Professional Documents

Culture Documents

Tiwari Spain

Uploaded by

jainskj16Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tiwari Spain

Uploaded by

jainskj16Copyright:

Available Formats

11th World Congress on Computational Mechanics (WCCM XI)

5th European Conference on Computational Mechanics (ECCM V)

6th European Conference on Computational Fluid Dynamics (ECFD VI)

R. Tiwari, T. Chakraborty and V. Matsagar

DYNAMIC ANALYSIS OF UNDERGROUND TUNNELS SUBJECTED

TO INTERNAL BLAST LOADING

ROHIT TIWARI1*, TANUSREE CHAKRABORTY2, VASANT MATSAGAR3

1

Graduate Student, Department of Civil Engineering,

Indian Institute of Technology (IIT) Delhi,

Hauz Khas, New Delhi - 110 016, India.

E-mail: rohit19862009@gmail.com.

*

Corresponding Author

Assistant Professor, Department of Civil Engineering,

Indian Institute of Technology (IIT) Delhi,

Hauz Khas, New Delhi - 110 016, India.

E-Mail: tanusree@civil.iitd.ac.in.

Associate Professor, Department of Civil Engineering,

Indian Institute of Technology (IIT) Delhi,

Hauz Khas, New Delhi - 110 016, India.

E-Mail: matsagar@civil.iitd.ac.in.

Key words: Blast Loading, Coupled Eulerian-Lagrangian Analysis, Finite Element Method,

Strain Rate, Underground Tunnel.

ABSTRACT

The present work deals with three dimensional nonlinear finite element (FE) analyses of

underground tunnels in soil subjected to internal blast loading. The coupled Eulerian-Lagrangian

(CEL) analysis tool in finite element software Abaqus/Explicit has been used for the analysis

purpose. The soil and reinforced concrete lining has been modeled using the Lagrangian

elements. The explosive TNT has been modeled using the Eulerian elements. The stress-strain

response of soil, concrete and reinforcement has been simulated using strain rate dependent

Drucker-Prager plasticity, concrete damaged plasticity and Johnson-Cook plasticity models,

respectively. The pressure-volume relationship of TNT explosive has been simulated using the

JWL equation-of-state. Parametric sensitivity studies have been performed for different (i) tunnel

lining thicknesses, (ii) charge weights and (iii) friction angles of soil. It is observed from the

results that pressure acting on the tunnel lining increases with the increase in charge weight. Both

the lining and the surrounding soil undergo significant deformation. Deformation of the tunnel

lining decreases with increasing lining thickness. Also, deformation of tunnel lining and soil

decrease with increasing friction angle of soil.

1. INTRODUCTION

Underground tunnels used for roadway and railway, utility lines and water pipelines are

indivisible part of the modern civil infrastructure. In the recent decades, explosion incidents

caused by terrorist activities have proved to be a growing threat to the human civilization and the

civil infrastructure. Internal explosion in a tunnel may lead to multiple reflections of the blast

induced shock wave and thus channeling of the shock wave. Hence, in order to safeguard the

tunnels, it is necessary to understand the response of these structures when subjected to blast.

Experimental determination of the response of underground tunnels under blast loading often

R. Tiwari, T. Chakraborty and V. Matsagar

becomes difficult due to socio-political issues. Thus, advanced numerical analysis of tunnels

subjected to blast loading is of utmost importance.

In the literature, analyses on the effect of blast loading on underground structures have been

carried out by many researchers. Chille et al. (1998) investigated the dynamic response of

underground electric plant subjected to internal explosive loading using three dimensional

numerical analysis methods. For traffic tunnels in rock mass, Choi et al. (2006) performed threedimensional finite element (FE) analyses to study the blast pressure and resulting deformation in

concrete lining. They found that the blast pressure on tunnel lining was not the same as the

normally reflected pressure obtained using CONWEP (Department of the Army, the Navy, and

the Air Force 1990). Lu et al. (2005) and Gui and Chien (2006) used FE procedure to perform

blast analysis of tunnels subjected to external blast loading. Feldgun et al. (2008) used the

variational difference method to analyze underground tunnels and cavities subjected to blast

loads. Subway tunnels under explosive load have been analyzed by Liu (2009) using the FE

method. Explosive load was modeled using CONWEP reflected pressure. The analysis performed

by Liu did not consider the high strain rate behavior of soils under explosive loading. The effect

of blast loading on tunnel considering the high strain rate behavior of soils has been studied in by

Higgins et al. (2012). However, their study considered only elastic stress-strain response of

concrete lining in the tunnel. The explosive was modeled using JWL equation-of-state.

Chakraborty et al. (2013) compared the performance of different shock absorbing foam materials,

steel and concrete tunnel linings under blast loading. The blast load was calculated through a

coupled fluid dynamics simulation in their analyses. However, rigorous three dimensional

simulations of lined underground tunnels in soil with properly simulated explosive load using

JWL equation-of-state is rather unavailable in the literature due to the challenging nature of the

problem.

