Professional Documents

Culture Documents

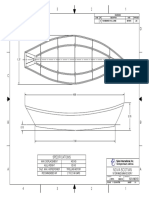

Redwood Canoe

Redwood Canoe

Uploaded by

leather_nun0 ratings0% found this document useful (0 votes)

9 views6 pagesOriginal Title

226356799-redwood-canoe

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views6 pagesRedwood Canoe

Redwood Canoe

Uploaded by

leather_nunCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

REDWOOD CANOE

Per eh

Ot mit

Woiilean build this 74-pound, 16-foot

Cae Peele canoe for $84. For a new canoe, that's a

or dine I err eee eee er see

old boat-building technique, a lie-flat blue-

print you'll find onthe following pages. The

Make the building form and attach templates

to the crosspieces. Nail a strip dawn the cen-

ter to hold the stems and templates in position.

prototype canoe took about three weekends

to build. She's broad of beam and flatbot-

tomed amidship. Two persons can sit side

by side in the center, with one person at

each end and plenty of room for

This canoe is formed around plywood

templates using ”-by-%” redwood strips,

glued edge to edge. You lay up the strips,

remove the form, and the canoe is com-

plete, except for fiberglassing and putting

in the seats.

How to start. First, lay out the patterns

full size on large sheets of heavy brown

wrapping paper. Since a canoe is sym-

metrical front to back and side to side,

you need draw full-scale pattems of only

half of each template. forming half of the

canoe. The patterns ‘are flopped to draw

the other half of each template; duplicate

templates are made from these for the

other half of the canoe. Draw the template

patterns using a 18” grid as shown in the

blueprint.

Build the form from four two-by-fours.

Make it square, solid, and level; the finished

canoe will be no better than the form it's

made on. If built as shown, it can be con-

verted into a bench for working on the

canoe right side up.

Cut the templates from &” plywood and

serew them to the building form. Make

sure they are centered and vertical. Put on

templates 1 and 9 first; then stretch a

string over the center of these between the

ends. This lets you line up the other tem-

plates. Next, make the canoe’s stempieces

172 | POPULAR SCIENCE

Redwood strips are tacked to the templates,

and edge-glued. Drive brads through into the

templates before putting on fiberglass. cloth.

and set them in place on the frame. Glue

two pieces of white pine together for each

stem, and trace the lines from the full-size

drawing on each. Bevel each piece to ac-

cept the redwood side strips. Tie together

the stempieces and the templates with a

W”-square strip of wood.

Next, rip the longer straight-grain red-

wood planks (see Materials List) into strips

4” wide. You need about 70 of these

strips to make the canoe hull.

Before planking the hull, put masking

tape along the edge of each template to

keep glue from sticking to it. Start planking

at the gunwales, using %” No. 18 brads to

Reinforcing strips are put on each stem after

the hull gets its first coat of resin. Hull is

then covered with two layers of glass and resin.

Bevel strips so they mest in front of stem.

A tight fit is not necessary, since the stems

are covered with two layers of cloth and resin,

nail each strip to the templates. Place the

strips so that the X” width forms the thick-

ness of the hull. Don’t nail the strips to the

endpieces yet.

After each strip is nailed in place, put

Elmer's Glue-All along its edge. As you

Jay each strip in place, hold it firmly against

the strip below and nail it to each plywood

template.

Do this until you have three or four

strips on each side in place. Then cut each

strip off 4” beyond the stempieces. With

a sharp knife, cut the inside of the strips

to an angle that lets them meet in a point

{See lie-flat blueprint on the following two pages. Text continued on pa

Hull is placed in tilted position on the build-

ing form for easy working on inside, Only one

layer of cloth and resin is needed on inside.

Ay Clamping its hold te strips in place when you

reach the point where twist gets bad. Scraps

from the beveled stem make good clamping pads.

beyond the stempieces. Glue them with

resorcinol and nail them with 3” copper

nails.

A little ingenuity is needed to clamp the

ends of the strips tight. A large rubber band

(cut from an old inner tube) tightened

ith a stick through ane end does a good

job.

When you have added about 19 strips on

each side, the twist at each end gets pretty

dad. Clamps, shown in photos, hold them.

