Professional Documents

Culture Documents

108436main Integrated Powerhead Demonstrator

108436main Integrated Powerhead Demonstrator

Uploaded by

ermkermk0 ratings0% found this document useful (0 votes)

2 views2 pagesugjjvjvjyyhjvugyjjyfgv

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentugjjvjvjyyhjvugyjjyfgv

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views2 pages108436main Integrated Powerhead Demonstrator

108436main Integrated Powerhead Demonstrator

Uploaded by

ermkermkugjjvjvjyyhjvugyjjyfgv

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

NASA Facts

National Aeronautics and

Space Administration

Marshall Space Flight Center

Huntsville, Alabama 35812

FS-2005-01-05-MSFC

January 2005

Next Generation Propulsion Technology:

Integrated Powerhead Demonstrator

NASA, the U.S. Air Force and leading aerospace industry

contractors have joined forces to develop the Integrated

Powerhead Demonstrator, a risk-reduction effort to

develop engine technologies that could, within decades,

power the next generation of Americas space eet.

The Integrated Powerhead Demonstrator, or IPD, is a joint

venture between NASAs Exploration Systems Mission

Directorate, managed for the Agency at the Marshall

Space Flight Center in Huntsville, Ala., and the Integrated

High Payoff Rocket Propulsion Technologies (IHPRPT)

program, managed for the Department of Defense by

the U.S. Air Force Research Laboratory at Edwards Air

Force Base, Calif.

The project is the rst phase of the Integrated High Payoff

Rocket Propulsion Technologies programs effort to

develop a ight-rated, full-ow, hydrogen-fueled, stagedcombustion rocket engine in the 250,000-pound thrust

class. This would be the rst engine of its kind, capable

of doubling the performance of state-of-the-art booster

engines. The Integrated Powerhead Demonstrator engine

will employ dual preburners that provide both oxygenrich and hydrogen-rich gases for the staged combustion

engine. This innovative approach is expected to keep

critical components of future engines cooler during ight,

achieving better reliability and improved safety.

The project is intended to address two major technological

challenges -- turbine life and bearing wear -- that

traditionally have limited performance among rocket

engines. By sending all of the propellant ow through

the turbine, the same amount of energy can be extracted

with a lower-temperature gas -- thus reducing the

likelihood of material fatigue caused by sustained high

temperatures.

The high-performance turbomachinery of the demonstrator

also will include hydrostatic bearings that fully support the

rotor of both the fuel and oxidizer pump. Because the

hydrostatic bearings actually cause the rotor to oat on a

layer of liquid during operation, bearing wear only occurs

for a few seconds during engine startup and shutdown.

Rocket turbomachinery, in comparison, typically uses

ball bearings or roller bearings, which rub continuously

whenever the rotor is spinning. Minimizing operational

contact eliminates bearing wear as a major life-limiting

factor for the turbomachinery.

Unique component technologies

The Integrated Powerhead Demonstrators liquidhydrogen fuel turbopump is designed to raise the pressure

of hydrogen entering the rocket engine above the pressure

in the thrust chamber. The turbopump extracts energy

from the hot gases owing through the turbine, causing

the turbopump rotor to spin very rapidly. As it spins, an

impeller -- a rotating device used to force uid in a desired

direction -- attached to the other end of the shaft pumps

the hydrogen to pressures greater than 5,000 pounds

per square inch.

Developed for NASA and the Air Force by the Boeing

Companys Rocketdyne Propulsion and Power Division

of Canoga Park, Calif., the turbopumps design addresses

key life limitations common to the Space Shuttle

main engine. In comparison, the Shuttle main engine

turbomachinery requires maintenance and refurbishment

after 10 ights; the Integrated Powerhead Demonstrator

engine is intended to y 100 times between maintenance

periods. Engineers also are seeking development of a

200-mission lifespan for the new engine more than

double that of the Shuttle main engine.

Boeing-Rocketdyne also is responsible for development

and testing of the demonstrators oxygen pump, main

injector and main combustion chamber.

Developed and tested for NASA and the Air Force by

Aerojet Corp. of Sacramento, Calif., the oxidizer preburner -- which initiates the combustion process -- is

designed to generate oxygen-rich steam for use by the

oxygen turbopumps turbine. The preburner burns a large

quantity of liquid oxygen with a small quantity of hydrogen

to produce this steam, which then mixes with additional

hydrogen fuel to be burned in the main combustion

chamber.

The oxidizer preburner is the rst ight-capable, oxygenrich preburner developed in the United States for a largescale engine. The Space Shuttle main engine makes use

of a preburner that generates hydrogen-rich steam -- the

only American rocket engine to do so. But whereas the

Shuttle main engine burns only a small amount of oxygen

prior to entry into the main combustion chamber, all the

oxygen used in the demonstrator engine system will be

sent through the preburner.