The specific objectives of the present study are to perform three dimensional (3D) nonlinear

finite element analysis underground tunnel subjected to internal blast loading and to understand

the response of tunnel lining and surrounding soil when subjected to blast loading. The finite

element (FE) analyses have been performed using the commercially available FE software

Abaqus Version 6.11 (Abaqus manual version 6.11). Herein, finite element model of soil and

reinforced concrete (RC) lining of the tunnel have been prepared using the Lagrangian analysis

tool in Abaqus. Soil stress-strain behavior has been modeled using the Drucker-Prager

constitutive model (Liu 2009). The RC lining has been modeled using the concrete damaged

plasticity model (Chakraborty et al. 2013). The steel reinforcement is modelled using the

Johnson-Cook (JC) plasticity (Johnson and Cook 1985) model. In case of blast loading the strain

rate can reach upto 102 to 104 per second (Ngo and Mendis. 2008). Hence, strain rate dependent

stress-strain response have been used for soil, steel and concrete. The TNT explosive and the

surrounding air have been modeled using the Eulerian analysis tool in Abaqus. The pressurevolume relationship of the explosive is simulated using the Jones Wilkens Lee (JWL) (Zukas and

Walters 2003) equation-of-state. Parametric sensitivity studies have been performed by varying

(i) the concrete lining thickness (tw), (ii) the weight of explosive (TNT) used and (iii) the angle of

internal friction of soil (). The analysis results have been studied for stresses and deformation in

soil and tunnel lining and damage of RC lining.

2

THREE DIMENSIONAL FINITE ELEMENT MODELLING

2.1 Lagrangian Finite Element Modelling of Soil and RC Concrete Lining

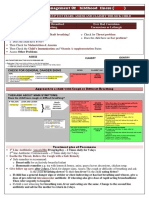

The three dimensional finite element model of the tunnel in soil has been developed using

Abaqus with the Lagrangian analysis option. The FE mesh of the soil, tunnel lining, and

reinforcement are shown in Figures 1(a) to 1(c). A 20 m long tunnel has been modeled in soil

with reinforced concrete lining thickness of 350 mm with the center point of the tunnel at a

minimum depth of 7.5 m from the ground surface. The reinforcement has been modeled with 10

R. Tiwari, T. Chakraborty and V. Matsagar

mm and 12 mm diameter Fe415 bars in longitudinal and hoop reinforcement directions,

respectively. The hoop reinforcement rings are placed at 250 mm center to center spacing. The

longitudinal reinforcement bars are placed at a distance of 850 mm along inner arc. The distance

between inner and outer hoop reinforcement is 120 mm. The 20 m long tunnel is placed in a soil

domain of 20 m long, and 15 m 15 m cross section. The FE models of the soil and RC lining

geometry has been developed using the three dimensional part option in Abaqus/CAE using eight

node reduced integration brick element with hourglass control and finite membrane strains

(C3D8R). Mesh convergence and boundary convergence studies have been performed and higher

mesh density has been used in tunnel lining and soil close to lining. The minimum element size in

tunnel lining is considered 60 mm. The steel reinforcement has been embedded in tunnel lining

and modeled using the two node beam elements (B31). Proper bonding between concrete and

reinforcement bars has been assured by applying embedded region constraints option available in

Abaqus. The bottom plane of the soil domain has been fixed in all Cartesian directions, x, y and z.

The vertical side planes and the front and back side planes of the soil domain and tunnel lining

have been provided with pinned support as detailed in Figure 1 by constraining the normal

displacements perpendicular to the plane (U) and the out-of-plane rotations (UR). The contact

between tunnel lining and soil has been modeled with the general contact option in Abaqus with

hard contact in the normal direction and frictionless contact in the tangential direction.

2.2 Eulerian Finite Element Modelling of Explosive

The explosive material has been modeled using the Eulerian modeling technique in Abaqus.

Figure 1(d) shows a typical FE mesh of explosive. To model Eulerian explosive material and the

surrounding air domain inside the tunnel, Eulerian continuum three dimensional eight node

reduced integration elements (EC3D8R) have been used. The Eulerian and Lagrangian elements

can interact with each other through the general contact defined between explosive, air and tunnel

lining surface. Free outflow boundary condition has been defined at the boundary of air domain,

thus, blast pressure when reaches boundaries of air domain, it propagates freely out of the air

domain without any kind of reflection. A fine mesh of Eulerian elements is necessary to

efficiently capture the propagation of blast wave through air, the surrounding concrete lining and

the soil. Mesh convergence study has been performed in the present study to decide the smallest

element size as 35 mm. The pressure-volume relation of explosive has been simulated using

Jones Wilkens Lee (JWL) equation-of-state. In this model, the pressure (Ps)-volume (v)

relationship can be represented as the sum of functions given by

1

v

(1)

Ps Ae

Be

C

v0

where v0 is the initial specific volume of explosive material. The parameters A, B, C, R1, R2 and

are material constants in which A, B and C have dimensions of pressure and rest of the constants

are dimensionless. In JWL equation of state, the first two exponential terms are high pressure

terms and the last term on the right hand side is a low pressure term which deals with the high

volume of cloud due to explosion. The material properties used herein for JWL has been listed in

Table 1 as obtained from Zukas and Walter (2003) and Abaqus manual version 6.11.

