Professional Documents

Culture Documents

ET 2010november TechPaper

ET 2010november TechPaper

Uploaded by

helloitskalaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ET 2010november TechPaper

ET 2010november TechPaper

Uploaded by

helloitskalaiCopyright:

Available Formats

Technical Paper

What successful Cost Estimators know. . . . and you should, too.

>>>>>>> AN ESTIMATORS GUIDE TO POLICIES,

>>>>>>>>>>> PROCEDURES, AND STRATEGIES

ESTIMATE THE COST OF

Reinforcing Steel in

Shallow Foundations

submitted by Jonathan A. Rogers, CPE

After graduating from Georgia Techs school of

Architecture in 1993, Jonathan A. (Andy) Rogers

1) Introduction

and remodeling. In 1996 his career path led him to

2) Types and Methods of Measurements

single and multi-family developers providing design,

3) Overview of Labor, Material, Accessory, & Other Costs

management services. In 1999, a geographic move

4) Ratio & Analysis

construction. Since that time, Andy has developed

5) Specific Factors Affecting Take-off and Pricing

commercial multi-family and institutional projects.

6) Specific Risk Considerations

started his career in single family home construction

preconstruction, where he worked as a consultant to

cost estimating, and purchasing systems set-up and

prompted a career change into strictly commercial

and utilized his experience predominantly in

Andy Rogers, CPE works as a Preconstruction

Services Manager for Hardin Construction

7) Sample Drawings and Details

Company, LLC in Atlanta, Georgia.

www.aspenational.org

13

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

Introduction

The intent of this technical paper is

to explain the systematic approach to

estimating the cost of reinforcing steel

in shallow foundations. The desire is to

define basic terminology, explain common details, and demonstrate a simplified approach to the take-off of the most

common components encountered in

shallow foundation design. The reader

should therefore be able to apply these

principles to more complex systems and

adapt them as needed to specific project

details, design standards, and environmental conditions.

The basis for this paper is the Construction Specification Institute Master Format (2004 Edition).

BTTM: Bottom

CONT: Continuous

EA: Each

EE: Each end

EF: Each face

ES: Each side

EW: Each way

LLH: Long leg

horizontal

LLV: Long leg vertical

LW: Long way

OC: On Center

SW: Short way

T&B: Top and bottom

FOC: Face of Concrete

TF / T.O.F.: Top of

Footing

F.F.E.: Finished Floor

Elevation

TP / T.O.P.: Top of Pier

FS: Footing step

VERT: Vertical

Division: 03 00 00 Concrete

Subdivision(s): 03 21 00 Reinforcing Steel

HORIZ: Horizontal

For the purpose of limiting the

breadth of this article, this paper does

not delve into concepts associated with

reinforcing in deep foundations, slabson-grade, or vertical concrete structures. Rather, it focuses on subgrade

foundation components only. Many

of the same concepts covered in this

paper, however, may be employed in

developing quantitative analysis of mild

reinforcing in other concrete structures.

Additionally, this article assumes that

the estimator has access to 90-95%

complete construction documents with

necessary details, schedules, and specifications included. This paper, therefore,

focuses on final or contract estimating.

Common terms used in referring to

shallow foundation reinforcing are:

Types and Methods

of Measurement

Terminology

Footing and foundation schedules and

details utilize a common set of abbreviations and terms. Familiarity with these

is vital to understanding the placement,

quantity, and length of various members

in the reinforcing design. Some of the

most common abbreviations used are

listed below.

14

November 2010

Coverage: the distance between the outermost piece of reinforcing steel and the outside

face of concrete which protects resteel from

coming in contact with the elements. For this

article, 3 minimum coverage has been used

throughout.

Dowel: short length of reinforcing steel left

extended from the face of a concrete pour in

order to tie additional reinforcing and secondary pours together.

Lap length: the minimum distance two reinforcing bars must overlap to create a lap splice

Longitudinal bar: reinforcing bar which runs

the length of a footing or wall

Mat: a single layer of reinforcing steel combining longitudinal and transverse bars

Net length: the length of a

reinforcing bar determined

by deducting minimum

coverage(s) from a footing,

pier, or wall dimension

Rebar, Resteel: terms

used interchangeably for

reinforcing steel

Splice: any of three methods (lap splice, mechanical

splice, or welded splice)

used to join two pieces of

reinforcing steel to create a

single line of reinforcing

Tie: method of joining two pieces of reinforcing steel using plastic ties, steel wire,

smaller reinforcing bars or other means to

create and secure lap splices, cages, and

dowels prior to placing concrete.

Transverse Bar: reinforcing bar which runs

the width of a footing or wall, generally

perpendicular to the longitudinal bars.

Straight length: the total length of a fabricated (bent) piece or reinforcing steel.

Other terminology and abbreviations

may be encountered specific to the

geographic region or the project and/

or the design firm responsible for the

contract documents.

Units of Measure

Reinforcing steel is most typically

estimated by weight and imperially in

pounds which are commonly converted to tons. For contractors who

self-perform fabrication of reinforcing

steel, these weights may be further

converted to pieces for the purposes

of quantifying and ordering straight

reinforcing bars. Reinforcing steel

in shallow foundations is most commonly specified as Grade 40 (metric

Grade 280), Grade 60 (metric Grade

420), or Grade 75 (metric Grade 520),

deformed bars and available in 20-foot

and 60-foot lengths with weights per

linear foot as listed in Table 2.1.

Additionally, because the weight of

reinforcing steel is related directly to

the number of fabricated parts, calculations which result in fractional parts

(i.e. decimal places) are commonly

rounded either up or down to the

whole piece to provide more accurate

resulting total weight. For the pur-

Table 2.1

Common Reinforcing Bar Sizes

Bar

Nominal

Designation

Diameter (inches)

#3

0.375

#4

0.500

#5

0.625

#6

0.750

#7

0.875

#8

1.000

#9

1.128

#10

1.270

#11

1.410

#14

1.693

#18

2.257

Weight

(lbs/lnft)

0.376

0.668

1.043

1.502

2.044

2.670

3.400

4.303

5.313

7.650

13.600

Estimating Today

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

pose of this paper, where values have

been rounded, the symbols = shall

represent equals value rounded-up

and = shall represent equals value

rounded-down.

