Professional Documents

Culture Documents

Checking Tandem Pump: Special Tools and Workshop Equipment Required

Uploaded by

Diana SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checking Tandem Pump: Special Tools and Workshop Equipment Required

Uploaded by

Diana SilvaCopyright:

Available Formats

Checking tandem

pump

Special tools and workshop equipment required

Tandem pump tester -VAS

5187- with banjo bolt -VAS

5187/1A-

Procedure

Observe rules for cleanliness

Chapter.

Observe test conditions

Chapter.

Pull dipstick -1- out of

guide tube.

Pull off engine cover panel

-arrows-.

Re-insert dipstick in guide

tube.

WARNING

Risk of injury - fuel system

operates under pressure.

Wrap a clean cloth

around the connection

before opening the fuel

system. Then release

pressure by carefully

loosening the

connection.

Wear protective gloves.

Wear safety goggles.

The fuel can become

extremely hot. This can

cause injuries.

In extreme cases the

temperature of the fuel

lines and the fuel can be

up to 100 C after the

engine is switched off.

Allow the fuel to cool

down before

disconnecting the lines -

danger of scalding.

Wear protective gloves.

Wear safety goggles.

Remove screw plug

-arrow-.

Note

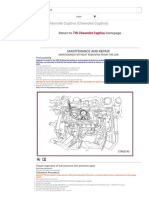

Illustration shows tandem

pump with engine removed

from vehicle.

Connect tandem pump

tester -VAS 5187- as

shown in the illustration.

Start engine.

Increase engine speed

to 4000 rpm.

Read the pressure on

the gauge:

Specification: at least

10.5 bar

Clamp off return hose

between fuel filter and

tandem pump using

hose clamp.

Increase engine speed

to 4000 rpm.

Read the pressure on

the gauge:

Specification: at least

10.5 bar

If specification is now

obtained: pressure is being

lost at unit injectors.

Renew O-rings at unit

injectors.

If specification is not

obtained:

Renew tandem pump

Chapter.

Note

After removing pressure

tester, tighten screw plug to

25 Nm. Renew the seal.

You might also like

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Document57 pagesChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Cummins QSK 23 Fuel PumpDocument10 pagesCummins QSK 23 Fuel PumpPedro SchembriNo ratings yet

- Bladder Accummulators InspectionsDocument7 pagesBladder Accummulators InspectionsJamin S. PanderajaNo ratings yet

- Mercedes Axor Fuel System Repair ManualDocument20 pagesMercedes Axor Fuel System Repair ManualStephenson75% (4)

- VPOWER Genset Operations, Service and Maintenance ManualDocument23 pagesVPOWER Genset Operations, Service and Maintenance ManualMahesh Mirajkar100% (1)

- Detroit Diesel-MTU S4000Document134 pagesDetroit Diesel-MTU S4000Dino Martin Mercado Quispe93% (30)

- Service Manual2008 Captiva Maintenance and RepairDocument37 pagesService Manual2008 Captiva Maintenance and RepairMuh Tadin100% (1)

- ShoeBox Compressor ManualDocument7 pagesShoeBox Compressor ManualSteveZ59100% (1)

- 980a3676 PDFDocument49 pages980a3676 PDFMichael Davenport0% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Mud Pumps Manual PDFDocument48 pagesMud Pumps Manual PDFMohamed Benlarbi100% (5)

- D6R Maintenance Interval ScheduleDocument12 pagesD6R Maintenance Interval Schedulepedro sanchezNo ratings yet

- 3736a g9t Common Rail SystemDocument180 pages3736a g9t Common Rail SystemKornelija Balandė50% (2)

- Powapak Air Ultra Operating ManualDocument45 pagesPowapak Air Ultra Operating ManualBenrub Flores75% (4)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Audi A4 8k Diesel Filter ReplacementDocument1 pageAudi A4 8k Diesel Filter Replacementrafa_r0No ratings yet

- Bomba de Alta Precion de CombustibleDocument10 pagesBomba de Alta Precion de Combustiblehamilton mirandaNo ratings yet

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument5 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Serviciohamilton mirandaNo ratings yet

- Initial Check: Note: Frequent Filter Replacement To Get Full Power FromDocument7 pagesInitial Check: Note: Frequent Filter Replacement To Get Full Power FrommunhNo ratings yet

- Standard Operating Procedure-Standard Maintenace ProcedureDocument11 pagesStandard Operating Procedure-Standard Maintenace ProcedureVikram JitNo ratings yet

- Galant CH 5 Fuel System PDFDocument16 pagesGalant CH 5 Fuel System PDFjustcheerfulNo ratings yet

