Professional Documents

Culture Documents

SOP For Piling Work PDF

Uploaded by

Suhaidi Alias0 ratings0% found this document useful (0 votes)

66 views33 pagesOriginal Title

258972882-SOP-for-piling-work-pdf.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

66 views33 pagesSOP For Piling Work PDF

Uploaded by

Suhaidi AliasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 33

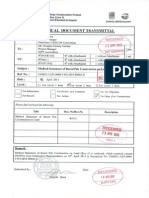

Hear SAFETY & EnROnMENTAL METVO00 STATEMENT

Toniactor Bary Ping Systems Limited | Contract Name!

J Contract Scope: Piling Operation Location: 121

BPSUSttN0

HEALTH, SAFETY & ENVIROMENTAL METHOD STATEMENT FRONTSHEET

Contractor: Berry Piling Systoms Limited.

Contract Name: Daniols Department Store Phat

Contract Scope: Piling Operations

Revison | pare | writen | APPROVED | CLIENT | COWMENTS

By | BYFORBPS | APPROVED

0 | 71010 | B.evans | B.Evane

| have read, understood and shall abide by all methods taid out in this method

Statement and risk assessments. Furthermore should | see or be made aware of any

Unsate working or doviabons from the methede laid out | wil contact the site

Sparse immediately

NAME

IVED | —

_ 1g FEB 2001

PLANNING iy

Heavy, SAFETY 6 EnWRONMENTAL METHOD STATEMENT

‘ontractr: Barry Piling Systems Limited | Contract ame: Gant Department Stora Phase

‘Contract Scope: Piling Operations Location: 121-125 Peascop Stret, Windsor, Berkshire, SL@

1.Scove oF WoRKS

Berry Piling Systems will carry out pling operations within the confines ofthe sto at

121125 Peascop Street, Windsor, Berkshire, SLA TDP. Al works fo be undertaken

within the intemal boundary of the site.

‘Our scope of works includes the following

‘+ To bore and construct approximately 119No. 450mm O/D nominal alameter

CFA piles fo form & contiguous embedded reaining wall to two boundaries of

the slle which Includes party wall Boundary. Contiguous piles wil be bored

‘and consiucted in a Nit one miss three sequence of al the foreman's

{iscretion. Dailing ples in a sequence ofthis nature alows contiguous ples

time to cure prior tothe sols direct adjacent being dsturbod

‘+ To bore and construct approximately 103No. 450mm O/D nominal diameter

CFA piles to depths no less than 8.0m and no greater than 20.5m to provide

foundations for he main superstructure

Pile method we intend 10 use is @ Continuous fight auger bored method which is

one percussive and none vibraloy.

‘All works are fo be carried out in accordance and within the parameters of the Safe

‘Systom of Work issued by the cit, the agreed sit design and the contracts works

‘drawings and specifications, In this case the cient i Galifors Try Construction,

The piling works will be carried out from a single, level piling platform, cutoff levels

‘and pling platform levels to be agreed pir to piling works commencing

‘A Ping operation methodology is attached in APPENDIX A

2. SEQUENCE OF THE WORK

To construct piles in a logical sequence but in ine with our sequence detailed in the

above scope of works. All sequencing of works tobe discussed and agreed with

Galifors Try Construcion prior to pling works commencing. Upon completion of

‘each section of works the pling ares wil be fenced of for 7 days before piles can be

broken down.

‘2. PLANT ano MATERIAL DELIVERY

Allplant wil be delivered taste on beaver talediiab equipped vehicles

‘At his stage Main Access fo the site for tne rg willbe via 121 - 125 Peascop Steet,

‘Windsor, Berkshire, SLA TOP,

‘Acoass tothe site willbe via the site entrance on 121 - 125 Peascop Steet. Here the

Lorries wil unload with the aid of the lory mounted crane to deposit the ancilary

‘equipment close tothe point of pling. The png rg wil be tracked off ts lorry using

‘the beaver tal ramp. Al al sk surfaces must be protected by others prior to the

piling mobiisation. The concrete pump'wil be delivered to the rear ofthe store and

Setup in the goods vara

‘The Principal Contractor is responsible for ensuring that waste materials and pile

spoil arising is removed from sie in aczoreance with their procedures and in

‘accordance wih all environmental requirements,

© 2

[ Gontractor Bary Plog Systems Limit ‘Name! Dano

‘Contract Scope: Piling Operation Location: 121- 125 Peascop Street, Windsr, Berkshire, SL@

DP. BPSU46H1/10 —_

“The site has been inspected to allow safe vehicle delivary withthe use of banks men

‘when unloading the ping ig. The rig wil be moved under lis own power, an operator

and banks man will bo in postion to achieve this. The ping rig wil ot be moved

‘without an operator er barks man in allendance, ensuring its sale and controled

movement.

Once delivery is completo the vehices will depart site and the pling ig wil ether be

‘maneuvered to its fst pile posiion or pul in a sale positon unt instructed to

Continue by the pancipal contractor's representative onsite.

Al. ancilary equipment wil be devoted to site and be located within 20 mates of ho

piling operational area. All materials will be dellered to ste and stored in a holding

{ompound or at an agreed location on the ste.

For the constuction of the pling work, its proposed to uilse the following plant,

‘he technica specicaion of which are shown in APPENDIX 8,

Klemm 709 Ping Rig 1No,

Container Toolbox (Small) 1No,

Diesel Jotwash 1No.

44 Concrete Hoses (60/80m) 1 No,

Conerete Pump AN

Sundry Equipment

“Tracked Excavator (or equivalon!) provided by the Main Contractor 1 No

The above to be fully contolled by ping Foreman or rq Banksman to ensure no

‘resh ples are tacked over and damaged.

Mess, Drying Room and Welfare in accordance with curent legislation (ols and

washing Tacive incuding hot running water) to be provided by the Principal

Contractor. This wil be located at King Edward Court Undor ero, Bridgowalr way.

4, Liemmo Eoupwent

‘The pling rig wil have ls curent Certificate for Safe Operation (LOLER), This willbe

hele by the site supervisor and a check wil be cariod cut to ensure tat i ie vals

‘and uptodate. Any fing chains or straps wil be fuly certfied.

