Professional Documents

Culture Documents

Galoneras

Uploaded by

franameliaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Galoneras

Uploaded by

franameliaCopyright:

Available Formats

BERMAD Waterworks

BERMAD Waterworks

BERMAD Waterworks

700 Series

700 Series

700 Series

Model 720

Model 720

Model 720

Pressure Reducing System for Municipal Networks

Dimensions and Weights

Network design requires establishing various pressure zones due to topography, distances, demands, energy costs,

reservoir availability, etc.

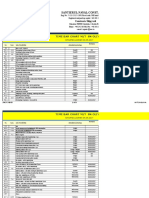

Size

mm inch

40 11/2

50

2

65 21/2

80 3

100 4

150 6

200 8

250 10

300 12

350 14

400 16

450 18

500 20

A, B

mm inch

350 14

350 14

350 14

370 15

395 16

430 17

475 19

520 21

545 22

545 22

645 26

645 26

645 26

C

mm inch

180 7

180 7

180 7

230 9

275 11

385 15

460 18

580 23

685 27

685 27

965 38

965 38

965 38

L

mm inch

205 8.1

210 8.3

222 8.7

250 9.8

320 12.6

415 16.3

500 19.7

605 23.8

725 28.5

733 28.9

990 39.0

1000 39.4

1100 43.3

Flow Chart

H

mm inch

239 9.4

244 9.6

257 10.1

305 12.0

366 14.4

492 19.4

584 23.0

724 28.5

840 33.1

866 34.1

1108 43.6

1127 44.4

1167 45.9

Weight

kg lbs

9.1 20

10.6 23

13 29

22 49

37 82

75 165

125 276

217 478

370 816

381 840

846 1865

945 2083

962 2121

Pressure Reducing System Typical Installation

Pressure Reducing Valve

Model 720

Relief Valve

Model 73Q

500 1,000

5,000 10,000

1.0

0.9

0.8

0.7

0.6

0.5

10

9

8

7

6

5

24

0.4

3"

1.5"

0.3

2"

10"

6"

12"

8"

4"

14"

16"

18"

20"

2.5"

0.2

4

28"

30"

32"

0.1

50

10

500

100

1,000

5,000

Control System

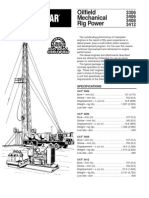

Valve Patterns: Y (globe) & angle

Size Range: 11/232 (40-800 mm)

End Connections (Pressure Ratings):

Flanged: ISO PN16, PN25

(ANSI Class 150, 300)

Threaded: BSP or NPT

Others: Available on request

Working Temperature:

Water up to 80C (180F)

Standard Materials:

Body & Actuator: Ductile Iron

Internals:

Stainless Steel, Bronze & coated Steel

Diaphragm:

NBR Nylon fabric-reinforced

Seals: NBR

Coating:

Fusion Bonded Epoxy, RAL 5005 (Blue)

NSF & WRAS approved or Electrostatic

Polyester Powder, RAL 6017 (Green)

Standard Materials:

Accessories:

Bronze, Brass, Stainless Steel & NBR

Tubing: Copper or Stainless Steel

Fittings: Forged Brass or Stainless Steel

Pilot Standard Materials:

Body: Brass, Bronze or Stainless Steel

Elastomers: NBR

Springs: Galvanized Steel or Stainless Steel

Internals: Stainless Steel

Sector

WW

By-Pass

Pressure Reducing Valve

Model 720

In addition to the Model 720 Pressure Reducing Valve, BERMAD recommends that the system also include:

Strainer Model 70F prevents debris from damaging valve operation

Relief Valve Model 73Q provides:

Protection against momentary pressure peaks

Visual indication of need for maintenance

By-Pass Pressure Reducing Valve saves on maintenance costs. The larger (more costly to maintain) valve operates

during peak demand. The smaller by-pass valve cuts operating hours of the larger valve, achieving greater

return on investment.

For high differential pressure systems, see BERMAD publication 720-PD Proportional Pressure Reducing Valve.

For high pressure systems, see BERMAD publication 820 Piston Actuated Pressure Reducing Valve.

Waterworks

Size

6

1 1/2 - 32

720-

No Additional Feature

Closing and Opening Speed Control

Automatic Regulation Override

High sensitivity pilot

Check Valve

Solenoid Controlled & Check Valve

Multi-Setting Levels - Electrically Selected

Downstream Over Pressure Guard

Hydraulic Control

Solenoid Controlled

Electric Override

Multiple choices permitted

Pattern

00

-

Pressure Reducing

00

03

09

12

20

25

45

48

50

55

59

Throttling noise reduction

System maintenance savings

10,000

Body

Material

-Y

-C

Oblique (up to 20)

Y

Angle (up to 18)

A

Globe (24-32 only) G

Ductile Iron Standard

Cast Steel

St. Steel 316

Nickel Alumin. Bronze

ISO-16

ISO-25

ANSI-150

ANSI-300

JIS-16

JIS-20

Valve Size

Pilot

Setting (bar)

11/2-10

40-250 mm

<15

>15

6-14

150-350 mm

<15

>15

16 -32

400-800 mm

<15

>15

Standard model

End

Connections

Coating

16

Epoxy FB Blue

Polyester Green

Polyester Blue

Uncoated

EB

EB

PG

PB

UC

C

S

N

U

16

25

A5

A3

J6

J2

The Model 720 Pressure Reducing Valve is a hydraulically

operated, diaphragm actuated control valve that reduces

higher upstream pressure to lower constant downstream

pressure regardless of fluctuating demand or varying

upstream pressure.

Pilot Valve Selection

#2PB

Pilot Type

#2

#2HC

with high pressure setting kit

Please specify the requested valve in the following sequence: (for more options, refer to Ordering Guide)

Additional

Feature

Cavitation damage protection

Data is for Y-pattern, flat disk valves

For more flow charts, refer to Engineering Section

Main Valve

Primary

Feature

Flow and leakage reduction

Flow Rate - m3/h

How to Order

Strainer

Model 70F

Pressure Reducing

Valve

Burst protection

Data is for Y-pattern, flanged, PN16 valves

Weight is for PN16 basic valves

C enables removing the actuator in one unit

L, ISO standard lengths available

For more dimensions and weights tables, refer to Engineering Section

The pump supplies water to the network and to the reservoir. System pressure is too high for the residential

neighborhood, requiring a pressure reducing system.

