Professional Documents

Culture Documents

Weatherable Rigid PVC - The Effect of Light and Thermal Stabilizers PDF

Weatherable Rigid PVC - The Effect of Light and Thermal Stabilizers PDF

Uploaded by

Pamela Chacón0 ratings0% found this document useful (0 votes)

11 views5 pagesOriginal Title

Weatherable rigid PVC_ The effect of light and thermal stabilizers.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views5 pagesWeatherable Rigid PVC - The Effect of Light and Thermal Stabilizers PDF

Weatherable Rigid PVC - The Effect of Light and Thermal Stabilizers PDF

Uploaded by

Pamela ChacónCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

Weatherable Rigid PVC: The Effect of Light

and Thermal Stabilizers

GERALD CAPOCCI

Additives Division

Ciba-Geigy Corporation

Ardsley, New York

Rigid PVC compositions used in outdoor applications such as siding. profiles.

windows, and soffit predominantly contain a tin mercaptide thermal stabilizer. It

is well known that tin mercaptides impart outstanding thermal stability to vinyl

compounds, however, it is also well known that they provide only marginal light

stability. Mercaptides can be used in these applications primarily because they

are combined with high levels of titanium dioxide. They are not well suited for

dark colored PVC and compositions without titanium dioxide. These require a

more weatherable thermal stabilizer, such as a tin carboxylate. In this paper,

principles for formulating rigid weatherable vinyl will be discussed. The influence

of thermal stabilizers and the interdependence of light stabilizers and thermal

stabilizers on PVC photostability will be emphasized. Data will be presented

showing how one can formulate weatherable dark brown and pastel PVC through

the use of tin carboxylate thermal stabilizers, the appropriate light stabilizers,

and pigments. Traditional approaches to achieving weatherability will be com-

pared to what can be attained by capitalizing on the latest advances in stabiliza-

tion technology. Finally, methods for reducing TiO, concentration will be shown.

INTRODUCTION

{gid PVC compositions used in outdoor appica-

tions such as siding, window profiles, and soffit

predominantly contain tin mercaptide thermal sta-

bilizer and between eight and twelve parts of tta-

nium dioxide, This combination ofan efficient ther-

mal stabilizer and a good light scattering pigment

allows most white and pastel colored PVC to be used

‘outdoors for many years. However. this traditional

method of achieving good light stability isnot appro-

priate for dari brown pigmented PVC or for compo-

sitions containing reduced or low levels of titanium

dioxide. These more demanding systems require new

technical approaches to the maintenance of PVC

photostability.

In this paper, the influence of thermal stabilizers

and the Importance of proper selection of thermal

Stablizers and light stabilizers to achieve good

‘weatherability s discussed. (The discussion is limited

to PVC homopolymers.) Data ts presented showing

how one ean formulate weatherable dark brown and

pastel PUC through the use ofa tin carboxylate ther-

mal stabilizer, the appropriate ultraviolet (UV) light

stabilizers, and lightfast pigments.

Reported for the first time isthe efficacy of hind-

ered amine light stabilizers (HALS) tn rigid PVC. Also

‘included is a method for reducing titanium dioxide

concentrations in a pastel PVC while maintaining

good weativerabity

JOURNAL OF VINYL TECHNOLOGY, DECEMBER 1969, VOL

EXPERIMENTAL

Samples discussed In this paper were produced

from dry blends prepared using a high intensity

‘mixer, They were elther directly extrudedor compres-

sion molded following two-roll-milling. Temperature

profiles were those typically encountered in commer:

cial systems.

Yellowness Index was measured according to

‘ASTM D-1925. Delta E was measured according to

the Hunteriab system with the spectral component

included.

Impact strength was obtained with a Dynatup In-

strumented impact Tester equipped with a Nicolet

Digital Oscilloscope and an IBM Personal Computer.

‘The impact tester was controlled by an in-house.

developed computer program.

‘Accelerated weathering was run using an Atlas

Blectrle, CI 65 Xenon Weatherometer equipped with

borosilicate inner and outer filters, set at 0.95 w/m?

‘radiance, with continuous light and a 102 minute

dry and 18 minute spray cycle.

RESULTS AND DISCUSSION

Effect of Thermal Stabiltzer

To achieve good weatherability, PVC must be for-

mulated and processed properly. One formulation

variable which has a great influence on the photo-

stability of a PVC compound is the choice of thermal

11, NO. 4 198

Gerata Capocet

stabilizer. While tin mercaptides are known to be

‘excellent thermal stabilizers, they are also known to

provide marginal fo poor light stability (1, 2). Thelr

[Baftability for outdoor applications depends to agreat

Gegree on being combined with high levels of ita

hum dioxide oF other sultable light scattering pig-

‘ment, This performance dependence 1s illustrated in

Table 1. Methyltin or butyltin mercaptides combined

‘with titanium dioxide are by far the most widely used

thermal stabilizer/light stabilizer system in the US.

