Professional Documents

Culture Documents

1921 GB174544

1921 GB174544

Uploaded by

Nemanja Stojanovic0 ratings0% found this document useful (0 votes)

3 views5 pagesNIkola tesla

Original Title

1921_GB174544

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNIkola tesla

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views5 pages1921 GB174544

1921 GB174544

Uploaded by

Nemanja StojanovicNIkola tesla

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

30

35

“elastic

PATENT SPECIFICATION

Application Date: Apr. 1, 1921. No. 9729/21.

Complete Left: Sept. 2, 1921.

Complete Accepted: Feb. 2, 1922.

PROVISIONAL SPECIFICATION.

Improvements in Methods of and Apparatus for the Generation of

Power by Elastic Fluid Turbines.

I, Nixota “Testa, Mechanical and

Electrical Engineer, citizen of the United

Stetes of America, of 8, West 40th Street,

New York City, U.S.A., do hereby declare

the nature of. this wention to be as

follows :—

In the transformation of the heat of

media, by meens of turbines,

two methods ere now extensively

employed. In one, the working fluid is

expanded through ‘2 stationary- nozzle and

the free jet, impinging against: vanes or

equivalent devices integrel with the rotor,

gives. up to'.it. velocity energy, thus

setting it in motion by action. In the

other, the fluid is admitted at full

pressure to ,curved bledes or chennels in

the rotor where it expands imparting

energy to the same and causing it to

tarn” by, reaction... For. well-known

technical reasons. turbines, operating

purely .on either the first or the second

principle are scarcely. ever used, both

processes being: jointly applied in modern

machines, - Furthermore, elmost _invari-

ably . staging. is resorted to with the

. object of ‘subdividing the velocity- and

pressure-drop ;and improving thereby the

performence in conformity with funda-

mental laws of propulsion.

‘As is obvious from. theoretical con-

siderations and heat diagrams, the

reaction turbine with pressure stages is

generally capable of a higher thermo-

dynamiic efficiency because it has a bigger

“reheat factor”, that. is to say, it trans-

forms into mechanical effort a consider-

ably larger portion of friction heat than

recovered in the action turbine, with

velocity stages.', On the other hand, it

will be equally apparent that the former

is more limited in the tomperature range

and, in view of this hendicap, its

superiority would not be so pronounced

were it not for the fact that the relative

velocity of the fluid is greater in the latter

turbine, this detracting still more from:

its efficiency.

These respective qualities end short-

comings have been fully recognized by

engineers long ago end have gradually

led to the employment of impulse: and

reection-wheels merged into one ~ unit

which is thus better edapted for meeting

the requirements and should be. more

economicel. But although this idea

seems sound, the temperature renge has.

not been very much increased through its

applicetion and the gain, so fer effected,

is moderate indeed, to the point of being

doubtful in many . instances. Definite

limits to progress in this direction have

beon reached in the existing commercial

apparatus and the discovery of other ways

and means for saving fuel and reducing

the cost of installment and operation has

become a problem rendered especially

pressing throughout the world by the

greatly increased cost of this commodity.

The advantages of the action and

reaction principles cen be more com-

pletely realized through a process which

constitutes my present invention and,

briefly stated, consists in deriving motive

power from the heat of an elastic medium

first by means of friction and then by

reaction, The best instrumentelities for

the purpose, of which I em aware, are a

turbine of the kind described in my

British Patent No. 24,001 of 1910 and

one of the Parsons type, both being con-

nected or worked independently. The

174,544

45.

50

60

65

70

80

10

55

70

15

80

174,044

fluid is admitted to my turbine through

a suitable nozzle which may be expand-

ing, straight or converging, end in

traversing the spaces between the disks

exercises a frictional drag, thus trans-

forming a part of the available heat into

mechanical work. _ Upon exhausting

under proper temperature and pressure

conditions it is passed through the

Parsons turbine in which another portion

of its calorie energy is usefully converted

by reaction. Careful scientific investiga-

tion, supported by experiment, hes shown

that important economic results can be

secured by the new method and that this

particular combination of apparatus

possesses features of unusual merit.

