Professional Documents

Culture Documents

Pop Outs

Uploaded by

Matias Menichelli BallarioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pop Outs

Uploaded by

Matias Menichelli BallarioCopyright:

Available Formats

CIP 40 - Aggregate Popouts

WHAT is Popout?

A popout is a small, generally cone-shaped cavity in

a horizontal concrete surface left after a near-surface

aggregate particle has expanded and fractured. Generally, part of the fractured aggregate particle will be

found at the bottom of the cavity with the other part of

the aggregate still adhering to the point of the popout

cone. The cavity can range from in. (6 mm) to few

inches in diameter.

WHY do Concrete Popouts Occur?

The aggregate particle expands and fractures as a result of a physical action or a chemical reaction:

Physical

The origin of a physical popout usually is a near-surface aggregate particle having a high absorption and

relatively low relative density (specific gravity). As

that particle absorbs moisture; or if freezing occurs under moist conditions, its swelling creates internal pressures sufficient to rupture the particle and the overlying concrete surface. The top portion of the fractured

aggregate particle separates from the concrete surface

taking a portion of the surface mortar with it. In some

cases the aggregate forces water into the surrounding

mortar as it freezes thus causing the surface mortar to

pop off, exposing an intact aggregate particle. Clay

balls, coal, wood or other contaminants can uptake

water and swell even without freezing, but the resulting pressure rarely is great enough to cause popouts.

Also, there are reported cases of grain (soybeans, corn)

contamination of aggregate shipments that have resulted

in surface popouts. Such occurrences are not within

the scope of this document.

Popouts as a result of physical action are typically only

a problem with exterior flatwork in climates subject to

freezing and thawing under moist conditions and resulting expansion. Even aggregates which meet the

requirements of ASTM C 33 Class 5S, for architec-

Aggregate Popout

Courtesy PCA

tural concrete in severe exposure, allow several types

of particles which may cause popouts when exposed

to freezing and thawing in the saturated condition. The

most common type of particles resulting in popouts are

low density chert in natural aggregate deposits.

Crushed aggregates are less likely to contain lightweight, absorptive particles which are more susceptible to popouts.

Chemical

The cause of a popout due to a chemical reaction is

often related to alkali-silica reaction (ASR). Alkalis

from cement or other source cause an environment of

high pH (high concentrations of OH ions) causing the

breakdown of silica and formation of an ASR gel, which

absorbs water and expands, removing a small portion

of the surface mortar with it. These are called ASR

Popouts. They are typically small and are often accompanied by a small spot that is discolored and/or

appears to be damp. The aggregate particle does not

often fracture and split as is the case of popouts from

physical action. However, the ASR phenomenon can

result in micro-fractures within the aggregate particles.

Some alkali-silica reaction popouts can occur within a

few days after the concrete is placed.

lated at the surface as a result of evaporation of

bleed water.

3.

Permit the use of Class F fly ash or slag cement as

Most popouts are aesthetic defects that do not impact

a partial cement substitute to reduce the permeabilthe structural performance of the concrete members.

ity of the paste and mitigate deleterious reactions

A large number of popouts however make it easier for

due to ASR.

water and other harmful chemicals to enter the concrete, which can ultimately lead to other forms of deteHOW to Repair Concrete Popouts?

rioration such as corrosion of steel reinforcement. The

following steps can be taken to avoid concrete popouts. Prior to undertaking a repair program, it is advisable to

confirm the cause of the popouts by obtaining core

Physical Popouts

1. Avoid using aggregates which contain particles which samples containing one or more typical popouts and

may cause popouts, or that have a history of popouts. having them studied by a qualified petrographer.

However, in some parts of the United States, the Popouts can be repaired by chipping out the remaining

available natural gravels contain some particles that portion of the aggregate particle in the surface cavity,

are likely to result in surface popouts. Due to the cleaning the resulting void, and by filling the void with a

unavailability of economical alternate aggregates, the proprietary repair material such as a dry pack mortar,

occurrence of popouts on sidewalks and pavements epoxy mortar, or other appropriate material following

is an accepted , albeit undesirable, likelihood in those procedures recommended by the manufacturer. It will

locations.

be difficult to match the color of the existing concrete.