S,PoRTABLe Toots

+ Angle Grinder Peto riven

{Hand tots suchas spanners and cub hammers

+ Onste welding unt (General frig repars ony).

[A todls to be checked by the supervisor each day for fit for use (PUWER 1908:

Provision and Use of Work Equipment Regulations). Those tools found unft are to

be tagged and removed from ste for repair or disposal

Hea. SAFETY & ENWeROMMENTAL METHOD STATEMENT

arty Pllig Systems Limited | Contract Name: Daniels Department Store Phase?

‘Gontract Scope: Pling Operations Location: 421 125 Peascop Street, Windsor, Boric

| sor: eesieetsi10

S.NOISE AND ViBRaTION

‘The predicted noise and vibration levels are to be kept within the local authority

levels using silenced equipment. Please note due to the piling technique being

lized on this project no vibration wil be generated

Works wil take place during normal working hours 6:00am-600pm Monday to

Friday. No weekend working i intended,

AiR Quausry aNo Dust

‘The items of plant and processes which emit ar polation are

+ Diesel Power Pack

+ Petrol Angle Grinders

+ Road vehicles

‘The Png Foreman to ensure that exhaust emissions are kept within the lage limits,

All venicesipiant tobe parked and engines turned off when notin use,

8. PLN PLarroRM

Ful ple platform design wil be required. A further revision of this method statement

wl be require fo highight platform thickness and make up.

9. CONCRETE INSTALLATION

Pies we be concreted using the open bore method. Pes wil be bored to depth, and

‘concreted using the top fil method; a concrete pump wil be sited so that it can be

easily accessed by Ready-mix Lorries. The Concrete willbe discharged into the

Conctote pump and tothe head ofthe pile va 4” hoses, Concrete wil be poured t0

‘round level and the steel reinforcement placed. The concrete Is supplied by others

inthis cave.

10, Remrorcewent

Reinforcement bar and helical wil be delivered to sito and fabricated on site to the

pile design spectications. The minimum cover to the reinforcement will be SOmm

(tac)

‘The main ber wil be set up on ste! fixing trestles so that the steel fixer can work in

the standing postion, The helca wil be wound onto the main reinforcement bar and

tied accordingly using. Cares certificate forthe steal reinforcement to be supplied

Please note that a clear and visible segregated area must be erected for the steel

fixer to work in safely

1, CO-ORDINATION WITH OTHERS

The Following dotals any arrangements for co-ordination with sub-contractors,

adjacent contractors and ical authori etc

Contactor: Ba

Heat, SAFETY & ExvigOMMENTAL MET#O0 STATEMENT

ing Systems Limited | Contract Name: Danile Depadimant Store Phase 2

All personnel wil Book into site though the construction ste offices; they wil then

receive 8 site induction by te Principal contractors representative onsite.

‘The Bemy pling supervisor will ensure that all personnel involved in the Piling

‘operation are briefed on the contents ofthis method statement and eafe working on

‘or around the pling rigs and any other machinery wih the pling area. The con's

Fopreseriatve on ste is responsible for ensuring that al Ste personnel are briefed

‘and made aware ofall rsks involved in wrking on or ound ping operations,

12.Pus Locanions

Apling layout has been supplied (No X102021 SK100 REV P2) with a constuction

issue at the time of commencament to be held on sie. any davialons from the

Instructions on th layout willbe cleared through Bary Ping Management prior fo

proceeding. The pling layout drawing wil be checked with the principal contactors

Fopresertatve on site to endure It's the last construction issue avaiable before

piling works commence. Setting cut of ples willbe the responsibility of others.

413, Lasous Force

‘The folowing max deals the number and level of competency ofthe workforce.

Personnel —~ ——— | Hamiber [Level of Compotoney.

Contrects Manager: Barry Evans 1 [5 days Site Manager (SMSTS)

7770 963147 2 day FPS Site Supervisor.

Project Supervisor OWer Cantle T | 2 day site supervisor safely rained

o7r2t set495 Experienced’ and Trained in

RigiPiing Operations

Piling Foreman: Marin Picket T [2 day site supervisor safely ined

Experienced and Trained in Rig

_ Oparations "

‘SRIEG pig oparaives S| Experienced and Trained WRI

Operations

14 Teams

‘Al Berry Piing personne! wil be trained in safe and competent use of the rg. Only

{rained and experienced personnel wil be permiled to operate on or around the

pling rg. Bary pling personnel have undergone CSCSICPCS training. Copies of

Cenitcates and training records are held at Berry ling main offices. All employees.

{ohave tes relative cards ready for inspection atthe ste induction.

Hon th job Safety training is necessary it willbe undertaken by Olver Gentle Berry

piling Health and Safety representative.

The following are o be included into the site induction

‘This Method Statement

Working 0 or near pubic services

Site Security

Equipment Security

‘Working within the vility ofthe general public

Emergoncy evacuation pins in the eveat of Fre/Emergency

‘Site setup an¢ locations of Wotfare and fst Ald facies

Contract Scape: Piling Operations Location: 121 - 125 Poascop Steet, Windsor, Beishive, SLA |

‘DP, BPSMGI1/10 “}

HeALT#, SAFETY & EXVRONVENTAL METHOD STATEMENT

[Contractor Besty Piling Systems Limited | Contract Name: Daniols Departrent Stare Phase 2

‘Contract Scope! ling Operations ‘Location: 121-125 Peassop Strost, Windsor, Berkshire, SUA]

PSUsN0

15, PROTECTION oF THe EMPLOvERS ASSETS

dently in the table below wunerabie

‘employer assets and deta the method of

protection.

‘Brea requiring protection Wathod of Protection

Work Area Barriers and signage:

Party Wal be praia by ihe Nain Conair

" pio to ping works commencing

Beiow & ADO GrOURE GONTEES, ‘Service information drawings suppied By

the Planning superisodclent. Al

ices to be highlighted and. clearly

marked out on sit, Prolecon of services

Wwhere required by MC. Site Safety

briefing to all ping personnel to take

place to make Sure care and attention is

faken when working close to. the

ighighted services.