In the first place my turbine is

exceedingly suited for very elevated tem-

peratures and also high pressures, while

the Parsons excels in the efficiency “of

the, thermo-dynamic transformation at

moderate temperatures and low pressures.

Again, the former permits the fluid to be

expanded either in the nozzle, the rotor

or both, and this flexibility facilitates the

establishment and maintenance _of

pressure and temperature conditions

favorable to both turbines, thus enhancing

economy. ‘Their combination is, how-

ever, of quite exceptional value in cases

when reversible units are indispensable,

as on shipboard, where it provides a

simpler, more efficient and far more

effective apparatus for forward propul-

sion as well as backing, my turbine being

much better adapted for reversing pur-

poses than other forms with small clear-

ances and delicate blading —_ easily

damaged.

While my turbine will yield the best

results in co-operation with the Parsons

it is eminently qualified to serve as first

stege, or stages, in conjunction with

other types of turbines, of whatever kin

also with rotating end _ reciprocating

engines, and in this broader sense my

improved process may be defined as one

in which the available heat of an elastic

medium is usefully transformed first by

friction, .as indicated, and then by action

or reaction.

Dated this 3st day of March, 1921.

NIKOLA TESLA.

COMPLETE SPECIFICATION.

Improvements in Methods of and Apparatus for the Generation of

Power by Elastic Fluid Turbines.

I, Nrxora Tusta, Electrical and

Mechanical Engineer, citizen of the

United States of America, of 8, West 40th

Street, New York, N.Y., USA, do

hereby declare the nature of this inven-

tion and in what manner the same is to

be performed, to be particularly described

and ascertained in and by the following

statement :—

In the transformation of the heat energy

of elastic media, by means of turbines,

two methods are now _ extensively

employed. In one, the working fluid is

expanded through a stationary nozzle and

the free jet, impinging against vanes or

equivalent devices integral with the rotor,

gives up to. it velocity energy, thus

setting it in motion by action, In the

other, the fluid is admitted at full

pressure to curved blades or channels in

the rotor where it expands imparting

energy to the same and causing it to

turn by reaction, For — well-known,

technical reasons turbines. operating

purely on either the first or the second

principle are scarcely ever used, - both

processes being jointly applied in modern

machines. Furthermore, almost —invari-

ably staging is resorted to with tho

object of subdividing the velocity- and

pressure-drop and improving thereby the

performance in conformity with funda-

mental laws of propulsion.

‘As is obvious from theoretical con-

sideration and heat diagrams, the

reaction turbine with pressure stages is

generally capable of a higher thermo-

dynamic efficiency because it has a bigger

“reheat factor”, that is to say, it trans-

forms into mechanical effort consider-

ably larger portion of friction heat then

is recovered in the action’ turbine, with

velocity stages. On the other hand, it

will be equally apparent that the former

is more limited in the temperature range

and, in view of this handicap, its

superiority would not be so pronounced

were it not for the fact that usually the

relative velocity of the fluid is greater

in the latter turbine, this detracting still

more from its efficiency.

‘These respective qualities and short-

comings have been long recognized by

engineers and have gradually led to

30

40

45

85

90

95

100

105

174,544

lo

16

25

30

35,

40

50

55

60

the employment of impulse and

reaction-wheels merged into one unit

which is thus better adapted for meeting

the requirements and should be more

eoonomical. But although this idea

seems sound, the temperature range has

not been very much increased through its

application and the gain, so far effected,

is moderate indeed, to the point of being

doubtful in meny instances. Definite

limits to progress in this direction have

been reached in the existing commercial

apparatus end the discovery of other ways

and means for saving fuel and reducing

the cost of instellation has become

a problem rendered especially pressing

throughout the world by the greatly

increased cost of this commodity.