2. If popouts are unacceptable, an alternate source of If the popouts in a surface are too numerous to patch

aggregates must be located. If appropriate, two- individually, a thin bonded concrete overlay may be used

course construction can be used, whereby the popout to restore a uniform surface appearance. Specific recsusceptible aggregate is used for the lower course ommendations for such overlays are beyond the scope

and the pop-out free aggregat that is likely to be of this publication.

more expensive is used for the surface course.

3. Aggregates can be beneficiated to remove lightweight materials, but the added cost of beneficiation

can be prohibitive for most uses.

4. Reduce the water to cementitious materials ratio of

the concrete, as this will reduce the likelihood of

saturation and will increase the resistance to swelling forces. Provide proper curing for exterior

flatwork, as this results in improved strength of the

References

cementitious materials, especially on the surface.

1. Popouts: Causes, Prevention, Repair, Concrete Technology

This will reduce permeability thereby lowering the

Today, PL852, Portland Cement Association, www.cement.org

amount of water migrating to coarse aggregate par2. Guide to Residential Cast-in-Place Concrete Construction, ACI

ticles. These steps can reduce the frequency, but

332R, American Concrete Institute, Farmington Hills, MI,

will not necessarily, eliminate popouts.

www.concrete.org

5. Reduce the maximum aggregate size, as smaller 3. Closing in on ASR Popouts, Concrete Technology Today,

aggregates will develop lower stresses due to freezCT022, Portland Cement Association, www.cement.org

ing, and fewer popouts will occur. Those that do 4. R. Landgren, and D. W. Hadley, Surface Popouts caused by

Alkali-Aggregate Reaction, Portland Cement Association,

will be smaller and less objectionable.

HOW to Avoid Concrete Popouts?

RD121, www.cement.org

Chemical Popouts

5. N. E. Henning, K. L. Johnson, and L. J. Smith, Popouts, Con1. Use a low-alkali cement or a non-reactive aggrestruction Bulletin, March 4, 1971, Upper Midwest News

gate. This is often not a practical option in many

Weekly.

regions

6. Richard H. Campbell, Wendell Harding, Edward Misenhimer,

and Leo P. Nichelson, Surface Popouts: How are they Affected

2. Flush the surfaces with water after the concrete

by Job Conditions?, ACI Journal, American Concrete Institute,

has hardened and before applying the final curing.

June 1974, pp. 284-288.

This will remove the alkalis that may have accumu2007

You might also like

- Blank Traverse SheetDocument41 pagesBlank Traverse SheetCandra KrisnaNo ratings yet

- Alt. Alt. Lec. Ang. H. Ang. V. Dist. Ang. H. Inst. Mira Sup. G M S G M S M. RadDocument28 pagesAlt. Alt. Lec. Ang. H. Ang. V. Dist. Ang. H. Inst. Mira Sup. G M S G M S M. RadSherley Fiorela Melgarejo AlvaradoNo ratings yet

- California Infrastructure Projects: Legal Aspects of Building in the Golden StateFrom EverandCalifornia Infrastructure Projects: Legal Aspects of Building in the Golden StateNo ratings yet

- ULMA Bridge FormworkDocument25 pagesULMA Bridge FormworkTamaduianu IoanNo ratings yet

- Construction and Design of MultistoreyDocument37 pagesConstruction and Design of MultistoreyFawadNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Nanosized Tubular Clay Minerals: Halloysite and ImogoliteFrom EverandNanosized Tubular Clay Minerals: Halloysite and ImogoliteNo ratings yet

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980From EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980No ratings yet

- Dynamics of Plate Tectonics and Mantle ConvectionFrom EverandDynamics of Plate Tectonics and Mantle ConvectionJoao C. DuarteNo ratings yet

