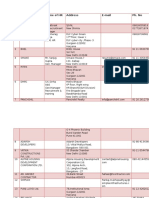

Professional Documents

Culture Documents

BC Masonary WRK

BC Masonary WRK

Uploaded by

AnjalySinha0 ratings0% found this document useful (0 votes)

149 views70 pagesxyz

Original Title

Bc Masonary Wrk

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentxyz

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

149 views70 pagesBC Masonary WRK

BC Masonary WRK

Uploaded by

AnjalySinhaxyz

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF or read online from Scribd

You are on page 1of 70

6]

Masonry-2 :

Brick Masonry

6.1. INTRODUCTION

Brick masonry is made of brick units bonded together with

mortar, Two essential components of brick masonry are therefore :

(Bricks

(i). Mortar

The mortar used for brick masonry should have the same

characteristics as discussed in Chapter 5 for stone masonry. Mortar

acts as a cementing material and unites the individual brick units

together to act as a homogeneous mass. Following types of mortar

may be used. in brick masonry :

1. Cement mortar

2. Lime mortar

3. Cement-lime mortar

4. Lime-surkhi mortar and

5. Mud mortar

Mud mortar is used only for low-rise buildings which carry

light loads. Cement mortars are used for high-rise buildings, where

strength is of prime importance. Lime mortar and lime-surkhi mortars

are used for all types of construction.

Bricks are manufactured by moulding clay in rectangular blocks

of uniform predetermined size, drying them and then burning them

in a kiln. Clay is a plastic earth, constituted largely of sand and

alumina with traces of chalk, iron, manganese, dioxide etc, Good

bricks should be thoroughly burnt so that they become hard and

durable. Satisfactory burning of bricks is ascertained by a hard ringing

sound emitted when two bricks are struck together. The bricks should

be free from cracks, chips, and large particles of lime.

The strength of brick masonry chiefly depends upon: () quality

)

a BUILDING CONSTRUCTION

(i) Second class bricks. Second class bricks also conform 10

the standard size, but they are slightly, irregular in shape and colour.

They are also fully burnt, and ringing sound is emitted when two

bricks are struck together. When immersed in water for one hour,

they do not absorb water more than one-fourth of their weight.

(iid) Third class bricks. Tnese are the one which are quite

irregular in their size, shape and finish, They are not burnt fully,

due to which they arc of reddish-yellow colour. These bricks have

Jow crushing strength. They are not used for quality brick-masonry.

Moulded bricks. Moulded bricks are those which are manufac-

tured in special shapes and sizes to be used for giving architectural

shapes. Such bricks are used for copings, cornices, string courses,

sloping walls etc. Fig. 6.1 shows some commonly used specially-shaped

bricks.

63. SOME DEFINITIONS

1, Stretcher. A stretcher is the longer face of the brick (ce.

19cm x 9cm) as seen in the elevation of the wall. A course of

bricks in which all the bricks are laid as stretchers on facing is

known as a stretcher course or stretching course.

2. Header. A header is the shorter face of the brick (ie.

9cm x 9em) as seen in the elevation of the wall. A course of bricks

in which all the bricks are laid as headers on the facing is known

as header course ot heading course.

3. Lap. Lap is the horizontal distance between the vertical

joints of successive brick courses.

es

as

Biles

= L_1

aa sing

=

‘Quoin Verticar ‘Siretcher

‘Closer solar Course

FIG. 62. ELEVATION OF A BRICK WALL.

MASONRY—2: BRICK MASONRY ms

4. Perpend. A perpend is an imaginary vertical line which

includes the vertical joint separating two adjoining. bricks.

5. Bed. Bed is the lower surface (19cm x 9 cm) of the brick

when laid flat.

6. Closer. It isa portion of a brick with the cut made longitudinally,

and is used to close up bond at the end of the course. A closer

helps in preventing the joints of successive sources (higher or lower)

to come in a vertical line. Closers may be of various types, defined

below.

7. Queen-closer. It is a portion of a brick obtained by cutting

a brick lengthwise into two portions (Fig. 6.3 6). Thus, a queen-

closer is a brick which is half as wide as the full brick. This is

also known as queen-closer-half.

When a queen-closer is broken into two pieces, it is known

as queen-closer-quarter. Such a closer is thus a brick piece which

is one-quarter of the brick size (Fig. 6.3 c).

fo) Ful (b) Queen-Ctoser

Brick (ait)

Le Se

{d) King Closer (ec) Bevelled Closer Closer

(9) Holt Bot (h) Three’ Quarter Bat (1) Bevelled Bat

FIG. 63. VARIOUS FORMS OF BRICK PORTIONS.

26 BUILDING CONSTRUCTION

8. King closer. It is the portion of a brick which is so cut

that the width of one its end is half that of a full brick, while

the width at the other end is equal to the full width (Fig. 6.3 d).

It is thus obtained by cutting the triangular piece between the centre

of one end and the centre of the other ay) side. It has half-header

and half-stretcher face.

9. Bevelled closer. It is a special form of a king closer in

which the whole length of the brick (ce.. stretcher face) is bevelled

in such a way that half width is maintained at one end and full

width is maintained at the other end (Fig: 6.3 e).

10. Mitred closer. It is a portion of a brick whose one end

is cut splayed or mitred for full width. The angle of splay may vary

from 45° to 60°. Thus, one longer face of the mitred closer is of

full length of the brick while the other longer face is smaller in

length (Fig. 6.3 f).

LL. Bat. It is the portion of the brick cut across the width:

Thus, a bat is smaller in length than the full brick. If the length

of the bat is equal to half the length of the original brick, it is

known as half bat (Fig. 6.3 g). A three-quarter-bat (Fig. 6.3 h) is

the one having its length equal to three-quarters of the length of

a full brick. If a bat has its width bevelled, it is known is bevelled

bat (Fig. 63 i).

12, Arris. It is the edge of a brick.

13. “Bull nose. It is a special moulded brick with one edge

rounded (single bull nose, Fig. 6.1 a) or with two edges rounded

(double bull nose, Fig. 6.1 b). These are used in copings or in such

Positions where rounded comers are preferred to sharp arises.

14. Splays. These are special moulded bricks which are often

used to form plinth. Splay stretcher (plinth stretcher) and splay header

(plintt’ header) are shown in Fig. 6.1 (j) and (&) respectively.

15. Dogleg or angle. It is also special form of moulded bricks

(Fig. 6.1 1) which are used to ensure a satisfactory bond at quoins

which are at an angle other than right angle. The angle and lengths

of the faces f sming the dogleg vary according to requirements. These

are preferred “9 mitred closer.

It is a comer or the external angle on the face

Generally, quoins are at right angles. But in some

cases, they m be at angles greater than 90° also.

17, Fro, :r kick, A frog is an indentation in the face of

a brick to form + key for holding the mortar. When frog is only

on one face, tha! brick is laid With that face on the top. Sometimes,

frogs are provided on both the faces. However, no frogs are provided

in wire-cut bricks. A pressed brick has two frogs (as a rule) and

a hand-made brick has only one frog.

MASONRY—2: BRICK MASONRY ur

18, Racking back. It is the termination of a wall in a stepped

fashion, as shown in Fig. 6.2,

19, Toothing. It is the termination of the wall in such a

fashion that each alternate course at the end projects, in order to

provide adequate bond if the wall is continued horizontally at a

later stage (Fig. 6.2).

6.4, BONDS IN BRICK WORK

Bond is the interlacement of bricks, formed when they lay

(or project beyond) those immediately below or above them. It is

the method of arranging the bricks in courses so that individual

units are tied together and the vertical joints of the successive courses

do not lie in same vertical line. Bond of various types are distinguished

by their elevation or face appearance. Bricks used in masonry are

all of uniform size. If they are not arranged (or bonded ) properly,

continuous vertical joints will result. An unbonded wall, with its con-

tinuous vertical joints has little strength and stability. Bonds help

in distributing the concentrated loads over a larger area. Since bricks

are small units, having uniform dimensions, the process of bonding

is easily performed.

Rules for bonding

For getting good bond, the following rules should be observed:

1, The bricks should be of uniform size. The length of the

brick should be twice its width plus one joint, so that uniform lap

is obtained. Good bond is not possible if lap is non-uniform.

2. The amount of lap should be minimem 1 brick along the

length of the wall and i brick across the thickness of the wall.

