Professional Documents

Culture Documents

What Is Reverse Engineering

What Is Reverse Engineering

Uploaded by

brpnaidu21570 ratings0% found this document useful (0 votes)

11 views2 pagesdesign

Original Title

What is Reverse Engineering

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdesign

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesWhat Is Reverse Engineering

What Is Reverse Engineering

Uploaded by

brpnaidu2157design

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

What Is Reverse Engineering?

Engineering is the profession involved in designing, manufacturing, constructing,

and maintaining of products, systems, and structures. At a higher level, there are

two types of engineering: forward engineering and reverse engineering.

Forward engineering is the traditional process of moving from high-level

abstractions and logical designs to the physical implementation of a system. In

some situations, there may be a physical part without any technical details, such

as drawings, bills-of-material, or without engineering data, such as thermal and

electrical properties.

The process of duplicating an existing component, subassembly, or product,

without the aid of drawings, documentation, or computer model is known as

reverse engineering.

Reverse engineering can be viewed as the process of analyzing a system to:

1. Identify the system's components and their interrelationships

2. Create representations of the system in another form or a higher level of

abstraction

3. Create the physical representation of that system

Reverse engineering is very common in such diverse fields as software

engineering, entertainment, automotive, consumer products, microchips,

chemicals, electronics, and mechanical designs. For example, when a new

machine comes to market, competing manufacturers may buy one machine and

disassemble it to learn how it was built and how it works. A chemical company

may use reverse engineering to defeat a patent on a competitor's manufacturing

process. In civil engineering, bridge and building designs are copied from past

successes so there will be less chance of catastrophic failure. In software

engineering, good source code is often a variation of other good source code.

In some situations, designers give a shape to their ideas by using clay, plaster,

wood, or foam rubber, but a CAD model is needed to enable the manufacturing

of the part. As products become more organic in shape, designing in CAD may be

challenging or impossible. There is no guarantee that the CAD model will be

acceptably close to the sculpted model. Reverse engineering provides a solution

to this problem because the physical model is the source of information for the

CAD model. This is also referred to as the part-to-CAD process.

Another reason for reverse engineering is to compress product development

times. In the intensely competitive global market, manufacturers are constantly

seeking new ways to shorten lead-times to market a new product. Rapid product

development (RPD) refers to recently developed technologies and techniques

that assist manufacturers and designers in meeting the demands of reduced

product development time. For example, injection-molding companies must

drastically reduce the tool and die development times. By using reverse

engineering, a three-dimensional product or model can be quickly captured in

digital form, re-modeled, and exported for rapid prototyping/tooling or rapid

manufacturing.

Following are reasons for reverse engineering a part or product:

1. The original manufacturer of a product no longer produces a product

2. There is inadequate documentation of the original design

3. The original manufacturer no longer exists, but a customer needs the

product

4. The original design documentation has been lost or never existed

5. Some bad features of a product need to be designed out. For example,

excessive wear might indicate where a product should be improved

6. To strengthen the good features of a product based on long-term usage of

the product

7. To analyze the good and bad features of competitors' product

8. To explore new avenues to improve product performance and features

9. To gain competitive benchmarking methods to understand competitor's

products and develop better products

10.The original CAD model is not sufficient to support modifications or current

manufacturing methods

11.The original supplier is unable or unwilling to provide additional parts

12.The original equipment manufacturers are either unwilling or unable to

supply replacement parts, or demand inflated costs for sole-source parts

13.To update obsolete materials or antiquated manufacturing processes with

more current, less-expensive technologies

Reverse engineering enables the duplication of an existing part by capturing the

component's physical dimensions, features, and material properties. Before

attempting reverse engineering, a well-planned life-cycle analysis and

cost/benefit analysis should be conducted to justify the reverse engineering

projects. Reverse engineering is typically cost effective only if the items to be

reverse engineered reflect a high investment or will be reproduced in large

quantities. Reverse engineering of a part may be attempted even if it is not cost

effective, if the part is absolutely required and is mission-critical to a system.

Reverse engineering of mechanical parts involves acquiring three-dimensional

position data in the point cloud using laser scanners or computed tomography

(CT). Representing geometry of the part in terms of surface points is the first

step in creating parametric surface patches. A good polymesh is created from

the point cloud using reverse engineering software. The cleaned-up polymesh,

NURBS (Non-uniform rational B-spline) curves, or NURBS surfaces are exported to

CAD packages for further refinement, analysis, and generation of cutter tool

paths for CAM. Finally, the CAM produces the physical part.