- Support Pile EmbankmentDocument6 pagesSupport Pile Embankmentjuniarso 29No ratings yet

- Design and Performance of Deep Excavations in Soft ClaysDocument27 pagesDesign and Performance of Deep Excavations in Soft Claysozdemir_bNo ratings yet

- Bridging the Strait: The Story of The Confederation Bridge ProjectFrom EverandBridging the Strait: The Story of The Confederation Bridge ProjectRating: 5 out of 5 stars5/5 (2)

- Understanding Morandi's Post-Stressed Concrete Cable StaysDocument6 pagesUnderstanding Morandi's Post-Stressed Concrete Cable StaysacetopposNo ratings yet

- 1974 - CivilEng - Seminars - Reinforced Concrete PipeDocument52 pages1974 - CivilEng - Seminars - Reinforced Concrete PipeChen YishengNo ratings yet

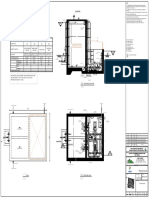

- Fire-Pump Room - Rev.cDocument1 pageFire-Pump Room - Rev.cwael72No ratings yet

- Khowpa Engineering College: Purbancal UniversityDocument8 pagesKhowpa Engineering College: Purbancal UniversitySudan ShresthaNo ratings yet

- Riverbank Protection MeasuresDocument11 pagesRiverbank Protection MeasuresHrisikeshNo ratings yet

- Aslan TBM Soft Eye Asia Pacific EDocument12 pagesAslan TBM Soft Eye Asia Pacific EpraupdNo ratings yet

- Plans TIF 1Document37 pagesPlans TIF 1sharilyn6156No ratings yet

- Design Guidelines FOR Accessible Bus Stops: BC Transit Municipal Systems ProgramDocument29 pagesDesign Guidelines FOR Accessible Bus Stops: BC Transit Municipal Systems ProgramAndresNo ratings yet

- Towards A Unified Soil Mechanics Theory: The Use of Effective Stresses in Unsaturated Soils, Revised EditionFrom EverandTowards A Unified Soil Mechanics Theory: The Use of Effective Stresses in Unsaturated Soils, Revised EditionNo ratings yet

- Table 60001 Concrete DurabilityDocument1 pageTable 60001 Concrete DurabilityZaid JamilNo ratings yet

- Indian Standard: Code of Practice For Design in Tunnels Conveying WaterDocument29 pagesIndian Standard: Code of Practice For Design in Tunnels Conveying WaterswabrightNo ratings yet

- Design of Earthen Canals PDFDocument18 pagesDesign of Earthen Canals PDFHumbertoRalphOrtizAbacheNo ratings yet

- A Rational Approach To The Hydraulic Design of Pipe ConduitsDocument15 pagesA Rational Approach To The Hydraulic Design of Pipe ConduitsZeBocaoNo ratings yet

- Design & Construction Guidelines For A Soil Nail Wall SystemDocument27 pagesDesign & Construction Guidelines For A Soil Nail Wall Systemgabby80No ratings yet

- Stone Arch Bridges: A Practical Manual For Local GovernmentsDocument83 pagesStone Arch Bridges: A Practical Manual For Local Governmentsjhllkjlghkjl100% (2)

- Riprap Revetment Ahn Polvi TrabantDocument10 pagesRiprap Revetment Ahn Polvi TrabantdihsadhisahdaNo ratings yet

- Bearing PDFDocument24 pagesBearing PDFggvavinashNo ratings yet

- ARMA-2013-137 - Fiber Reinforced Concrete Performance Parameters Using ASTM-C-1550 and En-14488-5 For Rock Support in Tunnels, MexicoDocument7 pagesARMA-2013-137 - Fiber Reinforced Concrete Performance Parameters Using ASTM-C-1550 and En-14488-5 For Rock Support in Tunnels, Mexicocastille1956No ratings yet

- Detailed Site Investigation PDFDocument303 pagesDetailed Site Investigation PDFAbdulrahman AlnagarNo ratings yet

