avoided

Flame and Induction Hardening:

Heat quickly to the required case

depth at 850C 870C and quench

immediately in water or oil.

Tempering at 150C 200C will

reduce stresses in the case with

minimal effect on its hardness.

All de-carburised surface material

must first be removed to ensure best

results.

Nitriding:

Heat to 500C 530C and hold for

sufficient time to develop the depth of

case required

Parts should be pre-hardened and

tempered as required and also premachined leaving a small grinding

allowance only.

Heat treatment details for guidance

only.

www.tatasteelnz.com

0800 109 999

You might also like

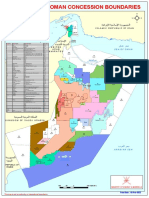

- Oman Concession Map 2023Document1 pageOman Concession Map 2023wellengineer50% (2)

- AISI 1020 Low Carbon/Low Tensile Steel: Element ContentDocument4 pagesAISI 1020 Low Carbon/Low Tensile Steel: Element ContentRatno Wijaya100% (1)

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyNo ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- High Tensile Steel - Aisi 4140Document2 pagesHigh Tensile Steel - Aisi 4140tetirichieNo ratings yet

- High Tensile Steel 4340Document2 pagesHigh Tensile Steel 4340Arun KumarNo ratings yet

- High Tensile Steel 4340Document2 pagesHigh Tensile Steel 4340CarmenJuliaNo ratings yet

- High Tensile Steel 4140Document2 pagesHigh Tensile Steel 4140Sadullah TaşkınNo ratings yet

- MeduimTens AISI1045Document2 pagesMeduimTens AISI1045Rajesh R RajeshNo ratings yet

- High Tensile Steel 4140Document2 pagesHigh Tensile Steel 4140Lazzarus Az GunawanNo ratings yet

- Medium Tensile Steel A Is I 1045Document2 pagesMedium Tensile Steel A Is I 1045Madhav RajpurohitNo ratings yet

- EN26Document3 pagesEN26Moldoveanu TeodorNo ratings yet

- CaseHard BS970-1955EN36ADocument2 pagesCaseHard BS970-1955EN36AtechzonesNo ratings yet

- AISI 8620 Case HardeningDocument2 pagesAISI 8620 Case HardeningjarnebergNo ratings yet

- 4140 High Tensile SteelDocument3 pages4140 High Tensile SteelJean Paulo SalvatiNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- 1018 Mechanical PropertiesDocument2 pages1018 Mechanical PropertiesjangaswathiNo ratings yet

- Alloy SteelDocument7 pagesAlloy SteelRavinJohnNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerNo ratings yet

- 8620 Case Hardening SteelDocument3 pages8620 Case Hardening Steelkumarsathish2009No ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFdiego.peinado8856No ratings yet

- CaseHard AISI8620Document2 pagesCaseHard AISI8620Anonymous B3I6zYNhqdNo ratings yet

- Duplex Stainless Steel EN 1.4460 PDFDocument2 pagesDuplex Stainless Steel EN 1.4460 PDFtienNo ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Document2 pagesHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261No ratings yet

- Sus 306 - Aisi 306Document24 pagesSus 306 - Aisi 306Jacob StrifeNo ratings yet

- Case Hardening Steel 18 CR Ni Mo 7Document2 pagesCase Hardening Steel 18 CR Ni Mo 7anu swamiNo ratings yet

- Hoja de Especificaciones Del Acero T-410Document2 pagesHoja de Especificaciones Del Acero T-410cristobal_tl2277No ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- SS 1.4122Document2 pagesSS 1.4122Bipin Sadasivan100% (2)

- 431 Stainless SteelDocument2 pages431 Stainless Steeldeden ibnuNo ratings yet

- AISI 1020 Low CarbonLow Tensile SteelDocument3 pagesAISI 1020 Low CarbonLow Tensile SteelNaman TanejaNo ratings yet

- 1045-Bright-Carbon-Steel-Bar (Les Différentes Traitements Thermiques, Recuit de Normalisation)Document3 pages1045-Bright-Carbon-Steel-Bar (Les Différentes Traitements Thermiques, Recuit de Normalisation)Mouna KallelNo ratings yet

- AISI 1040: Typical AnalysisDocument2 pagesAISI 1040: Typical Analysisho_chauhanNo ratings yet

- Fti Vhssm50 InglesDocument2 pagesFti Vhssm50 InglesAntonio Melgaço da SilvaNo ratings yet

- 1 4122Document1 page1 4122Zeeshan AnwarNo ratings yet

- Case Hardening Steel A Is I 8620Document2 pagesCase Hardening Steel A Is I 8620fahriNo ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- 817m40 PDFDocument4 pages817m40 PDFjeyakumarNo ratings yet

- 1 4021 PDFDocument2 pages1 4021 PDFSarah FitzgeraldNo ratings yet

- MildSteel AISI 1018Document2 pagesMildSteel AISI 1018ramanamurtytv7176No ratings yet

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- Datasheet Sandvik 12c27 enDocument4 pagesDatasheet Sandvik 12c27 enRizqi D. KurniantoNo ratings yet

- 1020 Bright Carbon Steel Bar 2Document3 pages1020 Bright Carbon Steel Bar 2thyskieNo ratings yet

- Uns s32760Document3 pagesUns s32760NitinNo ratings yet

- PK2SPDocument3 pagesPK2SPEmanuelValenciaHenaoNo ratings yet

- Caracteristicas Do Aço 40CrMnMo7Document2 pagesCaracteristicas Do Aço 40CrMnMo7Gabriel GonçalvesNo ratings yet

- Alloy SteelDocument4 pagesAlloy SteelDalibor CetojevicNo ratings yet

- 316l Austenitic Stainless Steel BarDocument3 pages316l Austenitic Stainless Steel Barதமிழன் இராமசாமிNo ratings yet

- Carpenter Stainless Custom 630 PDFDocument9 pagesCarpenter Stainless Custom 630 PDFGrafton MontgomeryNo ratings yet

- Fiche z38cdv5Document1 pageFiche z38cdv5Emmanuel LAIZETNo ratings yet

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- Alloy 330 Spec SheetDocument2 pagesAlloy 330 Spec SheetAA.KarandishNo ratings yet

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 pagesRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456No ratings yet

- AISI 4130 Alloy SteelDocument2 pagesAISI 4130 Alloy SteelKandeepanNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- 27 Sentences To Transform Your Writing: (Better Than Your English Teacher Could)Document29 pages27 Sentences To Transform Your Writing: (Better Than Your English Teacher Could)wellengineerNo ratings yet

- Special - Non STD Product TorquesDocument16 pagesSpecial - Non STD Product TorqueswellengineerNo ratings yet

- 350xt Data Sheet EnglishDocument1 page350xt Data Sheet EnglishwellengineerNo ratings yet

- Critical Sour H2S Under Balanced Drilling IRP Enform 6-2004Document244 pagesCritical Sour H2S Under Balanced Drilling IRP Enform 6-2004wellengineerNo ratings yet

- الخطوة الأولى نحو الضوءDocument29 pagesالخطوة الأولى نحو الضوءAhmed Nasr100% (2)