Professional Documents

Culture Documents

Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen Hall

Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen Hall

Uploaded by

SMBEAUTYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen Hall

Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen Hall

Uploaded by

SMBEAUTYCopyright:

Available Formats

Chapter 11: Refrigeration

Rules of Thumb for Chemical Engineers, 5th Edition

by Stephen Hall

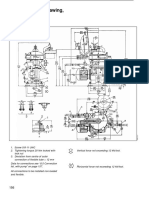

MECHANICAL REFRIGERATION SYSTEM

REV

0

1

2

1

2

3

4

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

PREPARED BY

DATE

APPROVAL

CLIENT

EQUIP. NO

PAGE

W.O.

REQUISITION NO.

SPECIFICATION NO.

PROCURED BY

INSTALLED BY

UNIT

AREA

Service Conditions

Capacity

Tons

Manufacturer

Compressor Suction

Condenser Refrigerant Flow

Cooling Water Supply

Cooling Water Requirement

Evaporator Refrigerant

Evaporator Process Fluid

Compressor Driver provided by

Refrigerant

Process Fluid

Model

psig

psig

Temperature Control

Level Controls (specify):

Pressure Gages:

lb/h

Discharge

Maximum gpm

F

F inlet

Driver type

hp

Condenser

Evaporator

Tubes

Number

Tube Sheet

Furnished by

Tubes

Number

Tube Sheet

F

F exit

psig

psig

rpm

Specifications

Instruments & Controls

Elec. Area Classification

Connections (flange type):

Connection Sizes, inch

Inlet

Outlet

Condenser Cooling Water

Refrigerant to Evaporator

Suction Cross Exchanger

Compressor Suction

Compressor Discharge

Steam Supply

Power Supplies

Driver

Fouling Factors for

Cooling Water

Condenser Tube Water Velocity Limits

Refrigerant Charge

psig

lb/h

F

F exit

lb/h

F outlet

IP Code

Class/Group/Div

Flanges

Rating, psig

Face

N/A

N/A

psig

F

V/Ph/Hz

Instruments

ft-h-F/Btu

Process Fluid

ft/s

to

lb

V/Ph/Hz

ft-h-F/Btu

ft/s

Materials of Construction

OD

inch

Tube Wall

Length

ft

Pitch

Channel

BWG

BWG

OD

Length

BWG

BWG

inch

ft

Tube Wall

Pitch

Channel

Notes

1. Vendor to specify make and model for flow, temperature, and pressure control valves; hand valves;

thermometers and steam traps; electrical components; and miscellaneous equipment and components.

STEAM JET REFRIGERATION SYSTEM

REV

0

1

2

1

2

3

4

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

PREPARED BY

DATE

APPROVAL

CLIENT

EQUIP. NO

PAGE

W.O.

REQUISITION NO.

SPECIFICATION NO.

PROCURED BY

INSTALLED BY

UNIT

Type

Chilled Water

Supply

Make-Up Water

Booster Jet Stream

(a)

(b)

Secondary Jet Stream

(a)

(b)

Cooling Water

psig

Fouling Factor for Water

Capacity:

lb/h

lb/h

lb/h

lb/h

lb/h

F

AREA

Service Conditions

tons | Manufacturer

F

Return

lb/h

psig

psig

psig

psig

Primary Condenser:

Secondary Condenser:

Model:

lb/h

F

F

F

F

F

lb/h

lb/h

F exit

F exit

ft-h-F/Btu

Specifications

Steam Hand Valves provided by:

Level Controls (specify):

Pressure Gages:

Connections (flange type):

Connection Sizes, inch

Inlet

Outlet

Flanges

Rating, psig

Face

Flash Tank Chilled Water

Make-Up Water

Primary Condenser Steam

Secondary Condenser Steam

Primary Condenser Cooling Water

Secondary Condenser Cooling Water

Condenser Tube Water Velocity Limits

Flash Tank

Booster Ejector Nozzle

Primary

Tubes

Number

Tube Sheet

Surf Condenser Furnished by

Tubes

Number

Barometric Primary Condenser

Shell

Baffles

Spray Noz

ft/s

to

ft/s

Materials of Construction

Corr Allw

Barometric Leg

Secondary Ejector Nozzles

OD

inch

Tube Wall

Length

ft

Pitch

Channel

OD

Length

Corr Allw

Corr Allw

No.

inch

Tube Wall

ft

Pitch

Barometric After Condenser

Shell

Baffles

Spray Noz

Corr Allw

BWG

BWG

BWG

BWG

Corr Allw

Corr Allw

No.