R1V

R 2V

MATERIAL PROPERTIES

3.1 Mateial Properties for Concrete

The concrete in tunnel lining has been modelled as M30 grade (ultimate compressive strength

of 30 MPa) using the concrete damage plasticity model in Abaqus. The yield function in the

concrete damaged plasticity model is given by Lubliner et al. (1989). The elastic properties of

concrete are listed in Table 2. For concrete, modulus of elasticity Es = 27.4 GPa, compressive

strength of concrete fck = 30 MPa, mass density = 2400 kg/m3 and Poissons ratio = 0.2 have

R. Tiwari, T. Chakraborty and V. Matsagar

been considered. Figures 2(a) and 2(b) show the stress-strain curves for M30 concrete in

compression and tension, respectively (Carreira and Chu 1985, 1986). Similarly, Figures 2(c) and

2(d) show the damage-strain curves for M30 concrete in compression and tension, respectively

(Carreira and Chu 1985, 1986). For strain rate dependent material properties, dynamic increase

factors (DIF) of 2.1 and 6 have been used for compressive and tensile stress-strain responses,

respectively at 100/sec strain rate (Bischoff and Perry 1991).

3.2 Material Properties for Steel

The stress-strain behavior of steel reinforcement has been modelled using Johnson-Cook (JC)

model (Johnson and Cook 1985). The Fe 415 grade of steel has been considered for the lining

reinforcement. The elastic material properties of steel are given in Table 2. For steel, modulus of

elasticity Es= 200 GPa, tensile yield strength fy= 415 MPa, mass density = 7800 kg/m3 and

Poissons ratio = 0.3 have been considered. For strain rate dependent modeling as per JC

model, the material constants are obtained from mechanical testing and adopted herein for strain

rate of 100/sec, as, A = 360 MPa, B = 635 MPa, n = 0.114, C = 0.075. These values are computed

based on tensile test data of the material as per the JC model (Goel et al. 2011). The effect of

temperature on JC model has been neglected herein.

3.3 Material Properties of Soil

The soil surrounding the tunnel has been modeled using the Drucker Prager plasticity model.

Here, linear Drucker Prager criteria has been used in the modelling of soil which provides a

noncircular yield surface in the deviatoric plane to match different yield values in triaxial tension

and compression. A non-associated flow rule is considered in the present analysis by considering

the dilatancy angle of sand to be different from the friction angle. The material properties used for

sand are given in Table 3. For sand, modulus of elasticity Esoil = 28 MPa, mass density = 1560

kg/m3, Poissons ratio = 0.2, friction angle = 30 and dilation angle = 5 have been

considered. The strain rate dependent stress-strain response of sand has been obtained from

Veyera and Ross (1995).

4. TYPES OF ANALYSES

The numerical simulations have been performed for two RC lining thicknesses - 350 mm and

550 mm for 50 kg TNT explosive and 30 friction angle of sand. Parametric studies have been

performed for three different charge weights of 25 kg, 50 kg and 100 kg for 350 mm lining

thickness and 30 friction angle of sand. Analyses have also been carried out for three different

angles of friction - 25, 30, 35 for 50 kg charge weight and 350 mm lining thickness. The

analyses have been performed in a single dynamic explicit step. Gravity loading has been applied.

For studying the response of the complete 20 m tunnel section, the duration of analysis is

maintained such that the shock wave can travel through the complete tunnel length. Analysis

duration of 16 msec has been maintained in all simulations.

5. VALIDATION OF FINITE ELEMENT ANALYSIS

To ensure the validity of the numerical simulations, the results of CEL simulation for blast

loading on a concrete slab has been compared with the results where blast loading is simulated

using TM5-1300. A 1.2 m 1.2 m 0.09 m reinforced concrete (RC) slab has been analyzed

numerically using the CEL method. The slab is subjected to a blast loading caused by 1.69 kg

TNT charge weight at three different scaled distance of 0.5, 1.0, 5 m/kg1/3. In CEL, TNT

explosive has been simulated using JWL equation-of-state. The boundaries of the concrete slab

are restrained in three Cartesian directions, e.g., x, y and z. In another analysis, the blast load has

been calculated using TM5-1300 (Departments of the Army and Navy and the Air Force 1990)

and the modified Friedlanders equation (Goel et al. 2012) for the same charge weight and scaled

R. Tiwari, T. Chakraborty and V. Matsagar

distances as mentioned above. Figure 3 shows the comparison of central node displacement

calculated through CEL simulation and the simulation using TM5-1300. It is clearly seen from

the figure that both the results compare with reasonable accuracy.

6. RESULTS AND DISCUSSION OF PARAMETRIC STUDIES

Parametric sensitivity studies of an underground tunnel in soil has been carried out for

different (i) concrete lining thickness (tw), (ii) weight of explosive (TNT) used and (iii) angle of

internal friction of soil mass (). Figure 4 shows the paths in the tunnel along which the results

are extracted. It may be noted that for minimizing the boundary effect only central 10 m path

length has been considered for extracting the results.