It can be said that reverse engineering begins with the product and works

through the design process in the opposite direction to arrive at a product

definition statement (PDS). In doing so, it uncovers as much information as

possible about the design ideas that were used to produce a particular product.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- As TronicDocument100 pagesAs TronicJunior da Silva91% (11)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Scarab Mistral Parts Book CANbus 2 ModelsDocument241 pagesScarab Mistral Parts Book CANbus 2 ModelsScarab SweepersNo ratings yet

- BRE Constructing The Future Magazine - 44Document16 pagesBRE Constructing The Future Magazine - 44aynoneemouseNo ratings yet

- Siting Policy - 2016 - 30-6-2016 - 4Document8 pagesSiting Policy - 2016 - 30-6-2016 - 4Babla SNo ratings yet

- Stone Matrix AsphaltDocument17 pagesStone Matrix AsphaltLilaNo ratings yet

- PM 305Document1 pagePM 305Anonymous oiEpknyRnNo ratings yet

- Nokia 5G Connected Homes Ebook EN PDFDocument12 pagesNokia 5G Connected Homes Ebook EN PDFMohamed Abdel MonemNo ratings yet

- Generator ClassDocument93 pagesGenerator ClassSam100% (6)

- ACBDocument29 pagesACBtafseerahmedNo ratings yet

- Purchase History AnalysisDocument570 pagesPurchase History AnalysisSAHR SAIFNo ratings yet

- Plumbing and Pipe FittingDocument94 pagesPlumbing and Pipe Fittingalex54550% (2)

- 07 - 373 - Salib, Abdel-Sayed - Dynamic Behaviour and Seismic Response of FRP Light Poles in High SeismDocument8 pages07 - 373 - Salib, Abdel-Sayed - Dynamic Behaviour and Seismic Response of FRP Light Poles in High SeismAnonymous EVM4dONo ratings yet

- Architects in Bangalore House Residential Architects in Bangalore at Architects4DesignDocument28 pagesArchitects in Bangalore House Residential Architects in Bangalore at Architects4DesignNaveen BansalNo ratings yet

- A Study On Foamed Concrete With Silica Fume and Polypropylene FibersDocument3 pagesA Study On Foamed Concrete With Silica Fume and Polypropylene FibersDeepthyNo ratings yet

- g1 - Gym HighbayDocument5 pagesg1 - Gym HighbayjackNo ratings yet

- Marking Gauge Plan PDFDocument8 pagesMarking Gauge Plan PDFEucap MdzNo ratings yet

- Et STM32F103 PDFDocument25 pagesEt STM32F103 PDFabd01111100% (2)

- THU32Document16 pagesTHU32Roman CorralesNo ratings yet

- Business Proposal On ZeppelinDocument11 pagesBusiness Proposal On ZeppelinvijayNo ratings yet

- Mini Hydal Power PlantDocument18 pagesMini Hydal Power PlantNoufalNo ratings yet

- AW101 Utility PDFDocument24 pagesAW101 Utility PDFtomay777100% (1)

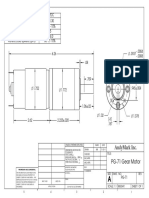

- PG71 Layout Am 0914Document1 pagePG71 Layout Am 0914Roberto ServinNo ratings yet

- ST TST: Automatic Sliding Door SystemsDocument36 pagesST TST: Automatic Sliding Door SystemsEddy Suyono ArchitectsNo ratings yet

- Prestige Falcon City Kanakapura Road BangaloreDocument40 pagesPrestige Falcon City Kanakapura Road BangaloreJaipalreddy PropladderNo ratings yet

- Maritime Technical DictionaryDocument5 pagesMaritime Technical DictionaryDefensor Del Marino MercanteNo ratings yet

- Sigmacover 456: Overcoating table for dft up to 150 μmDocument2 pagesSigmacover 456: Overcoating table for dft up to 150 μmEngTamerNo ratings yet

- HSR Basic Rate 2018Document10 pagesHSR Basic Rate 2018R A P RathnaseeliNo ratings yet

- Heat Transfer Equipment PDFDocument71 pagesHeat Transfer Equipment PDFDinesh KulkarniNo ratings yet

- Commissioning of Lighting Systems2Document20 pagesCommissioning of Lighting Systems2Cassandra StapelbergNo ratings yet

- Cyclone Ventilador para Parking PDFDocument2 pagesCyclone Ventilador para Parking PDFAlex EstacioNo ratings yet