Flow Rate - gpm

100

50

Pressure Loss - psi

Technical Data

Pressure Loss - bar

Typical Applications

24VAC/50Hz - N.C.

24VAC/50Hz - N.O.

24VDC - N.C.

24VDC - N.O.

24VDC - L.P.

220VAC/50-60Hz N.C.

220VAC/50-60Hz N.O.

4AC

4AO

4DC

4DO

4DP

2AC

2AO

Use when additional electric control

feature is selected

info@bermad.com www.bermad.com

The information herein is subject to change without notice. BERMAD shall not be held liable for

PC7WE20 05

any errors. All rights reserved. Copyright by BERMAD.

Voltage &

Position

Tubing

& Fittings

Major Additional Features

Line pressure driven Independent operation

UL Listed for fire protection FP-720-UL

In-line serviceable Easy maintenance

Solenoid control 720-55

Double chamber design

Additonal

Attributes

CB

VI

Copper Tubing & Brass Fittings CB

Plastic Tubing & Brass Fittings PB

St. St. 316 Tubing & Fittings

NN

Valve Position Indicator

V-Port Throttling Plug

Large Control Filter

Electric Limit Switch

3-Way Control Loop

Valve Position Transmitter

St. St. 316 Control Accessories

St. St. 316 Internal Trim (Closure & Seat)

St. St. 316 Actuator Internal Assembly

Delrin Bearing

Viton Elastomers for Seals & Diaphragm

Pressure Gauge

Multiple choices permitted

Features and Benefits

I

V

F

S

X

Q

N

T

D

R

E

6

Check valve 720-20

Moderated valve reaction

Solenoid control & check valve 720-25

Protected diaphragm

Proportional 720-PD

Automatic regulation override 720-09

Flexible design Easy addition of features

Variety of accessories Perfect mission matching

High sensitivity pilot 720-12

"Y" or angle, wide body Minimized pressure loss

Emergency pressure reducing valve 720-PD-59

Semi-straight flow Non-turbulent flow

Downstream over pressure guard 720-48

Stainless Steel raised seat Cavitation damage resistant

Electrically selected multi-level setting 720-45

Obstacle free, full bore Uncompromising reliability

Electronic multi-level setting, Type 4T 720-4T

V-Port Throttling Plug Low flow stability

Electronic pressure reducing valve 728-03

See relevant BERMAD publications.

BERMAD Waterworks

BERMAD Waterworks

700 Series

700 Series

700 Series

Model 720

Model 720

Model 720

Operation

The Model 720 is a pilot controlled valve equipped with an adjustable, 2-Way pressure reducing pilot.

The needle valve [1] continuously allows flow from the valve inlet into the upper control chamber [2]. The pilot [3] senses

downstream pressure.

Should this pressure rise above pilot setting, the pilot throttles, enabling pressure in the upper control chamber to accumulate,

causing the main valve to throttle closed, decreasing downstream pressure to pilot setting.

Should downstream pressure fall below pilot setting, the pilot releases accumulated pressure, and the main valve

modulates open.

The integral orifice between the lower control chamber and valve outlet moderates valve reactions.

The needle valve controls the closing speed. The downstream cock valve [4] enables manual closing.

1 -10

with #2PB Pilot

6-14

with #2 Pilot

1/2

[3]

[3]

Pressure Reducing Systems in High-Rise Buildings

Higher Zone Installation A

Water supply system design requirements for high-rise

buildings present unique issues:

Supply cut-off is unacceptable and single source supply

is common.

Valves are located in areas where water damage can

be extremely expensive.

Pressure reducing systems are often located next to

prestigious residential and office space. Extraneous

noise and maintenance activities are to be avoided.

The main supply line of high-rise buildings is exposed

to greater head at lower zones while pressure for the

consumer must be kept within recommended levels.

As a result, lower zone pressure reducing systems deal

with greater differential pressure.

In addition to the municipal pressure reducing system for a high-rise building, BERMAD recommends the

system also include:

Parallel Redundant Branches ensuring uninterrupted supply by enabling unskilled personnel to temporarily

shut off one of the branches.

Emergency System including a downstream pressure switch and an Emergency Valve Model 720-PD-59.

Pressure Switch [6] signals a control panel of excessive downstream pressure.

Emergency Valve [2] is fully open during normal operation. Triggered by the control panel, it becomes a

proportional pressure reducing valve.

D

G

[1]

[5]

[2]

[3]

[1]

[1] Strainer Model 70F

[2] Emergency Pressure Reducing

Valve Model 720-PD-59

[4]

[3] Pressure Reducing Valve

Model 720

[5]

[2]

[2]

[6]

Control Panel

The Model 720 Pressure Reducing Valves together

with BERMADS accumulated experience address these

issues and provide appropriate solutions.

[1]

BERMAD Waterworks

[4] By-pass Pressure Reducing

Valve Model 720

[3]

[5] Relief Valve Model 73Q

[4]

[4]

[6] Pressure Switch

A

Note: For 16" and larger valves,

see "Pilot Valve Selection" table at the last page.

Engineer Specifications

The Pressure Reducing Valve shall reduce higher upstream pressure to lower preset downstream pressure regardless of

fluctuating demand or varying upstream pressure.

Lower Zone (Two-Stage) Installation B

When dealing with high differential pressure systems in lower zones of a high-rise building, BERMAD recommends a

two-stage pressure reducing system. In addition to the typical higher zone installation, this high differential pressure

system also includes:

Proportional Pressure Reducing Valve Model 720-PD, as the first pressure reducing stage, absorbs part of the

high differential pressure. By spreading the load of pressure reducing onto two components, cavitation damage and

noise are reduced.

