Professional Documents

Culture Documents

316L SS WeldingWireSpec PDF

316L SS WeldingWireSpec PDF

Uploaded by

SaravanKumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

316L SS WeldingWireSpec PDF

316L SS WeldingWireSpec PDF

Uploaded by

SaravanKumarCopyright:

Available Formats

T H E

H A R R I S

P R O D U C T S

L I N C O L N

E L E C

4501 Quality Place Mason, OH 45040 U.S.A

G R O U P

T R I C

C O M P A N

Tel: 513-754-2000 Fax: 513-754-6015

TECHNICAL SPECIFICATION SHEET

316L STAINLESS STEEL WELDING WIRE

STATEMENT OF LIABILITY- DISCLAIMER

Any suggestion of product applications or results is given without representation or warranty, either expressed or implied. Without

exception or limitation, there are no warranties of merchantability or of fitness for particular purpose or application. The user must fully

evaluate every process and application in all aspects, including suitability, compliance with applicable law and non-infringement of the

rights of others. The Harris Products Group and its affiliates shall have no liability in respect thereof.

NOMINAL COMPOSITION:

Carbon

Nickel

Copper

Phosphorus

Molybdenum

Normal Ferrite Range

.03% max.

11.0-14.0%

.75% max.

.03% max.

2.0-3.0%

5-12

Chromium

Manganese

Silicon

Sulfur

Iron

18.0-20.0%

1.0-2.5%

.30-.65% max.

.03% max.

Balance

TYPICAL MECHANICAL PROPERTIES AS WELDED:

Yield Strength (psi)

Tensile Strength (psi)

Charpy V

Rockwell B Hardness

59,000

88,000

80 ft./lb. room temp.

85 HRB

Elongation

Reduction of Area

Brinell Hardness

35%

40%

160 HB

APPLICATION:

This alloy is used to weld molybdenum-bearing alloys and similar alloys containing .03% maximum carbon

RECOMMENDED WELDING PARAMETERS:

*GMAW (MIG) Parameters (DC Reverse Polarity) Electrode Positive Short-Circuiting transfer

Wire Diameter

Amps

Volts

.030

.035

.045

60-125

75-160

100-200

17-22

17-22

17-22

90% Helium + 7.5% Argon +

2.5% CO2 (cfh)

20-25

20-25

20-25

Wire Feed (ipm)

150-430

120-400

100-240

*GMAW (MIG) Parameters (DC Reverse Polarity) Electrode Positive Spray transfer

Wire Diameter

.030

.035

.045

1/16

3/32

Amps

160-225

180-300

200-450

225-500

250-600

Volts

24-28

24-29

24-30

24-32

24-32

Argon / 1-2% O2

25

30

30-35

40

50

Wire Feed (ipm)

440-650

430-500

220-400

110-210

50-80

All statements, information and data given are believed to be accurate and reliable but are presented without guarantee, warranty or responsibility of any

kind, expressed or implied.

Additional information available at our web site: www.harrisproductsgroup.com

9/99 DC

1

*GTAW (Tig) Parameters (DCSP) Electrode negative

Material

1/16

3/32

1/8

3/16

1/4

1/2"

2% Thoriated

1/16

1/16

3/32

3/32

1/8

1/8

Filler Wire Size

1/16

1/16

1/16

3/32

1/8

1/8

Amps

80-120

100-130

120-150

150-250

200-350

235-375

Gas Cup

3/8

3/8

7/16

7/16

1/2

1/2

Argon(cfh)

20

20

20

25

25

25

* All parameters are suggested as basic guidelines and will vary depending on joint design, number of passes and

other factors.

SPECIFICATION COMPLIANCE: ANSI/AWS A5.9 &ASME SFA 5.9 ER 316L

WARNING: PROTECT yourself and others. Read and understand this information.

FUMES AND GASES can be hazardous to your health.

ARC RAYS can injure eyes and burn skin.

ELECTRIC SHOCK can KILL.