3. Use of brick bats should be discouraged, except in special

locations,

4. In alternate courses, the centre line of header should coincide

with the centre line of the stretcher, in the course below or above

it.

5. The vertical joints in the alternate courses should be along

the same perpend.

6. The stretchers should be used only in the facing; they should

not be used in the hearting. Hearting should be done in headers

only.

7. It is preferable to provide every sixth course as a header

course on both the sides of the wall.

Types of bonds.

Following are the types of bonds provided in brick work :

1. Stretcher bond.

2. Header bond.

248 BUILDING CONSTRUCTION

English bond.

Flemish bond.

Facing bond.

English cross bond.

Brick on edge bond.

Dutch bond.

Raking bond.

Zigzag, bond.

|. Garden wall bond.

6.5, STRETCHER BOND

‘Stretcher-bond or stretching bond is the one in which all the

bricks are laid as stretchers on the faces of walls. The length of

the bricks are thus along the direction of the wall. This pattern

is used only for those walls which have thickness of half brick (ie.

9 cm). Such as those used as partition walls, sleeper walls, division

walls or chimney stacks. The bond is not possible if the thickness

of the wall is more.

PREIAVEA YS

ES

K

(a) Isometric View (>) Elevation

fe) Plan (4) Plan

FIG. 6.4, STRETCHER BOND.

46. HEADER BOND

Header bond or heading bond is the one in which alt the bricks

are laid as headers on the faces of walls. The width: of the brick

are thus along the direction of the wall. The pattein is. used only

when the thickness of the wall is equal to one’brick (ie.. 18 cm).

The overlap is usually kept equal to ‘half-the.width of brick (te.

MASONRY—2:: BRICK MASONRY 0

44 cm). This is achieved by using three-quarter brick bats in each

alternate courses as quoins. This bond does not have strength to

transmit pressure in the direction of the length of the wall. As such,

it is unsuitable for load bearing walls. However, the bond is specially

useful for curved brick work where the stretchers, if used, would

(2) Elevation

1,3,6 -7- Courses

(@) Pion

FIG. 65. HEADER BOND

project beyond the face of the wall and would necessitate inconvenient

cutting, This is also used in construction of footings.

6.7. ENGLISH BOND

This is the most commonly used bond, for all wall thicknesses.

‘This bond is considered to be the strongest. The bond consists of

akernate courses of headers and stretchers. In this bond, the vertical

joints of the header courses come over each other; similarly, the

= nusan recs

S = STRETCHER ; H = HEADER ; Q = QUEEN CLOSER

FIG. 64. ENGLISH BOND.

250 BUILDING CONSTRUCTION

vertical joints of the stretcher courses also come over cach other.

In order to break the vertical joints in the successive courses, it

is essential to place queen closer after the first header (quoin header)

Meoser

| course a frstetcner course

i

stretener ysens ciesar

HI Peourse S| ft Header Course

oo

6 --- Courses

We) Plan fori Brick Taek Wet

a fe

co

7H

+ fa] f(a fs

Courses 2.4,

(e), Plon for 2-Brlck Thick Wall

co mesg

= Courses

we

H

e

3

‘5, 8-—-Courses

(2) Plan tor 24 Brick Thiek Wat

S = STRETCHER FACING ; H = HEADER FACING ; Q = QUEENS CLOSER ;

By = QUARTER BAT ( QUARTER QUEEN'S CLOSER )

FIG. 67. ENGLISH BOND

250 BUILDING CONSTRUCTION

vertical joints of the stretcher courses also come over each other.

In order to break the vertical joints in the successive courses, it

ial to place queen closer after the first header (quoin header)

Le nace

Course: s| [7 Stretener Course

a Stretcher }Queens Closer (Q)

HO] Fcourse: IS If! Freccer course

q| T—

5 1 ewe

4 Briek Thick Well

Fy

2.

sts

1,357" Courses 2.4

(bd Plan tor

‘Cour

Brick Thick Walt

7

w

e

nH] [a

1s [sts

2 43,8---Coursee

(e), Plon for 2-Brlck Thiek Wall

=

1,3,9-~courses

(a) Plon tor 24 Brick Thick Wat

‘$= STRETCHER FACING ; H = HEADER FACING ; Q = QUEENS CLOSER ;

By = QUARTER BAT ( QUARTER QUEEN'S CLOSER )

FIG. 67. ENGLISH BOND

MASONRY—2: BRICK MASONRY 251

“Courses,

0) Pten tor 1b.

fo) Pion tor td

(b) Phen for 2—

sis

|

|

raul

2,4,6--- Courses

(€) Plan for 3 Brick Thick Welt

S = STRETCHER FACING ; H = HEADER FACING ; © = QUEENS CLOSER

i 1 3,

By = BAT; Ba= BAT; By = ZBAT

FIG. 68. ENGLISH BOND.

( ALTERNATIVE ARRANGEMENTS )

282 BUILDING CONSTRUCTION

in each heading course. Also, only headers are used for the hearting

of thicker walls. Fig. 6.6 shows the general elevation of the English

bond. Fig. 6.7 and 6.8 shows English bonds for walls of various

thicknesses.

Essential Features. Following are the essential features of

English bond.

1. Alternative courses will show either headers or stretchers

in elevation,

2. Every alternate header comes centrally over the joint between

two stretchers in course below.

3. In the stretcher course, the stretchers have a min. lap of

ih their length over headers.

4. There is no continuous vertical joint.

5. Walls of even multiple of half bricks (e. 15 brick thick

wall, 2-bricks thick wall, 3-bricks thick wall) present the same ap-

pearance on both faces. Thus a course showing stretchers on the

front face will also show stretchers on the back face.

6, Wall of odd multiple of half bricks (Je 15 brick thick

wall, 2} brick thick wall etc.) will show stretchers on one face and

headers off the other face.

7. The hearting (middle portion) of each of the thicker walls

consists entirely of headers.

8. At least every alternate transverse joint is continuous from

face to face,

9. A header course should never start with queen's closer,

as it will get displaced. The queen's closer should be placed just

next to the quoin header. Queen’s closers are not required in stretcher

courses.

10. Since the number of vertical joints in the header course

are twice the number of vertical joints in the stretcher course, the

joint in the header course are made thinner than the joints in the

stretcher course.

68. FLEMISH BOND

In this type of bond, each course is comprised of alternate

headers and stretchers. Every alternate course starts with a header

at the corner (ie. quoin header).. Quoin closers are placed next

to the quoin header in alternate courses to develop the face lap.

‘Every header is centrally supported over the stretcher below it.

Flemish bonds: are of two types :

(Q Double flemish bond

(@) Single femish bond.

MASONRY—2: BRICK MASONRY 253

1. Double flemish bond

In the double flemish bond, each course presents the same

appearance both in the front face as well as in the back face. Alternate

headers and stretcher are each course. Because of this, double

flemish bond presents better appearance than English bond. Fig.

69 shows the general elevation of flemish bond, for all the wall

thicknesses. Fig.6.10 shows the double flemish bond in plan, for

walls of various thicknesses.

rz

3|

Peale lolz

a a

MTS Ta s RLS ATs

FIG. 69. FLEMISH BOND (ELEVATION).

Special features of double flemish bond

1, Every course consists of headers and stretchers placed al-

ternately.

2. The facing and backing of the wall, in each course, have

the same appearance.

3. Quoin closers are used next to quoin headers in every alternate

course.

4. In walls having thickness equal to odd multiple of half

bricks, half bats and three-quarter bats are amply used.

5. For walls having thickness equal to even multiple of half

bricks, no bats are required. A header or stretcher will come out

as header or stretcher on the same course in front as well as back

faces.

2. Single flemish bond

Single flemish bond is comprised of double flemish bond facing

and English bond backing aid hearting in each course. This bond

thus uses the strength of the English bond and appearance of flemish

bond. However, this bond can be used for those walls having thickness

at least equal to 14 brick. Double flemish bond facing is done with

good quality expensive bricks. However, cheaper bricks can be used

for backing and hearting.

MASONRY—2: BRICK MASONRY 253

1. Double flemish bond

In the double flemish bond, each course presents the same

appearance both in the front face as well as in the back face. Alternate

‘headers and stretcher are laid in cach course. Because of this, double

flemish bond presemts better appearance than English bond. Fig.

6.9 shows the general elevation of flemish bond, for all the wall

thicknesses. Fig.6.10 shows the double flemish bond in plan, for

walls of various thicknesses.

