Professional Documents

Culture Documents

Us 20080302377 A 1

Us 20080302377 A 1

Uploaded by

Musheer Basha0 ratings0% found this document useful (0 votes)

23 views3 pagespatent

Original Title

Us 20080302377 a 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpatent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views3 pagesUs 20080302377 A 1

Us 20080302377 A 1

Uploaded by

Musheer Bashapatent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

us United States

c2) Patent Application Publica

Nauryzbaey et al.

(54) METHOD FOR EXTRACTION OF NICOTINE

FROM TOBACCO RAW MATERIAL

(75) Inventors: Michall Kassymovieh,

Nauryzbuev. Almaty (KZ): Datei

Yurievieh Korulkin, Almaty (KZ);

Serikbol T fe

Shalghymbaev. Almaty (KZ);

Timur Michallovich Nauryzbuey

Almaty (KZ)

Correspondence Address:

DEFILLO & ASSOCIATES, INC.

P.O. Box 14104

Clearwater, FL 33766 (US)

(21) Appl.Nos 12012070

(2) Filed Jan. 31,2008,

G0) Forcign Application Priority Data

Jun, 5.2007 (KZ) 20070762.1

'US 200803023741

iON (10) Pub. No.: US 2008/0302377 Al

(43) Pub, Date Dec. 11, 2008

ication Classification

(1) Inve

ADB 1526

US.CL

(2006.01),

1317298

ABSTRACT

The invention relates to methods of nicotine extraction fom

tobacco, caporal and tobaceo crumb.

The proposed method for extraction of nicotine from tobaoco,

caporal and tobacco crumb implies continuous extraction

from raw material with lowboiling solvents st vapor phase

Followed by solvent stripper and recurrence for futher rouse

in the process.

The technological advantages are the opportunity to use both

primary raw material and production wastes, shorter time

equired for extraction, eost reduction and process simpli

tation for extraction of nicotine, eduction of concomitant

Substances in the target produc, and no need in using acids

These advantages are achieved by the proposed extraction

sethod with low-boiling organic solvents what results ia

Tower consumption of chemicals, lower temperature, shorter

time reine forthe process and additional purification ofthe

target product and eliminates needs for high pressure to be

‘ed in technological process.

US 2008/0302377 Al

METHOD FOR EXTRACTION OF NICOTINE

(OM TOBACCO RAW MATERIAL,

(CROSS REFERENCE TO RELATED

APPLICATION

[0001] This is a conventional application based on KZ

Pateat Application No, 200770762.1y filed Jun. 5, 2007,

TECHNICAL FIELD OF THE INVENTION

[0002] | Theinvention relates to methods of nicotine extrc-

tion ftom tobaeeo, eaporal and tobacco ezumb,

BACKGROUND OF THE INVENTION

10003] There is a known method for extraction of nicotine

Jom lobacco with earbon dioxide, nitrous exile, aepon,sul-

Sur hexafluoride [US. Pat. No. 4,153,063, May 8, 1979], The

‘extraction i performed at temperatures 80-70” C. and pres

ures up to 1,500 atm. (preferably 70-350 atm.) then tem-

perature and pressure are set lower and nicotine is extracted

from the gas flows using sorbents

10004} -Forexample, for kzoftobacco with adjusted water

‘content of 15% ta 25%!

10005] CO, 70° C:; 300 atm; the gassobacco weight

iti is between 4.91 and 6.31:

0006} CO, $0° C.; 1.000 aim: the gas:tobaceo weight

ratios between 7:1 and 9:1;

0007] "Argon, 20° C.; 320 atm: the gasstohaceo weight

ratio is betweun 35:1 and 4.51:

[0008] SF, 70°C: 300 atm; the gastobaceo weight ratio

is between 6: and LO

10009] Disadvantages ofthis method are:

0010] Soase hardly avaiable gases, in particular, sulfur

hhoxalluride, argon and nitrous oxide are required;

[0011] Supercritical pressure

[0012] Tn this method, there are indications that it is pos-

sible o uilize halogenhydroearbons, but the conditions are

not specified

10013] There is a known method for extraction of nicotine

from tobacco and exporal with nicotine istiation by team

{allowed by precipitation with phosphowungstic acid: foreach

2 g of tobaceo, it is required 34-36 g of sodium chloride,

14.15 ml of SH sodium hydroxide water solution, 8 ml of

5.6% of pereipient’s solution (phosphotungstic seid) [SU

Patent No. 728831, publ. No. 15, 1980}

10014) Disadvantages of this method are that itis need a

Special instalation for distillation of quite complex desiga

‘andusing expensive phosphotungstic acd for precipitation

this acid conventionally used for qualitative analysis at

‘dentiication of alkaloids, but i not paniculaely specific for

nicotine [Shmuk, A. A, The Chemisty and Technology of

‘Tobaceo, Pishchepromizalat, Moscow, 1953, p. 225]

