Professional Documents

Culture Documents

Well Control Inspection 06 July 2105

Uploaded by

Fortuna Hunila0 ratings0% found this document useful (0 votes)

44 views3 pagesExample for Well Inspection

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentExample for Well Inspection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views3 pagesWell Control Inspection 06 July 2105

Uploaded by

Fortuna HunilaExample for Well Inspection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

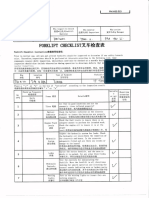

PL.DAQING JAYA PETROLEUM me

o ENGINEERING

inepaction tne ‘Who organize Whe inepect & record Who meniior ‘Whe review

‘pel ‘ane alan ‘nak ‘aoe

WELL CONTROL WEEKLY CHECKLIST

FRR

Well: NT #01 Rig: DQ #060 Date : 06-7-2015

#e MS: BM:

BOP Closis it. i Gr

DOOWESUART Sos ee

Waniford pressure 1400 -1500 psi V7 pat | Driers gauge manifold pressure

SLED BBS SRSCEA 1400 -1500 psi

‘ecumulafor pressure B70 BO555S | 7 pq, | Brilers gauge acrumulor pressure

we : BE RWI 2700 - 3000psi__

Annular closing pressure 1400 -1500 psi Vv Pst Driller’s gauge annular pressure

RERAEA ABSETRAVED 1400-1500 psi

‘Accumulator fad volume Le | Humbe: of pre-charge boties

BERTAM (OWARZR: 40L ) ALATA

‘Volume to overfiow accumulator tank Tir] Lest pre-charge on acaumulator unt

‘HER eM (FKQ00-7E, > 750L) ‘BHM MEN ( 950-1100psi)

a 5 pheumatic pump switches in “on”

Aicgup pressure. 9610150 oe

RERSOT

“ir purnp tested Electric hydraulic pump eed

SRESCSM Aon | een seme

‘Recumulator solation valve(@) open Aan | elctcal pump swiichos in "AUTO" postion

BRBRLMESRT TM ON| gRAARERT “Batt th

Discharge / Suction pump valves open’ Yon ‘Shear/Blind ram covers in place

Se/AS ae SAit HV SAMRSHRASRES

"Annular in-ine valves open ei

ESS Lee ST S e

BOP stack

ae Zi

SOP hand wheel avaliable wan

BOPEASESE

Choke/ KillLnes and Warifold

PREFEBSEL

Last choke panel gauge certification ‘Ar Supply pressure to choke panel

seapeencneememrae | Yer | Seeger cet oure)

Choke panel manvfold manual gauge

ressure 7, wpa | Stoke panel manifold pressure ee

SREVARERRTED (14.20 PRSSORETEEED

MPa)

‘Choke panel standpipe pressure Drilere gauge etandpipe pressure

PRSADRE ANTE MPa | syiesien REA aes

Choke panel clean & inspectedfor leaks | 7, | Manual pumpon choke panel esied daily En

SRSGRARS SAH RE ON | sRESIGFHERAS SM es

inner choke & inner kiline valves open | 7%” | Otter choke & Outer killine valves csed |X

ANTRAL EIT oN | er RAUNNES Ee RNR E ET

Choke manifol ined up for hard shut-in with super choke in closed postion WEN

FALSE 20

(s PEDAOINGJAYA PETROLEUM

(J ENGINEERING

[PaeL Laer eS! a

Hielraule cheke type:

rR A~ at4o ah or

Rig Floor

ae

Fall Opening Safety Valve (FOSV), required XO, and handle wit lifing cap on rig for aa