Quantity Survey

Upon receipt of construction documents, the estimators first responsibility is to survey the documents, become

familiar with the project details, and

develop an outline of the primary

components of the shallow foundation

design. The most common of those

components are:

1) spread footings

2) strip footings

3) piers

4) foundation walls

1) SPREAD FOOTINGS

Once a basic outline of the components is generated, take-off for each

component can be done utilizing the

formulas demonstrated in the examples below. These formulas may

be completed manually, calculated

using common spreadsheet software,

or programmed into more complex

estimating software where assemblies

may be used to quantify reinforcing

steel as part of a complete foundation

concrete package.

Prior to discussing the take-off for

each foundation component, it is important to address waste. If reinforcing

steel members are fabricated off-site,

some allowance may be given to ordering extra pieces and/or straight bars

to allow for culling of materials and

for errors in installation which would

Table 2.2

Sample Footing Schedule

Footing

Mark

Size

otherwise delay the installation. Additionally, waste may be considered for

reinforcing bar supports, bends, hooks,

splices, overlaps and other such bar

specific details as might be required for

the proper fabrication and installation

of the reinforcing steel. For contractors who self-fabricate reinforcing steel,

waste factors will vary greatly depending

on the specific design, ordered material

lengths, and resulting off-cuts. Additionally culled waste may be used by

the self-fabricator to offset some waste.

For the purposes of this paper, we will

assume all reinforcing bars are shipped,

pre-fabricated, allowing for a 5% waste/

cull factor which includes the aforementioned bar specific details.

Spread footings, also called column

and/or pier footings, should be counted

by type. Information regarding reinforcing

members for each footing type is shown

in a footing schedule (see Table 2.2).

For purposes of demonstration, we

will utilize this sample footing schedule

and the partial foundation plan shown in

the appendix, Figure 1.

Two types of spread footings are

examined, starting with spread footing

type F4. Reinforcing bars are noted as

9-#5 E.W. (9 each, #5 bars, each way).

Referring to Figure 2, the typical spread

footing detail, the net length of the longitudinal reinforcing bars in footing F4 is

calculated:

(footing length) (minimum coverage(s)) =net

length of longitudinal bars

7.0 - (3 + 3) = 6.5

Reinforcing

F1

4-0 x 4-0 x 12

5-#5 E.W.

F2

5-0 x 5-0 x 12

6-#5 E.W.

F3

6-0 x 6-0 x 18

8-#5 E.W.

F4

7-0 x 7-0 x 18

9-#5 E.W.

F5

8-0 x 8-0 x 18

8-#6 E.W.

F7

9-0 x 9-0 x 24

10-#6 E.W. T&B

F8

7-0 x SEE PLAN x 24

F9

8-0xSEE PLAN x 24

LW: 7-#6 T&B

SW: #6@10 O.C. T&B

LW: 8-#6 T&B

SW: #6@10 O.C. T&B

The weight of longitudinal bars in footing

F4 is then calculated:

(net length) x (number of

bars) x (weight per linear

foot)

6.5 x 9 bars x 1.043 lbs/lnft

= 61 lbs

The weight of transverse bars is calculated

in the same manor.

For this example, the

length and weight of

longitudinal bars and transverse bars is

the same.

(net length) x (number of bars) x (weight per

linear foot)

(7.0 (3 + 3)) x 9 bars x 1.043 lbs/lnft = 61 lbs

The sample foundation plan indicates

there are 3-each, F4 footings. The resulting total weight of reinforcing steel for

footings type F4 is calculated:

((weight of longitudinal bars) + (weight of transverse bars)) x (number of footings)

(61 lbs + 61 lbs) x 3 each = 366 lbs

For the second example, consider

footing type F8. The same principles

are used in calculating the weight of

reinforcing steel for this footing. Footing type F8, however, has no indicated

length on the footing schedule. Instead

the estimator must reference the foundation plan to determine the length of

footing(s) F8. In this case the length for

the one footing type F8 is 57-0. Longitudinal reinforcing is noted as LW: 7-#6

T&B (long way, 7 each, #6 bars, top and

bottom) and calculated:

(net length) x (number of bars @ top + number of

bars @ bottom) x (weight per linear foot)

(57.0 (3 + 3)) x (7 bars + 7bars) x 1.502 lbs/lnft

= 1,188 lbs

An additional step is required to

calculate the weight of transverse bars in

footing F8. Transverse bars are indicated

as SW: #6@10 OC T&B (short way, #6

bars at 10 on center, top and bottom) for

the length of the footing. Therefore, the

quantity of transverse bars is calculated:

((footing length (minimum coverages)) / bar

spacing) x (number of mats) = quantity of transverse bars

((57.0 (3 + 3)) / 10) x 2 mats = 136 bars

The resulting bar quantity should be

rounded up for both top and bottom

mats, thus allowing that the maximum

bar spacing be no more than 10 as indicated. The weight, then of transverse

bars is calculated:

(net length) x (number of bars) x (weight per

linear foot)

(7.0 (3 + 3)) x 136 bars x 1.502 lbs/lnft =

1,328 lbs

www.aspenational.org

15

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

The resulting total weight of reinforcing steel for the footings type F8, having

length 570, is calculated:

((weight of longitudinal bars) + (weight of transverse bars)) x (number of footings)

(1,188 lbs + 1,328 lbs) x 1 each = 2,516 lbs

Note that were there more than one

footing type F8, then reinforcing steel for

each footing length would be calculated

separately as the net length of longitudinal bars and the quantity of transverse

bars would vary.

