Professional Documents

Culture Documents

Universal Joint

Uploaded by

ReaderRider0 ratings0% found this document useful (0 votes)

32 views4 pagestechnique

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttechnique

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views4 pagesUniversal Joint

Uploaded by

ReaderRidertechnique

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

UNIVERSAL

JOINT

TROUBLE

SHOOTING

ss

ST

ill

AE is

Ameridrives::2'2

AN AMERIDRIVES INTERNATIONAL COMPANY

AMERIDRIVES UNIVERSAL JOINT

Trouble Shooting

The purpose of this guide is to offer a general failure analysis which can be performed through a

visual inspection of worn or failed universal joint components. Following is a parts description

breakdown along with a list of the most common problems, probable causes, and necessary

corrective action for universal joints.

INGE YOKE

TAINS RING

HING AND LUBE FYTDOMG

CARING ASSEOLY

RUNNION (BEARING ABEA OF CROSS)

‘wnvesrn ine

ACTALHING

SEARING ASSEMBLY

Problem Probable Cause Corrective Action

| Complete Unit

Excessive lubrication escaping past ‘Seals not compatible with Replace seal with seal suited to

seals environment. ‘operating environment.

Avoid damaging seals during

‘Seal damaged during assernbly. ‘assembly procedures.

Tighiness in bearings Wom bearing surfaces or tight fits. Replace bearings.

Deformed crosses and yokes from Replace yokes and crosses if they

high loads. are deformed.

‘Caked lubrication Indicates lubrication is breaking Replace bearings it necessary.

down.

Lubrication may breakdown due to Use an uncontaminated lubrication

‘contamination or high operating recommended by lubrication

temperature. manufacturer. I high operating

‘temperatures exist contact the

lubrication manufacturer.

‘Noise or vibration ‘Wom bearings, Keys, splines, bent Repair or replace damat

‘shaft, or loose connections on the: ‘components. A balanced universal

universal joint, joint may be required.

Excessive backlash ‘Worn splines or bearings. Replace damaged components.

Overheating Insufficient lubrication, excessive Determine cause and correct.

loads, wor beavings, excessive

‘operating speeds.

‘Continued operation at excessive

temperatures may result in bearing

fall.

Crosses

Fractured or distorted cross

“Torque overloads, over

misalignment, or axial overloads.

Check all drive train components for

Joint size to match ratings. Check

‘actual misalignment. Reduce

‘misaignmentif it exceeds the

universal int capaci,

heck fange to flange or shaft to

ott length requirement and

universal joint length capacity,

Correct required.

Problem Probable Cause Corrective Action

Yokes

Fracture Excessive loads ‘Check universal joint loads against rating. Reduce loads or

increase $e if required.

Distorted Excessive loads Check distance between retainer grooves in yoke eyes in four

bearing eye places to determine if distored. Replace yoke and bearing

assemblies if distorted. Reduce loads or increase universal joint

size if necessary.

Trunnion and Bearing Surfaces

Brinalling Mibration or shock False brinelling appears as bright rectangular marks and is

Joading ‘caused by intemal bearing vibration. Correct by isolating

bearings and using greases with antwear additives. True

brineling & caused by static or impact loads which exceed

elastic imit ol the material. Bearing surfaces with indications of

tue brineting must be replaced.

Spaling High dynamic Spallng isa fatigue fallue of beaving surfaces resulting from

loading high loading. Check load rating on universal joint. Bearing

replacement is required,

Blue or black ‘Overheating ‘Overheating results from lubrication failure. Lack of lubrication

surfaces and excessive speeds are two causes of kibication failure.

Flepiace bearings and increase frequency of lubrication,

liregular dents on Lubiication This is a common cause of bearing failure and resuits when an

surface coniaination abresive substance is present on a loaded bearing surtace.

Feplace bearings and elminate sources of contarination.

Galling on end of Excessive or (Check angles, runnouts, and lubrication. Comect as required

trumion uneven angles,

‘Outof balance

‘assembly.

Lubication failure,

Corosion Lubrication ‘Greases contaminated with corrosives can pit and discolor

coniamination bbeaing surfaces. If piting s present in nor-oad carrying

frees, corrosion isa probable cause, Check both grease and

seas.

‘Note: The causes of bearing failures are dificult to determine f the surlaces are not examined in the early stages of

failure, The inital failure mode may introduce ecictional failure modes.

—

AMEHIAPIVES 222.2280.

INTERNATIONAL (614) 489-5000 Form 364-SH, 1297,

4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SECURITE Elec Suite4Document1 pageSECURITE Elec Suite4ReaderRiderNo ratings yet

- Vgood Levage PironDocument88 pagesVgood Levage PironReaderRiderNo ratings yet

- IntroductiontoMetalFatigue1sted2018 PDFDocument98 pagesIntroductiontoMetalFatigue1sted2018 PDFAhmadHerjunoNo ratings yet

- SECURITE Elec Suite2Document1 pageSECURITE Elec Suite2ReaderRiderNo ratings yet

- SECURITE Elec Suite5Document1 pageSECURITE Elec Suite5ReaderRiderNo ratings yet

- Securite ElecDocument1 pageSecurite ElecReaderRiderNo ratings yet

- SECURITE Elec Suite3Document1 pageSECURITE Elec Suite3ReaderRiderNo ratings yet

- Fillet Weld DesignDocument2 pagesFillet Weld Designsaj0205037No ratings yet

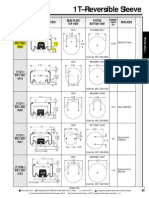

- Reversible Sleeve 1T Style Springs Assembly DiagramDocument2 pagesReversible Sleeve 1T Style Springs Assembly DiagramReaderRiderNo ratings yet

- SECURITE Elec Suite4Document1 pageSECURITE Elec Suite4ReaderRiderNo ratings yet

- Street ArtDocument1 pageStreet ArtReaderRiderNo ratings yet

- Draw FtsDocument1 pageDraw FtsReaderRiderNo ratings yet

- Street Art 7Document1 pageStreet Art 7ReaderRiderNo ratings yet

- SECURITE Elec Suite1Document1 pageSECURITE Elec Suite1ReaderRiderNo ratings yet

- SECURITE Elec Suite4Document1 pageSECURITE Elec Suite4ReaderRiderNo ratings yet

- Street Art 6Document1 pageStreet Art 6ReaderRiderNo ratings yet

- Street Art 7Document1 pageStreet Art 7ReaderRiderNo ratings yet

- Street ArtDocument1 pageStreet ArtReaderRiderNo ratings yet

- Street Art 3Document1 pageStreet Art 3ReaderRiderNo ratings yet

- Street Art 4Document1 pageStreet Art 4ReaderRiderNo ratings yet

- Pierre RabbiDocument1 pagePierre RabbiReaderRiderNo ratings yet

- Belleville Wall 14Document1 pageBelleville Wall 14ReaderRiderNo ratings yet

- Street Art 2Document1 pageStreet Art 2ReaderRiderNo ratings yet

- Street Art 5Document1 pageStreet Art 5ReaderRiderNo ratings yet

- Belleville WallDocument1 pageBelleville WallReaderRiderNo ratings yet

- FreudDocument1 pageFreudReaderRiderNo ratings yet

- Book Card Magic of Le PaulDocument1 pageBook Card Magic of Le PaulReaderRider0% (1)

- Ball PALMDocument1 pageBall PALMReaderRiderNo ratings yet

- Fiche D'execices BissectriceDocument1 pageFiche D'execices BissectriceReaderRiderNo ratings yet