ZAARIM - PSERUORAKIMGS ANS ORLRGERELES =

IBOP & FOSV valve function tested ‘Super choke function tested hourly

nouriy Won | BREE RTIAEM whan

BOP 1 Fosy RABI ASHALAE

Grayinside SOP & FOSV valve open |, ,| FOSV& BOP reais n good condiion Geen

pormerteemesari | ¥Y8N| rosy miso unRase e

Pop-off settings on pumps epGEN

RISSR EEE 2 -

Flow alarm set for gain floss (%) PVT alarm. Ic (bb:

uanewunanasoe” Ms ee ‘

General

Bae

Cold slat air compressor “Annular rubberé on locaion

EEASEDS SER Gon] FoR nn ane won

Tast BOP test date Donn g] NEtBOP fox date

ER BOP MAE GC] FsBop wet) =

EIT depth MOPTVD Lest Fi date

FIT AERC MD/TVD 6 1 eri RENE U-h«

FIT test MW FIT Equivalent MW

HERMIEMMNERSR & RS | wassmemanum ere (% sc

“Annular itermedate SICP Max allowable casing pressure

SPEED (SY PS! pieces pet

tolerance Barta on location

FY FBsbeFARB (25 BBL) 5 sce ss

Mud system volume ‘Allequipment has FS trim

=a Yorn 80 | rama mATTEE ES Ke

Zarite to weight up mud system 01

MmAeaMiLe 0.t2g MOH | (y sKs

Bon

Walked wall controllinee to enaureno concems wih ine up? Fy

Pena ered 8

‘Are we in compliance with Rumaila Standards on all well control equipment? WON

FAHPRSSA RH ERPO 2 x

Annular intermedate SICP reporied on Diling Rigs every Monday? ad

RHERESE-HSTS? 2 ae ze 4 ES

Person in charge of checking sign-in roster in case of well control situation:

Sees REAM

Wet ere you goingte do fwehave shutin ihe seleyrams? Gud Gy ak Ermey

DRRRBAARSAMG BHAT? GF

How are your going to get pressure ang how will you equalize the pressure across the BOP7CLe. Cape ACK)

RA THINERARERI 7 ASMTBBL BOP FATED ? at panel hedld

“Note: Al igs need 1000 psi gauge to record pressure f we nave to shun he safety rams.

SR: MRENASASASS MM VFAAGABSERS 1000psi VERICRET «

HOW ARE YOU GOING TO SHUT IN THE WELL IF YOU LOSE ELECTRIC POWER & AIR TO THE RIG?

Eos eaT BMS - RIFTS?

Bn es Sahl Equipment Ratings

Ramee

PLDAQINGJAYA PETROLEUM

o ENGINEERING

FMAHS.020

Pressure Rating (PSI)

‘Component Sie

Bu Rt EASe

Kil ine ESR rs a

Choke line BREA 4a

| Choke manifold SiR Urs

Annular #2 Bale?

Pipe rams Mth a

Bind rams 231 T3750

Wethead 2@SU#O -Fer

| Casing BS ware

Completed by: ARNOLE) Signature: hr Position. TDC PUSHER,

‘9A:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- ERP Materi TrainingDocument54 pagesERP Materi TrainingFortuna HunilaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Boat Inspection ChecklistDocument2 pagesBoat Inspection ChecklistFortuna HunilaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- ERP Materi TrainingDocument54 pagesERP Materi TrainingFortuna HunilaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Fork Lift Inspection.ADocument1 pageFork Lift Inspection.AFortuna HunilaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Definition of HSE Performance RecordsDocument2 pagesThe Definition of HSE Performance RecordsFortuna HunilaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Definition of HSE Performance RecordsDocument2 pagesThe Definition of HSE Performance RecordsFortuna HunilaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Attendance List Breafiing Depensive DriveDocument1 pageAttendance List Breafiing Depensive DriveFortuna HunilaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Wire Line Safety GuidanceDocument29 pagesWire Line Safety GuidancePaul Ninian75% (4)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- What Is The Difference Between TstiDocument4 pagesWhat Is The Difference Between TstiFortuna HunilaNo ratings yet

- Pit # 1 Pit # 2 Pit Control: Gen Set 2 Gen Set 1Document1 pagePit # 1 Pit # 2 Pit Control: Gen Set 2 Gen Set 1Fortuna HunilaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Report Break Down RigDocument4 pagesReport Break Down RigFortuna HunilaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)