FIG. 69. FLEMISH BOND (ELEVATION).

Special features of double flemish bond

1. Every course consists of headers and stretchers placed al-

ternately.

2. The facing and backing of the wall, in each course, have

the same appearance.

3. Quoin closers are used next to quoin headers in every alternate

course.

4. In walls having thickness equal to odd multiple of half

bricks, half bats and three-quarter bats are amply used.

5. For walls having thickness equal to even multiple of half

bricks, no bats are required. A header or stretcher will come out

as header or stretcher on the same course in front as well as back

faces.

2. Single flemish bond

Single flemish bond is comprised of double flemish bond facing

and English bond backing ad hearting in each course. This bond

thus uses the strength of the English bond and appearance of flemish

bond. However, this bond can be used for those walls having thickness

at least equal to 15 brick. Double flemish bond facing is done with

good quality expensive bricks. However, cheaper bricks can be used

for backing and hearting.

BUILDING CONSTRUCTION

3,8 Courase,

2,4,6-~ Courses,

(0) Plan for one Brick Thick Wait

8s.

3] Te

83 1,3,5-~Coorses 2,4,6--- Courses

(0) Plan tr tore Tee wou

fe) Pion for 2 Briex Thick Well

‘S = STRETCHER ; H = HEADER ; Q = QUEENS CLOSER ;

Bre HALF BAT: B= TRICK ;B,-QUARTER RAT

FIG. 610. DOUBLE FLEMISH BOND.

MASONRY—2: BRICK MASONRY 255

Hig 611 shows the plan of single lemish bond fr various

thicknesses of the wal

1,3,8-—Coorses

(er ran for 1 ween Ten Wot

() Pian tor 2 Griek Taek Wall

S = STRETCHER ; Q = QUEENS CLOSER ;

Da=HALP BAT ; By =3BRICK ; B= QUARTER BAT

FIG. 6.11. SINGLE FLEMISH BOND.

‘Comparison of English Bond and Flemish Bond

1. English bond is stronger than flemish bond for walls thicker

than 15 brick,

2, Flemish bond gives more pleasing appearance than the English

bond. .

3, Broken bricks can be used in the form of bats in Flemish

bond. However, more mortar is required.

256 BUILDING CONSTRUCTION

4, Construction with Flemish bond requires greater skill in

comparison to English bond.

6.9. FACING BOND

This bond is used where bricks of different thickness are to

be used in the facing and backing of the wall. In this bond, a header

course is provided after several stretcher courses. Since the thickness

of bricks are different in the facing and backing, the vertical distance

between the successive header courses is kept equal to the least

common multiple of the thickness of backing and facing bricks. Thus,

if the nominal thickness of facing bricks is 10 cm and that of backing

bricks is 9 cm, the header course is provided at a vertical interval

of 90cm. This type of bond is not structurally good and load distribution

is not uniform.

6.10. ENGLISH CROSS BOND

This is a modification of English bond, used to improve the

appearance of the wall. This bond combines the requirements of

beauty and strength. Special features of the bond (Fig. 6.12) are

as follows :

1, Alternate courses of headers and stretchers are provided

as in English bond.

2. Queen closers are placed next to quoin headers.

3. A header is introduced next to the quoin stretcher in every

alternate stretcher course.

H = HEADER ; $= STRETCHER ; Q = QUEEN'S CLOSER

FIG. 6.12, ENGLISH CROSS BOND

256 BUILDING CONSTRUCTION

4, Construction with Flemish bond requires greater skill in

comparison to English bond.

69. FACING BOND

This bond is used where bricks of different thickness are to

be used in the facing and backing of the wall. In this bond,

course is provided after several stretcher courses. Since the thickness

of bricks are different in the facing and backing, the vertical distance

between the successive header courses is kept equal to the least

common multiple of the thickness of backing and facing bricks. Thus,

if the nominal thickness of facing bricks is 10 cm and that of backing

bricks is 9 cm, the header course is provided at a vertical interval

of 90cm. This type of bond is not structurally good and load distribution

is not uniform.

6.10. ENGLISH CROSS BOND

This is a modification of English bond, used to improve the

appearance of the wall. This bond combines the requirements of

beauty and strength. Special features of the bond (Fig. 6.12) are

as follows :

1, Alternate courses of headers and stretchers are provided

as in English bond.

2. Queen closers are placed next to quoin headers.

3. A header is introduced next to the quoin stretcher in every

altemate stretcher course.

H = HEADER ; S = STRETCHER ; Q = QUEEN'S CLOSER

FIG. 6.12, ENGLISH CROSS BOND

‘MASONRY-~t;"BRICK MASONRY 257

oe tee

6.11, BRICK ON EDGE:BOND (SILVERLOCK’S BOND OR

‘SOLDIER'S.GOPRSE) *

This type of bond ses stretcher bricks on edges instead of

bed. This bond is weak in strength, but is economical. Hence it

is used for garden walls, compound walls etc. Bricks are kept standing

vertically on end. The bricks are arranged as headers and stretchers

“sin such a manner that headers are placed on bed and stretchers are

placed on edge thus forming a continuous cavity. Due to this, the

‘bond consumes Iess number of bricks.

FIG. 613, SILVERLOCK’S BOND.

6.12, DUTCH BOND

‘This is another modified form of English bond. In this bond

the comers of the wall are strengthened. Special features of this

type of na%f istas follows (Fig. 6.14) :

1, Alternate courses of headers and stretchers are provided

as in Engligh bond.

“3

Hi o= HEADER ; § 4 STRETCHER ; Bs «3/4 BRICK BAT.

FIG. 6.14, DUTCH BOND.

258 BUILDING CONSTRUCTION

‘

2. Every stretcher course starts at the quoin with a three-

quarter bat.

3. In every alternate stretcher course, a header is placed next

to the three-quarter brick bat provided at the quoin.

613. RAKING BOND

This bond is used in thick walls. In this type of bond, the

bonding bricks are kept at an inclination to the direction of the

wall. Due to this, the longitudinal stability of thick wall built in

English bond is very much increased. This bond is introduced at

certain intervals along the height of the wall. Following are special

features of raking bond :

1. The bricks are arranged in inclined direction, in the space

between the external stretchers of the wall.

2. The raking or inclination should be in opposite direction

-in alternate courses of raking bond.

3. Raking bond is not provided in successive courses. It is

provided at a regular interval of four to eight courses in the height

of a wall.

4, The raking course is generally provided between the two

stretcher courses of the wall having thickness equal to even multiple

of half-bricks, to make the bond more effective.

FIG. 615. RAKING BONDS.

Raking bonds are of two pes :

1. Diagonal bond (Fig. 6.15 (a)]. In this type of bond, bricks

are arranged at 45° in such a way that extreme comers of the

series remain in contact with the external line of stretchers. Bricks

cut to triangular shapes and_of suitable sizes are packed in the

small triangular spaces at the ends. This bond is best suited for

walls which are 2 to 4 bricks thick. The bond is introduced at regular

vertical interval, generally at every fifth or seventh course. In every

altemate course of the bond, the direction of bricks is reversed.

2. Herring-bone bond [Fig. 6.15 (b)]. This bond is more suitable

for walls which are thicker than four bricks thick. Bricks are arranged

MASONRY—1 : BRICK MASONRY 259

at 45° in two opposite directions from the centre of the wall thickness,

as shown in [Fig. 6.15 (6)]. The bond is introduced in the wall

at regular vertical interval. In every alternate course, the. directions

of bricks are changed. The bond is also used for ornamental finish

to the face work, and also for brick flooring. .

6.14. ZIG ZAG BOND

‘This bond is similar to herring-bone bond, except that “the

bricks are laid in zig-zag fashion, as shown in Fig. 6.16. This bond

is commonly used for making ornamental panels in the brick flooring.

FIG. 6.16. ZIG-ZAG BOND.

6.15. GARDEN WALL BONDS

As the name suggests, this type of bond is used for the con-

struction of garden walls, boundary walls, compound walls, where

the thickness of the wall is one brick thick and the height does

not exceed two metres. This type of bond is not so strong as English

bond, but is more attractive. Dur to this reason, it is sometimes

used in the construction of outer leaves of cavity walls.

Garden wall bonds are of three types :

(@ Garden wall English bond

(i) Garden wall Flemish bond

(iif) Garden wall Monk bond.