J6. MATERIALS

‘The folowing lst deals materials tobe used forthe contract.

Dery ~ diesel for plant

Grease

(Grout Sand / Cement / Concrete

Hydraule Of

Engine Oi

Al relevant COSHH related documents, such as manufacture's hazardous data

heels nd test certificates and assessments (where applicable), wil be available on

Site in the ‘Contract Health and Safely Contal fa

417, STORAGE AND HANDLING OF CHEMICALS

‘The following table details the chemicals to be usod forthe contrac:

Column 4 references the COSHH assessment for each chemical, which contains

information on how the chemical shoulé be slored, handle, used and clsposed of In

‘order fo minimise environmental risks

Type of | Guantiies | Projected use | Environmental | COSHH

chemical ” | impacts ‘Assessment

Petro! Sie Fuel Tor angle | See Above To be

ringers altsched 10

site fle

‘OisiLubreant | Various | Slate & Major | See Above To be

5 Plant allached to

| 2 Site Fle

Grout ‘As roqulred” | Pleshple cap | Bunds wil bo] To be

provides attached to

site fl

6

HEALTH, SAFETY & ENVIRONMENTAL METHOO STATEMENT _ __

‘Goniractor Baty Ping Systoms Limited — | Contract Nome: Daniels Department Store Phase?

‘Contract Scope! Piling Operations Location: 421- 128 Peascop Stet, Windsor, Berkshire, SL

a ‘bP. BPSUGIIH0 "

TROL oF Wonk wir HAZARDOUS SUBSTANCES AND PROCESSES

[Assessments or all hazardous substances and all hazardous processes will be

lunderiaken. Copes of these assessments are available In the Health and Safety

Control File on site. All operatives are made aware ofthese assessments by the

Piling Foreman and thor locaton. Ths nication wil be carried outin te form ofa

ste induction andlor too box talks throughout the period of works

19, TewPoRagy STRUCTURESIFALSEWORK

[A temporary works are to be carried out and compited by the principal contractor.

All tomporary works cotficates, drawings and calculaine ara to be made avaiable

to Bery Ping

20, Wong a Heroes

NA

21, PERMITS AND LICENSES

Berry Png Systoms are fo ensure that the cfent has arranged for all necessary

licences and construction consents relating tothe project fo Be hela on site and made

‘avaiable for audit. A Permit to Dig wil bo issued by the principal contracio’s

reprosentaiveon ste prior o pling works commencing,

22. EXCAVATION

No excavations wil take place, completed open bores are to be protected by

securing ply sheeting over the holes to acid bps and fals. Exposed reinforcament is

tobe boxed and or capped,

23, TEMPORARY LIGHTING AND POWER

‘The pling rig will be powered buy is own desel power pack. Were extra power ie

requled for ur pant wil we use a diesel powered generator or power supplied by

tha princple contractor. Task lighting may be required power for which wile from

site sources and al power to be 110.

Where Generators are used they are tobe placed ovin @ bunded area to ensure that

‘any spilages that coud occur are contained,

‘The dlent isto ensure that suitable suficient storage areas are allocated for Ping

equipment and materials, these areas are to be tapedtTenced aff rom the rest of he

works

25, PERSONAL PROTECTIvE EQUEMENT (PPE)

The following PPE isto be used!

HeALn, SAFETY & EwvROWMENTAL METHOD STATEMENT

‘Contractor Berry Piling Systoms Limited — | Contract Name: Daniels Depa |

Contract Scope: Ping Operations Location: 121-125 Peascop Sires, Windsor, Beriahire, SL&

‘bP, BPS4GI1/10

+ High visibly vests $6629 Yellow

+ Safely helmets EN397

+ Safety Boots BS 1870 EN 345 /EN 346

+ Safety gogolesiGtasses BS 2092 /ENT6S

+ Gloves EN420,

+ Earprotecion EN352 PART 4

+ Face masks ENt49

[Altitems marked in RED are mandatory

26.imst AD

‘A fist id box and accident book for the pling gang will bo kept with a nominated

‘operative. The Firs Aid box willbe checked daly fo ensure its contents are stocked

‘and of a usable condition. Each team wil have a tained frst Alder. Olher First Ad

‘arrangements wil be made through the princpal cntraciorsrepresentalve on sie.

27. FRe

Provision for adequate fre precautions wil be made on ste by the Piing Foreman

and the principal contractor's representative on site, A fire point is to be located

Wwitin the immediata work area and to be identfied {0 the work foree in the sit

Induction

28, Housexesng

Work aroas willbe kept Udy both during and atthe end ofeach shit, Materials wil be

stacked tilly and safely so as not to cause obstruction for access,

28. ACCIDENTS, NCDENTS AND REPORTING OF INJURIES, Dis

‘OCCURRENCES (RIDDOR) 1995

‘All Accidents and incidents willbe reported directy to the principal contractor's

representative on site, he wil then inform all hose responsible in accordance with his

‘company procedures.

‘The Boxy Pling site foreman wil be responsible for informing the Bery Ping

management of al accidents and incidents mmeciately. The principal Contractor wil

be responsible fr al accident investigation and subsequent reporting to HMR

[Accidents and incidents (including near mises) wil be reported and managed by the

Berry Piing Systams Management team Mr Barry Evans! br Olver Gent and they

wil be responsible for carving out investigatons into incidents and reporting the

incidentaceident tothe HSE on an F2508 form where required

30, EMERGENCY PRoceDURES

Contact the following in the event of an emergency (work, and motile numbers)

Chis Beery Managing Director 07785 771709

Barry Evans Contracts Manager — 07770 963147

Olver Gentle Contracts Supervisor - 07721 381405

THSP (H&S advisors) Work 08456 122 144

_ eALT, SAFETY & ExvROMMENTAL MEIHOD STATEMENT

‘Coniraetor- Berry Piling Systems Lirted | Contract Nome’ Daniels Department Store Phas

Contract Seape: Ping Operations Location: 121-125 Peascop Street, Windsor, Berkshire, SLE