[0015] There is a known method for extraction of nicotine

from tobacco using organic solvents hardly. miscible or

immiscible with water and consequent treatment of the

‘extracts by the acid-water solution,

[0016] In this method for each Kilogram of tobacco, itis

required 25.200 | of solvent per hour. Dichlormethane, ben-

zl, cyclohexane, disopropyl ether, 1,]1-tichloroethane,

trichloroehylene,12-dichlorvethane, tetrachloride ethylene

are used as solvents [CA Patent No, 809968, 1969.04.08}

10017] For example, tobacco is treated by alow of organic

solvent bardly miseible or immiscible with water and then

‘extraction from the solvent is performed by aeid-water solu

Dee. 11, 2008

tion, In onder to assure uniform extraction and achieve

economy of the method, extraction of tobaeco with organic

solvent ad extraction fom solvent with acid-water solution

fare relized in continuous process at counter Now of the wo

eeds. At that, the contact time foe tobacco and organic sol-

‘ent comprises 45-180 min using w solvent to tobacco ratio of

25-200 of solvent per 1 ky af tobacco per hour, Acid-water

solution is removed at nicotine content from 5% to 25%:

removed solution is replaced with the appropriate quantity of

clean acid-water solution and extracted tobacco is contin

ously removed with residual organic solvent in it (in the

‘amouat of 5-4 per { kyo tobacea) then organic solvent is

‘evaporated and regenera

[018] Disadvantages ofthis method include:

[0019] large consumption of solvents (25-200 1, ie. the

Faw materialextractant weight ratio is benwecn I:1Oand

1: 100;

0020} "extraction with organic solvent is performed in

stages, at pH-2.0 and 2.Sby acid treatment of theextract,

(using chlorine-bydrogen dei, sulphuri acid or ortho-

phosphorie acid)

0021] the above-mentioned acids may cause corrosion

‘of the equipment

SUMMARY OF THE INVENTION

[0022] An objectof de invention isto provide a method for

extraction of nicotine from tobacoo and caporal as well as

{rom waste products (from a tobacco crumb)

[0023] Another object ofthe invention isto provide a pos-

sibility for processing of primary raw materials and produe-

‘ion wastes, a shorter, less expensive and technologically

simple nicotine extraction, lower contents of accompanying

substances in the target product and elimination of usage of

acids

[0024] ‘Theseobjectsare achieved by the method forextrac-

‘ion of nicotine from tobaceo raw material using extraction

treatment of raw material by means of organic solvent and

subsequent solvent stripping. but unlike the previously

‘known methods, there are used the low-boiling solvents (pe-

‘roleum ether, chloroform, methylenechloride) at the ra

materialsolvent weight ratio of about 1:3; tobacco, capora,

and tobseeo crumb (production waste) are used as the 8

‘material, and extraction of nicotine i earred ou fr around $

bin vapor phase

DETAILED DESCRIPTION OF PREFERRED

EMBODIMENT OF THE INVENTION

0025}. Te proposed method makes it possible to reduce

the ratio of raw material to solvent, to e-use the solveat

stripper at extraction, eliminates need! for high pressure, high

{emperature acids used in extraction, thatimprovesquality of

nicotine, reduces equipment corrosion an, tur, decreases

production cost

[0026) The present invention makes it possible:

0027] to use easly accessible ow-boiling extractants;

[0028] tocanry out theone-satecontinnovs process du

ing 5S hours with temperatures not exceeding 70” C. and

subsequent concentration of extracts at boiling tempera

tures of extoctans (petroleum ether —T,,-40-70" C.,

chloroform —Th.-6S"C., methylenechloride

Tj 40” C. at 760 mm Hg)

0025} to use any tobacco raw material, tobacco waste

‘and any extraction performance at normal pressure:

[0030] to reduce the aw materiaextracant weigh! ratio

tol

US 2008/0302377 Al

[0031] A mass of 100 g of crushed tobacco raw material

was inserted into the paper caridge of a Soxhlet extraction

apparatus; 300 ml of petroleum ether was placed in a ask

(theraw materialsolveat weight ratio :3) and was eflusedat

40-65" C.

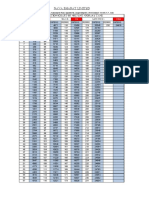

10032] "The percent extraction of nicotine atthe extraction

time of 2h, 3h, 4h. § hand 6 h were respectively 725%,

80.79%, 86.6%, 89.2%, and 90.5%

Example 2

10033] A mass of 100 g of crushed tobacco raw material

was inserted into the paper earteidge of a Soxhlet extraction

apparatus; 300 ml of petroleum ether was placed in a Bask

(dheraw materiasolvent weight ratio 1:3) and wasrefluxedt

60-65" C.

10034] "The percent extraction of nicotine atthe extraction

time of 2h, 3h, 4h. § hand 6 h were respectively 66.4%,

T1196, 78.5%, 83.5%, and 84.2%

Pxample 3

10035] A mass of 100 g of crushed tobacco raw material

‘was inserted info the paper cartridge of a Soxhlet extraction

apparatus; 300 ml of petroleum ether was placed in a ask

(the raw materiaksolvent weight ratio 1:3) and was refluxed at

40°C.