1. Garden wall English bond {Fig. 6.17(6)]

In thi: bond, the header course is provided only after three

to five stretchers courses. In exh header course, a queca closer

is placed next to quoin header, to provide necessary lap. In stretcher

courses, quoin headers are placed in alternate courses.

{2 Gardea wall Tlemish bond [Fig. 6.17(c)]

In this bond, each course contains one header after three

to five stretchers continuously placed, (hougnout the ivagth of the

euurse, Each alternate course containes a three fourth brick bat placed

next te the quoin header, develop necessary lap, and a header laid

over the middte of cach central stretcher.

This bond is also known as scotch bond or sussex bond.

Garden well Monk bond [Fig 6.17()]

This is special type of garden-wall Flemish bond in which

each course contains one hea ler two successive stretchers. Every

MASONRY—1 : BRICK MASONRY 259

at 45° in two opposite directions from the centre of the wall thickness,

as shown in [Fig. 6.15 (6)}. The bond is introduced in the wall

at regular vertical interval. In every alternate course, thé. directions

of bricks are changed. The bond is also used for ornamental finish

to the face work, and also for brick flooring. ‘

6.14, ZIG ZAG BOND

‘This bond is similar to herring-bone bond, except that “the

bricks are laid in zig-zag fashion, as shown in Fig. 6.16. This bond

is commonly used for making ornamental panels in the brick flooring.

RYws TAH

SSS4

SS

4

FIG. 6.16. ZIG-ZAG BOND.

6.15. GARDEN WALL BONDS

As the name suggests, this type of bond is used for the con-

struction of garden walls, boundary walls, compound walls, where

the thickness of the wall is one brick thick and the height does

not exceed two metres. This type of bond is not so strong as English

bond, but is more attractive. Due to this reason, it is sometimes

used in the construction of outer leaves of cavity walls.

Garden wall bonds are of three types :

@ Garden wall English bond

(@) Garden wall Flemish bond

(ii) Garden wall Monk bond.

1. Garden wall English bond [Fig. 6.17(0)}

In this bond, the header course is provided only afier three

to five stretchers courses. In earh Sealer course, a queca closer

is placed next to quain header, to provide necessary lap. In stretcher

quoin headers are placed in alternate courscs.

2. Gardea wall Tlemish bond [Fig. 6.17(c)]

Im this hond, each course contains one header afier three

to five stretchers continuously placed, througnout the ieagth of the

wuise, Each alivrnate course containes a three fourth brick bat placed

next te the quoin header, develop necessary lap, and a header taid

vver the middle of cach central stretcher.

mnd_is also kaywn as scefch bond or sussex bond.

2. Garden swell Monk ond (Fig. 6.17(c)]

This is spocial type of girden-wall Flemish bond in which

each course contains one header after two successive stretchers. Every

20 BUILDING CONSTRUCTION

alternate course contains a quoin header followed by a j brick bat.

Due to this, the header rests over the joint between two successive

stretchers.

S = STRETCHER ; HW = WEADER ; j=} BRICK RATS

FIG. 617. GARDEN WALL BONDS.

MASONRY—1 : BRICK MASONRY 261

6.16. BOND AT CONNECTIONS

Connection is the place where two walls coming from different

directions meet. The walls should be properly united at the connecting

point through some proper bond. The following three requirements

should be satisfied by the bond at the connection. (i) There should

be no continuity in the vertical joints, (if) use of brick bats should

eas minimum as possible, and (iif) the connection should bestructurally

strong to resist differential settlement, if any.

Connections are of the following two types

@) Junctions -

(6) Quoins.

Junction is that connection which is formed at the meeting

of one (subsidiary) wall at same intermediate position of another

wall. When both these walls meet at right angles, we get a tee-

junction. If the subsidiary wall crosses the main wall and continucs

‘beyond the junction, we have a cross.junction or intersection. However,

if the subsidiary wall meets the main wall at some intermediate

point, and if the angle formed between the two is other than a

Tight angle, a squint junction is formed.

Quoin is the connection formed when two external walls meet.

Alternatively, quoin is the connection which is formed when a wall

takes a turn. When the two walls meet at 90°, we have a right

angled ot square quoin. If the angle at the connection is other than

90°, a squint quoin is formed.

(A) JUNCTIONS

Junctions are of the following types :

(@) Right-angled junction

@ Tee-junction

(@ Intersection or cross-junction,

(©) Squint junction.

1. @ Teejunction

@ External and Internal walls in English bond

Tee-junction is formed when the internal wall at its end meets

external wall at some intermediate position. Tee-junctions can be

either in English bond or in Flemish bond.

Fig. 6.18 (a) shows the Tee-junction between a one-brick thick

external wall and a half-brick thick internal wall (partition wall),

both walls being constructed in English bond. Bond is obtained by

making alternate courses of internal wall entering into the stretcher

course of the main wall, Due to this, lap of half brick is obtained

through the brick (shown shaded). Alternate courses of both the

walls remain unbonded.

Fig. 6.18 (6) shows the Tee-junction between 1} brick thick

262 - BUILDING CONSTRUCTION

external wall and one-brick thick internal (cross) wall, both the walls

being constructed in English bond. Here, the header course of the

internal wall centres the stretcher course of the main wall through

half of its width. Due to this, lap of quarter-brick is obtained through _

the tie-brick, which is placed near the queen closer (Q). Alternate }

courses of both the walls remain unbonded.

1 Brick erick

External Walt Tinernot

watt

t

ala

Briek

External Wott

‘wet

1,3,5--Courses 2,4,6---Courses

PaeHALF BRICK ; B=} BRICK

FIG. 6.18, T-JUNCTIONS IN ENGLISH BOND

MASONRY—1 : BRICK MASONRY 253

Fig. 6.18 (¢) shows the Tee-junction between 1 4 brick thick

external wall and 1 brick thick internal wall, both the walls being

constructed in English bond. In altcrnate courses, the header brick

at the junction enters the stretcher course of the majn wall. The

tie-brick (shown shaded), placed near the queen closer (Q) furnishes

a lap of quarter brick. Additional lap is obtained in the same course,

through placing a 3 brick bat as shown. Alternate courses of both

the walls remain unbonded.

Fig 6.18 (d) shows the Tee-junction between 2-brick thick

main wall and 1 } brick thick cross-wall, both the walls being constructed

in English bond. Here, the header course of internal wall enters

the stretcher course of the main wall through half of its width.

Due to this, lap of quarter brick is obtained through the tie-brick

(header brick) which is placed near the queen closer (Q). Additional

lap is obtained in the same course, through placing a 3 brick bat

as shown. Here also, altemate courses of both the walls remain

unbonded.

(©) External wall in Flemish bond and Internal wall in English

By= 5 BRICK ; By =f BRICK

FIG. 6.19, TEEJUNCTION FOR EXTERNAL WALL IN FLEMISH BOND AN’

INTERNAL WALL IN ENGLISH BOND.

264 BUILDING CONSTRUCTION

Fig. 6.19 (a) shows the Tee-junction for a brick thick external

vall in Double Flemish bond and one brick thick internal wall in

English bond. The header course of internal wall enters into the

main wall, thus getting a lap of one-quarter brick. The tie-brick

(header course) is placed adjacent to a queen closer. Alternate courses.

of both the walls remain unbonded.

Fig. 6.19(6) shows the Tee-junction for 2-brick thick external

wall in Double-Flemish bond and ly brick thick internal wall in

English bond. Here also, the header course of the cross-wall (internal

@

w

ter

MASONRY—1 : BRICK MASONRY 265

wall) enters the main wall, thus getting a lap of quarter brick. The

/tie-brick (header brick) is placed next to a queen closer. Additional

lap is obtained through the stretcher brick of the same course of

the internal wall, which is placed adjacent to a } brick bat of the

main wall. The alternate courses of both the walls remain unbonded.

(©) Both external and internal walls in double Flemish bond

Fig. 6.20 (a) shows the Tee-junction for a 1-brick thick main

wall and 5 brick thick cross wall, both being constructed in Double

Flemish bond. The stretcher bricks of alternate courses of the cross-wall

enter into the main wall through half brick length. Due to this,

it is necessary to place a half-brick bat adjacent to it, in the main

wall. The alternate courses of each wall remain unbonded.