Before use, read and understand the manufacturers instructions, Material Safety Data Sheets (MSDSs), and your employer's safety practices.

Keep your head out of fumes.

Use enough ventilation, exhaust at the arc, or both, to keep fumes and gases from your breathing zone and the general area.

Wear correct eye, ear, and body protection.

Do not touch live electrical parts.

See American National Standard Z49.1, Safety in Welding, Cutting, and Allied Processes, published by the American Welding Society, 550

N.W. LeJeune Road, Miami, Florida 33126; OSHA Safety and Health Standards, available from the U.S. Government Office, Washington, DC

20402

All statements, information and data given are believed to be accurate and reliable but are presented without guarantee, warranty or responsibility of any

kind, expressed or implied.

Additional information available at our web site: www.harrisproductsgroup.com

9/99 DC

2

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Common Vulnerabilities and Exposures Project ReportDocument22 pagesCommon Vulnerabilities and Exposures Project ReportRishi JainNo ratings yet

- Introduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Document25 pagesIntroduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007ANILNo ratings yet

- Sintef PDFDocument80 pagesSintef PDFANILNo ratings yet

- Gross - Comment On SearleDocument12 pagesGross - Comment On SearleJLNo ratings yet

- What Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyDocument10 pagesWhat Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyANILNo ratings yet

- Name: Nilesh Ashok Wagh Mobile No.: +91 7588930595/7020322853 Technical AchievementsDocument2 pagesName: Nilesh Ashok Wagh Mobile No.: +91 7588930595/7020322853 Technical AchievementsANILNo ratings yet

- Prototype: Build Review Refine & IterateDocument7 pagesPrototype: Build Review Refine & IterateANILNo ratings yet

- L9 Nominal Taguchi 1Document38 pagesL9 Nominal Taguchi 1ANILNo ratings yet

- Season Classification Chart 2017: Alleppey Munnar Coorg Binsar Kanatal Shimla Kanha JaipurDocument2 pagesSeason Classification Chart 2017: Alleppey Munnar Coorg Binsar Kanatal Shimla Kanha JaipurANILNo ratings yet

- CarbideDocument1 pageCarbideANILNo ratings yet

- ASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingDocument1 pageASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingANILNo ratings yet

- Refrigeration and Airconditioning by S K Mondal T&Q .0001Document133 pagesRefrigeration and Airconditioning by S K Mondal T&Q .0001ANILNo ratings yet

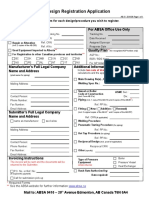

- AB-031 Design Registration ApplicationDocument1 pageAB-031 Design Registration ApplicationANILNo ratings yet

- Courses Welingkaronline Org Newlogin Subjectlist PortionDocument1 pageCourses Welingkaronline Org Newlogin Subjectlist PortionANILNo ratings yet

- Body Language For InterviewDocument5 pagesBody Language For InterviewANILNo ratings yet

- GD & T Stack Up Analysis PDFDocument12 pagesGD & T Stack Up Analysis PDFANILNo ratings yet

- Meeting Feedback: How Productive Was The Meeting?Document4 pagesMeeting Feedback: How Productive Was The Meeting?ANILNo ratings yet

- Application Form For LIFE Corporate Membership: 1. Corporate Name (In Block Letters)Document3 pagesApplication Form For LIFE Corporate Membership: 1. Corporate Name (In Block Letters)ANILNo ratings yet

- ThermodynamicsDocument57 pagesThermodynamicsANILNo ratings yet

- Curriculum Vitae: ObjectiveDocument4 pagesCurriculum Vitae: ObjectiveANILNo ratings yet

- HSBC - Call LetterDocument1 pageHSBC - Call LetterANILNo ratings yet

- AIR-Intelligence ASD-320 Aspirating Smoke Detection System: P/N 33-308100-002 January 2010Document58 pagesAIR-Intelligence ASD-320 Aspirating Smoke Detection System: P/N 33-308100-002 January 2010leunamsayanNo ratings yet