‘s0P. BPSUGII/10

‘The sito supervisor will ensure that all employees are aware of the emergency

procedures and evacustion and assembly points. Emergency procedures will be

{hose adopted by the principal canractor and staff an the site and pre-agroed before

works commence. Emergency information wil be held both inthe ‘Contract Health

land Safety Conirl file "and en the principal contractors sign boars with al relevant

associated information

131, Signs ano Nonces

Signs and notices for the works wil be located where necessary to ensure safety

requirements. These wil Include

No Unauthorised entry

anger Men at Werk

Hara Hat Ares

Rolovant PPE statutoy signs

132, SvsTeMs/Coves oF PRacnce

‘Special systams or code of practice willbe folowed, Thase incl:

+ BPF Standard Specication

+ BSEN Code of Pracice

+ HSE Guidance Notes

33, STATUTORY ReconDs:

‘The following statutory records willbe kopt in ‘Contract Health and Safaty Conta file:

1510 Accident Book

2506 Incident Riddor Forms

LOLER

PUWER

‘The Site Supervisors responsible for maintaining the records and the location where

records will be kept

24. WasTe MaNaceMENT

‘The outputs of materitsby productstwaste products from the contract are

+ Soll arsings from ping operations

+ Concrete overspil,

‘The principal contractor wil be responsible forthe disposal ofall waste materials

from pling operations.

|All Washing oft area's to be agroed with the principal contractor's representative on

site,

‘The typos of oftuont, quantities and how the effluent will be managed are described

in he table below

°

Contact Scope: Ping Operations ocallon: 121 - 125 Peascop Street, Windsor, Beitshive, SU

HeALT, SAFETY & EnviRoMwenTAL METHOD STATEMENT

7 Ping Systoms Limited [Contract Name: Daniels Department Store Phaze?

= oc

Psusttit0

yi —Tavani

‘Clean Water 20 Lites 7 Winuie shor] Normal Construction

uration Practices

‘The ste is subject to rainfall and creates storm water run off. The effluent will be

controlled by the principal contractor.

RAFEIC MANAGEMENT

‘The works traffic wil be mansged by principal contractor’ representative on site In

Corder to minimise environmental Impacts, such as noiss, air emission, dust, Mud

‘creation and minimise congeston at ar around the ste

‘ST.CONTAMINATED LANO

Iv any contamination 's caused the area affected isto be cleared and disposed off

under the EA 90 wih all waste being disposed of by licensed contraciors. All

contamination will be reported through the principal contractor's representative on

Sie, Al ste operatives wil be instructed in goos housekoaping and personal hygiene

‘when working in or around such potential risks

BLINSPECTION AN ENVIRONMENTAL AUOTING

Berry Ping Healtn and Safety Manager wil Visit site on normal routine to ensure that

‘all ervironmertal containment measures are being sed, where there is an

fevironmental non conformance then this Will be rected’ and reported to the

Principal contractor's representative onsite

‘38, RECORDS ANO DOCUMENTATION,

Deals of general legislative requirements can be found in the Bery Pring

Managemert System's Legal Register, legal requirements specific to the contract wll

be dentiied and communicated by Berry Ping Contracts Manag.

HEALTH, SAFETY & ExWiROAMENTAL METHOD STATEMENT

Ui Nr

r —

125 Peascop Street, Windsor, Berishire, SLA

APPENDIX A

METHODOLOGY

eam, SAFETY & ExwRonMeNTAL MerHon STATEMENT

‘Gontractor: Bart Piling Systems Limited —| Contract Name: Daniela Department Store Phase ?

Contract Scope: Pling Operations Location: 421 125,

2

3)

4

5)

8

n

8)

9)

10)

1”)

12)

13)

14)

asco Steet, Windsor,

ee 1D BPsiast10

METHOD STATEMENT

‘Nominal 450mm diameter CFA File Constuction

‘Track ig into pile position with mastin racking position

Manosuvte rig as close to required pile positon as possible. Shut oftlock track

controle

Operate hydraulic contol and pivot cil mast into vertical mode. Once in vertical

positon ralse/ower aril mast so that mast fooUsll guide i frmly seated on ground.

Hydraulcally agjust rig with rams to ensure rg and mast are vertical

‘Check mast fot for adequate bearing on ground,

Rotate auger unit end fights clockwise at same time as feeding rotation unit

downwards snd il auger ino sos,

ul excaveted spol to one side for removal by others using hand fools or the

allendant excavator

‘Once depth is attained, connect concrete delivery hose coupling to central delivery

port coupling and secure,

Under pressure, pump concrete from concreting station ‘through’ rotation unit and

‘down nallow auger stem to remove ‘bung’ in lead auger (bi). This then alows

concrete into the bore. Pressurse the systom,

Ratiove auger fight, rotating 2s necessary roqured at constant rate to ensure

slom and bore are constantly filed wih concrete untl all augers are withdrawn,

Instl reinforcing cage into pile bore wth wheeled spacers to required depth/pastion.

CCeniralise pling cage and brace info posiion unl concrete set

Clean siom of all augers.

Rplace bung seal in lead augercuting head

“Track rig into next pile position. Repeat set up and ding procedure.

Please note that all of our pling rigs are fully compliant wth the HSE guidance

for Min-pling. All of our machines have an interlocking safety cage. Once the

interlocking cage Is opened the rig realises reduced rotating speed, reduced

{feed speed and a hold to run controls.