Fig. 6.20 (b) shows the tee-junction for a 14 brick thick main

wall and one-brick thick cross-wall, both being constructed in double

Flemish bond. In alternate courses, the stretcher bricks of the.cross

wall enter into the main wall through quarter brick. A queen closer

(Q) is placed next to it in the main wall as shown. Alternate courses

of both the walls remain unbonded.

Fig. 6.20 (c) shows the tee-junction for two-brick thick main

wall and 15 brick thick cross-wall. Bonding is obtained through a

lap of one-quarter brick. It is essential to use a queen closer and

a } brick bat in the main wall, at the alternate courses in which

both the walls are bonded.

2. Cross-junction or Intersection

A cross-junction is formed when two internal walls cross each

other at right angles. One of the walls may be called as the main

wall while the other of lesser thickness as_cross-wall.

Fig. 6.21(a) shows a cross-junction between 1 !-brick thick main

wall and 1 brick thick cross-wall, both being constructed in English

bond. The header course of cross-wall enter into the main wall :

the tie bricks thus give a lap of quarter brick on both sides. Alternate

courses of both the walls remain unbonded.

6.21 (b) shows a cross-junction between two walls, each

of 14 -brick thick constructed in English bond. A lap of quarter

brick is obtained through header courses, on both the sides. Alternate

courses thus remain unbonded.

Fig. 6.21 (¢) shows a cross-junction between a 2-brick thick

main wall and 1 brick thick cross-wall. A quarter-brick lap is obtained

‘on both sides through the header course. Additional lap is also

obtained through } stretcher brick on one side and 3 stretcher brick

266 BUILDING CONSTRUCTION

‘on the other side. Alternate courses of both the walls remain unbonded.

~

ores eta wat

Te Brick

te

ot

“e ese

weit

13S courses 2,4,6-~-Courses

FIG. 621. CROSSJUNCTION IN ENGLISH BOND.

3. Squint junction

‘A squint junction is formed when an internal wall meets an

external continuous wall at an angle other than 90°. Usually, the

angle of squint is kept at 45°, though squint junctions are not very

common in brick work.

(@) Squint junction in English bond

Fig. 6.22 (a) shows a squint junction between a 1 }-brick thick

external wall and a 1-brick thick internal wall, both being constructed

in English bond, The header couses of the cross-wall is taken inside

the main wall, thus getting the required bond, Alternate courses

of both the walls remain unbonded.

MASONRY—1 : BRICK MASONRY 267

Fig. 6.22( b) shows a squint junction between two walls each

of 1 }-brick thickness and constructed in English both. The header

bricks are taken inside the main wall. Alternate courses remain un-

bonded.

7

Tatemel Walt

a

eS

\pBrick External Wott

rp price

FV

(wy

i ence went

FIG. 622. SQUINT JUNCTION IN ENGLISH BOND.

EiPerien externat Wott

1,3,5-—-Courees 2,

yarn

spr Walt

Ty erick Extereal wai

FIG. 623. SQUINT JUNCTION IN DOUBLE FLEMISH BONDS.

268, BUILDING CONSTRUCTION

(6) Squint junction in Double Flemish bond

Fig. 6.23 shows the squint junction for the walls constructed

in Double Flemish bond. These junctions are quite difficult to be

constructed.

(B) QUOINS

‘Quoin is the connection formed when two external walls meet.

Alternatively, quoin is the connection which is formed when an external

wall takes a turn. Quoins are of two types.

1. Right-angle or square quoin.

2. Squint quoin.

1, Square Quoin

ware quoins are quite common in all the buildings where

the external walls meet at right angles. Fig. 6.4 shows a square quoin

in stretcher bond. Fig. 6.5 shows a square quoin in header bond.

Figs. 6.7 and 6.8 show square quoins in English bond for various

wall thicknesses. Fig. 6.10 shows square quoins in Double Flemish

bond, for various wall thicknesses.

2, Squint Quoins

Squint quoins can be of two types:

(@) Acute squint.

(©) Obdtuse squint.

1g erick watt

1,3,5---Courses 2,4,6--~ Courses

(a) English Bond

1,3,5—— Courses

FIG. 624. ACUTE SQUINT.

MASONRY—1 : BRICK MASONRY 209

@) Acute squint

‘This is formed when the enclosed angle on the inside of the

two walls is fess than 90° . Generally, the acute angle is kept equal

10 60° . Fig. 6.24 (a) shows an acute squint for two walls of 1}brick

thick, each being constructed in English bond. Fig. 6:24 (0) shows

acute squint for two walls of 14 brick thickness, cach in double

Flemish bond.

©) Obese squint

‘This is formed when the enclosed angle on the inside of the

two walls is more than 90° . The angle gencrally varies from

105° to 135° , the more common being 120° . Fig. 625 (a) shows

the obtuse squint for two walls of 1 } brick thick, each being constructed

in English bond. Fig 6.25 (b) shows the obtuse squint in double

flemish bond.

teriee

wots

. s20°

riot

1,3,8-7= Courses 2,4,6--= Courses

fe) Englien Bona

2,4,.8--- Courses

(0) Double Flemin

FIG. 625, OBTUSE SQUINT

6.17, BOND IN BRICK PIERS

Piers of brick masonry are provided to have supports for beams,

trusses or other structural members. Piers are also known as columns

or pillars. These ‘piers may be of two types, depending upon their

location with reference to the adjoining load bearing wall (if, any):

zm BUILDING CONSTRUCTION

(a) Detached or isolated piers.

(6) Attached piers.

(A) ISOLATED PIERS

‘Though picts may be constructed in any type of bond, generally

English bond or-double Flemish bond is adopted, The size of the

pier as well as its shape (Le., square, rectangular or circular) depends

upon the magnitude of the load as well as architectural, fequirements.

1. Piers in English bond

Fig. 6.25 shows the piers of various thicknesi¢s, in English -

bond.

' 8 o

Ct Briek thie

40 of ovtee hee

(M1) 2-Brtek Thick

tiny afore Tce

(2) Generat (2) Pion of (e) Pon of

Elevations Courses 1,3,9--- Courses 2,

Q = QUEEN CLOSER ; By=3/4 BRICK BAT.

FIG. 626. PIERS IN ENGLISH BOND.

MASONRY—1 : BRICK MASONRY m

©) Piers in double Flemish: bond

Fig. 6.27 shows the piers of various thicknesses in double

flemish bond..

(1) of oriee Toten

SRasaed

wy hance thee

(2) Generat (>) Plan of te

Elevation 1,3, “Courses

Q “QUEENS CLOSER ; By ~2 BRICK BAT ; Bj «1 BRICK BAT

FIG. 627. PIERS IN DOUBLE FLEMISH BOND

m BUILDING CONSTRUCTION

(© Circular and Octagonal Piers

Fig. 6.28 shows bond for circular and octagonal piers.

®Q O

Elevation 1,3, 5---Courses

(a) Circular Pier

Spam

foormryg

Elevation 1,3,5---Courses 2,4, 67> Coure

(0) Oetogonat Pier

FIG. 628, BOND FOR CIRCULAR AND OCTAGONAL PIERS.

— Th JH Ui

het viet

(0) 1 Briek Wall: erick Pier

cM Lf

le 28

lex Wall: 2 Brick Pler

FIG. 629. ATTACHED PIERS IN ENGLISH BOND.

() ATTACHED PIERS

Attached piers are constructed along the wall for two purposes:

MASONRY—2: BRICK MASONRY 23

(@ to provide larger bearing area for supporting heavy girders,

roof etc, and

(ii) to provide stiffness to the wall.

@ English bond

Fig. 6.29 (a) shows attached-pier and wall in English bond.

‘The wall thickness is 1 brick, the pier width is 1 brick and the

pier projection is half brick. Fig. 6.29 (b) gives English bond for

wall of 1-brick thickness, pier of 13-brick thickness and pier

projection of } -brick. Fig, 6.29 (c) shows English bond for 1 4 -brick

wall with pier width equal to 2-bricks and pier projection equal

to } brick.

(© Double Flemish bond

Fig. 6.30 (a) shows double Flemish bond for wall 1 } -brick

thick, pier 1 brick wide and pier projection of } brick. Fig. 6.30(6)

shows double Flemish bond for wall 1 5 -brick thick, pier 1 5 -brick

wide and pier projection }-brick. Fig. 6.30 (¢) shows the double

Flemish bond for wall 1}-brick thick, pier 2 brick wide and pier

projection of 15 brick.