6.1 Variation of RC Lining Thickness

Figures 5 (a) and 5(b) show the displacement of reinforced concrete lining along two paths one along tunnel crown and the other along tunnel sidewall, for 350 mm and 550 mm RC lining

thicknesses at 16 msec for 50 kg TNT charge weight. Higher displacement is observed in the 350

mm lining along both tunnel crown and sidewall which may be attributed to higher damage of the

350 mm tunnel lining when subjected to blast loading as compared to the 550 mm tunnel lining.

The displacement is negative at the crown and positive at the side wall which signifies that the

tunnel crown moves downward and the left sidewall moves inward under blast loading. The 550

mm lining exhibits almost 90% lesser displacement as compared to the 350 mm lining. The

deformed shape of the tunnel cross section is inserted in Figure 5(c). Figure 5(c) shows the

displacement time history at the tunnel crown in the lining just above the explosive. For both the

lining thicknesses, displacement along tunnel crown increases with time. Higher displacement is

observed for 350 mm thick lining as compared to the 550 mm thick lining which is reasonable.

Figures 5(d) and 5(e) show the displacement of soil along the crown and the left side wall

surrounding the RC lining. Irregular displacement pattern is observed in soil for 350 mm tunnel

lining due to complete damage of the lining. The 550 mm lining exhibits comparatively lesser

damage which is expected. Figure 5(f) shows the displacement time history of soil at the tunnel

crown. At tunnel crown, soil exhibits almost 40% lesser displacement when 550 mm lining is

used as compared to that for 350 mm lining. Figure 6 shows the displacement at 250 mm inside

soil from the tunnel lining and along a path from tunnel crown. High displacement in soil is

observed even at 250 mm away from the lining. Up to 250 mm, the shock wave pushes tunnel

lining and soil together. However, above 250 mm, the soil moves downward under gravity.

Hence, the displacement is positive for the first 250 mm and then negative.

6.2 Variation of Charge Weights

Figures 7(a) and 7(b) show the displacement response at the tunnel crown and the left side

wall for three different charge weights of 25 kg, 50 kg, 100 kg. Higher displacement is observed

for 100 kg charge weight as compared to 25 kg charge weight which is expected. It may be

however noted that at tunnel crown, 50 kg explosive produces highest displacement whereas at

tunnel sidewall, 100 kg explosive produces the maximum displacement which may be attributed

to irregular damage pattern of the tunnel wall when subjected to blast loading. For 50 kg

explosive, almost 75% higher displacement at tunnel crown is observed as compared to 25 kg

explosive. Figure 7(c) shows displacement time history plot at tunnel crown. The displacement at

the crown increases with increasing time for all charge weights. Figures 7(d) and 7(e) show the

displacement response in soil both at the crown and at the sidewall. In both the cases, higher

displacement is observed for 100 kg charge weight as compared to that for 25 kg charge weight.

However, for 50 kg charge weight, more noise in displacement response is observed. Almost 78%

higher displacement is observed in soil for 50 kg explosive as compared to that for 25 kg

explosive. Figure 7(e) shows displacement time history plot in soil. The displacement in the soil

increases with increasing time for all charge weights.

R. Tiwari, T. Chakraborty and V. Matsagar

6.3 Variation of Soil Friction Angle

Figures 8(a) and 8(b) show the deformation of RC lining for the paths along the tunnel crown

and the left sidewall for three different angle of friction of soil - 25, 30, 35. The results show

clearly that the deformation of the lining decreases with increasing angle of friction. In tunnel

lining, almost 23% and 56% lesser displacement is exhibited for = 35 as compared to that for

= 30 and = 25. Figure 8(c) shows the time history of deformation at the tunnel crown. Here

also, the deformation decreases with increasing friction angle. Thus, sands with higher friction

angle may be used in blast resistant design of tunnels underground. Figures 8(d) and 8(e) show

the deformation in soil. Soil deformation decreases significantly for 30, 35 friction angles as

compared to that for 25 friction angle. In soil, almost 38% and 60% lesser displacement is

exhibited for = 35 as compared to that for = 30 and = 25. Figure 9 shows the displacement

contour in soil for different soil friction angles. Maximum influence zone for displacement is

observed in soil with 25friction angle.

7. CONCLUSIONS

In the present study, three dimensional nonlinear finite element (FE) analyses of underground

tunnels in soil subjected to internal blast loading have been carried out. The coupled EulerianLagrangian (CEL) analysis tool in finite element software Abaqus/Explicit has been used for the

analysis purpose. The explosive TNT has been modeled using the Eulerian elements. The stressstrain response of soil, concrete and reinforcement has been simulated using strain rate dependent

Drucker-Prager plasticity, concrete damaged plasticity and Johnson-Cook plasticity models,

respectively. The pressure-volume relationship of TNT explosive has been simulated using the

JWL equation-of-state. Parametric sensitivity studies have been performed for different (i) tunnel

lining thicknesses, (ii) charge weights and (iii) friction angles of soil. It has been concluded from

the analyses that blast induces damage in tunnel lining decreases with increasing lining thickness.

The 550 mm lining exhibits almost 90% lesser displacement as compared to the 350 mm lining.