The rigs also have Emergency Stop switches fitted. Both the Guard and the

“switches are tested atthe start of every shift fo ensure they are in full working

order.

osu Sar EnyRonwEnaL METI STATA

[Contactor Bary Ping Systems Limited | Gontroct Namo: Daniels Department

Store Phase™

ontrat Scope: Pillng Operations schon sat 8 Posecap Stoel Windaa Barish, SUP

OP. BPSUGI1i10

Hea. SAFETY & EwrmowotenTAL MeTHo0 STATEMENT

‘Contractor: Gory Ping Systema Limited ~ | Contact Ni els Department Store Pi

Contract 5 ons Location: 121- 125 Poascop Stret, Windsor

sbP, PSI4611/10

APPENDIX C

RISK ASSESMENTS

prey & ExrRonenTA METHOD STATEMENT

Contract Name: Daniels Department Store Pi

Location: 12-125 Peascop Street, Windsor, Berkshire, SLA

‘bP- BPSMGI1/10 i

T RISK ASSESSMENT SUMMARY PART 1

‘Sie: Daniels Dopariment Siore Phase 2 [Localon:_121- 125 Peascop Svosi Winder, Beishro, SLa 10P

Work Actwvy/Canract Type Road Delvery of equipment and pling operations ~

Persons Exposed - ‘Commens (aude ference Te daabiodainees, 6)

Employees = ¥

Other Wares Jv

Pubic: — ¥ 7 7:

Havas denied Xt presertfeauing contol NW Wabsenina sgnieant

[Physical Injury Hazards | Physical Agoats ‘Manual Handling

tobi Pan TX [ionising Radin A [anual Handing ry TX

oveg Pats of Wacipe | X-[ Lasers N— [Crushing Equpment fais [x

Moving Haier [| Uira viet URE N—[ Wiscstaneous

Fal rom Heights [| coi pects N—| Wester x

‘Aczoss Equpment [| Hot Objects N— [lone Working nN

Sls. Tips. Fals |X | Temperature N— [Confined Spaces N

Excavations [X-[Noseribraton X__|Restcea Access [N

Pressurized Sime —[ X_| Hazardous Substances Buried Series x

Eectical N[Hazardous Substances —[X [Avr Quaiy x

Hol Wort [| mew-ogensrs Nl oust x

Exposion 1c VerinfWeis Oisease |X| Hypodernienendies [TN

iether spoahy OT Fos a Pub

RISK EVALUATION =

Seore 12 Sonn irr Rak 1 Rosicual is

whore not (See Check st Above) (Aer Convo! Measures applied by Part 2)

pplcable _ —

UnikeiyPoRSBIaT Unethood | Severiy | —RBkNo | Uketnood” | Seventy kN

Likely | ttm | Score't3 | Scores | otra | Score | Scores Multipied

MoodMoserate! | Score 1-3 wtipied | Scorers | 3

Senous _

Physical iu t : L

‘Mobie Pant 3 2 3 7 z 2 j

Mow par of 3 3 9 + 3 3

machine.

Moving maverais_|—3 2 a z z

ats fom hei | 3 3 8 i 3 3

Sipe Tipe and] 3 2 3 7 2 2

Fal \ |

Excavations z z 7 i i 3

Pressurized 3 3 3 7 3 3

systome |

Hot Wonare —| 3 z a z 3

Physical Agents >

Nowe and z z 7 7 z z

| woraton 7

Hazardous

Substances

[Szsareesana | 3 3 7 3 3

materials

Vermin Wes z z 7 7 z z

disease

L _ _ 15

Depart Sore Phase ———

‘ereahire, SLT

Faisal z z 7 7 7 z

equoment _

Miscellaneous

Weather z i z z i i

Bured sonioos | 5 3 3 1 z =

7 Qually fl 2 2 1 4 i

ut 2 2 i z z

General Fable | —3 3 3 1 3 3

Chisren 3 3 3 1 sf 2

t ae Fi ae acon o>)

‘CONTROL EASURES SEE RISK ASSESSMENT SUMMARY FORM ZATTACHED:

Signed Psion

Date | |

RISK ASSESSWENT SUMMARY PART 2 —T

‘Site Daniels Daparimant Siow Pasa? | Location: 121-125 Peascop Svan Winds, Bavahe, SLA TOP.

“Assossmens for Signifiant risks:

Mobile Plant. All plant tobe sted within work area. Al plant to have test certificates. Al plant when mobile

Orn use to have banksmer/bariers around rout. Al pling operations fenced off so no untrained personnel

‘ean come into contact with png machinery

Moving parts of machinery. Rig drive to be disconnected before cleaning bore sections. Training,

instucton, Only use specialized tools for cleaning ensure that rig is disconnected from dive before

Ionnectingdisconnecting bore sections When connecting sectional augers using manual handling techniques.

the pilg 9 operators wil remove their hands from the contol levers. The iter-Lockng guaré wil be opened,

8 section o fight wil be placed by an operative that operatve wil then stand clear ofthe ping rig and close

the Inte-Locking Guard Only then wil the rig operator pace their hand back on the contro levers and resume

‘operating the pling rig, This soquence willbe folowed each ime a seston fs added or removed. |

Moving materials. All materials to be moved using mechanical means vere practicable, All materials to be

secure before moving

Fe

from height. All work tobe undertaken from sullable lowers or hand railed areas

‘Slip Trips and Falls. All areas to be kept clear of obstructions at al times. Public access areas tobe clearly

signed,

Excavations. All excavations in or aroun the work ste are to have secute barriers and vehicle stops placed

‘around them. All personnel be rifled anther locatons.

Pressurized systems. Rig and Power Pack and attachments to be checked prior to use for damage. Spray

systems tobe checked anc certified fi for use.

Noise and Vibration. Generators and compressors tobe silenced, Operatives to wear hearing protection

when using noise eriting equipment

Hazardous substances. All substances to have an on ste risk assessment which ie tobe elated to all

6

Contradior, Bary Ping System Linited ~ | Contract Name! Oaniela Department Stare Phase 2]

ontract Scope: Piling Operations Location: 121 125 Peascop Stree, Windsor, Berishire, SL@

$0P. BPSGII/IO

[ Speraives on sie pero the sar ofthe works, Al operainves To woar necessary PPE as Golaled by he

Manufacturer and the on silo Risk assessment

Exhaust Fumes: lobe controled using exhaust extensions and where practicable extraction systems

Vermin Wells disease. Alloperaives to be made aware ofthis risk and lo wear gloves during works. Good

personal hygiene.

Manual handling, Equipment and materia o be assessed for individual weight and a risk assessment tobe

carried out

CCrushing/Equipment Falls. | personnel tobe cleared from the iting arc ofthe crane and slung

equipment. Good contrls by the erene supervisor and banksmen. All equipment to be secure porto It. All

iting equipment to be checked prior to use.