Hj

TI

Pipi

1 1

() tf erick wot: tb erick Pier

ter uf orton wait: 2 sree Pir

FIG. 630. ATTACHED PIERS IN FLEMISH BOND.

28 BUILDING CONSTRUCTION

6.18. BOND IN FOOTINGS

Footings distribute the load of wall or pier, to a wider area

at its base, through the provision of steps or offsets. Each step

of the footing can be constructed either in single course of bricks

or in double or more courses. Footings of single course of brick

in each step is adopted for light loads. In such a case the bricks

are laid as headers on the outside. This would make it possible

to give greater bearing to the projecting portion (offset) inside the

wall or pier. In the case of double or multiple courses, the method

of construction and bonding is similar to that adopted for the wall

or pier.

3Briek Thick

FIG. 631. WALL FOOTING.

Fig. 6.31 shows an isometric view of wall footing in which

each step consists of one brick course only and the offset is equal

to brick. Each course consists of header bricks only.

ig. 6.32 shows the isometric view, elevation and plan (of

various courses) of a brick footing for brick pier. Here also, each

step contains only one course of bricks. Pier is 15 bricks x 15 bricks.

‘The first course is 2 bricks x 2 bricks, having an offset equal to

quarter brick all round. The second course is 25 bricks wide ; it

is essential to provide a hali-brick bat in the middle. Course 3 is

3 bricks wide, again having an all round offset of quarter brick.

In this course all the bricks are full bricks, The fourth course of

24 BUILDING CONSTRUCTION

6.18. BOND IN FOOTINGS

Footings distribute the load of wall or pier, to a wider area

at its base, through the provision of steps or offsets. Each step

of the footing can be constructed either in single course of bricks

or in double or more courses. Footings of single course of brick

in each step is adopted for light loads. In such a case the bricks

are laid as headers on the outside. This would make it possible

to give greater bearing to the projecting portion (offset) inside the

wall or picr. In the case of double or multiple courses, the method

of construction and bonding is similar to that adopted for the wall

or pier.

FIG. 631. WALL FOOTING.

Fig. 6.31 shows an isometric view of wall footing in which

each step consists of one brick course only and the offset is equal

to brick. Each course consists of header bricks only.

Fig. 632 shows the isometric view, elevation and plan (of

various courses) of a brick footing for brick pier. Here also, cach

step contains only one course of bricks. Pier is 15 bricks x 15 bricks.

The first course is 2 bricks x 2 bricks, having an offset equal 10

quarter brick all round, The second course is 25 bricks wide ; it

is essential to provide a halébrick bat in the middle. Course 3 is

3 bricks wide, again having an all round offset of quarter brick.

In this course all the bricks are full bricks. The fourth course of

MASONRY—2: BRICK MASONRY mS

footing is 3 } bricks wide. It has a Flemish bond pattern at its middle,

with a half-brick bat. Remaining all bricks are full bricks.

Faves

(0) Isometric View

Bricks Ba},

(2) Pion of Footing

Course 4 Foeting

3B rleke

1 Pron ot Footing (8) Pion f Fostia

course's canal

ty «2 price ;o: =} prick

HG, 632. FOOTING FOR’ BRICK PIER,

6.19. TOOLS FOR BRICK LAYING

‘The following tools are used in brick masonry construction.

1. Brick hammer : Used for cutting bricks; also for pushing

the bricks in courses.

2. Trowel : Used for lifting and spreading mortar

for cutting bricks.

3. Spirit level : Used, with straight edge, for getting horizo-

tal surface ; also used for levelling.

4, Plumb rule : Used for checking verticality of brick walls.

also

6 BUILDING CONSTRUCTION

5. Mason's square : Used for checking right angles.

6. Line and pins : Used for maintaining alignment of courses.

7. Scutch : Used for cutting soft bricks and dressing out

surfaces.

8. Bolster : Used for accurate cutting of bricks.

9. Jointer : Used for pointing the joints.

P] Db

IN) 7teece

FIG. 633, BRICK LAYING TOOLS.

6.20, BRICK LAYING

Brick masonry construction is a great art since laying must be

systematically done with respect to bonding, jointing and finishing, Brick

laying for wall construction is done in the following steps :

J. All the bricks to be used in construction are thoroughly

soaked in water so that they do not absorb the water of the mortar.

2. Moftar is spread on the, top of the foundations course,

over an area to be covered by the edges of the wall. The depth

of spread of mortar may be about 1.5 cm.

3. The corner of the wall is constructed first. For that, one

brick is laid first at the comer and pressed with hand so that the

thickness of bed-joint remains only about 1 cm. The first closer is

covered with mortar on its side and then pressed against the first

MASONRY—2: BRICK MASONRY am

corner brick, such that 1 cm thick vertical joint is obtained. The

excess mortar from the sides will squeeze out, which is cleaned off

with trowel (Fig. 6.34 a).

4. The level and the alignment is checked. If the brick or

closer is not in level, they are pressed gently further. Simiarly, the

placement of the edges of the bricks is checked so that correct

offset of concrete is available.

5, Few headers and stretchers are then laid in the first course,

adopting the same method as described in step 3 for the closer

brick. That is, mortar is applied on the side of the brick to be

laid and it is pressed against the previous brick laid earlier, so that

excess mortar squeezes out from the sides (Fig. 6.34 6). The level

and alignment of these are properly checked.

6. After having laid the first course at the comer, mortar is

laid and spread over the first course, to a depth of about 1.5 cm

and end stretcher is laid first, by pressing it into the mortar and

then hammering it slightly so that the thickness of bed-joint is 1

cm. Mortar is then applied on the side of another stretcher and

pressed to the side of the corner stretcher so that thickness of vertical

Concrete Be

1Sem Thick

Mortar Sp

FIG. 634, BRICK LAYING BY CONVENTIONAL METHOD.

2a BUILDING CONSTRUCTION

Joint is about 1 cm. Excess mortar which oozes out is cleaned off.

‘This way, stretchers and headers are laid for the second course.

7. Other courses (usually four to six) are then laid at the

corner. Similarly, the corner at the other end of the wall is laid.

Since the comer construction at each end works as a guide for

filling in-between bricks of various courses, the corner construction

should be done with great care, The plumb as well as alignment

should be thoroughly checked. Plumbing up by means of plumb rule

should be frequently resorted to as new brick work has a tendency

to overhang, Vertical face is obtained by tapping the handle of the

trowel against the overhanging bricks.

8. For building the in-beween portion of the wall, a cord

is stretched along the top of the first course laid at each comer,

as shown in Fig. 6.34 (c). A brick bat is attached at either €nd

of the cord so that it remains tout. The course is then built. The

line or cord is then shifted up, corresponding to the top level of

the second course, and the second course is also constructed. The

procedure is repeated till the in-between wall is constructed to the

height of comer masonry.

9. The corners of the wall are then raised further, and steps

7 and 8 are repeated. All the walls should be uniformly constructed

so that the load on the foundations is uniform. It should be ensured

that the difference in height between two adjoining walls is not

more than 1 m.

10. Perpends must be kept vertical. This should be checked,

as the work proceeds, with the help of straight edge and the square.

‘The straight edge is placed flat on the course and slightly projecting

beyond the face, The stock of the square is then set against the

underside of the straight edge with the blade coinciding with the

last-formed vertical joint.

11. Bricks with one frog should be aid with its frog on its

top face to ensure that they will be completely filled with mortar.

12. In the case of thick walls, mortar is first spread over

the entire bed and the outer bricks are laid as described above.

‘The inner bricks are then pressed and rubbed into position to cause

some of the mortar to rise between the vertical joints, which are

finally filled flush with liquid mortar so that no hollow spaces are

left.

13. All loose materials, dirt and set lumps of mortar which

may be lying over the surface on which the brick work is to be

freshly started, should be removed with wire brush and wetted slightly.

14, After having constructed the wall, jointing and pointing

is done. The procedure for jointing and pointing has been described

separately. However, all the joints should be cleaned and finished

MASONRY—2: BRICK MASONRY 79

after every day's work.

621. IMPRGVED METHOD OF BRICK -LAYING

‘An improved method of brick laying has been developed by

CBRI, wherein delays are eliminated by well-organised work place

layout using new gadgets consisting of (i) end frame (it) string holder,

and (iii) mortar board, and arranging the brick layers in sequence

‘of hand operation to give a rhythm to the movement pattern. The

method recommended in the Handbook of Building Construction Prac-

tices (Indian Standard Institution), is reproduced here.