Lining and soil displacement increases with increasing charge weight. Almost 78% higher

displacement is exhibited in soil for 50 kg explosive as compared to that for 25 kg explosive. The

displacement in the soil increases with increasing time for all charge weights. Lining and soil

displacement decreases with increasing friction angle of soil. In soil, almost 38% and 60% lesser

displacement is exhibited for = 35 as compared to that for = 30 and = 25.

TABLES

Table 1 JWL material properties for TNT explosive

Density ()

(kg/m3)

1630

Detonation Wave

Speed (V) (m/sec)

6930

A (MPa)

B (MPa)

R1

R2

373800

3747

0.35

4.15

0.9

Detonation Energy

Density (d) (J/kg)

3680000

Table 2 Concrete and steel material properties

Material

Concrete (M30)

Steel (Fe415)

Yield Strength (fy)

(MPa)

30

415

Elastic Modulus

(Ec) (GPa)

27.4

200

Poissons Ratio ()

Strain Rate

0.2

0.3

100/Sec

100/Sec

Table 3 Ottawa sand material properties

Density ()

(kg/m3)

1560

Elastic Modulus

(Esoil)

28 (MPa)

Poissons Ratio

()

0.2

Friction

angle ()

30

Dilation angle

()

5

Strain rate

1000/sec

R. Tiwari, T. Chakraborty and V. Matsagar

FIGURES

20 m

15 m

15 m

Ux = 0, URy = URz = 0

(Both Sides)

Uz = 0, URx = URy = 0

(Front and Back)

Ux = Uy = Uz = 0,

URx = URy = URz = 0

(Bottom)

(a) Tunnel with reinforced concrete lining in soil

Tunnel Crown at Soil Level

Tunnel Crown at Lining Level

Left Side Wall at Soil Level

Left Side Wall at Lining Level

(b) Enlarged mesh with geometrical detailing

RC Lining Thickness tw

120 mm

12 mm diameter

bar @ 250 mm

c/c

18 Nos. 10 mm

diameter bar

(c) Reinforcement details

(d) Explosive inside tunnel

Figure 1: Tunnel geometry and reinforcement details.

R. Tiwari, T. Chakraborty and V. Matsagar

Stress (MPa)

40

Compression

30

1.5

20

1.0

10

0.5

0

0.000

Damage

2.0

0.002

0.0

0.000

0.004

0.8

0.8

0.6

0.6

0.4

0.4

0.2

0.2

0.0

0.000

0.004

Tension

0.008

0.0

0.000

0.002

0.004

0.002

0.004

Strain

Strain

Figure 2: Stress-strain and damage-strain curves for M30 grade of concrete in compression and tension

Central Node Displacement (mm)

(Carreira and Chu 1985, 1986).

Current Simulations

Simulations using TM5-1300

4

0

-4

-4

-8

-8

-12

-12

-16

-20

0

Z = 0.5 m/kg1/3

20

40

60

80

100

120

140

-16

Z = 1.0 m/kg1/3

-20

0

20

40

Central Node Displacement (mm)

Time (msec)

6

60

80

100

120

140

Time (msec)

4

2

0

-2

-4

-6

0

Z = 2.0 m/kg1/3

20

40

60

80

100

120

140

Time (msec)

Figure 3: Comparison of central node displacement time histories for simulations using CEL and TM5-1300.

R. Tiwari, T. Chakraborty and V. Matsagar

Path from Tunnel Crown

(at Soil Level) to Ground

Path Inside Soil

Path Along Tunnel Crown

at RC Lining / Soil Level

Path Along Tunnel Left Side Wall

at RC Lining / Soil Level

(mm)

RC Lining

Displacement in

Displacement

(mm)

Lining(mm)

RCLining

Displacement

inRC

Displacementinin

Figure 4: Paths defined for visualization.

t = 16 msec

00

0

-40

-40

-40

-80

-80

-80

-120

-120

-120

-160

-160

-160

twtww==350mm

350mm

t = 350mm

-200

-200

twwtww==550mm

550mm

-200

tw = 550mm

0 0 22 44 66 88 10

10

0

2

4

6

8

10

50

50

50

40

40

40

30

30

30

20

20

20

10

10

10

00

000

0

120

120

120

80

80

80

80

40

40

40

40

000

0

-40

-40

-40

-40

40

40

40

40

000

0

-40

-40

-40

-40

-80

-80

-80

-80

-120

-120

-120

-120

-80

-80

-80

-80

-120

-120

-120

-120

(mm)

Soil(mm)

DisplacementininSoil

Displacement

Displacement

(mm)

Soil (mm)

in Soil

Displacementin

120

120

120

80

80

80

80

2222

10

4444

6666

8888

10

10

10

Lengthalong

alongCrown

Crown(m)

(m)

Length

Length

along

Crown

(m)

Length along Crown (m)

Displacementinin

in Y

YDirection

Direction

Displacement

Displacement

Direction

Displacement

inYY

Direction

t = 16 msec

22

2

44

4

66

6

88

8

20

20

20

00

0

-20

-20

-20

-40

-40

-40

-60

-60

-60

-80

-80

-80

-100

-100

10

10-10000

10

0

Y

Y X

Y X

X

55

5

10

10

10

15

15

15

100

100

100

80

80

80

60

60

60

60

40

40

40

40

20

20

20

20

000

0

-20

-20

-20

8 10

10 -20

5

10

15

0000

2222

4444

6666

8

000

10

15

10

88

10

0

555

10

15

Lengthalong

alongLeft

LeftSide

SideWall

Wall(m)

(m)

Time(msec)

(sec)

Length

Time

Length

along

Left

Side

Wall

(m)

Time

(sec)

Length along Left Side Wall (m)

Time (sec)

Displacementin

inXX

X Direction

Direction

Displacement at

at Crown

Crown

Displacement

Displacement

Displacement

in

Displacement

Displacement

in

X Direction

Direction

Displacement

at Crown

Figure 5: Displacement of RC lining and soil for different lining thicknesses.