Main Valve: The main valve shall be a center guided, diaphragm actuated globe valve of either oblique (Y) or angle pattern

design. The body shall have a replaceable, raised, stainless steel seat ring. The valve shall have an unobstructed flow path,

with no stem guides, bearings, or supporting ribs. The body and cover shall be ductile iron. All external bolts, nuts, and studs

shall be Duplex coated. All valve components shall be accessible and serviceable without removing the valve from the pipeline.

Control Panel

Control System: The control system shall consist of a 2-Way adjustable, direct acting, pressure reducing pilot valve, a needle

valve, isolating cock valves, and a filter. All fittings shall be forged brass or stainless steel. The assembled valve shall be

hydraulically tested and factory adjusted to customer requirements.

Quality Assurance: The valve manufacturer shall be certified according to the ISO 9001 Quality Assurance Standard. The main

valve shall be certified as a complete drinking water valve according to NSF, WRAS, and other recognized standards.

[2]

Actuator: The actuator assembly shall be double chambered with an inherent separating partition between the lower surface

of the diaphragm and the main valve. The entire actuator assembly (seal disk to top cover) shall be removable from the valve

as an integral unit. The stainless steel valve shaft shall be center guided by a bearing in the separating partition. The replaceable

radial seal disk shall include a resilient seal and shall be capable of accepting a V-Port Throttling Plug by bolting.

[3]

[10]

[5]

[7]

[9]

[1]

[1] Strainer Model 70F

[2] Emergency Pressure Reducing

Valve Model 720-PD-59

[3] Proportional Pressure Reducing

Valve Model 720-PD

[4] By-Pass Proportional Pressure

Reducing Valve Model 720-PD

[4]

[6]

[5] Primary Relief Valve Model 73Q

[8]

[6] By-Pass Relief Valve Model 73Q

[7] Pressure Reducing Valve

Model 720

B

A Higher zone pressure reducing system installation

B Lower zone pressure reducing system

(two-stage) installation

C Bottom reservoir level control system

D Roof reservoir level control system

E Potable water pumping system

F Fire protection pumping system

G Upper floors pumping system

C

C

E

E

FF

[3]

[5]

[7]

[9]

[8] By-Pass Pressure Reducing

Valve Model 720

[9] Relief Valve Model 73Q

[10] Pressure Switch

For high differential pressure systems, see BERMAD publication 720-PD Proportional Pressure Reducing Valve.

For high pressure systems, see BERMAD publication 820 Piston Actuated Pressure Reducing Valve.

BERMAD Waterworks

BERMAD Waterworks

BERMAD Waterworks

700 Series

700 Series

700 Series

Model 720

Model 720

Model 720

Pressure Reducing System for Municipal Networks

Dimensions and Weights

Network design requires establishing various pressure zones due to topography, distances, demands, energy costs,

reservoir availability, etc.

Size

mm inch

40 11/2

50

2

65 21/2

80 3

100 4

150 6

200 8

250 10

300 12

350 14

400 16

450 18

500 20

A, B

mm inch

350 14

350 14

350 14

370 15

395 16

430 17

475 19

520 21

545 22

545 22

645 26

645 26

645 26

C

mm inch

180 7

180 7

180 7

230 9

275 11

385 15

460 18

580 23

685 27

685 27

965 38

965 38

965 38

L

mm inch

205 8.1

210 8.3

222 8.7

250 9.8

320 12.6

415 16.3

500 19.7

605 23.8

725 28.5

733 28.9

990 39.0

1000 39.4

1100 43.3

Flow Chart

H

mm inch

239 9.4

244 9.6

257 10.1

305 12.0

366 14.4

492 19.4

584 23.0

724 28.5

840 33.1

866 34.1

1108 43.6

1127 44.4

1167 45.9

Weight

kg lbs

9.1 20

10.6 23

13 29

22 49

37 82

75 165

125 276

217 478

370 816

381 840

846 1865

945 2083

962 2121

Pressure Reducing System Typical Installation

Pressure Reducing Valve

Model 720

Relief Valve

Model 73Q

500 1,000

5,000 10,000

1.0

0.9

0.8

0.7

0.6

0.5

10

9

8

7

6

5

24

0.4

3"

1.5"

0.3

2"

10"

6"

12"

8"

4"

14"

16"

18"

20"

2.5"

0.2

4

28"

30"

32"

0.1

50

10

500

100

1,000

5,000

Control System

Valve Patterns: Y (globe) & angle

Size Range: 11/232 (40-800 mm)

End Connections (Pressure Ratings):

Flanged: ISO PN16, PN25

(ANSI Class 150, 300)

Threaded: BSP or NPT

Others: Available on request

Working Temperature:

Water up to 80C (180F)

Standard Materials:

Body & Actuator: Ductile Iron

Internals:

Stainless Steel, Bronze & coated Steel

Diaphragm:

NBR Nylon fabric-reinforced

Seals: NBR

Coating:

Fusion Bonded Epoxy, RAL 5005 (Blue)

NSF & WRAS approved or Electrostatic

Polyester Powder, RAL 6017 (Green)

Standard Materials:

Accessories:

Bronze, Brass, Stainless Steel & NBR

Tubing: Copper or Stainless Steel

Fittings: Forged Brass or Stainless Steel

Pilot Standard Materials:

Body: Brass, Bronze or Stainless Steel

Elastomers: NBR

Springs: Galvanized Steel or Stainless Steel

Internals: Stainless Steel

Sector

WW

By-Pass

Pressure Reducing Valve

Model 720

In addition to the Model 720 Pressure Reducing Valve, BERMAD recommends that the system also include:

Strainer Model 70F prevents debris from damaging valve operation

Relief Valve Model 73Q provides:

Protection against momentary pressure peaks

Visual indication of need for maintenance

By-Pass Pressure Reducing Valve saves on maintenance costs. The larger (more costly to maintain) valve operates

during peak demand. The smaller by-pass valve cuts operating hours of the larger valve, achieving greater

return on investment.

For high differential pressure systems, see BERMAD publication 720-PD Proportional Pressure Reducing Valve.