[0036] The percent extraction of nicotine atthe extraction

time of 2h, 3h, 4h, Sh, and 6h were wespectively 68.9%,

75.396, 84.2%, 86.8%, and 87.6%

Dee. 11, 2008

[0037] Therefore, the advantages of the proposed method

include

[0038] wider range of nicotine-contaning raw materials

for commercial processing:

0039] cheaper extraction process due to utilization of

cheaper extmcants and absence of expensive pment,

of gis extraction at high pressure, of expensive and

fenviroamentally hazardous acids (phosphotungstic,

hydrochloric, orthophosphori or sulphurie seid)

0040] "lower concentrations of aecessory agents in the

target product.

1. A method for extactng nivotine from a tobaee0 raw

‘material sing an extraction treatment ofthe raw material by

‘cans ofan organic solvent and subsequent solvent stripping

‘which comprises using as solvent a lo-boiling sven, the

‘AW mteria-solvent weiht rato being about 13; and eaery~

ing out the extraction of nicotine for around 5 h in vapor

phase.

2. The method aovording to claim 1 ia which said low-

boiling solvent is selected from the group consisting of pteo-

Jem ether, chloroform, and methylenechloride and mixtures

thereat:

'3. The method according to clams 1 in which suid robaceo

aw material is selected from the group consisting of tobacco,

eapora, and tobaevo crumb.

4. The method according to claim 2 in which sid tobacco

iw materials selocted from the group consisting oftohacc,

eaporl, and tobaceo era

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pellet Cooling and CrumblingDocument37 pagesPellet Cooling and CrumblingMusheer Basha50% (2)

- Knife Edge Gate Valve O&m ManualDocument6 pagesKnife Edge Gate Valve O&m ManualMusheer BashaNo ratings yet

- Instruction Manual: Compact Vibrating Fork Level SwitchDocument13 pagesInstruction Manual: Compact Vibrating Fork Level SwitchMusheer BashaNo ratings yet

- Cotton Seed Plant Processing DescriptionDocument9 pagesCotton Seed Plant Processing DescriptionMusheer BashaNo ratings yet

- Technical Manual Metsec Mezzanine FloorsDocument23 pagesTechnical Manual Metsec Mezzanine FloorsMusheer BashaNo ratings yet

- Centrifugal FanDocument1 pageCentrifugal FanMusheer BashaNo ratings yet

- Hexane Tank Calibration ChartDocument1 pageHexane Tank Calibration ChartMusheer BashaNo ratings yet

- Ladakh Road Map Vargis KhanDocument1 pageLadakh Road Map Vargis KhanMusheer BashaNo ratings yet

- Alphatech Steels FlyerDocument4 pagesAlphatech Steels FlyerMusheer BashaNo ratings yet

- Rice Bran Healthy OilDocument25 pagesRice Bran Healthy OilMusheer BashaNo ratings yet

- Model Sp4 Grain Spreaders: AttentionDocument14 pagesModel Sp4 Grain Spreaders: AttentionMusheer BashaNo ratings yet

- Rising Film Evaporator TimeDocument2 pagesRising Film Evaporator TimeMusheer BashaNo ratings yet

- Wodrich Design 1997Document235 pagesWodrich Design 1997Musheer BashaNo ratings yet

- Hammermill Hi-ResDocument4 pagesHammermill Hi-ResMusheer BashaNo ratings yet

- Mimic of Solvent Extraction PlantDocument1 pageMimic of Solvent Extraction PlantMusheer BashaNo ratings yet

- Pneumatic Grain ConveyingDocument16 pagesPneumatic Grain ConveyingMusheer BashaNo ratings yet

- Analysis and Design of Air-Jet Pumps For Pneumatic TransportationDocument302 pagesAnalysis and Design of Air-Jet Pumps For Pneumatic TransportationMusheer BashaNo ratings yet

- Complete Haj GuideDocument79 pagesComplete Haj GuideMusheer BashaNo ratings yet

- Cyclone Cum Wet ScrubberDocument1 pageCyclone Cum Wet ScrubberMusheer BashaNo ratings yet

- Complete Haj GuideDocument79 pagesComplete Haj GuideMusheer BashaNo ratings yet

- Cyclone Cum Wet ScrubberDocument1 pageCyclone Cum Wet ScrubberMusheer BashaNo ratings yet

- Vibrating ConveyorsDocument28 pagesVibrating ConveyorsMusheer BashaNo ratings yet

- Impact Crusher PDFDocument45 pagesImpact Crusher PDFMusheer BashaNo ratings yet

- TMMB 100-09Document22 pagesTMMB 100-09Musheer BashaNo ratings yet

- DB Pump CurvesDocument70 pagesDB Pump CurvesMusheer Basha75% (12)