R. Tiwari, T. Chakraborty and V. Matsagar

0

000

tw = 350mm

25

Kg

25Kg

Kg

25

50

Kg

50Kg

Kg

tw = 550mm

50

100

Kg

100Kg

Kg -100

-100

100

-100

-100

Displacement

(mm)

Soil(mm)

inSoil

(mm)

Displacementin

(mm)

Soil

in

Displacement

400

400

400

300

300

300

300

350

350

350

300

300

250

300

250

250

250

200

200

200

200

150

150

150

150

100

100

100

100

-200

-200

-200

-200

200

200

200

-300

-300

-300

-300

100

100

100

50

50

50

50

0000

00

-400

000

-400

-400

-400

0

10

888 10

10

000

1

2222

3333 4444

10

10

10 0000 2222 4444 6666 8

10 0

2222 4444 6666 8888 10

111

Length

along

Crown

(m)

Length

along

Left

Side

Wall

(m)

Length

from

Crown

to

Ground

(m)

Length

along

Crown

(m)

Length

along

Left

Side

Wall

(m)

Length

from

Crown

to

Ground

(m)

Length

along

Crown

(m)

Length

along

Left

Side

Wall

(m)

Length

from

Crown

Ground

(m)

Length along Crown (m)

Length along Left Side Wall (m) Length from Crown toto

Ground

(m)

Displacement

in

Direction

Displacement

in

XXXDirection

Direction

Displacement

ininYY

YYDirection

Direction

Displacement

ininX

Direction

Displacementin

Direction

Displacementin

Direction

Displacement

Displacement

(mm)

Soil(mm)

DisplacementininSoil

(mm)

Soil

Displacement

(mm)

Lining(mm)

RCLining

inRC

Displacementin

Displacement

Figure 6: Displacement in soil 250 mm away from the lining at crown and left side wall for different lining

thicknesses at 16 msec.

t = 16 msec

00

100

100

100

t = 16 msec

20

20

20

75

75

75

0

00

-50

-50

50

50

50

-20

-20

-20

-100

-100

25

25

25

-40

-40

-40

000

-60

-60

-60

-25

-25

-25

-80

-80

-80

-150

-150

-200

-200

-250

-2500

0

25

W=Kg

25 kg

25

Kg

50

W=Kg

50 kg

50

Kg

100

W= Kg

100 kg

100

Kg

22

44

666

888

-50

-50

-50

10

000

10

10

2

22

4

44

6

66

8

88

-100

-100

-100

10

10 0

10

00

120

120

120

60

60

80

80

80

50

50

50

00

40

40

40

25

25

25

000

-120

-120

-40

-40

-40

-180

-180

-240

-240

00

-80

-80

-80

22

44

666

888 10

10

10

Length

(m)

Length along

along Crown

Crown

(m)

Crown (m)

Displacement

in

Y

Direction

Displacement in

in Y

Y Direction

Direction

55

5

10

10

10

1515

15

100

100

100

120

120

-60

-60

75

75

75

0

00

-25

-25

-25

-50

-50

-50

-75

-75

-75

000

2

4

6

8

55

10

1515

10 0

10

22

44

66

88 10

10

00

5

10

15

Length

along

Left

Side

Wall

(m)

Time

(sec)

Length

along

Left

Side

Wall

(m)

Time

(sec)

Length along Left Side Wall (m)

Time (msec)

Displacement

Displacement

atatCrown

Crown

Displacement

ininX

XXDirection

Direction

Displacement

Displacementin

Direction

Displacementat

Crown

Figure 7: Displacement of RC lining and soil for different charge weights.

Displacement in RC Lining (mm)

Displacement in Soil (mm)

Displacement in RC Lining (mm)

Displacement in Soil (mm)

Displacement in RC Lining (mm)

R. Tiwari, T. Chakraborty and V. Matsagar

0

-40

-80

-120

-160

-200

250

50

t = 16 msec

-100

40

-200

30

20

-300

25

0

30

tw0= 350mm

0

-400

tw = 550mm

35

-40

Displacement in Soil (mm)