1. Special Gadgets

® End Frames

‘An end frame shown in Fig. 6.35 (a) is made of 25 mm

thick hard board or timber and the height is generally kept 1,25

m. In case wellseasoned timber is not available, this can be made

by making cored frame work of timber and fixing 5 mm thick shuttering

plywood or hard boards on both sides. At the sides, top and bottom

timber lapping is provided. The width of the board is kept equal

to the thickness of the wall. The vertical board and base board

are jointed at right angles by two pieces of angle iron, and a mild

steel tie rod is also fixed to keep the board in plumb. A mild steel

flat is fixed on the vertical board at height of 30 cm from base

(0) Eng Frome (1 The String-Hotaer

FIG. 635. SPECIAL GADGETS.

280 BUILDING CONSTRUCTION

board for fixing the end frame on to the wall. Depending upon

the average thickness of bricks and the horizontal mortar joint, marks

as the course levels are made on both sides of the vertical board

along its thickness.

(ii) String-holder

A string-holder, shown in Fig. 6.35 (b) is made of hard board

or timber in the form of L-shape. It is 5 cm high and the lengths

‘of the two flanges are 50 mm and 350 mm. The shorter flange

has 1 mm deep groove in the centre on the inner side to position

the thread and on the outer face it has two wood screws kept projecting

out by about 5 mm to which the brick layer’s thread is tied and

kept hanging. The longer flange has a through groove or slit, 2

mm wide and 40 mm long, in the centre to allow the thread to

be passed through it.

(iii) Mortar board

For keeping the mortar near the brick wall, hard boards of

500 x 500 x 25mm are used in place of conventional metal pans

and these are placed on bricks to keep them at a higher level.

This climinates the interference in brick layer’s hand motion due

to the sides of the metal pan.

2. Layout of the work place

‘The general layout arrangement of the work place is shown

in Fig. 6.36. Bricks and mortar boards are placed in alternate positions

at about 500 mm on centres along the wall length to be constructed,

at a distance of roughly S00 mm from wall surface to allow free

movement of the brick-layer. Bricks are stacked in a group of 12

bricks, placed on edge for easy grip by the brick-layer, to a height

of about 500 mm or so to roughly match with the quantity of bricks

required for laying at one time. This arrangement of stacking bricks

and placing mortar boards should be made along the wall length

before the brick layers start the laying work on the wall. It is preferable

to pre-soak the bricks to be stacked. However, wetting of the staked

bricks can also be done. Mortar is supplied on the mortar boards

continuously as the work proceeds.

3. Fixing brick laying gadgets

(a) At the end or corner of the wall

Before starting the brick-laying, the brick-layer fixes the end-

frames at the corners or ends of the wall to be built. For this,

the ground is levelled at the ends of the wall and the end frames

are placed to plumb abutting the corners already built up at the

‘base board. In case the wall has already been built upto plinth level

(je about 30 cm higher than the ground level), the end frames

can be fixed at the ends of the wall by placing a mild steel flat

along the vertical joint of the upper course at a distance about

MASONRY—2: BRICK MASONRY 281

750,.mm from the end of corner and inserting 10 mm mild steel

rods threaded at both ends into the grooves on the mild steel flats,

in and on the frame and tightening them by butterfly nuts. Having

fixed the end-frames, a string-holder, having brick-layers thread mainly

passing through the slit and part of thread tied to the wood screws

is positioned on the end-frame as fair face of the wall at appropriate

course level. The thread is kept pulled and the other end of the

thread is passed through the slit of second string-holder. Keeping

the length of thread equal to the wall, the thread is tied to the

wood screws of the string-holder and it is positioned at appropriate

level of the end frame.

‘End Frome

‘StringHolder

String Holder

Mortar Boards

Brick Stack

FIG, 636. LAYOUT AT WORK PLACE.

(b) At the opening for door and windows

In case the frames for doors and windows are not kept along

with the building of wall, these openings also need the plumbing

operation for each brick at the jambs. To reduce the plumbing time

in such case, end frames are fixed for the door and window opening,

as shown in Fig. 637 (0). In this case the end frames are fixed

by 10 mm dia. mild stecl rods fixed to a mild stecl flat placed

on the base board and the other one placed in brick joint in one

of the courses below the sill level. It is preferable to provide a

loop at the lower end of the mild steel rod and threads at the

upper end. The end frames fixed for the door window openings

also help in fixing the string-holders on to them, in case the brick-layers

build the wall in part lengths.

282 BUILDING CONSTRUCTION

(©) At corner for building cross walls simultaneously

At buildings sites, often a gang of brick layers work and more

than one walls are built simultaneously. Whén two walls at a corner

are built simultaneously, it is possible to build them using only one

end frame at the corner as shown in Fig. 6.37 (c) and (4). The

important consideration is that the two should not be built at the

same course level at a time but the wall along the end of which

(a) Fiting End-Frame on the Walt

‘1 HigherLevels Above Ground

(w) Fixing Eng Frames for Window (6) Fising of E

@ Deer Openings

FIG. 637. FIXING END FRAMES

MASONRY—2: BRICK MASONRY 283,

the end frame is kept parallel to its length, should be built in advance

by atleast one course than the wall at whose end the end frme

is fixed at right angles. This is essential so as to permit the string

of brick-layers threads from the same end frame at perpendicular

directions. In Fig. 6.37 (d), it may be seen that the corner does

not impose any difficulty in fixing the end frame as the 10 mm

dia. mild steel rod can be easily passed through mortar joint thickness.

@ At T-junctions

In buildings there are longitudinal walls and cross-walls. General-

ly, for bonding the cross-walls, some tooths are left in the longitudinal

wall which is built prior to it. For building the cross-wall, the end

frames are fixed parallel to wall length at a distance of about 150

mm from junction as shown in Fig. 6.38. In this case, the cross-wall

has been stopped at an opening and thus, the end-frame has been

‘shown fitted at the end of the cross-wall abutting along its width.

In case there is no opening and the cross-wall ig solid, the end-frames

near both ends could be fixed parallel to the length of the wall.

End Frome

LO

FIG. 6.38, FIXING AND USE OF END FRAMES FOR CROSS-WALL

CONSTRUCTION.

4. Method of

To break the joints in brick masonry, cut bricks (Le, closers)

are required in alternate courses at the corners. It is therefore recom-

284 BUILDING CONSTRUCTION

mended that the brick-layer should cut approximately the required

number of bricks and arrange the same at the corner stacks of bricks,

rather than cutting each time when needed, Afterwards, the end

frames are fixed at corners and other openings as per requirement,

as described above. The string holders are positioned at the appropriate

course level and thread kept to line. The brick laying opetations

are carried out as described below.

@ Spreading mortar

The brick layer picks up mortar on the trowel in right hand

from the mortar board at one corner and unloads on the wall. The

picking and unloading of mortar is carried at a stretch by the brick

layer moving forward for a length of about a metre or so (to place

8-10 bricks) at a time. Then while moving backward, he spreads

the mortar to level in a continuous stroke of the trowel. The unloading

of mortar to longer length and the spreading stroke in one stretch

allow the brick-layer to develop speed.

(ii) Laying bricks

Having levelled the mortar bed, the brick-layer turns towards

the brick-stack. He picks a brick by left hand and mortar or trowel

by right hand and carries both brick and mortar on to the Ih.

He lays the brick to line of the thread and presses in position.

‘The operation of picking up brick and mortar and laying them simul-

taneously is followed for laying 8-10 bricks in a cycle. Before proceeding

to lay the next cycle, the surplus mortar protruding from the horizontal

joint is finished by scrapping in a single stroke of the trowel and

collected on it for using with the next cycle.

‘The operation of spreading mortar [described in (i) above]

is repeated for the next cycle and the Yaying bricks’ is followed in

the same way. These operations are continued till the entire course

length is compicted. Afterwards, the string-holders are shifted with

the thread to the next course level as desribed in (ili) below. These

operations of mortar and brick-laying are continued in this sequence

for the subsequent courses. This develops a smooth flowing rhythm

leading to faster laying without increasing undue fatigue.