The economic advantages contemplated

can be more completely realized through

a process which constitutes my present -

invention and, briefly stated, consists in

converting part of the heat energy of an

elastic medium into mechanical work by

friction, preferably at a high tempere-

ture, and a further part by action or

reaction at a lower temperature. The

best. instrumentalities for the purpose, of

-which I am aware, are a friction turbine

of the kind described in my British Patent

No. 24,001 of 1910 and one of the reaction

type, such as the Parsons, both being con-

nected or worked independently. ‘The

fluid is admitted to my turbine through »

suitable nozzle which may be expanding,

straight or converging, and in traversing

the spaces between the discs exercises &

frictional drag, thus transforming a part

of the available heat energy into

mechanical work. Upon exhausting

under proper temperature and pressure

conditions it is passed through the

reaction turbine in which another portion

of its caloric energy is usefully converted

by reaction.

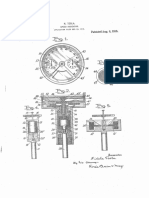

Tn the accompanying drawings Fig. 1

is intended to represent my improved

turbine and one of the Parsons type

operatively joined and with their shafts

flexibly connected ; Fig. 2 is a plan view

of the same with supply conduits and inlet

valves, and Fig. 3 a vertical cross-section

of my turbine.

Referring to the figures, 1 illustrates

the rotor of my turbine enclosed in a

casing 2, 2, provided with two inlets 3, 3

for the working medium, nozzles 4 and 5

~—one for normal operation and the other

for reversal—and two exhaust openings

6, 6 which lead through a conduit 7 to

the intake 8 and slide valve 9 of the

Parsons turbine 10. The exhaust 11 of

the latter communicates through a conduit

12 with the condenser to which is also

connected @ by-pass 13, branching out:

from exheust pipe 7 and equipped with a

valve 14. A throttle valve 15 controls the

admission of the elastic fluid to. my

turbine which has, besides, two suitable

valves 16 and 17, preferably joined by

mechanical means as choin 18, enabling

them to be turned together so that one

will be closed tight while the other is wide

open.

In normal operation valves 17 and 14

are closed and the medium is admitted to

my turbine through valves 15, 16 and

nozzle 4, whence it posses through the

rotor 1, exhaust openings 6, 6 and, pipe 7

to the intake 8 and velve 9 of the Parsons

turbine 10 and, after traversing the same,

is discharged ‘through exhaust 11 and

conduit 12 into the condenser, under

which conditions both the turbines are

actuated in the seme direction, rotation

taking place in the sense of the solid

arrow Fig. 3. en it is desired - to

operate in the reverse direction (indicated

by the dotted arrow), valves 16 and 9 are

closed and 17 end 14 opened wide, the

medium entering my turbine through

nozzle 5, and after passing through the

rotor 1, exhaust openings 6, 6, pipe 7 and

by-pass 13, discherges into the condenser.

‘The Parsons turbine is then driven in @

direction opposite to its blading. but offers

@ relatively small resistance owing to the

vacuum therein; my turbine, on the other

hand, develops an amount of power much

greater than when working as first

described on account of its direct eonnec-

tion with the condenser and correspond

ingly increased heat drop.

Careful scientific investigation, sup-

ported by experiment, has shown that

important economic results can be secured

by the new method and thet this particu-

lar combination of apparatus possesses

features of unusual merit.

In the first place my turbine is

especially suited for very elevated tem-

peratures and also high pressures, while

the Parsons is particularly adapted

to thermo-dynemic transformation - et

moderate temperatures end low pressures.

‘Again, the former permits the fluid to be

expanded either in the nozzle, the rotor

or both, and this flexibility facilitates the

establishment. and maintenance of

pressure’ and temperature conditions

favorable to both turbines, thus enhanc-

ing economy. ‘Their ccmbination is,

however, of quite exceptional value in

cases when reversible units are indispens-

able, as on shipboard, where it provides

a simpler and more effective apparatus for

70

15

80

80

95

120

25

60.