80

40

0

-40

200

150

-20

-40

100

-40

-80

5050

-60

10

40

-50

0

2 0 4 2 6 4 8 6 10 8 0 10 30

2 04

-80

-160

80

-2000

-80

0

120

tw = 350mm

tw = 550mm

2

80

6

-160

40

0

20

-120

Y

-80

0X

-160

-100

610 8 0 10-20 5 0

-120

160

120

20

t = 16 msec

10

26

48

20

120

100

-40

100

-60

1060

80

50

-80

0

0

0

-60

-40

-120

-80

120

-180

60

-100 0

8

10

0

40

-50

105

1510

15

10

15

20

100

-100

80

0

80

80

-320

-240

-150

-120

-120

60

-20

404 0

48

6 10 8 0 10 40

15

2

62

2 0 4 2 6 4 8 610 8 0 10 5 0

105

1510

Length

along

Crown (m)

Left Side

0 along

0 Length

Length

Crown

(m)

Length along

Leftalong

Side Wall

(m) Wall (m)40 Time (sec)Time (msec)

Displacement

in Y Direction

Displacement

in X DirectionDisplacement

Displacement

Displacement

in Y Direction

Displacement

in X Direction

at Crown at Crown

-40

-40

20

-80

-240

120

Figure 8: Displacement of

-80RC lining and soil for different soil friction angles.

-80

-120

-120

10

Length along Crown (m)

Displacement in Y Direction

= 25

10

Length along Left Side Wall (m)

Displacement in X Direction

= 30

-20

0

10

15

Time (sec)

Displacement at Crown

= 35

Figure 9: Deformation contour in soil for different friction angles at 15 msec, for 50 kg charge weight and 350

mm lining thickness.

R. Tiwari, T. Chakraborty and V. Matsagar

REFERENCES

[1] Abaqus/Standard Users Manual, Version 6.11. Dassault Systmes Simulia Corporation,

Providence, Rhode Island, USA.

[2] Bischoff, P. H. and Perry, S. H. Compressive behaviour of concrete at high strain rates.

Materials and Structures, Materiaux et Constructions (1991) 24:425-450.

[3] Carreira, D. J. and Chu, K. Stress strain relationship for plain concrete in compression. ACI

Journal, November-December (1985) 82-72:797-804.

[4] Carreira, D. J. and Chu, K. Stress strain relationship for reinforced concrete in tension. ACI

Journal, January-Febuary (1986) 83-3:21-28.

[5] Chakraborty, T., Larcher, M. and Gebbeken, N. Comparative performance of tunnel lining

materials under blast loading. 3rd International Conference on Computational Methods in

Tunnelling and Subsurface Engineering, Ruhr University Bochum (2013).

[6] Chille, F., Sala, A. and Casadei, F. Containment of blast phenomena in underground

electrical power plants. Advances in Engineering Software (1998) 29:7-12.

[7] Choi, S., Wang, J., Munfakh, G. and Dwyre, E. 3D nonlinear blast model analysis for

underground structures. GeoCongress 2006 ASCE (2006):1-6.

[8] Du, H. and Li, Z. Numerical analysis of dynamic behaviour of rc slabs under blast loading.

Trans. Tianjin University (2009) 15:061-064.

[9] Feldgun, V. R., Kochetkov, A. V., Karinski, Y. S. and Yankelevsky, D. Z. Internal blast

loading in a buried lined tunnel. International Journal of Impact Engineering (2008)

35:172-183.

[10] Goel, M. D., Matsagar, V. A. and Gupta, A. K. Dynamic response of stiffened plates under

air blast. International Journal of Protective Structures (2011) 2:139-155.

[11] Goel, M. D., Matsagar, V. A., Gupta, A. K. and Marburg, S. An abridged review of blast

wave parameters. Defence Science Journal (2012) 62:300-306.

[12] Gui, M.W. and Chien, M. C. Blast resistant analysis for a tunnel passing beneath Taipei

Shongsan airport - a parametric study. Geotechnical and Geological Engineering (2006)

24:227-248.

[13] Higgins, W., Chakraborty, T. and Basu, D. A high strain-rate constitutive model for sand

and its application in finite element analysis of tunnels subjected to blast. International

Journal for Numerical and Analytical Methods in Geomechanics (2012) 37:2590-2610.

[14] Johnson, G. R., and Cook, W. H. A constitutive model and data for metals subjected to

large strains, high strain rates and high temperatures. Proceedings of 7th International

Symposium on Ballistics Hague, Netherlands (1983) 541-547.

[15] Liu, H. Dynamic analysis of subway structures under blast loading. Geotechnical and

Geological Engineering (2009) 27:699-711.

[16] Lu, Y. Underground blast induced ground shock and its modelling using artificial neural

network. Computers and Geotechnics (2005) 32:164-178.

[17] Lubliner, J., Oliver, J., Oller, S. and Onate, E. A plastic damage model for concrete.

International Journal of Solids and Structures (1989) 25:299-329.

[18] Ngo, T. and Mendis, P. P. Modelling reinforced concrete structures subjected to impulsive

loading using concrete lattice model. Electronic Journal of Structural Engineering (2008)

8:80-89.

[19] TM5-1300 Structures to resist the effects of accidental explosions. US Departments of the

Army and Navy and the Air Force (1990).

[20] Veyera, G. E. and Ross, C. A. High strain rate testing of unsaturated sands using a splithopkinson pressure bar. 3rd International Conference on Recent Advances in Geotechnical

Earthquake Engineering and Soil Dynamics (1995) 1.11.

