Professional Documents

Culture Documents

Box Basics - Boxmaster

Uploaded by

michelbgggCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Box Basics - Boxmaster

Uploaded by

michelbgggCopyright:

Available Formats

Box Basics - Boxmaster

1 of 7

http://boxmaster.com/products/box-basics/

(http://boxmaster.com)

Home (http://boxmaster.com/)

Products (http://boxmaster.com/products/)

Design (http://boxmaster.com/design/)

Food Safe (http://boxmaster.com/food-safe/)

Community (http://boxmaster.com/community/)

Sustainability (http://boxmaster.com/sustainability/)

About Us (http://boxmaster.com/history-british-columbia/)

News (http://boxmaster.com/news/)

Quote Request (http://boxmaster.com/quote-request/)

09-04-2015 16:47

http://boxmaster.com/products/box-basics/

Box Basics - Boxmaster

2 of 7

Half Slotted

Die Cut Custom

Containers

These are custom corHalf slotted containers

rugated boxes devel-

are similar to regular

oped to exact specifi-

slotted containers ex-

cations depending on

cept that they have

customer requirements. Boxmaster can

only one set of flaps.

The opposite side of

manufacture custom

the box is open, which

boxes with FULL color,

allows it to slide over

available in all styles

an item. Ideal for: large

and custom sizes.

and heavy objects

Ideal for: unique prod-

such as refrigerators

ucts with special re-

and washing ma-

quirements such as

cosmetic product

chines.

boxes, toy product

boxes, gift product

boxes.

Full Over Lap

Roll End Tuck Top

The outer flaps overlap

the full width of the box

These are simple

unglued boxes that

making it especially re-

need to be folded when

sistant to rough han-

assembled. These are

dling. All flaps are the

great for shipping nar-

same depth, and their

row items. Ideal for: vi-

depth equals the width

tamin packaging, retail

of the box. Ideal for:

packaging, coffee

heavy objects that require extra support

packaging, tea packaging.

such as refrigerators

and washing machines.

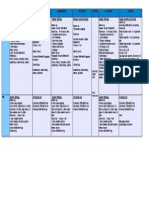

Corrugated Box Flute Types

Corrugated Box Construction

09-04-2015 16:47

Box Basics - Boxmaster

3 of 7

http://boxmaster.com/products/box-basics/

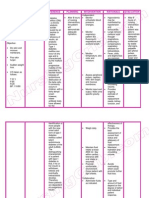

Types of Printing Methods

Printing

Description

Advantages

The most basic type of printing

on corrugated.

Allows the addition of company or

package content info to the surface of the

Method

Flexo Line

box, at a relatively low cost. Graphics

tend to be basic line art and text, utilizing

between 1 and 3 colours.

Flexo Process

Flood Coated

Used for higher end graphics

Because 4 colour print plates are

utilizing the 4 process colours.

required, the total print plate costs tend to

It provides a stronger visual

be more expensive than Flexo Line.

impact, and enables photo

quality images to be used.

Minimum run quantities tend to be much

higher than Flexo line.

Allows the use of a solid 100%

Flood coats can be applied with stock

coverage of colour. Most

print plates, so die costs are not an

commonly used with POP

expense for the client.

displays and packaging for

retail applications.

Label Laminate

Achieved by gluing printed

It provides a clean professional

sheets to the outer surface of

the corrugated material.

appearance that looks comparable to

high end packaging similar to that used

Enables the application of a

with software and electronics. Labels can

glossy process colour (photo

be applied as a 100% coverage, or as a

quality) image, and is a

spot label in conjunction with other Flexo

reasonable cost option for low

line printing.

to medium quantity runs. Label

size is limited by the maximum

sheet size of most commercial

presses (28" x 40").

Screen Print

Another way of applying

This process is most commonly used for

graphic intensive images

POP displays and retail packaging

directly to the outer surface of

applications, and can be more cost

the corrugated package.

effective is short run quantities. Size

limitations are larger than label laminate,

and colour combinations greater than 4

are possible.

Litho Laminate

Provides a similar finished

The printed surface is actually part of the

product as label laminate, but

packaging material, as opposed to label

requires much higher minimum

laminate which is added manually.

runs (typically 10-20K).