(iii) Shifting of frame

When one course is laid, the string-holders are shifted to

the next course level by simply pushing on the end frame, when

all the brick courses equal to the height of the end frames are

laid, these-should be shifted to higher level. For doing so, a joint

at a distance of about 750 mm from the end frame is kept unfilled

with mortar at a level of about 250 mm below the top of the end

frame (marked with two lines), to position the mild stcel flat for

refixing the end frame. The end frames are removed from the existing

Position by loosening the butterfly nuts and removing the mild steel

tie rods. The mild stee! flat from the joint is taken out and placed

MASONRY—2: BRICK MASONRY 28s

in the next position. The end-frame is checked for uprightness and

alignment, and is secured to the wall with the help of mild steel

tie rods and butterfly nuts. The string-holders are fixed in position

in the usual way on the end frame.

5. Striking joints

(@ In cases where no pointing or plastering is required, the

green mortar shall be ncatly struck flush. Where pointing and plastering

is required the joints should be racked out to a depth of not less

than 10 mm.

(ii) Plaster work on the walls shall be deferred for a period

preferably not less than 28 days sufficient to let shrinkage in reinforced

concrete and masonry take place before plastering.

(iii) The face of brick work shall be cleaned and mortar dropping

removed the very day that brick work is laid.

6. Joining old brick work with new brick work

(@ Joining shall be done in such a way that there shall not

be any hump or projection at the joint. The thickness of each course

of new work shall be made equal to the thickness of the corresponding

course of the old work by adjusting thickness of horizontal mortar

joints, and the wall wherever necessary shall be made exactly to

the same thickness by adjusting the thickness of vertical joints.

(i) Toothing. The usual practice in joining new cross-wall to

old main wails is to cui owt a number of rectangular recesses in

the main walls equal in width to. the width of the cross-wall, three

courses in height and half a brick depth, a space of three courses

being left between the sinkings. The new cross-wall is bonded into

the recesses with cement mortar to avoid any settlement. It is necessary

that the sinkings should not be less than 225 mm apart, as the

cutting portion is likely to become shaken and cracked.

622, SUPERVISION OF BRICK WORK

The following points should be kept in mind while supervising

brick masonry :

1. The bricks to be used for the site should conform to the

specifications laid down by the designer. For first class work, the

bricks should be sound,-hard and well burnt. The bricks should

be of uniform size and shape, with plane surfaces.

2. The bricks should be soaked in water before use for a

period for the water to just penetrate the whole depth of the bricks.

‘This period of soaking may be casily found at site by a field test

in which bricks are soaked in water for different periods and then

broken to find the extent of water penetration. The least period

that corresponds to complete soaking will be the one to be allowed

for in the construction work. When bricks are soaked, they should

be removed from the tank sufficiently early so that at the time of

286 BUILDING CONSTRUCTION

laying, they are skin dry. Such“soaked bricks should be stacked on

a clean place, where they are not spoilt by dirt, earth etc.

When mud mortar or fat lime mortar is to be used, bricks should

not be soaked in water before use.

3. The bricks should be properly laid on their beds. They

should be so laid that the frog is on the top surface. The mortar

should cover completely the bed and the sides on the bricks. The

bricks should be lightly pressed into the bed mortar so that uniform

joint thickness is obtained.

4, The bricks, while laying, should be pushed sideways, to

have uniform thickness of vertical joints. All joints should be properly

flushed and filled with mortar of greater consistency so that no cavity

is left in between.

5. For the thicker walls, the joints should be grouted in every

course in addition to the bedding and flushing.

6. The brick work should be carried out perfectly in line.

Ends or corners of the wall should be constructed first.

7. The brick work should be perfectly in level.

8. The brick work should be truly in plumb. The vertical faces

should be checked by means of a plumb bob and the inclined surfaces,

if any should be checked by means of wooden templates.

9. The brick work should be done in proper bond suggested

by the designer.

10. Use of brick bats should be minimum. They should be

used only where these are essential from bond point of view.

11, The mortar to be used should be of specified quality.

Old mortar should not be used.

12. The brick work should be raised uniformly. The difference

in heights, at any stage, between adjacent walls, should not be more

than 1m,

13. Where cross-wall is to be inserted later, steps or toothing

or recesses should be provided during construction.

14, At plinth, window sill, floor or roof level and at the top

of the parapet wall, the bricks course should be laid with bricks

on edge.

15, When piers are tied up or buttersses, counterforts are

used with wall, they should be built up course by course, so as

to maintain proper bond with the main wall.

16. Iron fixtures such as hold fasts for doors etc., should be

embeded in cement mortar or in cement concrete.

17. All the joints of the wall face (to be plastered later) should

be raked to a minimum depth of 10 to 15 mm when the mortar

is still green.

286 BUILDING CONSTRUCTION

laying, they are skin dry. Such’ soaked bricks should be stacked on

a clean place, where they are not spoilt by dirt, earth etc.

When mud mortar or fat lime moriar is to be used, bricks should

not be soaked in water before use.

3. The bricks should be properly laid on their beds. They

should be so laid that the frog is on the top surface. The mortar

should cover completely the bed and the sides on the bricks. The

bricks should be lightly pressed into the bed mortar so that uniform

joint thickness is obtained.

4, The bricks, while laying, should be pushed sideways, to

have uniform thickness of vertical joints. All joints should be properly

flushed and filled with mortar of greater consistency so that no cavity

fs left in between.

5. For the thicker walls, the joints should be grouted in every

course in addition to the bedding and flushing.

6. The brick work should be carried out perfectly in line.

Ends or corners of the wall should be constructed first.

7. The brick work should be perfectly in level,

8. The brick work should be truly in plumb. The vertical faces

should be checked by means of a plumb bob and the inclined surfaces,

if any should be checked by means of wooden templates.

9. The brick work should be done in proper bond suggested

by the designer.

10. Use of brick bats should be minimum. They should be

used only where these are essential from bond point of view.

11, The mortar to be used should be of specified quality.

Old mortar should not be used.

12. The brick work should be raised uniformly. The difference

in heights, at any stage, between adjacent walls, should not be more

than 1m,

13, Where cross-wall is to be inserted later, steps or toothing

or recesses should be provided during construction.

14, At plinth, window sill, foor or roof level and at the top

of the parapet wall, the bricks course should be laid with bricks

on edge.

15. When piers are tied up or buttersses, counterforts are

used with wall, they should be built up course by course, so as

to maintain proper bond with the main wall.

16, Iron fixtures such as hold fasts for doors etc, should be

embeded in cement mortar or in cement concrete.

17. All the joints of the wall face (to be plastered later) should

be raked to a minimum depth of 10 to 15 mm when the mortar

is still green.

MASONRY—2: BRICK MASONRY 287

18. Where plastering or pointing is not to be done, the mortar

joints should not be raked. They should be struck flush and finished

at the time of laying.

19. After construction, the brick work should be kept wet

for one to two weeks.

20. It is desirable to provide about 18 mm to 25 mm

expansion joints after every 30 to 45 m length of the wall.

21. For carrying out brick work at higher level, single scaffolding

should be adopted. This is done by removing required headers from

the wall to provide supports for the scaffolding. The removed headers

are repacked later when scaffolding is removed.

6.23, COMPARISON OF BRICK MASONRY AND STONE

MASONRY

(@) Points in favour of brick masonry

1. Brick work is cheaper at places where stones are not available.

If stones are available at some distance, the transportation costs

are very high.

2. Generally, brick masonry can be constructed with less skilled

masons, in comparison to stone work. Hence brick work is cheaper.

3. Bricks are easy to handle. They can be lifted by manual

labour. No special lifting arrangement is required.

4. Brick masonry can be constructed in any type of mortar.

For low rise houses, where the loads are moderate, even mud mortar

can be used which is cheaply available.

5. Bricks are of regular size and shape. Due to this proper

bond can be maintained. Stones require dressing for maintaining

the bond.

6. Brick work requires lesser mortar because of thin mortar

joints required.

7. Because of plane surface obtained, the thickness of plaster

in brick work is much less than in stone work.

& Since bricks are in regular sizes, thinner walls can be con-

structed. In bricks, single brick thick walls (20 cm) can be constructed

while in stone masonry, it is difficult to construct walls of thickness

lesser than 30 cm.

9. The dead load of the walls is much less in brick masonry

than in the stone masonry, because of lesser minimum thickness

of walls. This is important factor in the arca, where the bearing

capacity of soils is low.

10. It is easy to form openings to construct connections in

brick work. In stone work, dressing of stones is required to achieve

this,

288, BUILDING CONSTRUCTION

Bricks are better fire-resistant than stones. Bricks do not