Finally, refer again to Figure 2. The L

shaped reinforcing bars, or dowels, in

the footing are not taken off as part of

the footing reinforcing. Instead, because

the bar size and quantity is integrated

with the pier design, they are taken-off

with the concrete piers (see subsection

#3 below).

2) STRIP FOOTINGS

The process for estimating reinforcing

steel in strip footings, also known as continuous footings, is very much the same

as for spread footings. The primary

difference in the take-off of strip footings is in the location of the reinforcing

steel design information. Unlike spread

footings, strip footings are not generally

scheduled. Instead they are referenced

by detail.

Referring to the sample foundation

plan, a section cut through the foundation between columns A1 and A2

references Figure 4. Longitudinal bars

are indicated as 6-#5 T & 3-#5 B (6 each,

#5 bars at top and 3 each, #5 bars at bottom). The estimator must either scale

from the foundation plan or add labeled

dimensions to determine the footing

length (in this case, 47-0 long between

columns A1 and A2 only). The weight of

longitudinal reinforcing steel for the strip

footing is calculated:

(net length) x ((number of bars @ top) x (weight

per linear foot)) + ((number of bars @ bottom) x

(weight per linear foot))

(47.0 (0 + 0)) x ((6 bars x 1.043 lbs/lnft) + (3

bars x 1.043 lbs/lnft)) =441 lbs

*note that there are no reductions in the footing

length for minimum coverages since this footing

is bounded on each end by spread footings, thus

16

November 2010

eliminating any exposure of these bars to the

elements.

Next we calculated transverse bars

which are noted as #6@12 (#6 bars at

12 on center). The quantity of transverse bars is calculated:

(net length) / 12 = quantity of transverse bars

ing on concrete strength, rebar size,

and spacing. The use of dowels and lap

splices minimizes the length of exposed

rebar which reduces the risk of damage

to the reinforcing steel. Lap splice calculations are based on ACI 318-02. Table

2.3 shows lap splice lengths for common

shallow foundation design.

Notes:

47.0 / 12 = 47 bars

1. Values are based on Grade 60 reinforcing

bars and normal-weight concrete.

The weight of transverse bars is calculated:

(net length) x (number of bars) x (weight per

linear foot)

2. Compression development lengths and

lap splice lengths are based on ACI 318-02,

Sections 12.3 and 12.16.

(3.0 (3 + 3)) x 47 bars x 1.502 lbs/lnft = 176 lbs

Finally, we must calculate the footing dowels. Unlike the spread footing

dowels which are often estimated as

part of the pier reinforcing, strip footing

dowels are both a function of the strip

footing length (which determines dowel

quantity) as well as the foundation wall

design (which determines bar size). In

some cases, however, the footing dowel

may be tied to reinforcing in a CMU wall

instead of a concrete wall. For that reason, the estimator might be less apt to

miss this reinforcing if it is taken off with

the strip footing.

3. Lengths are in inches.

4. ACI 318-02 does not allow lap splices of

#14 [#43] and #18 [#57] bars.

Utilizing the lap splice lengths for #6

reinforcing bars as scheduled above, the

vertical dimension of the footing dowel

shown in Figure 3 is calculated:

To calculate the dimensions of the

footing dowels, the estimator must

understand lap splices in reinforcing

steel. Lap splices are the most common

method for attaching two pieces of reinforcing steel to form a continuous line of

rebar. The length of laps varies depend-

(footing thickness (minimum coverage(s)at footing) + (minimum coverage(s) at wall) + (lap splice

length)

(18 3 + 3) + 23 = 41 = 3.42

The horizontal dimension is calculated:

(footing offset + wall thickness) - (minimum

coverage(s)at footing) - (minimum coverage(s) at

wall)

(6 + 18) 3 3 = 18 = 1.5

Table 2.3

Grade 60 Rebar, ACI Compression Development and Lap Splice Lengths

Bar

Designation

#3

#4

#5

#6

#7

#8

#9

#10

#11

#14

#18

Compression Development Lengths per fc

fc=3,000psi

9

11

14

17

19

22

25

28

31

37

50

fc=4,000psi

8

10

12

15

17

19

22

24

27

32

43

fc=5,000psi

8

9

12

14

16

18

21

23

26

31

41

Lap Splice Length

12

15

19

23

27

30

34

38

43

n/a

n/a

Estimating Today

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

The weight of each footing dowel is

calculated:

((vertical Leg) + (horizontal Leg)) x (weight per

linear foot)

(3.42 + 1.50) x 1.502 lbs/lnft = 7 lbs

The total weight for footing dowels, is

calculated by finding the number of dowels multiplied by the weight per dowel.

(net length of footing) / (dowel spacing) x (weight

per dowel)

(47.0 / 12) = 47 dowels x 7 lbs = 329 lbs

Finally, the total weight of reinforcing

steel in footing type F8 is calculated:

using the information collected in Table

2.5, we calculate the vertical leg of the

pier dowel:

(18) (3) + (3) + (23) = 41 = 3.42

The length of the horizontal leg of

the pier dowel is calculated using a

minimum dowel length which is usually

specific in the structural notes. This dimension will vary by design, but for shallow foundations, a good rule of thumb is

30 times the bar diameter. In this case,

for #6 bars, the horizontal dowel length

is calculated:

30 x (bar diameter) = minimum dowel length =

horizontal leg length

(441 lbs) + (176 lbs) + (329 lbs) = 946 lbs

30 x .75 = 22.5 = 1.875

Information regarding reinforcing in

piers is scheduled in the same way as

spread footings, although additional

details are often referenced in the pier

schedule (see Table 2.4). For each pier

type, the top and bottom elevation

should be charted individually in order

to calculate the height of the pier and

thereby the length and weight of the

vertical bars and the number of horizontal ties (see Table 2.5). This information may be found on the foundation

plan (noted as T.O.F. and T.O.P.) or by

referencing section cuts and details (see

Figure 4).