Weather, All operatives to have avaiable wet weather protection and cathes

Buried services. A CAT Scan to be carried out ofthe areas tobe excavated and results logged and

| marked,

| Air uatity. At generators/compressors to have in date service records and omission test these areto be |

| nel in the sto fla. Equipment tobe replaced atte fist sign of excessive exhausl emission

Dust. All Vegetation to be damper! down prior o cutting where practicable. Warning signs to be erected

operatives fo wear dust mask dunng operations.

General Public. All working aress to have suitable fencing erected and gates to be locked. Al vai

| movement external io ence to have trafic menagement personnal in attendance.

‘Arsenic Contamination. All operatives to be made aware of tis risk and fo wear gloves during works, Good

personal hygiene

oni We Datals of Gontror Measures

‘Documents, “Method Statomont

Procedures ete oo _

Taermation Personnel advised oF tho above Tsks and of procedure S51 Oath malod statement

Instruction Folow method statement procedure.

Training ‘xing in actiaty wih all personnel tobe made eware of method statement and risk

‘assessment content

| Supowison ~~] Sugprisr to oaek tata personnal Fave raqured PPE aid are aware Fal

| aati procectres.

Aetess ‘Ensure was of work ae Soar ofrubBshinatoras ote. and ae opt ean, Good

hhousekoeping to be employed etal times.

| Enanmmant Tol appa —

[Emergencies | First Ala Kit and First Aider to be on sie af alimes

‘COSHH

eam, Super

Contac Bony pig Stems Lnted |

rat Scope: Pig |

$DP. BPSIABTI10

PPE “Ais required by manufacturer and Local RiGk Ass@ssmonis

‘Other Procedures | New Road and Steot Works At

Manufactures Guidance

_ Heavy SAFETY & EnvRonMENTAL METHOD STATEMENT

[[Conactor” Barry Piling Systoms Limited | Contract Name: Dante Department Store Pha

Contract Scope’ Pling Operations Location: 121 125 Peascop Street, Windsor,

40P, BPSI4611/10

BERRY PILING SYSTEMS LIMITED

k Assessment Interface Worksheet (Sheet 1 of 2)

Job No BPSHOI1/I0 Reference: Daniels Department Store Phase 2 Design Elements): Piling

o

Trtartace T eiatng | aa

| Causes & | sone | Control | Proposed action | Estimate | Confirmed actions!

Ret, | Hazard | Elementiniraces | “fatres” | Consequence | affected | Risk ‘oneloment | Following | earled forward

eading to er | eetimate | “lesigners | ‘Design

hazard ‘tions _|

z z L S[cre. Sur

BPS! |Prelntataton | Sto | Plog |ncorec: Si | minoriniry [Ping 0] 8|mM|Roviewsoisana ole |e

investiga orsgnieant Operators ‘ensure ancher

ton Stference esigrers ave

sols Stermaton fo alow

roceagn of anchare

BPSZ_| Pie rsisiaion | Sia | Pig | adoquaie | Najorinury | Sa’ —[C]C[M [Ensure adequate [DO]

Preparat pe peepareton of sing

fen orate Bitom

atom

BPST_| Pre etalaton|| Ping | Parg | Inearect | Majoriqury | Ping | ©] CW [Erre wiaie TO] OTC

handing of Operators feuipmert is being

boring uns ‘od & correty

cages

BPS] Pie saison | Ping | Spat —[inconeat — ajormuay | Ping |} © FW | Esra suatie bins | O[O]

removal | handing / Opsrators skis ang moving

bepoea of Teta equipment

spot ‘valenle and uses

- iy

eat, SAFETY & EWvRoNMeXTAL METHOD STATEMENT

[Contactor

‘Berry Piling Systems Limited | Contract Name: Daniels Dopartant Store Phase

‘Contract Scape: Ping Operations Location: 121 - 125 Peascop Steet, Windsor, Berkshire, SU |

ABP. BPSUGLIIG

Key S=SovertyRating —L=Lkelnood Rating R= Risk Rating (See Severy Likelihood and Rsk Rating Tales)

‘Severity, Lkelnood and Risk Rating Teble

Tikanood Risk

‘A Death st persons [ram ‘A [Regia occurrence Tigh H Fah

‘8 | Wajorinury to persons Madam [8 | Frequent occurence | Medurm | W Toston

‘C— [War inuryo one pson—| Medium | C| Occasional oceurends [Medan Low

‘3 —[ ino inunyies ow 1D | Possbie occurence [Law

EL Trvl muri Low E_mprobabe oocurenca [Law

20

HEALTH, SAFETY A ExRONENTAL MeTH00 STATEMENT

[Contractor Bary Ping Systems Limited | Contract Name: Daniels Department Store PhaseZ ————]

‘Gontract Scope: Piling Operations ‘Location: 121 - 125 Peaseop Strest, Windsor, Berkshire, SL

Lape: epsiesisi10

BERRY PILING SYSTEMS LIMITED

Designer Risk Assessment Worksheet (Sheets 1 of 2)

JobNe BPSi4611I10 Reference: __Darlels Department Store Phase 2 Design Element iting

re]

Lite cycle, Persona | Control | Risk Contr! Contiemed

Ret | Phace/Mode | Hazard Consequences | Affected | “Risk ‘Measures Actions!Garied

Estimate Forward

- Sit fe

Rect | Bored ale Irstating ples | ncoreet stor | sionicant | Contactors | 0 | 8 || cecksoss

Consiicton Seuteart | adcnonal pte | Stat arsings

erence | engin! pes heck movement

tole, requires owl

revise design

FG? | Bored Pie insiatng ples | Falureto ——] Pingratala [Ping [©] ©] W] Ensure Ping

Constrveton prove em & | over Operators Platorm caety

feet ping Inetales

ptt

RFGS [atone ‘Unoading ane Uneatabe | Tay se DYE fm | Convaror

Ecupment | movamertat | handing operatives! fxcavaton sage 1

detvery mmateras! | metress Sit | Pratection of

equipment ‘ecavaton stage 1

FGI [Bored Fie ‘Spalerioval_| Wang ols | inry Sie TLE [we Conraror

Construction (aot sabe operatives ‘excavation stage 2

spol Protection of

heapstoins ‘excavation stage 2

a

( (Contractor Bary Ping Systems Limited |

Heat, SAFETY & EwRomwenrAL MET0D STATEMENT

‘Gootract Name: Daniels Department Store Phae 7 —

‘Contact Seape: Png Operations Location: 121 ~ 125 Peascop Sires, Windsor, Berkshire, SL®

