Professional Documents

Culture Documents

Pre Eng Process

Uploaded by

api-264092079Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pre Eng Process

Uploaded by

api-264092079Copyright:

Available Formats

Patrick Mumford

9/24/2015

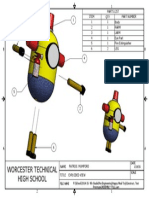

When building our design, we first looked into the list of constraints that we had

previously laid out in the design brief. Then, we brainstormed multiple ideas that

would effectively, safely, and efficiently satisfy the listed constraints. Once we

decided on our final idea, we began building using parts in the VEX

kits. During

the building process, there were multiple occasions where we realized that we

needed to alter our original design to meet our criteria and constraints, and to

create the most effective design.

During our first testing, we had a system comprised of two gears, two pulleys, and a

reel for the string. Once we began testing, it became apparent that the pulley

system would not be effective in its current state. We proceeded to modify the

system to accommodate our needs. After those modifications, we determined that

our machine was operating in a sufficient manner, and that further modification

would be unnecessary. Our compound machine is able to properly perform the

assigned task.

As mentioned above, we did have to modify our design during the test phase. This

was necessary because the rope was not able to stay attached to the pulley system

when we had only two pulleys. This was likely because the rope was on the same

side of both pulleys, and in this scenario, there was not thing pulling the pulley

down in the middle. To combat that, we added a third pulley between the first two.

This pulled the pulley down in the center, and helped to keep the rope on the

system. After that was resolved, we determined that the gears were loose, and were

skipping often. To fix that, we added supports on either side of the axles, and made

sure that the parts supporting the axles were tight enough.

This page created by Patrick Mumford on: Thursday, September 24, 2015 at

18:47:11.

You might also like

- 1 3 1 A Vex Solarhydrogensystem PlainDocument7 pages1 3 1 A Vex Solarhydrogensystem Plainapi-264642523100% (1)

- Design Brief Comp MachDocument1 pageDesign Brief Comp Machapi-264092079No ratings yet

- Decision Matrix For MinionDocument1 pageDecision Matrix For Minionapi-264092079No ratings yet

- Assembly Full-1Document1 pageAssembly Full-1api-264092079No ratings yet

- Decision Matrix For AccessoryDocument1 pageDecision Matrix For Accessoryapi-264092079No ratings yet

- Energy SourceDocument4 pagesEnergy Sourceapi-264092079No ratings yet

- 3 1 1 A Vex InputsoutputsDocument3 pages3 1 1 A Vex Inputsoutputsapi-264092079No ratings yet

- Final Calculations - For MergeDocument2 pagesFinal Calculations - For Mergeapi-264092079No ratings yet

- Fire ExtinguisherDocument1 pageFire Extinguisherapi-264092079No ratings yet

- DrawingsarmDocument1 pageDrawingsarmapi-264092079No ratings yet

- Research DocumentationDocument2 pagesResearch Documentationapi-264092079No ratings yet

- t9 TrailerhitchDocument1 paget9 Trailerhitchapi-264092079No ratings yet

- Worcester Technical High School: Date 1/19/15Document1 pageWorcester Technical High School: Date 1/19/15api-264092079No ratings yet

- DrawingsbodyDocument1 pageDrawingsbodyapi-264092079No ratings yet

- DrawingsexpDocument1 pageDrawingsexpapi-264092079No ratings yet

- Design BriefDocument1 pageDesign Briefapi-264098585No ratings yet

- t9 BedDocument1 paget9 Bedapi-264092079No ratings yet

- DecisionmatrixDocument1 pageDecisionmatrixapi-264092079No ratings yet

- DesignbrieftemplateDocument1 pageDesignbrieftemplateapi-264092079No ratings yet

- t9 TrailerDocument1 paget9 Trailerapi-264092079No ratings yet

- Group NormsDocument1 pageGroup Normsapi-264092079No ratings yet

- t9 Front-1Document1 paget9 Front-1api-264092079No ratings yet

- Brainstorming IdeasDocument1 pageBrainstorming Ideasapi-264092079No ratings yet

- Track StraightDocument1 pageTrack Straightapi-264092079No ratings yet

- Linkage ArmDocument1 pageLinkage Armapi-264092079No ratings yet

- Trainassembly 2 ExplDocument1 pageTrainassembly 2 Explapi-264092079No ratings yet

- Group NormsDocument1 pageGroup Normsapi-264092079No ratings yet

- Gantt ChartDocument1 pageGantt Chartapi-264092079No ratings yet

- Die Kuh CatcherDocument1 pageDie Kuh Catcherapi-264092079No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)