[21] Zukas, J. A. and Walters, W. P. Explosive effects and applications. Springer-Verlag New

York, 1998 (2003).

You might also like

- Syllabus - Found of Leadership - Young India Fellowship - Jaggard July 14 2018-Revised-CompressedDocument53 pagesSyllabus - Found of Leadership - Young India Fellowship - Jaggard July 14 2018-Revised-Compressedjainskj16No ratings yet

- Case Analysis - The Team That Wasn't 19 July 2018Document4 pagesCase Analysis - The Team That Wasn't 19 July 2018jainskj16No ratings yet

- Manmohan Dass GoelDocument1 pageManmohan Dass Goeljainskj16No ratings yet

- Counselling DTUDocument5 pagesCounselling DTUjainskj16No ratings yet

- Enrolment Form: Admission No.Document2 pagesEnrolment Form: Admission No.jainskj16No ratings yet

- International Tennis FederationDocument148 pagesInternational Tennis Federationjainskj16No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Boundary ScanDocument61 pagesBoundary ScanGéza HorváthNo ratings yet

- Astm D974-97Document7 pagesAstm D974-97QcHeNo ratings yet

- Industrial Revolution OutlineDocument8 pagesIndustrial Revolution OutlineGeraldine GuarinNo ratings yet

- Pelton2014 Para-Equilibrium Phase DiagramsDocument7 pagesPelton2014 Para-Equilibrium Phase DiagramsAbraham Becerra AranedaNo ratings yet

- Rumah Cerdas Bahasa Inggris Belajar Bahasa Inggris Dari Nol 4 Minggu Langsung BisaDocument3 pagesRumah Cerdas Bahasa Inggris Belajar Bahasa Inggris Dari Nol 4 Minggu Langsung BisaArditya CitraNo ratings yet

- Certificate of No Damages in EarthquakeDocument5 pagesCertificate of No Damages in EarthquakeLemlem BardoquilloNo ratings yet

- Muharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFDocument154 pagesMuharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFjeff tehNo ratings yet

- Introduction To Kalman FilterDocument4 pagesIntroduction To Kalman FilterArghya MukherjeeNo ratings yet

- AIC - AirROCT35 - Spare Parts ManualDocument153 pagesAIC - AirROCT35 - Spare Parts ManualMuhammad Arqam Al Ajam67% (3)

- Buckthorpe Etal 23 Optimising Early Stage ACL Rehab ProcessDocument24 pagesBuckthorpe Etal 23 Optimising Early Stage ACL Rehab ProcessCole VincentNo ratings yet

- Strange Christmas TraditionsDocument2 pagesStrange Christmas TraditionsZsofia ZsofiaNo ratings yet

- Product Specifications: MB3F-PSA4-19DEDocument2 pagesProduct Specifications: MB3F-PSA4-19DEВадим ЧеховскийNo ratings yet

- Bahasa Inggris PATDocument10 pagesBahasa Inggris PATNilla SumbuasihNo ratings yet

- مستر رمضان عوضDocument24 pagesمستر رمضان عوضSamuel SaadNo ratings yet

- Unit 3 InfiltrationDocument5 pagesUnit 3 InfiltrationHRIDYA MGNo ratings yet

- SweetenersDocument23 pagesSweetenersNur AfifahNo ratings yet

- 基礎居合講座Document33 pages基礎居合講座任平生100% (1)

- A Collection of Ideas For The Chemistry Classroom by Jeff HepburnDocument14 pagesA Collection of Ideas For The Chemistry Classroom by Jeff HepburnPaul SchumannNo ratings yet

- IMCI UpdatedDocument5 pagesIMCI UpdatedMalak RagehNo ratings yet

- Activity - Alien DNA - CompleteDocument36 pagesActivity - Alien DNA - CompleteJennifer ShawkiNo ratings yet

- Notice - Appeal Process List of Appeal Panel (Final 12.1.24)Document13 pagesNotice - Appeal Process List of Appeal Panel (Final 12.1.24)FyBerri InkNo ratings yet

- FP Lecture Midterm Exam Sec - Sem.2020Document4 pagesFP Lecture Midterm Exam Sec - Sem.2020SAEEDA ALMUQAHWINo ratings yet

- 1.1 Introduction To KennametalDocument40 pages1.1 Introduction To KennametalVig PankajNo ratings yet

- Digital ElectronicsDocument18 pagesDigital ElectronicsHarry BeggyNo ratings yet

- Water Reuse RoundtableDocument10 pagesWater Reuse RoundtableajiiithNo ratings yet

- Fo Transfer ProcedureDocument8 pagesFo Transfer ProcedureadityasahayNo ratings yet

- The Field-Effect Transistor - August 1972 Popular ElectronicsDocument5 pagesThe Field-Effect Transistor - August 1972 Popular Electronicsmac9papNo ratings yet

- ADC ManualDocument47 pagesADC ManualRavi ShuklaNo ratings yet

- Third Quarter Pre-Test Mathematics 7 Directions: RDocument4 pagesThird Quarter Pre-Test Mathematics 7 Directions: RAhron RivasNo ratings yet

- Oasis AirlineDocument5 pagesOasis AirlineRd Indra AdikaNo ratings yet