Preprint

Providing a similar finished

It requires very high volume runs, and a

product to Flexo process, this

significant upfront investment by the

09-04-2015 16:47

Box Basics - Boxmaster

4 of 7

http://boxmaster.com/products/box-basics/

process involves the client

client, but can be a cost effective way to

purchasing pre printed rolls of

apply impactful graphics at those

paper that are used in

quantities. Most commonly used in the

manufacturing linerboard.

food and beverage industry, like beer

cases and mandarin orange boxes.

Corrugated Board Strength

Board strength are all the factors that define how strong the box should be. There are a number of questions you must ask yourself before you can accurately asses how strong a particular box should be manufactured to be such as:

The nature of the products being packaged

The total weight of the box

The size of the box

How the cardboard box will be stacked, stored, and transported.

Boxmaster provides you with two different levels of customization options when selecting box

strength. The first is the flute type and the second is using the edge crush test.

Corrugated Flutes are the S shaped waves/arches of a corrugated box that makes up the

board. This is called the boards corrugation. Flutes are essentially the reinforcement that

make up the board. They run parallel to the depth of the container and give it its rigidity and

crushing/stacking strength. As well as providing stacking strength, flutes also provide insulation that protects products from sudden temperature changes. Generally speaking, larger

flutes like A & B profile provide greater strength and cushioning, while smaller flute profiles like

D & E provide better printability and foldability.

B flutes have 42-50 flutes per foot and are 1/8 thick. They provide the second highest arch

size.

B flutes provide good stacking strength and crushing resistance. Ideally used for canned

goods and displays.

C flutes have 39-43 flutes per foot and are 11/64 thick. They are the medium between A flute

and B flute and are very common.

C flutes provide good cushioning, stacking and printing properties. Ideally used for glass, furniture and dairy.

E flutes have 94 flutes per foot and are 1/16 thick. The board profile is super-thin which in

turn reduces box size and saves store space.

E flutes provide the greatest crush resistance and a super printing surface which make it an

excellent choice for die-cut custom boxes.

09-04-2015 16:47

Box Basics - Boxmaster

5 of 7

http://boxmaster.com/products/box-basics/

Boxmaster provides you with the option of choosing between single and double-wall cardboard

construction.

Single Wall is the most common corrugation material - it simply consists of 1 layer of whatever flute type

you choose. Under normal circumstances, single wall construction will be sufficient as they are offered

from 23ECT to 44ECT.

Double Wall construction, also known as 'heavy duty' corrugation material is used for heavy or large

objects. A Double wall consists of 2 layers of flutes, usually 1 layer of B and 1 layer of C. They are

around 35% stronger than the regular single wall corrugation type. Boxmaster offers double wall

cardboard boxes from 44ECT to 61 ECT.

Flute Types

Flutes/Foot

Thickness

Advantages

B Flute

42 -50

1/8"

Good cushioning,

stacking & printing

C Flute

39-43

11/64"

Good stacking,

strength & crushing

resistance

E Flute

94

1/16"

Greatest crush

resistance & printing

surface

BC Flute

Double Wall

Very Thick

Can hold very large

& heavy items

09-04-2015 16:47

http://boxmaster.com/products/box-basics/

Box Basics - Boxmaster

6 of 7

Products

Design

About Us

Locate Us

Connect with Us

09-04-2015 16:47

Box Basics - Boxmaster

7 of 7

http://boxmaster.com/products/box-basics/

Cardboard Displays

(http://boxmaster.com

/products/cardboarddisplays/)

Graphic Design

(http://boxmaster.com

/design/graphicdesign/)

Custom Boxes

(http://boxmaster.com

/products/customboxes/)

Graphics

Requirements

(http://boxmaster.com

/design/graphicsspecs/)

Stock Boxes

(http://boxmaster.com

/products/stockboxes/)

Box Basics (FAQ)

(http://boxmaster.com

/products

/box-basics/)

Structural Design

(http://boxmaster.com

/design/structuraldesign-2/)

Food Safe

(http://boxmaster.com

/food-safe/)

News

(http://boxmaster.com

/news/)

Sustainability

(http://boxmaster.com

/sustainability/)

Care for the

Community

(http://boxmaster.com

/community/)

#100, 880 Belgrave Way,

Delta

(Annacis Island), B.C.