For high pressure systems, see BERMAD publication 820 Piston Actuated Pressure Reducing Valve.

Waterworks

Size

6

1 1/2 - 32

720-

No Additional Feature

Closing and Opening Speed Control

Automatic Regulation Override

High sensitivity pilot

Check Valve

Solenoid Controlled & Check Valve

Multi-Setting Levels - Electrically Selected

Downstream Over Pressure Guard

Hydraulic Control

Solenoid Controlled

Electric Override

Multiple choices permitted

Pattern

00

-

Pressure Reducing

00

03

09

12

20

25

45

48

50

55

59

Throttling noise reduction

System maintenance savings

10,000

Body

Material

-Y

-C

Oblique (up to 20)

Y

Angle (up to 18)

A

Globe (24-32 only) G

Ductile Iron Standard

Cast Steel

St. Steel 316

Nickel Alumin. Bronze

ISO-16

ISO-25

ANSI-150

ANSI-300

JIS-16

JIS-20

Valve Size

Pilot

Setting (bar)

11/2-10

40-250 mm

<15

>15

6-14

150-350 mm

<15

>15

16 -32

400-800 mm

<15

>15

Standard model

End

Connections

Coating

16

Epoxy FB Blue

Polyester Green

Polyester Blue

Uncoated

EB

EB

PG

PB

UC

C

S

N

U

16

25

A5

A3

J6

J2

The Model 720 Pressure Reducing Valve is a hydraulically

operated, diaphragm actuated control valve that reduces

higher upstream pressure to lower constant downstream

pressure regardless of fluctuating demand or varying

upstream pressure.

Pilot Valve Selection

#2PB

Pilot Type

#2

#2HC

with high pressure setting kit

Please specify the requested valve in the following sequence: (for more options, refer to Ordering Guide)

Additional

Feature

Cavitation damage protection

Data is for Y-pattern, flat disk valves

For more flow charts, refer to Engineering Section

Main Valve

Primary

Feature

Flow and leakage reduction

Flow Rate - m3/h

How to Order

Strainer

Model 70F

Pressure Reducing

Valve

Burst protection

Data is for Y-pattern, flanged, PN16 valves

Weight is for PN16 basic valves

C enables removing the actuator in one unit

L, ISO standard lengths available

For more dimensions and weights tables, refer to Engineering Section

The pump supplies water to the network and to the reservoir. System pressure is too high for the residential

neighborhood, requiring a pressure reducing system.

Flow Rate - gpm

100

50

Pressure Loss - psi

Technical Data

Pressure Loss - bar

Typical Applications

24VAC/50Hz - N.C.

24VAC/50Hz - N.O.

24VDC - N.C.

24VDC - N.O.

24VDC - L.P.

220VAC/50-60Hz N.C.

220VAC/50-60Hz N.O.

4AC

4AO

4DC

4DO

4DP

2AC

2AO

Use when additional electric control

feature is selected

info@bermad.com www.bermad.com

The information herein is subject to change without notice. BERMAD shall not be held liable for

PC7WE20 05

any errors. All rights reserved. Copyright by BERMAD.

Voltage &

Position

Tubing

& Fittings

Major Additional Features

Line pressure driven Independent operation

UL Listed for fire protection FP-720-UL

In-line serviceable Easy maintenance

Solenoid control 720-55

Double chamber design

Additonal

Attributes

CB

VI

Copper Tubing & Brass Fittings CB

Plastic Tubing & Brass Fittings PB

St. St. 316 Tubing & Fittings

NN

Valve Position Indicator

V-Port Throttling Plug

Large Control Filter

Electric Limit Switch

3-Way Control Loop

Valve Position Transmitter

St. St. 316 Control Accessories

St. St. 316 Internal Trim (Closure & Seat)

St. St. 316 Actuator Internal Assembly

Delrin Bearing

Viton Elastomers for Seals & Diaphragm

Pressure Gauge

Multiple choices permitted

Features and Benefits

I

V

F

S

X

Q

N

T

D

R

E

6

Check valve 720-20

Moderated valve reaction

Solenoid control & check valve 720-25

Protected diaphragm

Proportional 720-PD

Automatic regulation override 720-09

Flexible design Easy addition of features

Variety of accessories Perfect mission matching

High sensitivity pilot 720-12

"Y" or angle, wide body Minimized pressure loss

Emergency pressure reducing valve 720-PD-59

Semi-straight flow Non-turbulent flow

Downstream over pressure guard 720-48

Stainless Steel raised seat Cavitation damage resistant

Electrically selected multi-level setting 720-45

Obstacle free, full bore Uncompromising reliability

Electronic multi-level setting, Type 4T 720-4T

V-Port Throttling Plug Low flow stability

Electronic pressure reducing valve 728-03

See relevant BERMAD publications.

BERMAD Waterworks

BERMAD Waterworks

700 Series

700 Series

700 Series

Model 720

Model 720

Model 720

Operation

The Model 720 is a pilot controlled valve equipped with an adjustable, 2-Way pressure reducing pilot.

The needle valve [1] continuously allows flow from the valve inlet into the upper control chamber [2]. The pilot [3] senses

downstream pressure.

Should this pressure rise above pilot setting, the pilot throttles, enabling pressure in the upper control chamber to accumulate,

causing the main valve to throttle closed, decreasing downstream pressure to pilot setting.

Should downstream pressure fall below pilot setting, the pilot releases accumulated pressure, and the main valve

modulates open.

The integral orifice between the lower control chamber and valve outlet moderates valve reactions.

The needle valve controls the closing speed. The downstream cock valve [4] enables manual closing.

1 -10

with #2PB Pilot

6-14

with #2 Pilot

1/2

[3]

[3]

Pressure Reducing Systems in High-Rise Buildings

Higher Zone Installation A

Water supply system design requirements for high-rise

buildings present unique issues:

Supply cut-off is unacceptable and single source supply

is common.

Valves are located in areas where water damage can

be extremely expensive.

Pressure reducing systems are often located next to

prestigious residential and office space. Extraneous

noise and maintenance activities are to be avoided.

The main supply line of high-rise buildings is exposed

to greater head at lower zones while pressure for the

consumer must be kept within recommended levels.

As a result, lower zone pressure reducing systems deal

with greater differential pressure.

In addition to the municipal pressure reducing system for a high-rise building, BERMAD recommends the

system also include:

Parallel Redundant Branches ensuring uninterrupted supply by enabling unskilled personnel to temporarily

shut off one of the branches.

Emergency System including a downstream pressure switch and an Emergency Valve Model 720-PD-59.

Pressure Switch [6] signals a control panel of excessive downstream pressure.

Emergency Valve [2] is fully open during normal operation. Triggered by the control panel, it becomes a

proportional pressure reducing valve.

D

G

[1]

[5]

[2]

[3]

[1]

[1] Strainer Model 70F

[2] Emergency Pressure Reducing

Valve Model 720-PD-59

[4]

[3] Pressure Reducing Valve

Model 720

[5]

[2]

[2]

[6]

Control Panel

The Model 720 Pressure Reducing Valves together

with BERMADS accumulated experience address these

issues and provide appropriate solutions.

[1]

BERMAD Waterworks

[4] By-pass Pressure Reducing

Valve Model 720

[3]

[5] Relief Valve Model 73Q

[4]

[4]

[6] Pressure Switch

A

Note: For 16" and larger valves,

see "Pilot Valve Selection" table at the last page.

Engineer Specifications

The Pressure Reducing Valve shall reduce higher upstream pressure to lower preset downstream pressure regardless of

fluctuating demand or varying upstream pressure.

Lower Zone (Two-Stage) Installation B

When dealing with high differential pressure systems in lower zones of a high-rise building, BERMAD recommends a

two-stage pressure reducing system. In addition to the typical higher zone installation, this high differential pressure

system also includes:

Proportional Pressure Reducing Valve Model 720-PD, as the first pressure reducing stage, absorbs part of the

high differential pressure. By spreading the load of pressure reducing onto two components, cavitation damage and

noise are reduced.

Main Valve: The main valve shall be a center guided, diaphragm actuated globe valve of either oblique (Y) or angle pattern

design. The body shall have a replaceable, raised, stainless steel seat ring. The valve shall have an unobstructed flow path,

with no stem guides, bearings, or supporting ribs. The body and cover shall be ductile iron. All external bolts, nuts, and studs

shall be Duplex coated. All valve components shall be accessible and serviceable without removing the valve from the pipeline.

Control Panel

Control System: The control system shall consist of a 2-Way adjustable, direct acting, pressure reducing pilot valve, a needle

valve, isolating cock valves, and a filter. All fittings shall be forged brass or stainless steel. The assembled valve shall be

hydraulically tested and factory adjusted to customer requirements.

Quality Assurance: The valve manufacturer shall be certified according to the ISO 9001 Quality Assurance Standard. The main

valve shall be certified as a complete drinking water valve according to NSF, WRAS, and other recognized standards.

[2]

Actuator: The actuator assembly shall be double chambered with an inherent separating partition between the lower surface

of the diaphragm and the main valve. The entire actuator assembly (seal disk to top cover) shall be removable from the valve

as an integral unit. The stainless steel valve shaft shall be center guided by a bearing in the separating partition. The replaceable

radial seal disk shall include a resilient seal and shall be capable of accepting a V-Port Throttling Plug by bolting.

[3]

[10]

[5]

[7]

[9]

[1]

[1] Strainer Model 70F

[2] Emergency Pressure Reducing

Valve Model 720-PD-59

[3] Proportional Pressure Reducing

Valve Model 720-PD

[4] By-Pass Proportional Pressure

Reducing Valve Model 720-PD

[4]

[6]

[5] Primary Relief Valve Model 73Q

[8]

[6] By-Pass Relief Valve Model 73Q

[7] Pressure Reducing Valve

Model 720

B

A Higher zone pressure reducing system installation

B Lower zone pressure reducing system

(two-stage) installation

C Bottom reservoir level control system

D Roof reservoir level control system

E Potable water pumping system

F Fire protection pumping system

G Upper floors pumping system

C

C

E

E

FF

[3]

[5]

[7]

[9]

[8] By-Pass Pressure Reducing

Valve Model 720

[9] Relief Valve Model 73Q

[10] Pressure Switch

For high differential pressure systems, see BERMAD publication 720-PD Proportional Pressure Reducing Valve.

For high pressure systems, see BERMAD publication 820 Piston Actuated Pressure Reducing Valve.

BERMAD Waterworks

BERMAD Waterworks

700 Series

700 Series

700 Series

Model 720

Model 720

Model 720

Operation

The Model 720 is a pilot controlled valve equipped with an adjustable, 2-Way pressure reducing pilot.

The needle valve [1] continuously allows flow from the valve inlet into the upper control chamber [2]. The pilot [3] senses

downstream pressure.

Should this pressure rise above pilot setting, the pilot throttles, enabling pressure in the upper control chamber to accumulate,

causing the main valve to throttle closed, decreasing downstream pressure to pilot setting.

Should downstream pressure fall below pilot setting, the pilot releases accumulated pressure, and the main valve

modulates open.

The integral orifice between the lower control chamber and valve outlet moderates valve reactions.

The needle valve controls the closing speed. The downstream cock valve [4] enables manual closing.

1 -10

with #2PB Pilot

6-14

with #2 Pilot

1/2

[3]

[3]

Pressure Reducing Systems in High-Rise Buildings

Higher Zone Installation A

Water supply system design requirements for high-rise

buildings present unique issues:

Supply cut-off is unacceptable and single source supply

is common.

Valves are located in areas where water damage can

be extremely expensive.

Pressure reducing systems are often located next to

prestigious residential and office space. Extraneous

noise and maintenance activities are to be avoided.

The main supply line of high-rise buildings is exposed

to greater head at lower zones while pressure for the

consumer must be kept within recommended levels.

As a result, lower zone pressure reducing systems deal

with greater differential pressure.

In addition to the municipal pressure reducing system for a high-rise building, BERMAD recommends the

system also include:

Parallel Redundant Branches ensuring uninterrupted supply by enabling unskilled personnel to temporarily

shut off one of the branches.

Emergency System including a downstream pressure switch and an Emergency Valve Model 720-PD-59.

Pressure Switch [6] signals a control panel of excessive downstream pressure.

Emergency Valve [2] is fully open during normal operation. Triggered by the control panel, it becomes a

proportional pressure reducing valve.

D

G

[1]

[5]

[2]

[3]

[1]

[1] Strainer Model 70F

[2] Emergency Pressure Reducing

Valve Model 720-PD-59

[4]

[3] Pressure Reducing Valve

Model 720

[5]

[2]

[2]

[6]

Control Panel

The Model 720 Pressure Reducing Valves together

with BERMADS accumulated experience address these

issues and provide appropriate solutions.

[1]

BERMAD Waterworks

[4] By-pass Pressure Reducing

Valve Model 720

[3]

[5] Relief Valve Model 73Q

[4]

[4]

[6] Pressure Switch

A

Note: For 16" and larger valves,

see "Pilot Valve Selection" table at the last page.

Engineer Specifications

The Pressure Reducing Valve shall reduce higher upstream pressure to lower preset downstream pressure regardless of

fluctuating demand or varying upstream pressure.

Lower Zone (Two-Stage) Installation B

When dealing with high differential pressure systems in lower zones of a high-rise building, BERMAD recommends a

two-stage pressure reducing system. In addition to the typical higher zone installation, this high differential pressure

system also includes:

Proportional Pressure Reducing Valve Model 720-PD, as the first pressure reducing stage, absorbs part of the

high differential pressure. By spreading the load of pressure reducing onto two components, cavitation damage and

noise are reduced.

Main Valve: The main valve shall be a center guided, diaphragm actuated globe valve of either oblique (Y) or angle pattern

design. The body shall have a replaceable, raised, stainless steel seat ring. The valve shall have an unobstructed flow path,

with no stem guides, bearings, or supporting ribs. The body and cover shall be ductile iron. All external bolts, nuts, and studs

shall be Duplex coated. All valve components shall be accessible and serviceable without removing the valve from the pipeline.

Control Panel

Control System: The control system shall consist of a 2-Way adjustable, direct acting, pressure reducing pilot valve, a needle

valve, isolating cock valves, and a filter. All fittings shall be forged brass or stainless steel. The assembled valve shall be

hydraulically tested and factory adjusted to customer requirements.

Quality Assurance: The valve manufacturer shall be certified according to the ISO 9001 Quality Assurance Standard. The main

valve shall be certified as a complete drinking water valve according to NSF, WRAS, and other recognized standards.

[2]

Actuator: The actuator assembly shall be double chambered with an inherent separating partition between the lower surface

of the diaphragm and the main valve. The entire actuator assembly (seal disk to top cover) shall be removable from the valve

as an integral unit. The stainless steel valve shaft shall be center guided by a bearing in the separating partition. The replaceable

radial seal disk shall include a resilient seal and shall be capable of accepting a V-Port Throttling Plug by bolting.

[3]

[10]

[5]

[7]

[9]

[1]

[1] Strainer Model 70F

[2] Emergency Pressure Reducing

Valve Model 720-PD-59

[3] Proportional Pressure Reducing

Valve Model 720-PD

[4] By-Pass Proportional Pressure

Reducing Valve Model 720-PD

[4]

[6]

[5] Primary Relief Valve Model 73Q

[8]

[6] By-Pass Relief Valve Model 73Q

[7] Pressure Reducing Valve

Model 720

B

A Higher zone pressure reducing system installation

B Lower zone pressure reducing system

(two-stage) installation

C Bottom reservoir level control system

D Roof reservoir level control system

E Potable water pumping system

F Fire protection pumping system

G Upper floors pumping system

C

C

E

E

FF

[3]

[5]

[7]

[9]

[8] By-Pass Pressure Reducing

Valve Model 720

[9] Relief Valve Model 73Q

[10] Pressure Switch

For high differential pressure systems, see BERMAD publication 720-PD Proportional Pressure Reducing Valve.

For high pressure systems, see BERMAD publication 820 Piston Actuated Pressure Reducing Valve.

BERMAD Waterworks

BERMAD Waterworks

BERMAD Waterworks

700 Series

700 Series

700 Series

Model 720

Model 720

Model 720

Pressure Reducing System for Municipal Networks

Dimensions and Weights

Network design requires establishing various pressure zones due to topography, distances, demands, energy costs,

reservoir availability, etc.

Size

mm inch

40 11/2

50

2

65 21/2

80 3

100 4

150 6

200 8

250 10

300 12

350 14

400 16

450 18

500 20

A, B

mm inch

350 14

350 14

350 14

370 15

395 16

430 17

475 19

520 21

545 22

545 22

645 26

645 26

645 26

C

mm inch

180 7

180 7

180 7

230 9

275 11

385 15

460 18

580 23

685 27

685 27

965 38

965 38

965 38

L

mm inch

205 8.1

210 8.3

222 8.7

250 9.8

320 12.6

415 16.3

500 19.7

605 23.8

725 28.5

733 28.9

990 39.0

1000 39.4

1100 43.3

Flow Chart

H

mm inch

239 9.4

244 9.6

257 10.1

305 12.0

366 14.4

492 19.4

584 23.0

724 28.5

840 33.1

866 34.1

1108 43.6

1127 44.4

1167 45.9

Weight

kg lbs

9.1 20

10.6 23

13 29

22 49

37 82

75 165

125 276

217 478

370 816

381 840

846 1865

945 2083

962 2121

Pressure Reducing System Typical Installation

Pressure Reducing Valve

Model 720

Relief Valve

Model 73Q

500 1,000

5,000 10,000

1.0

0.9

0.8

0.7

0.6

0.5

10

9

8

7

6

5

24

0.4

3"

1.5"

0.3

2"

10"

6"