Fight weatherable vinyl industry.

Tin carboxylates. another class of thermal stabiliz~

cers, sacrifice some heat stabilizing efficiency relative

‘tomercaptides: however, they provide inherently bet-

ter ighe stability (3), The better light stability of tin

‘carboxylates can be primarily attributed to their UV

light absorption characteristics. Tin mereaptides are

“simply much stronger chromophores than in carbox:

ylates as illustrated In Fig. 1. The absorbed light

{from 300-250 nm) triggers a rapid photochemical

‘change in tin mereaptides reeulting in aevere diacol

‘ration. This is shown in Table 2

Because of the relatively high processing temper

atures of rigid vinyl, maleate free carboxylates are

preferred since tin maleates are known to be lacry-

fiators at elevated temperatures. This discussion tx

limited to a maleate free tin carboxylate, Tin Carbox

‘late T, which is identified in the Appendix.

‘Barium/eadmium soaps are also known to impart.

‘good light stability to rigid vinyl compounds. They

fire used widely in Europe and in some U.S. applica

tons. Their performance is ilustrated in Table 3,

However. bartum/eadmium based systems are also

known to be moisture sensitive, while cadmism is

lunder attack for environmental reasons. These (0,

points will make It difficult for barfum/eadmium

based products to become significant factors in the

U.S. rigid vinyl industry.

‘The remaining discussion wil focus on a specific

tun carboxylate. Tin Carboxylate T. and a butyitin

mercaptide.

Effect of Rheology

‘Tin carboxylates as a class possess thermal stabt-

Wing and lubrieant properties that are unlike mer~

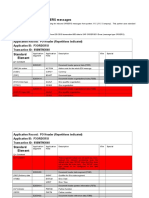

‘able 1, Etteot on Titanium Dios on Tn Mercaptie-

‘Stabiizea Rigid PUC™Floraa Expomure

Yellowness index

is", ___itel__12Mos.__24 Won

Cewawotoy 86 3-186

3 58 ite ot

3 58s ee

2 ety

Irpact Moir

Prseeos Ae

Absorption Spectra of Organotins

= te omoniter

| Te oconae

Fig, 1. Spectra ts from 1% solution in methylene chloride,

‘Table 2. Compareon of Photostabity of PYC Thermal

‘hacer Nance Wontheramever Expocure

el e-o8]>

eren-elo|

captides. Thus, they cannot be substituted for a mer~

feaptide on a one for one basis in a typleal rigid

composition. Reformulation is necessary. The Mew

Formulation should be a rheological match of the old

o ensure similar processing characterises, Reo!

ogy matching can be accomplished through the ase

of a torque rheometer

Table 4 shows how the rheology of a typical butyl

{un mercaptide thermal stabilizer was matched with

‘Tin Carboxylate T. To achieve similar fusion char~

acteristics and degradation times, It was necessary.

108 JOURNAL OF VINYL TECHNOLOGY, DECEMBER 1989, VOL. 11, NO. 4

Weatherable Rigid PYC: The Effect of Light and Thermat Stabilizers

to use higher levels of the Carboxylate T and lower

levels of lubricant.

Pastel PVE

‘Titanium dioxide ts not available in quantities suf-

ficient to meet the vinyl industry's demand. Ths has

Jed to higher prices and has prompted vinyl producers

{© look for ways to reduce their TiO, consumption

One way to achieve this geal is to substitute a more

weatherable thermal stabilizer for the tin mereaptide

Usually found in pastel PVC. Aa example of this Io

contained in Table 5. The table shows that after 24

months of weathering in Florida, Tin Carboxylate T

js more effective than the tin mercaptide in main-

(Glning good color when the TiO concentrations are

“Table 4 Rigid PVC: Rheology Comparison—Tin Mercaptide to

"Tin Cavoonyate

To camonvate

Merci

we wooo 050

‘arma Stabizee 18 28.