Canada V3M 5Y8

P. 604 521 4715

Toll Free 1 888 267 7754

Request a Quote

(http://boxmaster.com/quoterequest)

F.604 527 8514

History in British

Columbia

(http://boxmaster.com

/history-britishcolumbia/)

Contact Us

Quote Request

(http://boxmaster.com

Search

(https://www.facebook.com

/BOXMasterBC)

(https://twitter.com/BoxmasterBC)

(https://ca.linkedin.com

/company/boxmaster)

(http://boxmaster.com(http://boxmaster.com

/design/)

/quote-request/)

(http://boxmaster.com

/products/)

/contact-us/)

(http://boxmaster.com

/history-britishcolumbia/)

Boxmaster 2015 | Your Source for Food Safe Packaging | Website by Sparkjoy Studios (http://sparkjoy.com) | Log in

(https://sparkjoy.org/spark-login)

09-04-2015 16:47

You might also like

- TexasMethod - v1.7Document12 pagesTexasMethod - v1.7Dharmesh PersaudNo ratings yet

- Basketball Stretching ExerciseDocument6 pagesBasketball Stretching ExercisefredericktingsyNo ratings yet

- Beginner Pete PlanDocument15 pagesBeginner Pete PlanpetipotterNo ratings yet

- Run & Hurdle Technique Technique & Drills SpottingDocument3 pagesRun & Hurdle Technique Technique & Drills Spottingcacamerba90No ratings yet

- Under The High-Speed Capabilities Understand The Human Capacity To Ensure TheDocument8 pagesUnder The High-Speed Capabilities Understand The Human Capacity To Ensure ThepfluchoNo ratings yet

- Mass Gain Training Journal: Week 1 Example in Support Of: Helpful LinksDocument35 pagesMass Gain Training Journal: Week 1 Example in Support Of: Helpful LinksSANJAYSINH PARMARNo ratings yet

- The 2,500-Calorie Workout: Fight Fat Faster: Find Your Perfect-Body EquationDocument7 pagesThe 2,500-Calorie Workout: Fight Fat Faster: Find Your Perfect-Body EquationHoang_HonNo ratings yet

- Ivan Wiid - Phase 1.0Document14 pagesIvan Wiid - Phase 1.0BlowkeeNo ratings yet

- Scheduling 101 2010 Revised Jan 2011Document4 pagesScheduling 101 2010 Revised Jan 2011Luis Alfredo Curasi TrujillanoNo ratings yet

- The "Alfa Romeo" WorkoutDocument20 pagesThe "Alfa Romeo" WorkoutMichele MionNo ratings yet

- Examples Balance and Coordination ExercisesDocument1 pageExamples Balance and Coordination ExercisessuneelphysioNo ratings yet

- Form and Safety in Plyometric TrainingDocument5 pagesForm and Safety in Plyometric Trainingsalva1310No ratings yet

- Weight Training Day: First Thing Training: Meal: TimeDocument40 pagesWeight Training Day: First Thing Training: Meal: TimefaolanNo ratings yet

- Finals Lesson 1 Tabata ExerciseDocument20 pagesFinals Lesson 1 Tabata ExerciseJose Angelo TolentinoNo ratings yet

- Engineering Graphics and CAEDocument4 pagesEngineering Graphics and CAEAdlan JoannaNo ratings yet

- 6 Week Strength and Endurance ProgramDocument15 pages6 Week Strength and Endurance ProgrammubeenNo ratings yet

- Set Shot Lesson PlanDocument4 pagesSet Shot Lesson Planapi-353103487No ratings yet

- Wendler Strength Starter 1Document38 pagesWendler Strength Starter 1S.h. HanNo ratings yet

- Athletic Testing Battery ToolDocument13 pagesAthletic Testing Battery ToolLucaNo ratings yet

- Candito Linear ProgramDocument13 pagesCandito Linear ProgramAnonymous kJSxzO7hRhNo ratings yet

- Acceleration Speed Conditioning PDFDocument12 pagesAcceleration Speed Conditioning PDFBryan ClNo ratings yet

- Tennis Ball Launcher 2Document48 pagesTennis Ball Launcher 2boon1961No ratings yet

- Classic ScoreDocument8 pagesClassic Scoreapi-484998896No ratings yet

- 5 Myths About Eccentric Training Every Coach Ought To Know - SimpliFasterDocument1 page5 Myths About Eccentric Training Every Coach Ought To Know - SimpliFasterAyoub SELMINo ratings yet

- Push Pass Relay TechniqueDocument9 pagesPush Pass Relay Techniquemike18567% (3)