12"

8"

4"

14"

16"

18"

20"

2.5"

0.2

4

28"

30"

32"

0.1

50

10

500

100

1,000

5,000

Control System

Valve Patterns: Y (globe) & angle

Size Range: 11/232 (40-800 mm)

End Connections (Pressure Ratings):

Flanged: ISO PN16, PN25

(ANSI Class 150, 300)

Threaded: BSP or NPT

Others: Available on request

Working Temperature:

Water up to 80C (180F)

Standard Materials:

Body & Actuator: Ductile Iron

Internals:

Stainless Steel, Bronze & coated Steel

Diaphragm:

NBR Nylon fabric-reinforced

Seals: NBR

Coating:

Fusion Bonded Epoxy, RAL 5005 (Blue)

NSF & WRAS approved or Electrostatic

Polyester Powder, RAL 6017 (Green)

Standard Materials:

Accessories:

Bronze, Brass, Stainless Steel & NBR

Tubing: Copper or Stainless Steel

Fittings: Forged Brass or Stainless Steel

Pilot Standard Materials:

Body: Brass, Bronze or Stainless Steel

Elastomers: NBR

Springs: Galvanized Steel or Stainless Steel

Internals: Stainless Steel

Sector

WW

By-Pass

Pressure Reducing Valve

Model 720

In addition to the Model 720 Pressure Reducing Valve, BERMAD recommends that the system also include:

Strainer Model 70F prevents debris from damaging valve operation

Relief Valve Model 73Q provides:

Protection against momentary pressure peaks

Visual indication of need for maintenance

By-Pass Pressure Reducing Valve saves on maintenance costs. The larger (more costly to maintain) valve operates

during peak demand. The smaller by-pass valve cuts operating hours of the larger valve, achieving greater

return on investment.

For high differential pressure systems, see BERMAD publication 720-PD Proportional Pressure Reducing Valve.

For high pressure systems, see BERMAD publication 820 Piston Actuated Pressure Reducing Valve.

Waterworks

Size

6

1 1/2 - 32

720-

No Additional Feature

Closing and Opening Speed Control

Automatic Regulation Override

High sensitivity pilot

Check Valve

Solenoid Controlled & Check Valve

Multi-Setting Levels - Electrically Selected

Downstream Over Pressure Guard

Hydraulic Control

Solenoid Controlled

Electric Override

Multiple choices permitted

Pattern

00

-

Pressure Reducing

00

03

09

12

20

25

45

48

50

55

59

Throttling noise reduction

System maintenance savings

10,000

Body

Material

-Y

-C

Oblique (up to 20)

Y

Angle (up to 18)

A

Globe (24-32 only) G

Ductile Iron Standard

Cast Steel

St. Steel 316

Nickel Alumin. Bronze

ISO-16

ISO-25

ANSI-150

ANSI-300

JIS-16

JIS-20

Valve Size

Pilot

Setting (bar)

11/2-10

40-250 mm

<15

>15

6-14

150-350 mm

<15

>15

16 -32

400-800 mm

<15

>15

Standard model

End

Connections

Coating

16

Epoxy FB Blue

Polyester Green

Polyester Blue

Uncoated

EB

EB

PG

PB

UC

C

S

N

U

16

25

A5

A3

J6

J2

The Model 720 Pressure Reducing Valve is a hydraulically

operated, diaphragm actuated control valve that reduces

higher upstream pressure to lower constant downstream

pressure regardless of fluctuating demand or varying

upstream pressure.

Pilot Valve Selection

#2PB

Pilot Type

#2

#2HC

with high pressure setting kit

Please specify the requested valve in the following sequence: (for more options, refer to Ordering Guide)

Additional

Feature

Cavitation damage protection

Data is for Y-pattern, flat disk valves

For more flow charts, refer to Engineering Section

Main Valve

Primary

Feature

Flow and leakage reduction

Flow Rate - m3/h

How to Order

Strainer

Model 70F

Pressure Reducing

Valve

Burst protection

Data is for Y-pattern, flanged, PN16 valves

Weight is for PN16 basic valves

C enables removing the actuator in one unit

L, ISO standard lengths available

For more dimensions and weights tables, refer to Engineering Section

The pump supplies water to the network and to the reservoir. System pressure is too high for the residential

neighborhood, requiring a pressure reducing system.

Flow Rate - gpm

100

50

Pressure Loss - psi

Technical Data

Pressure Loss - bar

Typical Applications

24VAC/50Hz - N.C.

24VAC/50Hz - N.O.

24VDC - N.C.

24VDC - N.O.

24VDC - L.P.

220VAC/50-60Hz N.C.

220VAC/50-60Hz N.O.

4AC

4AO

4DC

4DO

4DP

2AC

2AO

Use when additional electric control

feature is selected

info@bermad.com www.bermad.com

The information herein is subject to change without notice. BERMAD shall not be held liable for

PC7WE20 05

any errors. All rights reserved. Copyright by BERMAD.

Voltage &

Position

Tubing

& Fittings

Major Additional Features

Line pressure driven Independent operation

UL Listed for fire protection FP-720-UL

In-line serviceable Easy maintenance

Solenoid control 720-55

Double chamber design

Additonal

Attributes

CB

VI

Copper Tubing & Brass Fittings CB

Plastic Tubing & Brass Fittings PB

St. St. 316 Tubing & Fittings

NN

Valve Position Indicator

V-Port Throttling Plug

Large Control Filter

Electric Limit Switch

3-Way Control Loop

Valve Position Transmitter

St. St. 316 Control Accessories

St. St. 316 Internal Trim (Closure & Seat)