- Ssangyong A150 - WML - 203Document24 pagesSsangyong A150 - WML - 203Milton MiltonNo ratings yet

- Power Team PE30 ManualDocument6 pagesPower Team PE30 ManualTitanplyNo ratings yet

- dp7490 Pump ManualDocument16 pagesdp7490 Pump Manualvipequi50No ratings yet

- GB Instructions LPG CNG Injector Cleaner SystemDocument2 pagesGB Instructions LPG CNG Injector Cleaner SystemChristian Arias MontoroNo ratings yet

- NissanDocument24 pagesNissanUbaldo SanchezNo ratings yet

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument7 pagesGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNo ratings yet

- Fuel System: SectionDocument18 pagesFuel System: SectionMihai IavorschiNo ratings yet

- Diesel High Pressure Pump Test Kit: 1. SafetyDocument4 pagesDiesel High Pressure Pump Test Kit: 1. SafetyVladimirAgeevNo ratings yet

- Bristol CompresoresDocument31 pagesBristol CompresoresBairon jaramilloNo ratings yet

- Bte-Bta10k Pump ManualDocument19 pagesBte-Bta10k Pump ManualAlexsandro CordeiroNo ratings yet

- D6TMaintenance Interval ScheduleDocument12 pagesD6TMaintenance Interval Schedulepedro sanchezNo ratings yet

- Manual Vacuum CoolairDocument8 pagesManual Vacuum CoolairasedayuNo ratings yet

- Cummins N14 Fuel TestDocument3 pagesCummins N14 Fuel TestAdrian SaucedoNo ratings yet

- Fuel Lift PumpDocument8 pagesFuel Lift PumpjengandxbNo ratings yet

- KraftstoffregelventiDocument6 pagesKraftstoffregelventiKlaus HeckmannNo ratings yet

- Inst and Serv Instructions Bristol Compressors Int. Inc PDFDocument31 pagesInst and Serv Instructions Bristol Compressors Int. Inc PDFjotalopecinco0% (1)

- CT Ecn 71.0 - EngDocument29 pagesCT Ecn 71.0 - Englucian.voinicaNo ratings yet

- 980a3578 PDFDocument49 pages980a3578 PDFMichael Davenport100% (1)

- Instalaçaõ Dos InjetoresDocument20 pagesInstalaçaõ Dos InjetoresJoão JlmacaeNo ratings yet

- 12 VW Tiguan 09 Multiples DTCDocument63 pages12 VW Tiguan 09 Multiples DTCJose Huesca100% (1)

- BA PM19478-19658 e 002Document5 pagesBA PM19478-19658 e 002AleksxxNo ratings yet

- Preparation and Start UpDocument5 pagesPreparation and Start UpBrenda DavisNo ratings yet

- Fuel Lift PumpDocument5 pagesFuel Lift PumptattinpipeNo ratings yet

- Diesel Electric Fire Pumpset Manual 2Document68 pagesDiesel Electric Fire Pumpset Manual 2ds_engenharia8817No ratings yet

- BlueDriver Compression Test Results SheetDocument3 pagesBlueDriver Compression Test Results SheeteelturkiNo ratings yet

- PT 102662 Iom UsDocument5 pagesPT 102662 Iom UsMo ZeroNo ratings yet

- Group 4 Tests and AdjustmentsDocument6 pagesGroup 4 Tests and AdjustmentsTaha RdmanNo ratings yet

- Engine Test EquipmentDocument63 pagesEngine Test Equipmentalipotjoshua2003No ratings yet

- Fuel System Pressure - Test: Testing and AdjustingDocument4 pagesFuel System Pressure - Test: Testing and AdjustingAbdoulaye Boua BERTHENo ratings yet

- KZ Slide Carb Tuning-1Document6 pagesKZ Slide Carb Tuning-1pertonpcNo ratings yet

- Emoving and Installing TurbochargerDocument7 pagesEmoving and Installing TurbochargerDamir MiholićNo ratings yet

- Hypress Compressor For VSP (Vertical Seismic Profile) JobDocument103 pagesHypress Compressor For VSP (Vertical Seismic Profile) JobIAN.SEMUTNo ratings yet

- Fuel Supply System Components: Screw, Spring or Clamp-Type ClipsDocument39 pagesFuel Supply System Components: Screw, Spring or Clamp-Type Clipsifu62319No ratings yet

- Hydropneumatic Trolley 2-Piston 15/30 "HN-230": Enquire@larzep - Co.uk WWW - Larzep.co - UkDocument10 pagesHydropneumatic Trolley 2-Piston 15/30 "HN-230": Enquire@larzep - Co.uk WWW - Larzep.co - UkAlain DefoeNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet