Professional Documents

Culture Documents

Elliptical Head Design Tool: Pressure Vessel Engineering LTD

Elliptical Head Design Tool: Pressure Vessel Engineering LTD

Uploaded by

Exsan Othman0 ratings0% found this document useful (0 votes)

13 views1 pagehead

Original Title

Elliptical Head

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthead

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTD

Elliptical Head Design Tool: Pressure Vessel Engineering LTD

Uploaded by

Exsan Othmanhead

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

1

Pressure Vessel Engineering Ltd.

Finite Element Analysis ASME Code Calculations

Canadian Vessel Registration Vessel Modeling and Drafting

3

4

5

6

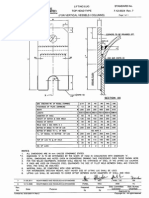

Elliptical Head Design Tool ver E4.01

8

9

10

11

12

13

14

15

16

Dimensions:

24.000

0.188

0.159

0.010

2.000

Do [in] - outside diameter of head

tb [in] - thickness before forming

tf [in] - thickness after forming (note 1)

Corr [in] - corrosion allowance

Skirt [in] - straight skirt length

Material and Conditions:

SA-240 304 Material

20,000 S [psi] - allowable stress

1.00 E - head longitudinal efficiency

50.0 P [psi] - interior pressure

17

18

21

Calculated Properties:

note 1: Suggested thickness after forming

0.125 in

22

Variables:

19

20

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Page 1 of 1

Elliptical Head Description

nt [in] =

D [in] =

h [in] =

ho [in] =

D/2h =

Do/2ho =

Ro [in]=

Approx. head weight based on steel, lbs = 43.56

Approx. head volume including skirt, cuft = 1.52

tf-Corr ~~ thickness with corrosion allowance removed

Do-2*nt ~~ ID with corrosion allowance removed

D/4 ~~ inside crown height

h+nt

D/(2*h)

Do/(2*ho)

Kzero*Do

0.159-0.01 =

24-2*0.149 =

23.701/4 =

5.925+0.149 =

23.701/(2*5.925) =

24/(2*6.075) =

0.889*24 =

0.149

23.701

5.925

6.075

2.000

1.975

21.334

Required Thickness: App. 1-4(c), UG-37(a)(1)

App1-4(f) = tf/(Kone*D)

0.159/(0.9*23.701) = 0.0075

App1-4(f)Calc = if(AND(0.0005=<App1-4(f),App1-4(f)<0.002),"Calculation Required","Calculation not requi

App. 1-4(f) Calculation Not Required

Treq [in] = (P*D*K)/(2*S*E-0.2*P)+Corr ~~ required minimum thickness

(50*23.701*1)/(2*20000*1-0.2*50)+0.01 = 0.040

CheckTreq = Treq<=tf

0.04<=0.159 = Acceptable

Maximum Pressure: App. 1-4(c), UG-37(a)(1)

Pmax [psi] = (2*S*E*nt)/(K*D+0.2*nt) ~~ maximum allowed design pressure

(2*20000*1*0.149)/(1*23.701+0.2*0.149) = 251.8

CheckPMax = Pmax >= P

251.8 >= 50 = Acceptable

App. 1-4(f) calculation is not included on this sheet

The UG-16(b) minimum thickness requirement has not been taken into consideration here.

Nozzles may be subject to a smaller required thickness depending on location in the head.

Only the knuckle required thickness is calculated on this sheet

Heads may be subject to stress relief if large elongation occurs - UCS-79(d), UNF-79(d), UHA-44(d)

Use the Weld Efficiency program to calculate E

This sheet cannot be used to check for allowable exterior pressure loads.

This sheet is for educational use only - use at your own risk.

Pressure Vessel Engineering Ltd.

