Professional Documents

Culture Documents

1 - Tool Holders and Their Maintenance

Uploaded by

NatKThOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 - Tool Holders and Their Maintenance

Uploaded by

NatKThCopyright:

Available Formats

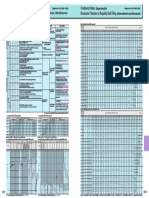

2014 - Router bits and chucks for CNC routers

TOOL HOLDERS

Useful information:

SISTEMI has always been known for the high quality of the products offered. Keywords of this success are the attention to production

materials and the use of the most modern construction techniques together with more accurate controls and the continuous research of

innovative products.

A large complete stock helps even more our customers to be more competitive in the market.

The tool holders made of stainless steel (see page 7.18) allow to solve permanently any possibility of oxidation.

All our standard collet chucks are balanced at G 6.3 (24.000 RPM) and, on request, can be also at G 2.5 (36.000 RPM).

The new collet chucks

(see page 7.16) are balanced at G 2.5 36.000 RPM for performing special executions.

Use instructions:

1) The collect chuck may be used only on router machines and machining

centers for processing wood and wood-based material with comparable

cutting characteristics.

2) The instructions of the machine manufacturer regarding the suitability

of the clamping device have to be observed.

3) The direction of rotation marked on the clamping device has to be observed

and followed. The direction of rotation of the tool and the collet chuck

have to be the same.

4) Do not exceed the maximum RPM n max marked on the collet chuck.

The maximum RPM of the system is determined by the tool, if the RPM

of the tool is lower than that of the chuck.

Safety regulations:

1) All European and national safety regulations shall be adhered to include the safety requirements

as set out in EN 847-1, EN 847-2 e EN 847-3.

2) The clamping device has to be mounted, secured and started up as per instructions of the machine manufacturer.

Check the machine set-up and the direction of the rotation.

Maintenance:

A regular and proper cleaning of mechanical components is critical to avoid jamming during processing

operations and the consequent risk of a poor finishing

of the piece or even tool breakage.

The worked pieces leave impurities and debris in the

collets holes, in the seats of tool holders or electrospindles. These should be therefore cleaned daily

using the right wipers (see items T137 and X137 at the

page 7.33)

In order to avoid the risk of tool breakage during the job, make sure you answered the following questions:

1- Are you using the proper tool for the desired job?

2- Collets and tool holders are clean and the tool is inserted properly?

3- RPM and feed speed are correct?

4- Is the depth cut not too excessive for the material processed?

5- Are there any evident vibrations of the mechanical parts?

6- No right answer to your problem? Stop running parts and check with your

distributor.

If you have to contact your distributor of technical support, have ready the following information:

a- Type of machine being used

b- Type of material being cut

c- Part number of tool,

item

d- RPM/feed speed/depth of cut

e- How long did the tool worked before it broke/damaged?

f- Have you done this operation in the past using the same tool?

7.07

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- DOE ShaininDocument200 pagesDOE ShaininNatKTh100% (2)

- Okuma Encoder SettingDocument1 pageOkuma Encoder SettingNatKThNo ratings yet

- Thoughts On Table TennisDocument38 pagesThoughts On Table TennisNatKTh100% (1)

- Cobas B 221 Interface Manual PDFDocument70 pagesCobas B 221 Interface Manual PDFReach Business Software Pvt LtdNo ratings yet

- Centerless Grinding TrobleshootingDocument13 pagesCenterless Grinding TrobleshootingNatKThNo ratings yet

- Ultimate List of ISO Standards For Medical Devices-1Document34 pagesUltimate List of ISO Standards For Medical Devices-1Sridharan PadmanabhanNo ratings yet

- H.F.I /ista Tu Berlin - Chair Offluid Dynamics - Mueller Breslau Str. 8, D-10623, BerlinDocument1 pageH.F.I /ista Tu Berlin - Chair Offluid Dynamics - Mueller Breslau Str. 8, D-10623, BerlinNatKThNo ratings yet

- Flexi Multiradio OverviewDocument18 pagesFlexi Multiradio OverviewJon Snow-Stark50% (2)

- CISA Training D1Document238 pagesCISA Training D1asebeNo ratings yet

- Vs-5ed Varicam NSDDocument60 pagesVs-5ed Varicam NSDNatKThNo ratings yet

- Atmosphere in FurnaceDocument6 pagesAtmosphere in FurnaceNatKTh0% (1)

- Me 222 Tolerance DesignDocument35 pagesMe 222 Tolerance DesignNatKThNo ratings yet

- HDS Powersports User GuideDocument65 pagesHDS Powersports User GuideNatKThNo ratings yet

- 65002e เล่มนี้ดี เอกสารเก่า PDFDocument348 pages65002e เล่มนี้ดี เอกสารเก่า PDFNatKThNo ratings yet