Ipact Mocter 30 eo

(became o on

(Caciom Stearate 40 <

oment yo

‘Rhea

Te

Ta carboxylate

Mercapsce

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Genelec OM 1031aDocument4 pagesGenelec OM 1031atinkoko750% (2)

- 01 Edi Mapping TemplateDocument12 pages01 Edi Mapping TemplatesatishNo ratings yet

- Db2 DBA PlanningDocument415 pagesDb2 DBA Planningapi-3742720No ratings yet

- Speed Control of DC Motor Under Varying Load Using PID ControllerDocument11 pagesSpeed Control of DC Motor Under Varying Load Using PID ControllerAI Coordinator - CSC Journals100% (1)

- Hydraulic Hammer Rammer E 68 Rammer E 68 City Rammer E 68 City-JetDocument26 pagesHydraulic Hammer Rammer E 68 Rammer E 68 City Rammer E 68 City-JetCanteras El VegonNo ratings yet

- Table 1 Required Geotechnical Special Inspections: System or Material Inspection RemarksDocument31 pagesTable 1 Required Geotechnical Special Inspections: System or Material Inspection RemarksAmro Ahmad AliNo ratings yet

- Total Quality Management: TQM TQM Tools and Techniques Case 7.1 Process Variation ExerciseDocument30 pagesTotal Quality Management: TQM TQM Tools and Techniques Case 7.1 Process Variation Exercisesanaa84No ratings yet

- Modelling of Frictional Joints in Dynamically LoadDocument26 pagesModelling of Frictional Joints in Dynamically LoadAaron GalvezNo ratings yet

- Power Systems PDFDocument172 pagesPower Systems PDFSiva Agora KarthikeyanNo ratings yet

- HANDBOOK Solenoid Valves 01-VS-ENG PDFDocument31 pagesHANDBOOK Solenoid Valves 01-VS-ENG PDFInstalatiiGeneraleNo ratings yet

- Luminaria IbgDocument15 pagesLuminaria IbgIsrael QuintanillaNo ratings yet

- Advanced Cmos Technology 2019: (The 10/7/5 NM Nodes)Document3 pagesAdvanced Cmos Technology 2019: (The 10/7/5 NM Nodes)Prasheel NandwanaNo ratings yet

- Infa PWX OraclecdcDocument18 pagesInfa PWX OraclecdcPradeep KothakotaNo ratings yet

- Enzyme Lab ReportDocument7 pagesEnzyme Lab Reportapi-309561913No ratings yet

- Steps To Process Palm Efb PelletDocument25 pagesSteps To Process Palm Efb PelletNata MiharjaNo ratings yet

- V I R Worksheet Ohms LawDocument2 pagesV I R Worksheet Ohms Lawirene299No ratings yet

- Safety:: (Badchodian) Haram Khori)Document4 pagesSafety:: (Badchodian) Haram Khori)Ishaq Khan IKNo ratings yet

- Alcohol Phenol Ether and Carbonyl Compounds. Assignment Q. (Adv) .Document8 pagesAlcohol Phenol Ether and Carbonyl Compounds. Assignment Q. (Adv) .Anurag RamachandranNo ratings yet

- Edge Triggered D Flip FlopDocument11 pagesEdge Triggered D Flip FlopM.Bilal JattNo ratings yet

- Engine ThesisDocument109 pagesEngine ThesisNajam Ul QadirNo ratings yet

- S.No Equipments Quantity Rate Price: Machinery RequirementsDocument5 pagesS.No Equipments Quantity Rate Price: Machinery RequirementsHarshit JainNo ratings yet

- Cable Tray Systems: Systems That Make SenseDocument184 pagesCable Tray Systems: Systems That Make SenseМарко МитиќNo ratings yet

- CO2 To Methanol-Single StepDocument2 pagesCO2 To Methanol-Single StepUmesh DeshNo ratings yet

- 07 DPC Control For HL, EH, and HB DryersDocument27 pages07 DPC Control For HL, EH, and HB DryersJoelNo ratings yet

- 2009 Present Marmaray Tunnel Project 1Document29 pages2009 Present Marmaray Tunnel Project 1demirmesut7575No ratings yet

- Building Contruction1, Taylors UniversityDocument49 pagesBuilding Contruction1, Taylors UniversityCadence CNo ratings yet

- 8-Bit Microcontroller With 2K Bytes of In-System Programmable Flash Attiny22 Attiny22L PreliminaryDocument11 pages8-Bit Microcontroller With 2K Bytes of In-System Programmable Flash Attiny22 Attiny22L Preliminarymike_helplineNo ratings yet

- R. Minard - The Preparation of The Local Anesthetic, Benzocaine, by An Esterification ReactionDocument6 pagesR. Minard - The Preparation of The Local Anesthetic, Benzocaine, by An Esterification ReactionNstm3No ratings yet

- Report 6230919143733901063Document4 pagesReport 6230919143733901063JESUSNo ratings yet

- PDF To The Max: Multifunctional Tool For PDF FilesDocument3 pagesPDF To The Max: Multifunctional Tool For PDF FilesMadhav KumarNo ratings yet