- Fitness FirstDocument5 pagesFitness FirstvarunNo ratings yet

- Demonfit: Beginner'S GuideDocument22 pagesDemonfit: Beginner'S GuideSeanNo ratings yet

- Break Workout - 2017Document2 pagesBreak Workout - 2017cfNo ratings yet

- Weekly Overview v1 LargeDocument1 pageWeekly Overview v1 LargeAshleyNo ratings yet

- Leg and Glute WorkoutDocument2 pagesLeg and Glute Workoutapi-267927024No ratings yet

- Compliant Linkage MechanismsDocument8 pagesCompliant Linkage MechanismsKGSG100No ratings yet

- Weight Training Medium Interval Training Medium Interval Training Weight Training Rugby Specific Skill CircuitDocument1 pageWeight Training Medium Interval Training Medium Interval Training Weight Training Rugby Specific Skill CircuitJess FarrellNo ratings yet

- Exercise Chart: Here Are Some Exercise Examples For Home or The GymDocument1 pageExercise Chart: Here Are Some Exercise Examples For Home or The Gymvegaskink100% (1)

- Agility Article 1Document3 pagesAgility Article 1Ryan GibneyNo ratings yet

- Weight Drop-Offs 1-10% Time Drop-Offs 1-10% Projected Maxes Rounded To 2.5Document1 pageWeight Drop-Offs 1-10% Time Drop-Offs 1-10% Projected Maxes Rounded To 2.5alex_carnall6060No ratings yet

- Alumni Giving - SpreadsheetDocument10 pagesAlumni Giving - SpreadsheetRavi ParekhNo ratings yet

- Stretching: Muscle Strength For SpeedDocument4 pagesStretching: Muscle Strength For SpeedGerardClarkeNo ratings yet

- Time Management: Gladys Sánchez-BelloDocument26 pagesTime Management: Gladys Sánchez-Belloلبنى خالدNo ratings yet

- Myfreelap Scenarios: Freelap Sa Av. Daniel Jeanrichard 2 Ch-2114 Fleurier +41 (0) 32 861 52 42 Contact@Freelap - CHDocument6 pagesMyfreelap Scenarios: Freelap Sa Av. Daniel Jeanrichard 2 Ch-2114 Fleurier +41 (0) 32 861 52 42 Contact@Freelap - CHAnonymous 3BBuadJXr2No ratings yet

- The Big Six: Level 1 Level 2 Level 3 Level 4 Level 5 Level 6Document90 pagesThe Big Six: Level 1 Level 2 Level 3 Level 4 Level 5 Level 6Ивайло КеновNo ratings yet

- Z Verzija J&T2Document10 pagesZ Verzija J&T2isjajaNo ratings yet

- Coaching StyleDocument4 pagesCoaching StylemoB0B100% (1)

- Full Month Jan 2023Document5 pagesFull Month Jan 2023AyçaNo ratings yet

- Bicycle Gear Shifting MethodsDocument8 pagesBicycle Gear Shifting MethodsKannan EsakkimuthuNo ratings yet

- High JumpDocument40 pagesHigh Jumpapi-453728680No ratings yet

- m2 - Magnificent Mobility ContentsDocument2 pagesm2 - Magnificent Mobility Contentsjokster100% (1)

- Ranger and Commando Physical Training POIDocument9 pagesRanger and Commando Physical Training POITroyNo ratings yet

- 0 Percent (Body Weight) : From 0 To 100: Know Your Percentages!Document5 pages0 Percent (Body Weight) : From 0 To 100: Know Your Percentages!karzinomNo ratings yet

- Sprint WorkoutDocument7 pagesSprint WorkoutshwoopadeedooNo ratings yet

- Injection Molding DesignDocument17 pagesInjection Molding DesignprasathbalaNo ratings yet

- Basic FeaDocument84 pagesBasic FeaSiddharth SridharNo ratings yet

- Lesson Plan Sprints RelaysDocument4 pagesLesson Plan Sprints Relaysapi-313645927No ratings yet

- StrongLifts 5x5 Tracker SheetDocument10 pagesStrongLifts 5x5 Tracker SheetAsim AliNo ratings yet

- Denis Knowles Discus TechniqueDocument6 pagesDenis Knowles Discus TechniqueruncodhitNo ratings yet

- 103 - Efficient and Accurate Conversions of 2D PDF To 3D Models - Jason Wooden PDFDocument18 pages103 - Efficient and Accurate Conversions of 2D PDF To 3D Models - Jason Wooden PDFexlibrisxyzNo ratings yet