BERRY] PILING) = csnsmoronane |

CONTRACT AMET

|__|

BPSHETIO

|

RISK ASSOCIATED WITH | PRECAUTIONS TO BE TAKEN TO REDUCE | PPE. REQUIREMENTS AND

“ACTIVITY THE RISK COMMENTS:

Gontaat with moving Trafio Toles around ste to be delineated to

machinery voit calision

Tonlact wih ve Sevens

| Perio Dig Wo obiain To ncicate presence and

Proxrnity ofall known sonvces

Perit to ig be sued

“Faling materais

“Ruger tobe Geared ofa hverads Fam he

ground

Fal fom aight

‘iy work above Zh opstaives lo Gah proper

aodess and safety harnesses wern and

tached when no protecion is avaiable,

bya competent person

Safaty Faresses tobe checked

before use and regular intervals

Toe

‘Contaminated ground]

Piant Faure

| Ear protection to be wor Fassesamant

incites levels above 858A

| Ground condiions tobe cheawed for ——

‘contamination. Full decontamination faciity

maybe required

| Ragilar nspaaions to cary ou on a ina

‘equipment

statement including erection and cismanting of

the rig, and craneage where necessary:

Please refer o specie risk assossmonis os

[rogues

“Ths work wil be covered by spoctie matnod |

assessed

~ | BRE as assensod and vequved,

weekly

‘Test Carica

2

‘Roproptate ear protection 85

to be kept in

Ste Offens

~[Foequiveiani to Be completed —|

__fRECEWE5} —___.

15 FEB 2001 KLEMM

KR 709-1 PLANNI Bohrtechnik

Die KLEMM KR 709-1 wrde epee

{tr Pahbavungen im Decmessor

Ki43 geandestet

Aterdem best dle Me

16500 mm Single Paes,

a Guat at nine

twee Sue 2 (COM? /EPAS)

‘arta ange to

Ey 00 mm (128)

4 Nn ptemare i uneraas

Besos ie 1 KR 7004

cay be ee or et rot ap

Seep 204

' KLEMM

KR 709-1 es Bohrtechnik

alee Typ 20213 mt sat versciabarer

Sehiten

{i mea type 202/13 wt sige shit te

‘Gomnrefechveriiung Typ, is 508 mm

“amangtreating deves pe ford. 809 mm

eerebap LEM KH 40

Opton Soratataes!

ptonal: sound pot coer

KLEMM |

KR 709-1 Bohrtechnik

ie Garacinamatx exaust den Ausglch von Bodenunebenhaten sowie das Batren von

Pern er Negung

The kiomatics ofthe KR 709-1 lw fo ads fr uneven tein and alo tod under

ange

‘Schwenkbereiche / Mast Movements

S| | vas

h

/

= Pa) |

KLEMM

KR 709-1 Bohrtechnik

‘Abmessungen | Dimensions

mit Lafette Typ 202/13 (4400 mm)

with drill mast type 202/13 (4400 mm)

Greantinge over angts 248mm

1 Geramnone. vant ght Samm

KLEMM

KR 709-1 Bohrtechnik

‘Abmessungen / Dimensions

mit Lafette Typ 202 (8000 mm)

with drill mast type 202 (8000

Gasaringe ovenengh 3 mn

Seaemhane’ ovat hire 335"rm

Seman ‘ise wes cn 204

KLEMM

KR 709-1 Bohrtechnik

‘Abmessungen / Dimensions

mit Lafette Typ 310 und 4 Gittermasten - HDI-Ausfihrung

with drill mast type 310 and 4 lettice masts - HPI-version

pantie Pee Bilary reste

Sebo Sige ewer et oe

KR 709-1 Bohrtechnik

es

Technische Daten | Technical Specifications

Motor Engine

cat car 3056 EATAAG

zeifizen nach ceonifed by ‘cow EPA2

mediumgektit ‘medium cooled

max. Leistung ‘max. power ouiput —KWIhp 1295/1768

Lessig be 2900 Utin rated ouput at 2300 rpm KW IM 42085178

Diesettnk fuel tank capacity 240

Hydeauliksystem Hydraulic system

Hygreuikpumpen hydraulic pumps

1 kresiaut Tatoreut Uimin 148,

2 krestaut 2nd creut limin 445

3: kreslaut Sra cxeut limin 38

4 kreslaut “ah orcut umn 2

Systomeruck operating pressure bar 250

Hyaraulkiank hyde oftank capacity 00

Raupenfahrwerk ——_Grawlor base

Lauwerk crewier type B

Zugkrati max. towing force kN 400

Fanrgeschwindigket crawler speed kovh 2.55

‘Spez Bodencruck ground pressure Nem 47

Gosamtrote vera with mm 2400

3-Steg Sodenrlatien web track shoes mm 500

Lange der Fahrschtle length ofcrewier units mm 3350

Lange (Achsabstand) length axle axle) mm 2768

Bodenfrehelt ground clearance mm 320

Bohrlaftte Typ Drit mast type 22 202s

rmit2-stuigem with speed

Vorsenubgetiebe ‘feed motor

zul Drehmement max permissbe torque kNm 3040

Worschubiange foedienath mm 6000 2400

Son Wiest banemacce ‘ecxoynn 2004

7 soy

KR 709-1

KLEMM

Bohrtechnik

Technische Daten / Technical Specifications

Bohriafette Typ

Vorschuibkratt

Rockzugkraft

Vorschubgeschwindigkelt foed r

Rockzuggeschwindigkelt retraction rato

Drill mast type 202 202K.