For example, refer to the table above

and to the sample foundation plan, to

follow the procedure for estimating reinforcing steel for pier P1 at column C3.

Using the same technique as for strip

footings, pier dowels must be calculated. The size of the pier dowels in a

function of both the pier height and

the dimension of the footing below. In

circumstances where the pier height is

close to or less than the scheduled lap

splice length, the vertical reinforcing

bar and the dowel may be fabricated as

a single piece. For the sake of explaining the take-off in more detail, consider

the vertical bar and dowel separately in

this example. Referring to Figure 5, and

Vertical reinforcing bar weight is

calculated:

(footing depth) - (minimum coverage) + (3) + (lap

splice length)

(weight of longitudinal bars) + (weight of transverse bars) + (weight footing dowels bars)

3) PIERS

(12.0) (3 + 3) = 11.5

The total straight bar length of the pier

dowel and resulting weight of dowels is

calculated:

((vertical leg length) + (horizontal leg length)) x

(number of dowels) x (weight per linear foot)

(3.42 + 1.875) x (8 bars) x (1.502 lbs/lnft) = 64 lbs

Vertical reinforcing bar length including the lap splice at pier dowels is

calculated:

(pier height) - (minimum coverage(s)) = vertical

bar length

Table 2.4

Sample Pier Schedule

Footing

Mark

Size

(vertical bar length) x (number of bars) x (weight

per linear foot)

(11.5) x (8 bars) x 1.502 lbs/lnft =138 lbs

Finally, reinforcing ties, or pier ties are

calculated. Pier ties are rectangular or

square bands of reinforcing steel with

hooks or bends at each end to secure

them to vertical bars. These hooks can

be counted as part of the total length of

the reinforcing tie, or may be assumed,

as in this case, to be included as part

of the established waste factor. The

straight bar length for pier ties at pier P1

is a function of the pier perimeter less

minimum coverages and is calculated:

(((pier dimension A) (minimum coverages)) x 2) +

(((pier dimension B) (minimum coverages)) x 2)

(((2.0) (3 + 3)) x 2) + (((2.0) (3 + 3)) x 2)

= 6.0

Next the number of pier ties is calculated. The height of the pier is divided

by the tie spacing as noted in the pier

schedule. In the case of P1 as shown in

Figure 5, the top 9 of the pier is reserved

for 3 bands at 3 on center. Therefore the

number of standard pier ties is calculated

using the equation below.

Reinforcing

Vertical

Ties

P1

24 x 24

8-#6

#3 @ 12 O.C.

P2

24 x 36

12-#6

#3 @ 12 O.C.

P3

24 x 40

12-#6

#3 @ 12 O.C.

Table 2.5

Pier Type P1 By Location

Pier

Pier

Pier

Dim.

Type

Location

A

P1

B1

20

P1

C1

20

P1

C3

20

P1

D1

20

P1

D4

20

P1

E1

20

P1

E3

20

Pier

Dim.

B

20

20

20

20

20

20

20

Footing

Type

F5

F5

F4

F5

F4

F5

F4

Bottom of

Pier (TF)

Top of

Pier (TP)

82.00

82.00

84.00

82.00

86.00

82.00

86.00

95.50

95.50

96.00

95.50

96.00

95.50

96.00

www.aspenational.org

Pier

Height

(feet)

13.50

13.50

12.00

13.50

12.00

13.50

12.00

17

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

((pier height) (minimum coverage) 9) / (band

spacing)

((12.0) (3) ( 9)) / 12 = 11 bands

The weight of pier reinforcing ties is

calculated:

((number of pier ties) + (number of ties in top 9

inches)) x (pier tie length) x (weight per linear feet)

((11 bands) + (3 bands)) x 6.0 x .376 lbs/lnft = 32 lbs

Finally, the total weight of reinforcing

steel in pier P1 at column C3 is calculated:

(weight of pier dowels) + (weight of vertical bars) +

(weight of horizontal pier ties)

(64 lbs) + (138 lbs) + (32 lbs) = 234 lbs

The procedure outlined above should

be complete for each pier type (P1, P2,

P3, etc.) and for each varying height. This

can be time consuming, so the estimator is encouraged to group like piers with

matching heights whenever possible.

4) FOUNDATION WALLS

Design data for foundation walls is

most often found in foundation details.

Sometimes, however, foundation walls

may be schedules similarly to spread

footings and piers. Referring to the

sample foundation plan, we consider the

take-off of foundation walls between columns lines A1 and A2, shown in section

at Figure 4. Measuring the walls length

from the foundation plan, we find it is

47-0 long.

The quantity of horizontal reinforcing

bars at each face of the foundation wall

is calculated:

((top of wall elevation) - (top of footing elevation)

(minimum coverage(s))) / (bar spacing)

(95.50 82.00 (3 + 3)) / 12 = 13 bars

Horizontal reinforcing bars in long

foundation components are subject to

lap splices every 20 or 60 feet depending

on the material length shipped. Since 20

foot bars are more commonly used and

easier to handle, we assume splices at

200 on center.

(wall length) / 200 = (number of splices) x (lap

splice length) = (total length of splices)

47.0 / 200 = 2 laps x 15 = 2.5

Since the detail indicates horizontal

18

November 2010

reinforcing in each face of the foundation wall, the weight of reinforcing can

be calculated:

reinforcing steel. The basic steps are:

((number of bars) x (number of faces) x (wall

length + length of splices) x (weight per linear foot)

2. Determine reinforcing bar types

(verticals, horizontals, ties, dowels, etc.)

(13 bars) x (2 faces) x (47.0 + 2.5) x .668 lbs/lnft

= 860 lbs

The presence of a brick ledge at the

outside face of the sample wall requires

that vertical reinforcing bars be estimated separately for each face. The weight

of vertical bars on the exterior face of

the wall is calculated by first determining

the number of vertical bars

(wall length) / (vertical bar spacing)

(47.0) / 12 = 47 bars

Vertical bars weight is calculated:

(wall height) +(bar overlap at brick ledge)

(minimum coverages) x (number of bars) x (weight

per lineal foot)

((13.5) + (3.0) (3 + 3)) x (47 bars) x 1.502

lbs/lnft = 1,130 lbs

The weight of vertical bars on the interior face of the wall is calculated by first

determining the number of vertical bars.