120 Randall Drive, Suite B

Waterloo, Ontario, Canada, N2V 1C6

www.pveng.com (519) 880-9808

You might also like

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNo ratings yet

- F&D Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolnaveen_86No ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolJaveed KhanNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaNo ratings yet

- B36.19M 1985 Stainless Steel Pipe PDFDocument13 pagesB36.19M 1985 Stainless Steel Pipe PDFMadidj_2014No ratings yet

- Pipe&Shell Design Tool 600KLDocument1 pagePipe&Shell Design Tool 600KLJoshua Rivera100% (1)

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- Asme BPVC II Part D Material Strengths 01Document7 pagesAsme BPVC II Part D Material Strengths 01bakellyNo ratings yet

- Calculation of Safety Factor Guarding Against Joint OpeningDocument12 pagesCalculation of Safety Factor Guarding Against Joint OpeningPandiyarajan RajuNo ratings yet

- Is 4049 Part 1Document7 pagesIs 4049 Part 1Otavio123No ratings yet

- Api 610Document3 pagesApi 610rajkmuarNo ratings yet

- 7-12-0024 Rev 7Document1 page7-12-0024 Rev 7cynideNo ratings yet

- Pressure Drop Calculation For Rect. DuctsDocument2 pagesPressure Drop Calculation For Rect. Ductsmahmutovicm3488No ratings yet

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 pagesASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNo ratings yet

- Design of Flanges - Welded-On Integral Type 2010Document59 pagesDesign of Flanges - Welded-On Integral Type 2010bakellyNo ratings yet

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 pageBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNo ratings yet

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIDocument5 pagesReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiNo ratings yet

- Copiar de ReinforcementAreaDocument6 pagesCopiar de ReinforcementArealavascudoNo ratings yet

- Roark's - Discontinuity Stress at Junction of Shell & HeadDocument13 pagesRoark's - Discontinuity Stress at Junction of Shell & HeadRey FiedacanNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- 3.3development and Scope of Asme CodeDocument1 page3.3development and Scope of Asme CodeArunraj PoikayilNo ratings yet

- 3 Saddle SupportsDocument15 pages3 Saddle Supportswasif78100% (1)

- Flow Over WeirDocument7 pagesFlow Over WeirShamiraNo ratings yet

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- 2WallTank NFPA ULDocument1 page2WallTank NFPA ULPolo VarsanNo ratings yet

- PV Enineering EHX - OutDocument144 pagesPV Enineering EHX - Out9913489806No ratings yet

- External Pressure - Pressure Vessel EngineeringDocument15 pagesExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- Nozzle Thermal Movement and Evaluation Sheet For VesselDocument27 pagesNozzle Thermal Movement and Evaluation Sheet For VesselJ A S JASNo ratings yet

- Pressure Drop in BendDocument5 pagesPressure Drop in BendfitratulqadriNo ratings yet

- Flange Asmeviii Div.1 App.2 Rev0Document10 pagesFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- VEFV1100 - Vessel S&T Heat Exchanger Standard DetailsDocument39 pagesVEFV1100 - Vessel S&T Heat Exchanger Standard DetailsYogi YuganNo ratings yet

- FPSO - Automating Structural DeflectionsDocument10 pagesFPSO - Automating Structural DeflectionsJP EDSNo ratings yet

- Example Sizing Ows Calculation Per API 421Document1 pageExample Sizing Ows Calculation Per API 421reninbabaskiNo ratings yet

- Sa516 70Document3 pagesSa516 70Thinh ViproNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- Blank Thickness CalculatorDocument1 pageBlank Thickness CalculatorNopparutNo ratings yet

- Pipeline Mechanical DesignDocument6 pagesPipeline Mechanical DesignArun Ramu100% (1)

- 50 BBL Surge Tank Design CalculationDocument22 pages50 BBL Surge Tank Design CalculationLaskar Pejuang100% (1)

- 7-12-0005 Rev6 (Skirt Opening Details)Document2 pages7-12-0005 Rev6 (Skirt Opening Details)sumit kumar100% (1)

- Saddle Supports (For Horizontal Tanks) VB-1075: Fiberglass Tanks & Process Vessels StandardsDocument1 pageSaddle Supports (For Horizontal Tanks) VB-1075: Fiberglass Tanks & Process Vessels Standardsxaaabbb_550464353No ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakelly0% (1)

- Asme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)Document2 pagesAsme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)anu radhaNo ratings yet

- FRP PipingDocument19 pagesFRP PipingprocesspipingdesignNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- Trun CalcDocument215 pagesTrun CalcmohamedeliasNo ratings yet

- 299 Elliptical Head Design Tool Ver E4 01Document1 page299 Elliptical Head Design Tool Ver E4 01Noman Abu-FarhaNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Elliptical Head DesignDocument1 pageElliptical Head Designrodriguez.gaytanNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolbai tap hoa vo coNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolnaveen_86No ratings yet