St. St. 316 Actuator Internal Assembly

Delrin Bearing

Viton Elastomers for Seals & Diaphragm

Pressure Gauge

Multiple choices permitted

Features and Benefits

I

V

F

S

X

Q

N

T

D

R

E

6

Check valve 720-20

Moderated valve reaction

Solenoid control & check valve 720-25

Protected diaphragm

Proportional 720-PD

Automatic regulation override 720-09

Flexible design Easy addition of features

Variety of accessories Perfect mission matching

High sensitivity pilot 720-12

"Y" or angle, wide body Minimized pressure loss

Emergency pressure reducing valve 720-PD-59

Semi-straight flow Non-turbulent flow

Downstream over pressure guard 720-48

Stainless Steel raised seat Cavitation damage resistant

Electrically selected multi-level setting 720-45

Obstacle free, full bore Uncompromising reliability

Electronic multi-level setting, Type 4T 720-4T

V-Port Throttling Plug Low flow stability

Electronic pressure reducing valve 728-03

See relevant BERMAD publications.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hybrid VehicleDocument26 pagesHybrid VehicleakashNo ratings yet

- C208BTechnical BriefingDocument94 pagesC208BTechnical BriefingEvans Ev100% (1)

- 308CCR Series Spec SheetDocument24 pages308CCR Series Spec SheetBang Kojek100% (4)

- Manitowoc 2250Document108 pagesManitowoc 2250Michael SerraNo ratings yet

- Esquema Electrico 320E - 300EDocument2 pagesEsquema Electrico 320E - 300EJuan Pablo Barron Marin100% (1)

- Service Station Manual: Typhoon 50Document160 pagesService Station Manual: Typhoon 50joseph mulenkaNo ratings yet

- Motor 4d56Document117 pagesMotor 4d56virgilio sevilla91% (22)

- Motors For Rotax Kiln DriveDocument17 pagesMotors For Rotax Kiln DrivesreeganeshrNo ratings yet

- 3126 MUI Fuel Systems C7 Control SystemsDocument2 pages3126 MUI Fuel Systems C7 Control Systemsالمهندسوليدالطويل100% (1)

- 4110001262驱动桥 后桥 看图王 Hoid MostDocument24 pages4110001262驱动桥 后桥 看图王 Hoid Mostenhbat batsuhNo ratings yet

- Panasonic Motor Selection GuideDocument6 pagesPanasonic Motor Selection GuideAnnish KumarNo ratings yet

- Smay Pressure Differential Systems Guidebook v514-EN PDFDocument138 pagesSmay Pressure Differential Systems Guidebook v514-EN PDFFarhsa Dhom Eemihahs DhomNo ratings yet

- Gstarcad8 User GuideDocument135 pagesGstarcad8 User GuideFarhsa Dhom Eemihahs DhomNo ratings yet

- Rotary Lift: Trouble Shooting Guide IndexDocument20 pagesRotary Lift: Trouble Shooting Guide IndexFarhsa Dhom Eemihahs DhomNo ratings yet

- Model(s) : HDS 35 / HDS 35X / HDS 40 / HDS 40X Description: Heavy Duty Four Post LiftsDocument2 pagesModel(s) : HDS 35 / HDS 35X / HDS 40 / HDS 40X Description: Heavy Duty Four Post LiftsFarhsa Dhom Eemihahs DhomNo ratings yet

- Project: Model: CHK'D: DateDocument55 pagesProject: Model: CHK'D: DateFarhsa Dhom Eemihahs DhomNo ratings yet

- Baseline Water Consumption WorksheetDocument2 pagesBaseline Water Consumption WorksheetFarhsa Dhom Eemihahs Dhom100% (1)

- 2009 UPC PresentationDocument81 pages2009 UPC PresentationFarhsa Dhom Eemihahs DhomNo ratings yet

- CFL Buyguide 040307Document1 pageCFL Buyguide 040307Farhsa Dhom Eemihahs DhomNo ratings yet

- B9091 Ecaro-25Document6 pagesB9091 Ecaro-25Farhsa Dhom Eemihahs DhomNo ratings yet

- For More Details:: Digitronic AEB Polymer Injector Nozzle Table Digitronic Injector RailsDocument6 pagesFor More Details:: Digitronic AEB Polymer Injector Nozzle Table Digitronic Injector RailsStore-BlackberryJhonnymarNo ratings yet

- Juk MB-373NS 377NSDocument32 pagesJuk MB-373NS 377NSRHoskaNo ratings yet

- Lessp13700 PC130F-7 PDFDocument14 pagesLessp13700 PC130F-7 PDFArdika GandhyNo ratings yet

- Omt 2021 Wip 008 R0Document1 pageOmt 2021 Wip 008 R0Prathamesh OmtechNo ratings yet

- White Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Document20 pagesWhite Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Central HydraulicsNo ratings yet

- PX 115 Disc Stack CentrifugeDocument2 pagesPX 115 Disc Stack Centrifugesmyhearts611No ratings yet

- Aqv 12 NsanDocument93 pagesAqv 12 NsanCarlos Fabián MessinaNo ratings yet

- c33d5 Ds93 CPGK RevcDocument3 pagesc33d5 Ds93 CPGK RevcmunhNo ratings yet

- Location of Chassis and Engine NumbersDocument9 pagesLocation of Chassis and Engine NumbersPrashantNo ratings yet

- Evolution BrochureDocument4 pagesEvolution Brochurelucas28031978No ratings yet

- TALHA DOUBLE GIDDER - WR1740 - AS7 BrochureDocument20 pagesTALHA DOUBLE GIDDER - WR1740 - AS7 BrochureSergioNo ratings yet

- Santierul Naval Constanta SaDocument9 pagesSantierul Naval Constanta SacpîndaruNo ratings yet

- Spare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aDocument3 pagesSpare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aeli saNo ratings yet

- VT-evo Kubota-Spare Parts - SP007-01-00-00Document25 pagesVT-evo Kubota-Spare Parts - SP007-01-00-00Justice Machiwana100% (1)

- 1 LZ60 CylinderDocument14 pages1 LZ60 CylinderaNo ratings yet

- 90kVA PDFDocument4 pages90kVA PDFXander DelinyaNo ratings yet

- ME 383 - Lesson 6 - Cam and FollowerDocument8 pagesME 383 - Lesson 6 - Cam and FollowerNanip, karen D BSME-1CNo ratings yet

- CaterpillarDocument4 pagesCaterpillarCarlos MartinezNo ratings yet