- PLC Transmit Instruction Mov Smov Cmov Bmov FmovDocument2 pagesPLC Transmit Instruction Mov Smov Cmov Bmov FmovNatKThNo ratings yet

- Table TennisDocument23 pagesTable TennisGodisgreate100% (1)

- Psychrometric Properties On A CalcDocument5 pagesPsychrometric Properties On A CalcNatKThNo ratings yet

- Ho PosthocDocument3 pagesHo PosthocJorge VillalobosNo ratings yet

- Mastering Meta Stock ManualDocument91 pagesMastering Meta Stock Manuallaxmicc100% (2)

- Gettingstarted ManualDocument63 pagesGettingstarted ManualTribhuvan ChettyNo ratings yet

- Technical Data (Thai) 4Document1 pageTechnical Data (Thai) 4NatKThNo ratings yet

- Technical Data (Thai) 3Document1 pageTechnical Data (Thai) 3NatKThNo ratings yet

- Furnace BrazingDocument26 pagesFurnace BrazingNatKThNo ratings yet

- Automatic Changeover Thrufeed Centerless Grinder MSL-600 Model and MFC-600 ModelDocument1 pageAutomatic Changeover Thrufeed Centerless Grinder MSL-600 Model and MFC-600 ModelNatKThNo ratings yet

- Henkel SelectionDocument18 pagesHenkel SelectionNatKThNo ratings yet

- ISO 11957 1996 en PreviewDocument5 pagesISO 11957 1996 en PreviewHoang TraNo ratings yet

- 2011 DTM Technical RegulationsDocument54 pages2011 DTM Technical RegulationsMatt KosonenNo ratings yet

- UA5000Document59 pagesUA5000pipiredNo ratings yet

- Clinical Trial Regulation in NepalDocument7 pagesClinical Trial Regulation in NepalB.pharm 16th BatchNo ratings yet

- Metrosils For High Impedance RelaysDocument4 pagesMetrosils For High Impedance RelaysSamatha VedanaNo ratings yet

- Zed-3 Se150 QSG LenDocument6 pagesZed-3 Se150 QSG LenClaudia TituañaNo ratings yet

- Manchester Encoding Using RS232Document4 pagesManchester Encoding Using RS232Izhar Rosli100% (1)

- Eurocod 2Document358 pagesEurocod 2Don Adrián Oniga100% (1)

- Instruction ManualDocument351 pagesInstruction ManualИван Великий100% (1)

- Math002 ReviewerDocument4 pagesMath002 ReviewerIan Bertonel BalcuevaNo ratings yet

- Rungta College of Engineering & Technology: Lab Manual CS-322364 (22) : Web TechnologyDocument58 pagesRungta College of Engineering & Technology: Lab Manual CS-322364 (22) : Web TechnologybinzbinzNo ratings yet

- Exercise 14Document2 pagesExercise 14Tuan NguyenNo ratings yet

- k219 2005-02 eDocument12 pagesk219 2005-02 eDoru HacaNo ratings yet

- Defence Standard 22-48 (NES 2048)Document34 pagesDefence Standard 22-48 (NES 2048)Hattar MNo ratings yet

- Modul SAP Fundamental JWB 02Document9 pagesModul SAP Fundamental JWB 02Faishal Anshary0% (1)

- Eio0000000734 13Document148 pagesEio0000000734 13Duvan TamayoNo ratings yet

- MEng Thesis - TanXinJiAlanDocument196 pagesMEng Thesis - TanXinJiAlanRamachandran PskNo ratings yet

- 5G Spectrum PositionsDocument12 pages5G Spectrum PositionsAdrian ZahraNo ratings yet

- C TADM70 19 PDF Questions and AnswersDocument5 pagesC TADM70 19 PDF Questions and Answersmanish agrawalNo ratings yet

- Lacp With STP Sim PDFDocument8 pagesLacp With STP Sim PDFKang Mas PaijhoNo ratings yet

- Gateway AS-Interface Gateway VBG-PN-K20-DMDDocument72 pagesGateway AS-Interface Gateway VBG-PN-K20-DMDOleoplan NordesteNo ratings yet

- Pan Os 7.0.3 RN - 2Document62 pagesPan Os 7.0.3 RN - 2Asus HaelNo ratings yet

- Contaminating Microorganisms in Products With ProbioticsDocument8 pagesContaminating Microorganisms in Products With ProbioticsJose Alfredo DiazNo ratings yet

- 04.525.101 W AGT-525 e Rev2Document2 pages04.525.101 W AGT-525 e Rev2André TeizenNo ratings yet

- Hewlett-Packard Vp6311 ManualDocument75 pagesHewlett-Packard Vp6311 ManualIngArnaldoParraNo ratings yet

- Amruta TagareDocument2 pagesAmruta Tagareapi-3739915No ratings yet