1. Locate pertinent details for each

foundation component

3. Calculate each bar type length

4. Multiply bar length by scheduled

quantities and by weight per linear foot

5. Tally results and add waste factor(s) to

determine total weight per foundation

component

This process is the same for both

simple and complex foundation systems.

With practice, the estimator will develop

a systematic approach to this take-off and

be able to tackle more complex systems.

Overview of Labor,

Material, Accessory,

& Other Costs

The total price for reinforcing steel is a

combined total value of reinforcing steel

labor, reinforcing steel material, and

reinforcing steel accessories. Individual

contractor equipment costs, mark-ups,

and indirect costs will also play a factor.

(wall length) / (vertical bar spacing)

(47.0) / 12 = 47 bars

Vertical bar weight is calculated:

(wall height) (minimum coverages) x (number of

bars) x (weight per lineal foot)

((13.5) (3 + 3)) x (47 bars) x 1.502 lbs/lnft =

918 lbs

As noted in subsection 2 above, wall

footing dowels are calculated as part of

the strip footing take-off. Therefore, the

total weight of reinforcing steel in the

foundation wall is calculated:

Labor Costs

Labor costs are primarily a function of

production rates and should be calculated and weighted to account for project

size, repetitive details, and current

market conditions. The best measure of

labor costs is to acquire competitive bids.

Reinforcing steel labor is generally quoted as a lump sum amount but

should be analyzed at a yielded cost per

ton. Some circumstances which may

result in premium costs for labor are:

(weight of horizontal reinforcing) + (weight of vertical reinforcing at exterior face) + (weight of vertical

reinforcing at interior face)

(860 lbs) + (1,130 lbs) + (918 lbs) = 2,908 lbs

Material Takeoff

Summary

The examples above, though different in some ways, represent a common

process for estimating the weight of

Field vs. shop fabrication

Project complexity

Project size

Mechanical or welded splices,

rather than lap splices

Material Costs

Extreme market volatility in recent

decades makes the cost of reinforcing

steel material difficult to project. In the

past 15 years, reinforcing steel has seen

more than a 300% increase in material

Estimating Today

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

cost. Due to the extreme consolidation

of the steel industry, major steel producers have not cut prices significantly in

response to lower demand starting in

2009. Competition among smaller fabrication shops and local distributors has

helped overcome some of the material

cost inflation.

Factors which affect material cost

include:

Overseas demand

Mill production capacity

Competition

Recycled content

tools used in reinforcing steel placement should generally be considered

expendable and may be assumed part

of general conditions costs (clamps, wire

cutters, pliers, etc.)

For the contractor who self performs

resteel fabrication, the investment in

rod benders, cutters, and sometimes

mechanized fabrication systems can be

significant. The cost of these items are

beyond the scope of this article, but

should be considered when developing a

total material rate for fabricated bars.

Ratios & Analysis

Once completed, all take-off quantities

should be compiled in a recapitulation

sheet (see table 4.1). Weights should be

subtotaled by location (spread footings,

strip footings, piers, walls, etc.). The

experienced estimator should develop

a series of checks using historically established rules-of-thumb to assess the

total project quantities. Such measures

can be developed as weight per cubic

yard of concrete, weight per square foot

of wall area, or percentage of total foundation volume.

To mitigate risk, the experienced estimator should solicit current, market driven

pricing for reinforcing steel materials.

Accessory Costs

In addition to reinforcing steel, material accessories must be considered as

part of the overall project cost. Reinforcing steel accessories include:

Tie wire used to connect lap splices and tie

vertical & horizontal bars together.

Bar ties precut wire drawn and annealed

from high-quality rod. Used as a quick

method of tying reinforcing steel.

Bar supports used to elevate reinforcing

bars above formed footing bottom. Supports

can be in the form of plastic chairs, concrete

bricks, or synthetic support blocks

Rebar caps used to protect workmen from

exposed rebar dowels protruding from concrete foundations. Required by OSHA.

Material prices for reinforcing accessories will fluctuate as with other steel

products. However, a good rule of thumb

is that accessories for shallow foundation

reinforcing steel should be between 1.5%

and 2.5% of total material cost.

Other Costs

Tools and equipment are other costs

that should be considered in the final

pricing of the reinforcing steel. For contractors who purchase reinforcing steel

pre-fabricated, these costs are minimal.

The only equipment which might be

used in the field for placing bars is hoisting equipment which is generally not a

major factor when considering shallow

foundations. For the most part, the

www.aspenational.org

19

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

Specific Factors

Affecting Take-off

and Pricing

Types and Grades of

Reinforcing Steel

While the focus of this article is the

analysis of deformed carbon steel reinforcing bars, other types of reinforcing

materials are used. The same concepts

are used to calculate the weight of

these other bars, however, the weights

per piece of these materials as well as

at the resulting total tonnage and unit

cost will vary. ASTM specifications for

common types of reinforcing bars which

might be encountered in shallow foundations include:

ASTM A82: Plain Steel Wire for Concrete

Reinforcement

ASTM A184/A184M: Fabricated Deformed Steel Bar Mats for Reinforcement

ASTM A185: Welded Plain Steel Wire

Fabric for Concrete Reinforcement

ASTM A496: Steel Wire for Concrete

Reinforcement

ASTM A497: Welded Deformed Steel

Wire Fabric for Concrete Reinforcement

ASTM A615/A615M: Deformed and

plain carbon-steel bars for reinforcement

ASTM A616/A616M: Rail-Steel Deformed and Plain Bars for Reinforcement

ASTM A617/A617M: Axle-Steel Deformed and Plain Bars for Reinforcement

ASTM A706/A706M: Low-alloy steel deformed and plain bars for reinforcement

ASTM A767/A767M: Zinc-Coated (Galvanized) Steel Bars for Reinforcement

ASTM A775/A775M: Epoxy-Coated Reinforcing Steel Bars

ASTM A934/A934M: Epoxy-Coated Prefabricated Steel Reinforcing Bars

ASTM A955: Deformed and plain stainlesssteel bars for concrete reinforcement

ASTM A996: Rail-steel and axle-steel

deformed bars for concrete reinforcement

Other Considerations

As with any estimate, special details

can greatly influence project cost and

20

November 2010

therefore break from the norm for costs

and weight ratios. Due to the implied

simplicity of shallow foundations, they

are perhaps less likely to be subject to

these abnormalities, but the estimator

should always be aware that careful consideration of the project details should

be paramount. Some common details

which may significantly increase costs

include:

Epoxy Dowels - Often used to tie existing

foundations to new foundations

Welded connections Though highly

uncommon due to the reduced fatigue

life of the bars, welding will influence labor rates significantly as well as material

costs as very few grades of reinforcing

steel are suitable for welding.

Mechanical splices Where lap splices

are not allowed, other methods of joining two pieces of reinforcing steel may be

used. Mechanical splices which include

threaded couplers, ribbed couplers, and

bolted couplers. These methods of splicing can required preparation of bar ends

and will greatly increase labor costs.

Multipliers As many of the foundation

details require bar and piece counts, the

estimator should not lose sight of component counts. A footing with 5 reinforcing bars should be taken-off as a weight

per each footing and then multiplied by

the footing count. This last step can be

forgotten if the estimator gets too immersed in the details.

Drawing coordination The estimator

should be aware that not all information

regarding reinforcing steel is found in the

structural plans. Review of all contract

documents is necessary for a complete

and accurate estimate.

Estimators should take advantage of

peer review whenever available. Furthermore, developing routine through

practice will reduce possible errors in the

quantity survey of shallow foundation

reinforcing steel.

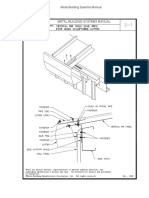

Sample drawings

And details

Specific Risk

Considerations

Figures 1 5 Include:

The experienced estimator will

develop a methodology for calculating

rebar quantities. Adhering to established

conventions will help avoid errors and

insure the validity of the take-off. Some

common errors which should be avoided

include:

2. Typical Spread Footing Detail

1. Sample Foundation Plan

3. Strip Footing Detail Enlargement

4. Foundation Wall Section

5. Foundation Pier Detail

Converting feet and inches The variety

of details and tables that must be used

to develop a complete take-off will often

combine measurements in feet (footing

sizes) with measurements in inches (bar

spacing). Being aware that accuracy

depends heavily on converting values to

a common convention will avoid errors in

the estimate.

Converting pounds to tons Similarly,

combining multiple quantity surveys for

each foundation component is necessary

to establish an overall project weight for

reinforcing steel. The estimator should

be careful to combine quantities whose

unit measure is the same (convert all or

none of subtotaled values to tonnage).

Estimating Today

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

www.aspenational.org

21

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

22

November 2010

Estimating Today

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

www.aspenational.org

23

Estimate the Cost of: Reinforcing Steel in Shallow Foundations

24

November 2010

Estimating Today

You might also like

- Final 2016 Tall Wall GuidelineDocument21 pagesFinal 2016 Tall Wall GuidelineDylanLi0% (2)

- MiTeK Gable End and BracingDocument4 pagesMiTeK Gable End and BracingSam LeungNo ratings yet

- Behaviour of Steel To Concrete JointsDocument5 pagesBehaviour of Steel To Concrete JointsTomNo ratings yet

- Anchoring Into Housekeeping Pads: ConcreteDocument2 pagesAnchoring Into Housekeeping Pads: ConcreteFredie UnabiaNo ratings yet

- Ansi Asabe Ep378.4 - 2010-06Document3 pagesAnsi Asabe Ep378.4 - 2010-06StephanNo ratings yet

- Precast Prestressed Concrete Parking Structure Recommended Practice For Design and Construction 3rd Edition MNL 129 15Document174 pagesPrecast Prestressed Concrete Parking Structure Recommended Practice For Design and Construction 3rd Edition MNL 129 15sdutta2591No ratings yet

- Consumer Customer Complain HandlingDocument30 pagesConsumer Customer Complain HandlingEmdad YusufNo ratings yet

- Structural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteFrom EverandStructural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Slab On GradeDocument13 pagesSlab On GradeEnam BondNo ratings yet

- Building Rebar InspectionDocument41 pagesBuilding Rebar Inspectionjackcan501No ratings yet

- 2.1 BCHD Peer Review Structural Engineering Fee Proposal SIGNEDDocument9 pages2.1 BCHD Peer Review Structural Engineering Fee Proposal SIGNEDRueleo MaoNo ratings yet

- Ds Rebar Splicing HBDocument76 pagesDs Rebar Splicing HBaapennsylvaniaNo ratings yet

- Two Way Slab Punching Shear CheckDocument1 pageTwo Way Slab Punching Shear CheckDaniyal AhmadNo ratings yet

- Code Notes FoundationsDocument8 pagesCode Notes FoundationsleeseeseeNo ratings yet

- BOABC Structural Welding Requirements The Building Official May 2015Document47 pagesBOABC Structural Welding Requirements The Building Official May 2015Abdulrahman AlnasharNo ratings yet

- How To Estimate The Cost of Masonry WallDocument10 pagesHow To Estimate The Cost of Masonry WallRicardo NovondoNo ratings yet

- Introduction To The Concrete Repair Code (ACI 562) : Learning ObjectivesDocument19 pagesIntroduction To The Concrete Repair Code (ACI 562) : Learning ObjectivesShekh Muhsen Uddin AhmedNo ratings yet