When about 25 are on, the strips meet

along the keel. Cut them to meet in a

staggered line along the keel

Finishing touches include adaing gunwales,

inwales, seats, yoke, and breast plates. You

weave seats with webbing as shown in blueprint.

is

a

y

MEST)

Bad Eres

ome aro)

Pears >

pares

TOGETH

eco)

Geeeae eerste

REDWOOD CANOE

Ener

ao

Penta’

ees

relat

as

aaa

i

Ti

Eros orted

STRIPS STAGGERED,

yeahs tae

Loree

emery eos 2

per

Peete)

Caste

Pe Seen

ener)

Ere tae tot

ene eee reer rey

crt Neecueeser

anette}

eee

Per eesraraeen te

Redwood Canoe You Can Build

[Continued from page 173)

When all strips are in place, sand the

hull and give the outside a coat of poly

ester or epoxy resin. When this has set,

make a thin-point nail set and punch all

nails in each strip through, into the form.

Cover the outside with ‘glass cloth and

another coat of resin. Start at the center

and work the cloth toward each end. A

few staples hold it while you apply the resin.

Use inexpensive paintbrushes to apply

the resin. Wear rubber gloves, and use a

squeegee to work the resin through fiber-

glass. After the first coat of resin, fit ai

extra strip of fiberglass at each end to over-

lap about 2” on each side.

When the resin is set, sand the rough

spots and apply the second coat. Two coats

of cloth and resin should be enough.

Removing the templates. After the out-

side is finished, take out the screws that

hold the templates to the form, and care-

fully remove the templates do this,

push them toward the larger part of the

hull. Tur the canoe right side up on the

building form to work on the inside.

Sand the inside and coat it with resin.

Shape and attach the keel before glassing

and finishing the interior. The blueprint

shows how to change the building form to

hold the canoe at an angle; it makes work-

ing inside easier.

Cover only half of the inside at a time.

This lets you overlap the glass at the center

for more strength. Before putting in the

full-length glass cloth, work some left-over

pieces in at the stems.

You can cut 60’wide cloth in half

and staple the selvage about %” over the

center line so that the keel screws are cov-

ered. Work it up the sides and toward

each end. A few staples may be needed

along the top edge until the resin is on;

they may then be pulled out. One layer of

resin and cloth is enough inside.

When the resin is set, trim off the excess

glass cloth. Attach the gunwales and in-

wales with either screws or bolts

Build and varnish the seats, breast plates,

and yoke, and fasten them in place.

These plans let you build a 13’ canoe,

too. You build it the same way, but you

eliminate templates 4 and 5, making tem-

plate 6 the center of the hull, Nothing else

need be changed. @

Compare this 16" Larson

ret) mee) 1c

200 | POPULAR SCIENCE

You might also like

- ElvisDocument1 pageElvismaui3No ratings yet

- Plans For 15' Super Sunray SailboatDocument7 pagesPlans For 15' Super Sunray SailboatHawkNo1No ratings yet

- The NicotinaDocument8 pagesThe Nicotinab0beiiiNo ratings yet

- Building The Osborne PlatterDocument9 pagesBuilding The Osborne PlatterHeman Lee50% (2)

- 0071477926Document242 pages0071477926DELA DAVID100% (1)

- Built Your Own Boat From ScratchDocument4 pagesBuilt Your Own Boat From ScratchBernice BunceNo ratings yet

- Plywood RowboatDocument7 pagesPlywood RowboatAlphamatrix01No ratings yet

- One OffarticleDocument6 pagesOne OffarticleBOREBGK100% (1)

- AutoSpeed - DIY Digital AnemometerDocument4 pagesAutoSpeed - DIY Digital Anemometerarjuna1210No ratings yet

- A Runabout Reborn - Fast Modern Schooner - Lapstrake Primer: The Magazine For Wooden Boat Owners, Builders, and DesignersDocument152 pagesA Runabout Reborn - Fast Modern Schooner - Lapstrake Primer: The Magazine For Wooden Boat Owners, Builders, and DesignersPablo BesserNo ratings yet

- Shrike Build Manual - English Revised 3rd December 2021Document59 pagesShrike Build Manual - English Revised 3rd December 2021Ronald ZezeanuNo ratings yet