- CopterX CX 450BA KIT Manual PDFDocument22 pagesCopterX CX 450BA KIT Manual PDFpHysiXNo ratings yet

- VITRONIC Poliscan FM1Document2 pagesVITRONIC Poliscan FM1Hamza Kr MoujibNo ratings yet

- Online Examination System For AndroidDocument7 pagesOnline Examination System For AndroidSri Sai UniversityNo ratings yet

- Refers To The Structure or The Arrangement of The Components or Elements of A CurriculumDocument3 pagesRefers To The Structure or The Arrangement of The Components or Elements of A Curriculumlilibeth odalNo ratings yet

- Mini Caisson Design-CalculationsDocument6 pagesMini Caisson Design-CalculationsRobert SiqecaNo ratings yet

- IIMA Year Book On IdeasdDocument57 pagesIIMA Year Book On IdeasdTejas JosephNo ratings yet

- DNA and RNA QuizDocument3 pagesDNA and RNA QuizDavid GiraldoNo ratings yet

- Reciprocal Teaching Chapter 2Document5 pagesReciprocal Teaching Chapter 2JOHNERROL CARCELLARNo ratings yet

- B11.5 Hormones in The Menstrual CycleDocument3 pagesB11.5 Hormones in The Menstrual CycleBenjamin WatsonNo ratings yet

- Scholarship Essay SampleDocument1 pageScholarship Essay SampleSipho Troy MoyoNo ratings yet

- Ender-3 Pro Assembly Instruction - EN V.2.1Document16 pagesEnder-3 Pro Assembly Instruction - EN V.2.1vwcxlNo ratings yet

- Major Project Statement Plug in Electric Vehicles Over Hybrid VehiclesDocument10 pagesMajor Project Statement Plug in Electric Vehicles Over Hybrid VehiclesS19M082 KRITHIK ANo ratings yet

- Physics For Shs GR 12Document4 pagesPhysics For Shs GR 12blezieNo ratings yet

- Introduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMDocument12 pagesIntroduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMKiranRao BiradarNo ratings yet

- 9 - IndustryDocument9 pages9 - IndustryAshish DhakalNo ratings yet

- HYUNDAI Placement Paper 2011Document14 pagesHYUNDAI Placement Paper 2011Ravi Karthik100% (3)

- Tarea No 7 ExergiaDocument3 pagesTarea No 7 ExergiaAndres RomeroNo ratings yet

- Wavecom CH W-Spectra BrochureDocument24 pagesWavecom CH W-Spectra BrochureJohn Bofarull GuixNo ratings yet

- Chapter 7Document24 pagesChapter 7Rhea Mae BubanNo ratings yet

- Christian-Ethics RelativismDocument15 pagesChristian-Ethics RelativismRamirez RayNo ratings yet

- AstarDocument20 pagesAstarPetter PNo ratings yet

- Characterization of AA6111 Aluminum Alloy Thin Strips Produced Via The Horizontal Single Belt Casting ProcessDocument8 pagesCharacterization of AA6111 Aluminum Alloy Thin Strips Produced Via The Horizontal Single Belt Casting ProcessUsman NiazNo ratings yet

- Mangrove Related Publications (1960 - 2022) by Prof. Sunanda KodikaraDocument42 pagesMangrove Related Publications (1960 - 2022) by Prof. Sunanda KodikaraKrishan Rajapakse - University of KelaniyaNo ratings yet

- How Thick Is Gold Finger PCB Plating and Its CostDocument15 pagesHow Thick Is Gold Finger PCB Plating and Its CostjackNo ratings yet

- Catalogo de Aisladores de Vidrio TECNICODocument48 pagesCatalogo de Aisladores de Vidrio TECNICOGlenys MuñozNo ratings yet

- Final Capstone Project Report Final EditDocument16 pagesFinal Capstone Project Report Final Editapi-385778405No ratings yet

- Fluid MechanicsDocument27 pagesFluid MechanicsKarl Radison AbreaNo ratings yet