- Specifying Concrete For Durability Cif Dec 05Document9 pagesSpecifying Concrete For Durability Cif Dec 05Veio MacieiraNo ratings yet

- Design TablesDocument28 pagesDesign TablesKhaled Alomari100% (1)

- Section 14 2006 FormworkDocument18 pagesSection 14 2006 FormworkRaj MaNo ratings yet

- Sample HOA Architectural ApplicationDocument5 pagesSample HOA Architectural ApplicationRichard BondNo ratings yet

- How To Reinforce Concrete To Control CrackingDocument3 pagesHow To Reinforce Concrete To Control Crackingchutton681No ratings yet

- Steel Framed FloorsDocument12 pagesSteel Framed Floorsyoki_triwahyudi50% (2)

- Rational Costing MethodDocument53 pagesRational Costing MethodSachinNo ratings yet

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFDocument4 pagesWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFtdegrobertNo ratings yet

- Barrier Cable System PDFDocument8 pagesBarrier Cable System PDFsdutta2591No ratings yet

- Seminar 318-19 ConcreteDesignStandard PDFDocument1 pageSeminar 318-19 ConcreteDesignStandard PDFLeroyNo ratings yet

- IDEA-Connection-Theoretical-Manual EN Ver 8 2Document65 pagesIDEA-Connection-Theoretical-Manual EN Ver 8 2Massimo LatourNo ratings yet

- Estimating Reinforcing Bars - tcm45-340894Document6 pagesEstimating Reinforcing Bars - tcm45-340894Alvaro Perez LopezNo ratings yet

- Bridge Design GuideDocument115 pagesBridge Design GuidekoreshNo ratings yet

- Direct Design Handbook Working October 4 2012Document122 pagesDirect Design Handbook Working October 4 2012RicaRDONo ratings yet

- Corner Details For Wall Horizontal Bars: IssuesDocument4 pagesCorner Details For Wall Horizontal Bars: IssuesBrooksNo ratings yet

- FEMA P2062 Guidelines For Wind Vulnerability Assessments of Existing Critical FacilitiesDocument222 pagesFEMA P2062 Guidelines For Wind Vulnerability Assessments of Existing Critical FacilitiesScribdemdNo ratings yet

- E Spec Guide BCI and VL PDFDocument36 pagesE Spec Guide BCI and VL PDFcphammond83No ratings yet

- NRMCA - Concrete in Practice - 44Document88 pagesNRMCA - Concrete in Practice - 44rajendraNo ratings yet

- Rebuild - Repair and Maintenance Needs of Concrete StructuresDocument20 pagesRebuild - Repair and Maintenance Needs of Concrete StructuresAbhishek NarasimhanNo ratings yet

- Hollow Core SpecificationsDocument8 pagesHollow Core SpecificationsJohn Carpenter100% (1)

- Masonry Bearing Wall 1Document3 pagesMasonry Bearing Wall 1Jacinto EstradaNo ratings yet

- Guide Specification: Guide Specification Must Be Edited To Fit The Conditions of Use. Particular Attention Should BeDocument45 pagesGuide Specification: Guide Specification Must Be Edited To Fit The Conditions of Use. Particular Attention Should BeAWNo ratings yet

- D&C Post-Tensioning Projects - Design For PDFDocument13 pagesD&C Post-Tensioning Projects - Design For PDFzfanNo ratings yet

- Ultimate Load Capacity of Reinforced Concrete SlabDocument8 pagesUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- 2012 - Retaining Walls - Soldier Pile Wall Provision (LRFD)Document8 pages2012 - Retaining Walls - Soldier Pile Wall Provision (LRFD)nurNo ratings yet

- This Crew of MineDocument15 pagesThis Crew of MineBook PreviewNo ratings yet

- Basic Structural ConceptsDocument5 pagesBasic Structural ConceptsAlpha0% (1)

- 2012 OrangebookDocument466 pages2012 Orangebookalaa4altaieNo ratings yet

- Conceptual Estimates in SteelDocument4 pagesConceptual Estimates in SteelΈνκινουαν Κόγκ ΑδάμουNo ratings yet

- ConcreteRebar101 - University (Compatibility Mode)Document105 pagesConcreteRebar101 - University (Compatibility Mode)Ronald Kahora100% (1)

- Structure Mag - 2018-08 - Anchorage of Wood Structural WallsDocument3 pagesStructure Mag - 2018-08 - Anchorage of Wood Structural WallstdegrobertNo ratings yet

- Advance Steel - AutoCAD Structural Detailing Comparison MatrixDocument2 pagesAdvance Steel - AutoCAD Structural Detailing Comparison Matrixdev_1989No ratings yet

- SFD Csa S16 09Document116 pagesSFD Csa S16 09Ly PisethNo ratings yet

- Design of Steel and Composite Beams With Web OpeningsDocument19 pagesDesign of Steel and Composite Beams With Web OpeningsAngelica Gamiz ArciniegaNo ratings yet

- Rebar Detailing 8907Document12 pagesRebar Detailing 8907blackwinterNo ratings yet

- Job-Task Analysis (JTA) For ACI Certification of Concrete Construction Special Inspector (Incl. Associate)Document17 pagesJob-Task Analysis (JTA) For ACI Certification of Concrete Construction Special Inspector (Incl. Associate)Scott HendersonNo ratings yet

- Roof Details Section 2.pdf MBMADocument31 pagesRoof Details Section 2.pdf MBMASilvanaNo ratings yet

- Quality Assured Steel Bridge Fabrication and Erection: September 2008Document23 pagesQuality Assured Steel Bridge Fabrication and Erection: September 2008amir0% (1)

- TFEC 4 2020 Design Guide For Timber Roof TrussesDocument72 pagesTFEC 4 2020 Design Guide For Timber Roof TrussesEinNo ratings yet

- BS648-Schedule of Weights of Building MaterialsDocument50 pagesBS648-Schedule of Weights of Building Materialslamine RidenNo ratings yet