- Samurai Swords (AKA Shogun) Game ManualDocument35 pagesSamurai Swords (AKA Shogun) Game ManualRichard VeghNo ratings yet

- The Handsewn SpritslDocument16 pagesThe Handsewn SpritsllocksafeNo ratings yet

- Tore Holm - Bronze Fastenings - Butterfly Skylight: The Magazine For Wooden Boat Owners, Builders, and DesignersDocument140 pagesTore Holm - Bronze Fastenings - Butterfly Skylight: The Magazine For Wooden Boat Owners, Builders, and DesignersPablo BesserNo ratings yet

- ModularPDR PDFDocument32 pagesModularPDR PDFocolibriNo ratings yet

- Ryobi BTS10 Table Saw Parts ListDocument5 pagesRyobi BTS10 Table Saw Parts Listb0beiiiNo ratings yet

- Mason 33 Practical ReviewDocument5 pagesMason 33 Practical ReviewManuelPérez-Sola100% (1)

- Coarse, Carp, Fly & Sea Fishing Tackle: Saturday 17th March 2018Document16 pagesCoarse, Carp, Fly & Sea Fishing Tackle: Saturday 17th March 2018Sorin MaleaNo ratings yet

- Gyro Skipper PlansDocument5 pagesGyro Skipper PlansJayantha KandegamaNo ratings yet

- Iturra Design Catalogue 2010Document240 pagesIturra Design Catalogue 2010jeltzz2100% (3)

- Kiwi RacerDocument4 pagesKiwi Racercipx2No ratings yet

- Shrike Build ManualDocument29 pagesShrike Build Manualvelok71No ratings yet

- The Lincoln Procedure Handbook of Arc WeldingDocument742 pagesThe Lincoln Procedure Handbook of Arc Weldingmario fisgaNo ratings yet

- How To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionsDocument2 pagesHow To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionstwinscrewcanoeNo ratings yet

- Notice: Spira International, IncDocument2 pagesNotice: Spira International, Incidix bloodjackersNo ratings yet

- HISTORY ON BIRCHBARK The Art of Tomah Joseph, PassamaquoddyDocument25 pagesHISTORY ON BIRCHBARK The Art of Tomah Joseph, PassamaquoddyHaffenreffer Museum of AnthropologyNo ratings yet

- Notice: Spira International, IncDocument2 pagesNotice: Spira International, InclcortezbrNo ratings yet

- Ebook Cruising Guide To The Coast of Brazil - Marcal Ceccon - (1994)Document69 pagesEbook Cruising Guide To The Coast of Brazil - Marcal Ceccon - (1994)alemospoaNo ratings yet

- Polysail International Boat Designs From The 1940'S: Treasures From The PastDocument5 pagesPolysail International Boat Designs From The 1940'S: Treasures From The PastAlphamatrix01No ratings yet

- Bait Boat BuildDocument9 pagesBait Boat Buildmagatsu2099No ratings yet

- Fao Buildin A Double Ended Cambodian Design PDFDocument27 pagesFao Buildin A Double Ended Cambodian Design PDFfridomeroNo ratings yet

- Build Your Own Sailboat-SPRAY 370 CDocument5 pagesBuild Your Own Sailboat-SPRAY 370 CJoao CalinhoNo ratings yet

- Kiribati CanoeDocument9 pagesKiribati CanoeSándor Tóth100% (1)

- Kepler Bottom Bracket Friction Drive For Sale (Finally) - Endless SphereDocument34 pagesKepler Bottom Bracket Friction Drive For Sale (Finally) - Endless SpheregiacummoNo ratings yet

- Boats BooksDocument10 pagesBoats BooksjobimjobimNo ratings yet

- Build A Scale To Weigh Bee HivesDocument8 pagesBuild A Scale To Weigh Bee HivesPopescuAlexandruIonNo ratings yet

- Austin Seven Sports 1930 ModelDocument2 pagesAustin Seven Sports 1930 Modelsjdarkman1930No ratings yet

- CIP ListeDocument8 pagesCIP ListeMaik MüllerNo ratings yet

- Ferrocement A Versitile Construction MaterialDocument113 pagesFerrocement A Versitile Construction MaterialplutocowNo ratings yet