- Pavement RepairDocument15 pagesPavement RepairtoddlbyrnesNo ratings yet

- Olompia UnderpassDocument60 pagesOlompia UnderpassEngineeri TadiyosNo ratings yet

- Geotechnical ReportDocument8 pagesGeotechnical Reportcollins unankaNo ratings yet

- Type of DamageDocument10 pagesType of DamageaizatulasmiraNo ratings yet

- Creep and Shrinkage Prediction Model For Analysis and Design of Concrete Structures: Model B3Document77 pagesCreep and Shrinkage Prediction Model For Analysis and Design of Concrete Structures: Model B3Concepción de PuentesNo ratings yet

- Design Reinforced Earth Retaining Walls For FlyoverDocument5 pagesDesign Reinforced Earth Retaining Walls For FlyoverSa SureshNo ratings yet

- Diaphragm Wall Construction PDFDocument53 pagesDiaphragm Wall Construction PDFAhmed ArafaNo ratings yet

- ALDECK3Document5 pagesALDECK3Mustafa ÇakırNo ratings yet

- BoxDocument16 pagesBoxAlfred KameyaNo ratings yet

- Beam - Column Connection For 7 Ton MonorailDocument1 pageBeam - Column Connection For 7 Ton Monorailتوان امتياس سامسدينNo ratings yet

- How To Design A Horizontal X Braces Connection (HXB) in Staad Pro - RAM - STAAD Forum - RAM - STAAD - Bentley CommunitiesDocument3 pagesHow To Design A Horizontal X Braces Connection (HXB) in Staad Pro - RAM - STAAD Forum - RAM - STAAD - Bentley Communitiesتوان امتياس سامسدينNo ratings yet

- Stainless Steel Rollup DoorDocument2 pagesStainless Steel Rollup Doorتوان امتياس سامسدينNo ratings yet

- Tutorial To SAP2000 For CE470: PresenterDocument12 pagesTutorial To SAP2000 For CE470: Presenterتوان امتياس سامسدينNo ratings yet

- Detailing and Placing Reinforcing BarsDocument6 pagesDetailing and Placing Reinforcing Barsتوان امتياس سامسدينNo ratings yet

- Detailing and Placing Reinforcing BarsDocument6 pagesDetailing and Placing Reinforcing Barsتوان امتياس سامسدينNo ratings yet

- Sikaflex 2c NS EZ Mix UsDocument3 pagesSikaflex 2c NS EZ Mix Usتوان امتياس سامسدينNo ratings yet

- Manholes PresentationDocument143 pagesManholes PresentationMar MaslanNo ratings yet

- C StrucDesign Voigt Aug13Document0 pagesC StrucDesign Voigt Aug13توان امتياس سامسدينNo ratings yet

- 0330 (500-599) - Concrete SlabsDocument16 pages0330 (500-599) - Concrete Slabsتوان امتياس سامسدينNo ratings yet

- Finishing Concrete FlatworkDocument0 pagesFinishing Concrete Flatworkتوان امتياس سامسدينNo ratings yet

- Steel Deck Construction PDFDocument48 pagesSteel Deck Construction PDFتوان امتياس سامسدينNo ratings yet

- STANDARD SPECIFICATIONS For HIGHWAY BRIDGESDocument0 pagesSTANDARD SPECIFICATIONS For HIGHWAY BRIDGESتوان امتياس سامسدينNo ratings yet

- Forex Day Trading SystemDocument17 pagesForex Day Trading SystemSocial Malik100% (1)

- E-Versuri Ro - Rihana - UmbrelaDocument2 pagesE-Versuri Ro - Rihana - Umbrelaanon-821253100% (1)

- Open Source NetworkingDocument226 pagesOpen Source NetworkingyemenlinuxNo ratings yet

- Civ Beyond Earth HotkeysDocument1 pageCiv Beyond Earth HotkeysExirtisNo ratings yet