- Wall and CeilingDocument16 pagesWall and CeilingAbhishek JaniNo ratings yet

- Microsoft Word - Design Station Purlins & Girts-Rev3Document31 pagesMicrosoft Word - Design Station Purlins & Girts-Rev3khairul4008No ratings yet

- Poppy PDFDocument136 pagesPoppy PDFEmdad YusufNo ratings yet

- Fire Fighting Fire Escape Requirement in High Rise Building - Izzat RamliDocument95 pagesFire Fighting Fire Escape Requirement in High Rise Building - Izzat RamliEmdad YusufNo ratings yet

- APP022Document2 pagesAPP022Emdad YusufNo ratings yet

- APP067Document3 pagesAPP067Emdad YusufNo ratings yet

- Analysing and Reporting Quantitative Data A How To... ' GuideDocument4 pagesAnalysing and Reporting Quantitative Data A How To... ' GuideEmdad YusufNo ratings yet

- COR1081 Code, Guidance and Disciplinary ProcedureDocument17 pagesCOR1081 Code, Guidance and Disciplinary ProcedureubabuNo ratings yet

- Health Surveillance CycleDocument1 pageHealth Surveillance CycleEmdad YusufNo ratings yet

- Leadership ExcellenceDocument5 pagesLeadership ExcellenceEmdad YusufNo ratings yet

- Roof Structure Collapse Report - HongkongDocument11 pagesRoof Structure Collapse Report - HongkongEmdad YusufNo ratings yet

- Is South Koreas Green Job Policy SustainableDocument20 pagesIs South Koreas Green Job Policy SustainableEmdad YusufNo ratings yet

- WRAP's 12 PrinciplesDocument3 pagesWRAP's 12 PrinciplesEmdad YusufNo ratings yet

- Water Quality Aspects in and Around Dhaka CityDocument4 pagesWater Quality Aspects in and Around Dhaka CityEmdad YusufNo ratings yet

- NFPA 70E - 20 Most Common FAQsDocument7 pagesNFPA 70E - 20 Most Common FAQsEmdad YusufNo ratings yet

- Sandvine PlatformDocument2 pagesSandvine Platformpraveen526No ratings yet

- 15ec64 Paper2Document2 pages15ec64 Paper2Lydia DarlaNo ratings yet

- MCS-012 Block 2Document102 pagesMCS-012 Block 2Abhishek VeerkarNo ratings yet

- An Ant Algorithm For Solving Qos Multicast Routing Problem: A. YounesDocument12 pagesAn Ant Algorithm For Solving Qos Multicast Routing Problem: A. YounesPethaperumal PerumalNo ratings yet

- Chennai Street Shopping - Which Street Famous For What !!!Document9 pagesChennai Street Shopping - Which Street Famous For What !!!chellaae2748No ratings yet

- Apresentacao Escala Risc Unitech-BullDocument49 pagesApresentacao Escala Risc Unitech-BullWanderson PedrosaNo ratings yet

- Course Manual ERPDocument26 pagesCourse Manual ERPUmang DubeyNo ratings yet

- 3com 600506Document13 pages3com 600506a_agustamaNo ratings yet

- Seating SolutionsDocument36 pagesSeating SolutionsSudhakar PNo ratings yet

- Project-Diamond Green BuildingDocument41 pagesProject-Diamond Green BuildingIsabella WomsiworNo ratings yet

- CFor Speed SetupDocument13 pagesCFor Speed SetupMahmoud Al-QudahNo ratings yet

- Olgiati Works ConceptsDocument11 pagesOlgiati Works ConceptsJohn JohnsonNo ratings yet

- Zulo Floodlight PDFDocument6 pagesZulo Floodlight PDFhairulNo ratings yet

- Immigration ClearanceDocument92 pagesImmigration Clearanceindia_proud50% (4)

- Motorola AP-7131 Series Access Point Product Reference Guide (Part No. 72E-139344-01 Rev. B) 13934401bDocument800 pagesMotorola AP-7131 Series Access Point Product Reference Guide (Part No. 72E-139344-01 Rev. B) 13934401bAdvantec SrlNo ratings yet

- Installations DetailsDocument8 pagesInstallations DetailsWesal RefatNo ratings yet

- WP 802.11axDocument38 pagesWP 802.11axchopanalvarez100% (1)

- Gprs SettingDocument14 pagesGprs SettingRathinavel DassNo ratings yet

- The Cracking of StormwaterDocument8 pagesThe Cracking of StormwaterBen SinambelaNo ratings yet

- Netbeans Ide 6.9.1 Installation Instructions: Log inDocument5 pagesNetbeans Ide 6.9.1 Installation Instructions: Log inEka AlifakihNo ratings yet

- CDBMC PDFDocument23 pagesCDBMC PDFDV chanNo ratings yet

- K3RN3LC0MP1L3RDocument3 pagesK3RN3LC0MP1L3RMurilo RamosNo ratings yet

- Responsibility Table CONDO or Unit OwnerDocument3 pagesResponsibility Table CONDO or Unit Ownerfriday7997No ratings yet

- Advanced GUI Code Example: Button List BarDocument9 pagesAdvanced GUI Code Example: Button List Barhernandezpalo100% (1)

- (M2 LA 1) Text 1Document2 pages(M2 LA 1) Text 1Muhammad Rusli100% (1)

- Building TechnologyDocument46 pagesBuilding Technologyhans abesamis100% (2)

- Lec 12Document33 pagesLec 12Mahrukh SaleemNo ratings yet

- Sagemcom Fast 1704 ENGDocument2 pagesSagemcom Fast 1704 ENGGeraldo PereiraNo ratings yet

- Proroc Bracing Manual09Document12 pagesProroc Bracing Manual09JonoNo ratings yet

- Custom ShortcutsDocument2 pagesCustom ShortcutsRandistya FahmyNo ratings yet