feed force kN 100130

retraction force KN 100130

491105 |

491105 |

Vorsehub sehnel, fast feed rate 16,2047

Ruckzug schnell fast retraction rate mimin 168133,6 16,2134,7

Hydrautkhammer Hydraulic deifter

‘empfonien| recommended KD 1624/KD 1828 R/ KD 2728 R

Hydr.Kraftdrehkopt Hyd. Rotary head

cempto recommended KH 16/KH27/ KH 43

Gewicht Weights

Bahigeratkomplett dif ig complete Utns 1318

‘THOROUGH EXAMINATION OF MECHANICAL EQUIPMENT

‘The particulars below are in accordance with the lifting operations & ling equipment

Regulations 1998

CERTIFICATENUMBER: BPSV0I2/10

DATE OFINSPECTION: 260472010,

{EQUIPMENT DESCRIPTION: MINI PILING RIG ON METAL TRACKS

‘MANUFACTURER; KLEMM MARK: 20014

‘MODEL: 700-1

COMPANY NAME & ADDRESS: (CUSTOMER SITE:

BERRY PILING SYSTEMS LIMITED 45.85 GEE STREET, LONDON C1

DETAILS OF THOROUGH EXAMINATION CARRIED OUT:

NO PARTS OPENED

pee

{hereby declare that he gupmentin his ecard was thoroughly exanine,o tested and

‘arog exanbned in accordance with he appropriate provisions and found be fom ay

defect likely to affect safety fff$AV4/10_and the above particulars are correct

SIGNATURE: ~~

‘Stephen Thatcher plant engineer workshop manager

DATE OF LAST INSPECTION: 28/04/2009

LAST INSPECTION NUMBER: BPS/™272009

DATE OF NEXT INSPECTION: 277042011

Reding rks Proc pple

um anaao att eanam eo eT cOPEOM ID

MEER cmDSARaTS

SPECIFICATIONS

PUMP SPECIFICATIONS

Tenor i Pope Be Fa

Ts ea en Oe ie

Geaee Oas anaes i

aoe aS

‘Caen ae

iepertnn

‘pr gy be TO

‘Gasiomman tm

eg DT

i Der he ae

‘aoreme ta oR

get aoa

Farah oh oak

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Laboratory Testing Manual (2000) PDFDocument330 pagesLaboratory Testing Manual (2000) PDFandressaoliveira2301100% (8)

- Laboratory Testing Manual (2000) PDFDocument330 pagesLaboratory Testing Manual (2000) PDFandressaoliveira2301100% (8)

- Good Quality Control 2005 PDFDocument59 pagesGood Quality Control 2005 PDFabdikarim_omarNo ratings yet

- JKRDocument89 pagesJKRgahsoon100% (3)

- Bored PileDocument74 pagesBored PileGan Wei HuangNo ratings yet

- GeoRockClrChart MunsellDocument12 pagesGeoRockClrChart MunsellYuri Andrei GarciaNo ratings yet

- Good Quality Control 2005 PDFDocument59 pagesGood Quality Control 2005 PDFabdikarim_omarNo ratings yet

- Method Statement of Bored Pile Construction On Land (For Const.)Document82 pagesMethod Statement of Bored Pile Construction On Land (For Const.)Nguyen Hai Linh100% (2)

- A3.8 Planning Scheduling - 20090812 - 115626 PDFDocument60 pagesA3.8 Planning Scheduling - 20090812 - 115626 PDFSuhaidi Alias100% (1)

- Method Statement of Bored Pile Construction On Land (For Const.)Document82 pagesMethod Statement of Bored Pile Construction On Land (For Const.)Nguyen Hai Linh100% (2)

- Bookchapter Fka07Document152 pagesBookchapter Fka07Suhaidi AliasNo ratings yet

- Mesyuarat Pengurusan July2011Document60 pagesMesyuarat Pengurusan July2011Suhaidi AliasNo ratings yet

- BDSLT Method Statement - BT Maung PDFDocument39 pagesBDSLT Method Statement - BT Maung PDFSuhaidi Alias100% (2)

- Asphalt PASERManualDocument32 pagesAsphalt PASERManualSuhaidi AliasNo ratings yet

- Guidelines On Trenching For Construction SafetyDocument10 pagesGuidelines On Trenching For Construction SafetyNURRUL FARIZA BT AB RAHMANNo ratings yet

- SHRP Distress Identification Manual For The LTPPDocument169 pagesSHRP Distress Identification Manual For The LTPPsalejandro2005No ratings yet

- Writing Work Method Statement Plain English Guidelines 0231Document24 pagesWriting Work Method Statement Plain English Guidelines 0231Vincent TengNo ratings yet

- Manual Microsoft Project 2010 (Engleza)Document49 pagesManual Microsoft Project 2010 (Engleza)Dinu Andra-OtiliaNo ratings yet

- 2000 03Document23 pages2000 03thanhynhanhNo ratings yet

- Ch05 Control Charts For VariablesDocument32 pagesCh05 Control Charts For VariablesSuhaidi AliasNo ratings yet

- Method Statement of Bored Pile Construction On Land (For Const.)Document82 pagesMethod Statement of Bored Pile Construction On Land (For Const.)Nguyen Hai Linh100% (2)

- 931 3558 1 PB PDFDocument9 pages931 3558 1 PB PDFSuhaidi AliasNo ratings yet

- 010-05Oct09-COP Demolition Works-Corrected On 30th Sept 2009-1Document148 pages010-05Oct09-COP Demolition Works-Corrected On 30th Sept 2009-1alberttenggarioNo ratings yet

- SP038 PDFDocument25 pagesSP038 PDFSuhaidi AliasNo ratings yet

- DesignManual DesignGuidelines DG05 PavementDesign PDFDocument36 pagesDesignManual DesignGuidelines DG05 PavementDesign PDFSuhaidi AliasNo ratings yet

- Surcharges Minimimize Post Construction Settlement PDFDocument38 pagesSurcharges Minimimize Post Construction Settlement PDFSuhaidi AliasNo ratings yet

- Settlement of Embankments On Soft Ground PDFDocument23 pagesSettlement of Embankments On Soft Ground PDFSuhaidi AliasNo ratings yet

- Quality Control Tests PDFDocument45 pagesQuality Control Tests PDFSuhaidi AliasNo ratings yet

- Volume 11 - Construction Management PDFDocument484 pagesVolume 11 - Construction Management PDFSuhaidi Alias100% (1)