& 174,544;

forward, propulsion’ as well, as backing, an clastic fluid by diso friction and &

my tirbine being much ‘mote dependanie hed part by blade action, substantially

than the present forms with buckets and as described. 40

tisdes ‘which are very liable to deteriors- 2. The hereinbefore described process

5 tion and easily demaged. of transforming the heat energy ‘of an

In the use of. different typos, as here elastic fluid into rotary mechaeoal warn

contemplated, the individual heat drops which consists in converting & part of the

in them may. be considerably varied in energy of the fluid by friction et high 45

magnitude, but to give a practical temperature and a further part by action

10 examplo I would say’ thet very good and/or oaotion at a lower temporeine

results, when working with suporhected substantially as described.

steam alone, are obtainable by admitting 3. In the conversion of heat energy of

the steam to the nozzle of the friction elestic fluids the combination of the 50

turbine at about 1100° F. and exhausting friction and reaction type of turbine, as

15 it at approximately 550° F. into a described.

reaction turbine capable of operating 4, "The combined use’ of a friction

safely at that temperature, turbine of the kind described with an

While my turbine in such combinations action and reaction engine in the trae 55

Will yield the best results in co-operation formation of the heat energy of clatio

20 with’ the Parsons, it is eminently. quali. fluids into mechaniosl work.

fied to serve as first stage, or steges, in 5. The combination of a friction.

conjunction with other types of turbines, turbine of the. type described with =

of whatever ‘kind. also with rotery and turbine of the reaction type mounted oF

reciprocating engines; and in this broeder the came sheft-or on conrected chats oo

25 sense my improved:process may be defined form an operative unit for the trasctonme.

as one in which the evailable heat energy tion of the heat energy of elastic fluids

of an clastic fluid is usefully transformed into mechanical work,

first by friction, as indicated, and then 6. The combination of a friction and a 65

by action or reaction. reaction turbine of the types. described .

p Having now ‘particularly described and commected to form a power unit so that

Os gpaving mow ‘particularly described and fon may operate. together in one

ascertained the nature of my said inven- direction or be driven’ in the opposite

tion,. and rf what paaniaeeyg nek ari "} direction by the friction turbine, the 7)

to be pe formed, I declare that what I [attine py aate running idle’ ‘as

claim is =, described.

35 1. The iniproved method ‘of thermo-

dynamic “transformation which consists in

converting a part of the heat energy of

Dated the 23rd day of ‘August, 1921.

NIKOLA TESLA.

inted for His Majesty's Stadlonowy Ob WUD DL a ne,

Hereford ; Printed for His Majesty's Stationery Office, by The Hereford ‘Times Ltd.

[We. 70125 /10/1923.]

(This Drawing isa fil szoreprodution of the Original We

COMPLETE SPECIFICATION

a

\

SS

NSEC

Wages ravi

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BMW r25 ManualDocument99 pagesBMW r25 ManualNemanja Stojanovic33% (6)

- Patented A110". 6, 19181..: LilllllliDocument5 pagesPatented A110". 6, 19181..: LilllllliNemanja StojanovicNo ratings yet

- Patented Jan. 3, 1922.,: Frequency MeterDocument4 pagesPatented Jan. 3, 1922.,: Frequency MeterNemanja StojanovicNo ratings yet

- Guitarrrr PDFDocument39 pagesGuitarrrr PDFNemanja StojanovicNo ratings yet

- Seaby Roman Silver Coins Vol V PDFDocument218 pagesSeaby Roman Silver Coins Vol V PDFNemanja StojanovicNo ratings yet

- Us 20020182054Document12 pagesUs 20020182054Nemanja StojanovicNo ratings yet

- 1921 GB186082Document4 pages1921 GB186082Nemanja StojanovicNo ratings yet

- Tommy Emmanuel Amazing GraceDocument6 pagesTommy Emmanuel Amazing GraceJennifer Johnson50% (4)

- UserGuide SimpoeWorksDocument1 pageUserGuide SimpoeWorksNemanja StojanovicNo ratings yet