- ConfuciusDocument12 pagesConfuciusCarlos Emanuel Gomes Sousa100% (1)

- Wooden Coorong Longtail Boat PlansDocument2 pagesWooden Coorong Longtail Boat Plansmarcusbennet4854No ratings yet

- Plans For 20' Splinter SailboatDocument5 pagesPlans For 20' Splinter SailboatHawkNo1100% (1)

- Auxsea StudentDocument124 pagesAuxsea StudentVictoria RadchenkoNo ratings yet

- The Russ Adams GarveyDocument4 pagesThe Russ Adams Garveyb0beiii100% (1)

- Manual Digitech Rp1Document30 pagesManual Digitech Rp1Exodisto Pordocimo100% (2)

- NovaScotianMetricStudy PDFDocument2 pagesNovaScotianMetricStudy PDFtrola666910100% (1)

- Passagemaker PDFDocument7 pagesPassagemaker PDFLong Tran100% (1)

- Blackpowder Pistols PDFDocument7 pagesBlackpowder Pistols PDFeppg82No ratings yet

- Cycle Magazine 9-77-1978 Hawk ReviewDocument14 pagesCycle Magazine 9-77-1978 Hawk Reviewpaul_costall100% (1)

- Pod Yak FlatDocument3 pagesPod Yak Flattwinscrewcanoe100% (1)

- Plywood Touring Canoe PlansDocument14 pagesPlywood Touring Canoe PlansRush Wingate100% (1)

- Perfect Poppers For The Topwater BiteDocument4 pagesPerfect Poppers For The Topwater BiteAllan MorganNo ratings yet

- Truth, Lies, and O-Rings - Inside The Space Shuttle Challenger Disaster (PDFDrive)Document626 pagesTruth, Lies, and O-Rings - Inside The Space Shuttle Challenger Disaster (PDFDrive)Marcin JastrzębskiNo ratings yet

- Traditional BoatsDocument124 pagesTraditional BoatsKatja G0% (1)

- Black Book of ExplosivesDocument75 pagesBlack Book of Explosivesjack007xrayNo ratings yet

- Airgun With EXplosive Air Release ValveDocument15 pagesAirgun With EXplosive Air Release ValveWeb devNo ratings yet

- Build A Greenland Kayak Part 3Document21 pagesBuild A Greenland Kayak Part 3manoel souzaNo ratings yet

- Inflatable SailboatDocument9 pagesInflatable SailboatSorin DirjanNo ratings yet

- Craftsman Wet/Dry Vacuum Owner's ManualDocument11 pagesCraftsman Wet/Dry Vacuum Owner's Manualb0beiiiNo ratings yet

- How To Make A Banjo and Banjo-GuitarDocument25 pagesHow To Make A Banjo and Banjo-Guitarb0beiiiNo ratings yet

- Ryobi BTS10 Table Saw Operator's ManualDocument24 pagesRyobi BTS10 Table Saw Operator's Manualb0beiiiNo ratings yet

- M2A-15 Guitar Amp ManualDocument3 pagesM2A-15 Guitar Amp Manualb0beiiiNo ratings yet

- How To Mill On A Drill PressDocument5 pagesHow To Mill On A Drill Pressb0beiii0% (1)

- Arbor Press PlansDocument3 pagesArbor Press Plansb0beiii100% (2)

- Homemade SnowblowerDocument5 pagesHomemade Snowblowerb0beiiiNo ratings yet

- Slingshots Now Super AccurateDocument4 pagesSlingshots Now Super Accurateb0beiii100% (2)

- Make An Aluminum Barrow For Your WheelbarrowDocument3 pagesMake An Aluminum Barrow For Your Wheelbarrowb0beiiiNo ratings yet

- Ice Fishing ShelterDocument2 pagesIce Fishing Shelterb0beiiiNo ratings yet

- New Lessons in Arc WeldingDocument332 pagesNew Lessons in Arc Weldingb0beiii100% (1)

- Welding Helps For FarmersDocument456 pagesWelding Helps For Farmersb0beiii100% (1)

- Metals and How To Weld ThemDocument406 pagesMetals and How To Weld Themb0beiii100% (5)

- Rowing RiggingDocument4 pagesRowing Riggingb0beiiiNo ratings yet