- 8 2 4 Speed TrainingDocument3 pages8 2 4 Speed Traininggalgo2448No ratings yet

- All American Workout PDFDocument6 pagesAll American Workout PDFAEROSMITH12No ratings yet

- Box Basics: History of Corrugated BoxesDocument7 pagesBox Basics: History of Corrugated BoxesYasser Badr100% (1)

- All About Corrugated BoxesDocument7 pagesAll About Corrugated BoxesAnkush SharmaNo ratings yet

- Instruction Manual On Corrugated BoxesDocument10 pagesInstruction Manual On Corrugated BoxesHussain100667% (3)

- How To Be A Wholesale DistributorDocument32 pagesHow To Be A Wholesale Distributormichelbggg100% (1)

- Rigid Box Solutions - Semi Automatic Rigid Box Making Machine, Fully Automatic Rigid Box Making Machines and Automatic Rigid BoDocument4 pagesRigid Box Solutions - Semi Automatic Rigid Box Making Machine, Fully Automatic Rigid Box Making Machines and Automatic Rigid BomichelbgggNo ratings yet

- Interview With Vinoth KumarDocument8 pagesInterview With Vinoth KumarmichelbgggNo ratings yet

- Kshatriya GoldenJubilee IDocument126 pagesKshatriya GoldenJubilee Imichelbggg100% (2)

- Barbed WireDocument6 pagesBarbed WiremichelbgggNo ratings yet

- Welcome To South India Corrugated Box Manufacturers AssociationDocument1 pageWelcome To South India Corrugated Box Manufacturers AssociationmichelbgggNo ratings yet

- Rigid Box Solutions - Semi Automatic Rigid Box Making Machine, Fully Automatic Rigid Box Making Machines and Automatic Rigid BoDocument4 pagesRigid Box Solutions - Semi Automatic Rigid Box Making Machine, Fully Automatic Rigid Box Making Machines and Automatic Rigid BomichelbgggNo ratings yet

- Solar Business Opportunities in India Shrirajendra S BlogDocument42 pagesSolar Business Opportunities in India Shrirajendra S Blogsunildubey02No ratings yet

- India Pack Expo 2015Document104 pagesIndia Pack Expo 2015michelbgggNo ratings yet

- Schneider Web in Ar Slides FinalDocument38 pagesSchneider Web in Ar Slides FinalmichelbgggNo ratings yet

- Supermarket Project Report2Document10 pagesSupermarket Project Report2michelbgggNo ratings yet

- CSA Book EnglishDocument89 pagesCSA Book EnglishmichelbgggNo ratings yet

- Module 1 Learning PrinciplesDocument2 pagesModule 1 Learning PrinciplesAngela Agonos100% (1)

- Useful C Library FunctionDocument31 pagesUseful C Library FunctionraviNo ratings yet

- 2013 Ford Fiesta 1.6l Sohc Fluid CapacitiesDocument1 page2013 Ford Fiesta 1.6l Sohc Fluid CapacitiesRubenNo ratings yet

- Rabbit Book PDFDocument20 pagesRabbit Book PDFMatumelo Rebecca DaemaneNo ratings yet

- Introduction To Entrepreneurship: Bruce R. Barringer R. Duane IrelandDocument29 pagesIntroduction To Entrepreneurship: Bruce R. Barringer R. Duane IrelandAnonymous Yp8H9QwNo ratings yet

- Os Unit-1Document33 pagesOs Unit-1yoichiisagi09No ratings yet

- Ap Reg W# 5-Scaffold For Transfer TemplateDocument2 pagesAp Reg W# 5-Scaffold For Transfer TemplateJunafel Boiser Garcia100% (2)

- Floating Solar Photovoltaic Systems - An Overview and Their Feasibility at Kota in Rajasthan - IEEE Conference Publication - IEEE XploreDocument3 pagesFloating Solar Photovoltaic Systems - An Overview and Their Feasibility at Kota in Rajasthan - IEEE Conference Publication - IEEE XploreJames KazoobaNo ratings yet

- Youth and Moral ValuesDocument6 pagesYouth and Moral ValuesAlka SinghNo ratings yet

- Lesson 3: Letters of RequestDocument4 pagesLesson 3: Letters of RequestMinh HiếuNo ratings yet

- Report Palazzetto Croci SpreadsDocument73 pagesReport Palazzetto Croci SpreadsUntaru EduardNo ratings yet