- Santu BabaDocument2 pagesSantu Babaamveryhot0950% (2)

- 3 Diversion&CareDocument2 pages3 Diversion&CareRyan EncomiendaNo ratings yet

- List of Sovereign States and Dependent Territories by Birth RateDocument7 pagesList of Sovereign States and Dependent Territories by Birth RateLuminita CocosNo ratings yet

- Feasibility Study For Cowboy Cricket Farms Final Report: Prepared For Prospera Business Network Bozeman, MTDocument42 pagesFeasibility Study For Cowboy Cricket Farms Final Report: Prepared For Prospera Business Network Bozeman, MTMyself IreneNo ratings yet

- Iaea Tecdoc 1092Document287 pagesIaea Tecdoc 1092Andres AracenaNo ratings yet

- ADC of PIC MicrocontrollerDocument4 pagesADC of PIC Microcontrollerkillbill100% (2)

- Participants ListDocument13 pagesParticipants Listmailway002No ratings yet

- Union Test Prep Nclex Study GuideDocument115 pagesUnion Test Prep Nclex Study GuideBradburn Nursing100% (2)

- ALE Manual For LaserScope Arc Lamp Power SupplyDocument34 pagesALE Manual For LaserScope Arc Lamp Power SupplyKen DizzeruNo ratings yet

- A Noble Noose of Methods - ExtendedDocument388 pagesA Noble Noose of Methods - ExtendedtomasiskoNo ratings yet

- Decision Trees For Management of An Avulsed Permanent ToothDocument2 pagesDecision Trees For Management of An Avulsed Permanent ToothAbhi ThakkarNo ratings yet

- Google Tools: Reggie Luther Tracsoft, Inc. 706-568-4133Document23 pagesGoogle Tools: Reggie Luther Tracsoft, Inc. 706-568-4133nbaghrechaNo ratings yet

- Pipe Cleaner Lesson PlanDocument2 pagesPipe Cleaner Lesson PlanTaylor FranklinNo ratings yet

- All Day Breakfast: .Served With Cappuccino or Espresso or Lime Juice or TeaDocument7 pagesAll Day Breakfast: .Served With Cappuccino or Espresso or Lime Juice or TeaBryan KuoKyNo ratings yet

- NABARD R&D Seminar FormatDocument7 pagesNABARD R&D Seminar FormatAnupam G. RatheeNo ratings yet

- Module 1 Lesson 2Document31 pagesModule 1 Lesson 2Angela Rose BanastasNo ratings yet

- Predator U7135 ManualDocument36 pagesPredator U7135 Manualr17g100% (1)

- Bandhan Neft Rtgs FormDocument2 pagesBandhan Neft Rtgs FormMohit Goyal50% (4)

- Expression of Interest (Consultancy) (BDC)Document4 pagesExpression of Interest (Consultancy) (BDC)Brave zizNo ratings yet

- Haier in India Building Presence in A Mass Market Beyond ChinaDocument14 pagesHaier in India Building Presence in A Mass Market Beyond ChinaGaurav Sharma100% (1)

- MME 52106 - Optimization in Matlab - NN ToolboxDocument14 pagesMME 52106 - Optimization in Matlab - NN ToolboxAdarshNo ratings yet

- Chapter 1Document6 pagesChapter 1Grandmaster MeowNo ratings yet

- CLG418 (Dcec) PM 201409022-EnDocument1,143 pagesCLG418 (Dcec) PM 201409022-EnMauricio WijayaNo ratings yet

- SABRE MK-3 CFT Gel SpecDocument1 pageSABRE MK-3 CFT Gel Specseregio12No ratings yet

- BIAN How To Guide Developing Content V7.0 Final V1.0 PDFDocument72 pagesBIAN How To Guide Developing Content V7.0 Final V1.0 PDFميلاد نوروزي رهبرNo ratings yet

- Csu Cep Professional Dispositions 1Document6 pagesCsu Cep Professional Dispositions 1api-502440235No ratings yet