The use of oxygen-rich steam to power the demonstrators

oxygen turbopump is intended to dramatically increase

safety of engine system operation, limiting seal failure

between the pump and the turbine that could leak

extremely hot gases into the turbine and cause them to

burn prematurely.

Aerojet also is responsible for development of the

demonstrator engines fuel preburner, designed to supply

the fuel turbopumps turbine with hot, hydrogen-rich

steam. The Aerojet team also has designed, fabricated

and tested the channel wall nozzle, a component that

directs the rocket engines exhaust.

Boeing-Rocketdyne will lead overall system integration for

NASA once component-level development and testing is

complete. Integrated system testing of the demonstrator

is scheduled to begin in 2005.

More about the project

The Integrated Powerhead Demonstrator is a corner

stone of the Integrated High Payoff Rocket Propulsion

Technologies program, which seeks to double the

performance and capability of todays state-of-the

art rocket propulsion systems while decreasing costs

associated with military and commercial access to space.

The intended full-ow engine cycle is a key component

in achieving this goal.

National Aeronautics and

Space Administration

George C. Marshall Space Flight Center

Marshall Space Flight Center, Alabama 35812

Pub 8-40355

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- NASA 174803main MSFC Prime ContractorsDocument10 pagesNASA 174803main MSFC Prime ContractorsNASAdocumentsNo ratings yet

- The Design Basics of Motor Protection Circuit BreakerDocument15 pagesThe Design Basics of Motor Protection Circuit BreakerKI OHNo ratings yet

- Boiler Combustion Theory and EfficiencyDocument84 pagesBoiler Combustion Theory and EfficiencyAhmed Hassan100% (1)

- FMDS-05-33 (04.2020) - Electrical Energy Storage SystemsDocument23 pagesFMDS-05-33 (04.2020) - Electrical Energy Storage SystemsFogo Neptún100% (1)

- Basic of Well CompletionDocument19 pagesBasic of Well Completionchaeqq100% (2)

- SICES Heat ExchangersDocument10 pagesSICES Heat ExchangersKarthik AnandanNo ratings yet

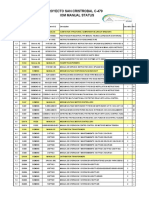

- Proyecto San Cristrobal C-479 Iom Manual StatusDocument18 pagesProyecto San Cristrobal C-479 Iom Manual StatusAllen Marcelo Ballesteros LópezNo ratings yet

- NASA 122211main M-567 TKC JNLDocument1 pageNASA 122211main M-567 TKC JNLNASAdocumentsNo ratings yet

- NASA 149000main Nasa 2005 ReportDocument66 pagesNASA 149000main Nasa 2005 ReportNASAdocumentsNo ratings yet

- NASA: 190101main Plum Brook MapDocument1 pageNASA: 190101main Plum Brook MapNASAdocuments100% (2)

- NASA 168206main CenterResumeDocument67 pagesNASA 168206main CenterResumeNASAdocumentsNo ratings yet

- NASA 168207main ExecutiveSummaryBrochureDocument2 pagesNASA 168207main ExecutiveSummaryBrochureNASAdocumentsNo ratings yet

- NASA: 178801main Goals ObjectivesDocument12 pagesNASA: 178801main Goals ObjectivesNASAdocuments100% (2)

- NASA: 190101main Plum Brook MapDocument1 pageNASA: 190101main Plum Brook MapNASAdocuments100% (2)

- NASA 149000main Nasa 2005 ReportDocument66 pagesNASA 149000main Nasa 2005 ReportNASAdocumentsNo ratings yet

- NASA 168207main ExecutiveSummaryBrochureDocument2 pagesNASA 168207main ExecutiveSummaryBrochureNASAdocumentsNo ratings yet

- NASA 151450main FNL8-40738Document2 pagesNASA 151450main FNL8-40738NASAdocumentsNo ratings yet

- NASA 122211main M-567 TKC JNLDocument1 pageNASA 122211main M-567 TKC JNLNASAdocumentsNo ratings yet

- NASA: 67453main Elv2003Document10 pagesNASA: 67453main Elv2003NASAdocumentsNo ratings yet

- NASA 168206main CenterResumeDocument67 pagesNASA 168206main CenterResumeNASAdocumentsNo ratings yet

- NASA: 55583main Vision Space Exploration2Document32 pagesNASA: 55583main Vision Space Exploration2NASAdocuments100% (5)

- NASA 171651main fs-2007-02-00041-sscDocument2 pagesNASA 171651main fs-2007-02-00041-sscNASAdocumentsNo ratings yet

- NASA 166985main FS-2006-10-124-LaRCDocument35 pagesNASA 166985main FS-2006-10-124-LaRCNASAdocumentsNo ratings yet

- NASA: 55583main Vision Space Exploration2Document32 pagesNASA: 55583main Vision Space Exploration2NASAdocuments100% (5)

- NASA: 55583main Vision Space Exploration2Document32 pagesNASA: 55583main Vision Space Exploration2NASAdocuments100% (5)