- Neoclassical CounterrevolutionDocument1 pageNeoclassical CounterrevolutionGraziella ValerioNo ratings yet

- BLDG Permit Form (Back To Back)Document2 pagesBLDG Permit Form (Back To Back)ar desNo ratings yet

- #5-The Specialities in The Krithis of Muthuswamy DikshitharDocument5 pages#5-The Specialities in The Krithis of Muthuswamy DikshitharAnuradha MaheshNo ratings yet

- Rights of An Accused Under Custodial InvestigationDocument17 pagesRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- POLAR BEARS-Biology ProjectDocument16 pagesPOLAR BEARS-Biology Projectserwaa21No ratings yet

- Parker (T6, T6D) Hydraulic Vane PumpsDocument12 pagesParker (T6, T6D) Hydraulic Vane PumpsMortumDamaNo ratings yet

- Light Design by Anil ValiaDocument10 pagesLight Design by Anil ValiaMili Jain0% (1)

- Tok EssayDocument2 pagesTok EssayNeto UkpongNo ratings yet

- Free DMAIC Checklist Template Excel DownloadDocument5 pagesFree DMAIC Checklist Template Excel DownloadErik Leonel LucianoNo ratings yet

- Module 8 - Facilitating Learner - Centered TeachingDocument4 pagesModule 8 - Facilitating Learner - Centered TeachingSheila Mae Paltep100% (3)

- D90KSDocument1 pageD90KSAmilton filhoNo ratings yet

- Nursing Care Plan Diabetes Mellitus Type 1Document2 pagesNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- Canadian Solar-Datasheet-All-Black CS6K-MS v5.57 ENDocument2 pagesCanadian Solar-Datasheet-All-Black CS6K-MS v5.57 ENParamesh KumarNo ratings yet

- Acute Conditions of The NewbornDocument46 pagesAcute Conditions of The NewbornCamille Joy BaliliNo ratings yet

- Solution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan MchughDocument36 pagesSolution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan Mchughquoterfurnace.1ots6r100% (51)

- 100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogDocument16 pages100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogtestNo ratings yet

- The Internet of ThingsDocument33 pagesThe Internet of ThingsKaedara KazuhaNo ratings yet

- IBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Document27 pagesIBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Milek Anil KumarNo ratings yet

- Intercostal Drainage and Its ManagementDocument36 pagesIntercostal Drainage and Its ManagementAnusha Verghese67% (3)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffFrom Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffRating: 5 out of 5 stars5/5 (19)

- Twelve Caesars: Images of Power from the Ancient World to the ModernFrom EverandTwelve Caesars: Images of Power from the Ancient World to the ModernRating: 3.5 out of 5 stars3.5/5 (9)

- Ikigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessFrom EverandIkigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessRating: 5 out of 5 stars5/5 (91)

- To Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryFrom EverandTo Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryRating: 4 out of 5 stars4/5 (26)

- Bare Bones: I'm Not Lonely If You're Reading This BookFrom EverandBare Bones: I'm Not Lonely If You're Reading This BookRating: 4 out of 5 stars4/5 (11)

- The Storyteller: Expanded: ...Because There's More to the StoryFrom EverandThe Storyteller: Expanded: ...Because There's More to the StoryRating: 5 out of 5 stars5/5 (13)

- The Gardner Heist: The True Story of the World's Largest Unsolved Art TheftFrom EverandThe Gardner Heist: The True Story of the World's Largest Unsolved Art TheftNo ratings yet

- I Didn't Come Here to Make Friends: Confessions of a Reality Show VillainFrom EverandI Didn't Come Here to Make Friends: Confessions of a Reality Show VillainRating: 3 out of 5 stars3/5 (47)

- Altamont: The Rolling Stones, the Hells Angels, and the Inside Story of Rock's Darkest DayFrom EverandAltamont: The Rolling Stones, the Hells Angels, and the Inside Story of Rock's Darkest DayRating: 4 out of 5 stars4/5 (25)

- No Lifeguard on Duty: The Accidental Life of the World's First SupermodelFrom EverandNo Lifeguard on Duty: The Accidental Life of the World's First SupermodelRating: 3.5 out of 5 stars3.5/5 (42)

- Summary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisFrom EverandSummary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (6)

- The Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisFrom EverandThe Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisRating: 3.5 out of 5 stars3.5/5 (49)