- NASA: 68481main LAP-RevADocument20 pagesNASA: 68481main LAP-RevANASAdocumentsNo ratings yet

- NASA 159998main MSFC Fact SheetDocument4 pagesNASA 159998main MSFC Fact SheetNASAdocumentsNo ratings yet

- Language Assistance Plan (LAP) Accommodating Persons With Limited English Proficiency in NASA/KSC-Conducted Programs and ActivitiesDocument11 pagesLanguage Assistance Plan (LAP) Accommodating Persons With Limited English Proficiency in NASA/KSC-Conducted Programs and ActivitiesNASAdocumentsNo ratings yet

- NASA: 188227main fs-2007-08-00046-sscDocument2 pagesNASA: 188227main fs-2007-08-00046-sscNASAdocumentsNo ratings yet

- NASA 167686main FY 2006 NASA PARpt3 508Document85 pagesNASA 167686main FY 2006 NASA PARpt3 508NASAdocumentsNo ratings yet

- NASA: 68198main AreaAttractions2003Document8 pagesNASA: 68198main AreaAttractions2003NASAdocumentsNo ratings yet

- A Simple Mathematical Approach To Assess The Impact of Solar PV Penetration On Voltage Profile of Distribution NetworkDocument6 pagesA Simple Mathematical Approach To Assess The Impact of Solar PV Penetration On Voltage Profile of Distribution NetworkĐăng Nguyễn HảiNo ratings yet

- Product Catalog - Spanner Re GMBHDocument24 pagesProduct Catalog - Spanner Re GMBHRadek OlszakNo ratings yet

- APDD 339A Sierra Long Term StorageDocument4 pagesAPDD 339A Sierra Long Term StorageCesar HernandezNo ratings yet

- Datasheet S6-EH3P (3-10) K-H-EU Global V2.8 2023 06Document2 pagesDatasheet S6-EH3P (3-10) K-H-EU Global V2.8 2023 06Ninh DoanNo ratings yet

- Sulphuric Acid Process Flow ChartDocument1 pageSulphuric Acid Process Flow ChartPoon CYNo ratings yet

- S26TNDocument2 pagesS26TNdanielbarbosagoncalvNo ratings yet

- Links: Line Charge Mvar Voltage LimitsDocument7 pagesLinks: Line Charge Mvar Voltage LimitsDevas ShuklaNo ratings yet

- TurbomachineryDocument4 pagesTurbomachineryDaniel SilvaNo ratings yet

- شيتات تربوDocument15 pagesشيتات تربومحمد عفيفىNo ratings yet

- Aircraft System SDocument2 pagesAircraft System SPravin HandeNo ratings yet

- EHSEC Toolbox Talk Fire SafetyDocument14 pagesEHSEC Toolbox Talk Fire SafetyGeorge ScroubelosNo ratings yet

- Dati Gruppi T-Zero - CompletiDocument1 pageDati Gruppi T-Zero - CompletiPabloNavarreteNo ratings yet

- Hydrogen Fuel Cells 101 Jan2022Document14 pagesHydrogen Fuel Cells 101 Jan2022crangelNo ratings yet

- FormulasDocument1 pageFormulasZi Sheng NeohNo ratings yet

- Approaching The Sun: Concentrated Solar Power Plants With LESER Safety ValvesDocument8 pagesApproaching The Sun: Concentrated Solar Power Plants With LESER Safety ValvesRaduNo ratings yet

- Lab Test Set Up of Pelton Wheel and TestDocument7 pagesLab Test Set Up of Pelton Wheel and TestHimansu GoswamiNo ratings yet

- Shaun Burnie - The Reality of The Fukushima Radioactive Water Crisis - Greenpeace Germany - Octubre 2020Document5 pagesShaun Burnie - The Reality of The Fukushima Radioactive Water Crisis - Greenpeace Germany - Octubre 2020Sergio WatsonNo ratings yet

- Bahan Turbine ENERGY LautDocument15 pagesBahan Turbine ENERGY Lautakhmadmarufnur609No ratings yet

- Diaphragm Pump Technology SystemsDocument9 pagesDiaphragm Pump Technology SystemsAsesoria TécniaNo ratings yet

- Panasonic Rotary Compressor CatalogueDocument2 pagesPanasonic Rotary Compressor CatalogueMakassar TeknikNo ratings yet

- Narada 6 GFMDocument2 pagesNarada 6 GFMАлександр АнатольевичNo ratings yet

- Overhauling Surprises of Unit # 4: Electrical & C&IDocument4 pagesOverhauling Surprises of Unit # 4: Electrical & C&ISony RamaNo ratings yet

- 381 En-Bi 201408 Air Treatment Planning 13Document4 pages381 En-Bi 201408 Air Treatment Planning 13RomanCHubaNo ratings yet

- Samsung Final VRFDocument4 pagesSamsung Final VRFchandravadiyaketan1504No ratings yet