Notes

1. Vendor to specify make and model for flow, temperature, and pressure control valves; hand valves;

thermometers and steam traps; electrical components; and miscellaneous equipment and components.

2. Flexibility (determines number of booster jets):

3. Temperature extremes and durations of cooling water:

4. Closed or open circuit cooling water:

5. Pumps (by Vendor or Owner; discharge heads if applicable):

6. Space limitations:

7. Cost of utilities (if Vendor required to do economic analysis):

You might also like

- Air Compressor Data SheetDocument6 pagesAir Compressor Data SheetdgmprabhakarNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Control Valve Data SheetDocument2 pagesControl Valve Data SheetRSNo ratings yet

- Datasheet AcDocument9 pagesDatasheet AcMohan VarkeyNo ratings yet

- Refrigeration Process DataDocument2 pagesRefrigeration Process DataDavid LambertNo ratings yet

- English Unit Spec SheetDocument3 pagesEnglish Unit Spec SheetDanang PrakosaNo ratings yet

- WPI-KE-1104-SP141-QM5433 (Datasheet)Document4 pagesWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémNo ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- Technical Comparison Format - Process Gas Reciprocating CompressorDocument11 pagesTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- InstruCalc Relief Device SizingDocument1 pageInstruCalc Relief Device SizinggeorgD2010100% (1)

- Data Sheet Pressure Relief ValveDocument10 pagesData Sheet Pressure Relief ValveAnonymous UArnIExNo ratings yet

- Orifice Plate: Data / Requisition Sheet ForDocument2 pagesOrifice Plate: Data / Requisition Sheet ForhasnacuNo ratings yet

- HD - Planta de PVCDocument7 pagesHD - Planta de PVCDavid LapacaNo ratings yet

- Air Cooled Data SheetDocument1 pageAir Cooled Data SheethuangjlNo ratings yet

- Control Valve DatasheetDocument2 pagesControl Valve DatasheetRahul DevaNo ratings yet

- Sizing Calculation of General Service PumpsDocument193 pagesSizing Calculation of General Service Pumpsmkha87No ratings yet

- Safety Relief Valve DatasheetDocument1 pageSafety Relief Valve Datasheetalmandhari330% (1)

- 11 - RefrigerationDocument4 pages11 - RefrigerationMuzzamil ShahzadNo ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallzhyhhNo ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallMuzzamil ShahzadNo ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallAslamNo ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallJamil AhmedNo ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen Hallojasmainkar123No ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallReza SaeeNo ratings yet

- Geothermal Powerplant Separator, Scrubber and Brine Disposal SystemDocument2 pagesGeothermal Powerplant Separator, Scrubber and Brine Disposal SystemVilla VallejosNo ratings yet

- Boiler SpecificationDocument18 pagesBoiler SpecificationAtul Jain100% (3)

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarNo ratings yet

- VRF PD Series Outdoor Unit Type GMV-PD: Air Conditioning and HeatpumpsDocument3 pagesVRF PD Series Outdoor Unit Type GMV-PD: Air Conditioning and Heatpumpsdino_pNo ratings yet

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658No ratings yet

- Product Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberDocument6 pagesProduct Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberMWBABARNo ratings yet

- Indirect Fired HeaterDocument2 pagesIndirect Fired HeaterJoshua CollierNo ratings yet

- Heat Exchanger Specification Sheet: in FT FT Performance of One UnitDocument10 pagesHeat Exchanger Specification Sheet: in FT FT Performance of One UnitAnonymous Wd2KONNo ratings yet

- DAT Centrifugal PumpDocument5 pagesDAT Centrifugal PumpEDUARDONo ratings yet

- Heat Exhanger DataDocument2 pagesHeat Exhanger DataEDUARDONo ratings yet

- 674 Reciprocating Pump DatasheetsDocument6 pages674 Reciprocating Pump DatasheetsAKSHEYMEHTANo ratings yet

- PSV Sizing (Steam)Document2 pagesPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Data Sheet: Hydraulic Power UnitDocument3 pagesData Sheet: Hydraulic Power UnitEDUARDONo ratings yet

- 42GWC New CatalogueDocument12 pages42GWC New CataloguehakankeNo ratings yet

- Fuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetDocument3 pagesFuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetZulfikar N JoelNo ratings yet

- Ventiloconvectoare CITIZEN 2011Document6 pagesVentiloconvectoare CITIZEN 2011office8200No ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- 145B9973 - Off Base Piping List of Lines PDFDocument4 pages145B9973 - Off Base Piping List of Lines PDFHumayun NawazNo ratings yet

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocument7 pages13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNo ratings yet

- Process Presentation Shell and Tube Heat Exchanger GalfarDocument84 pagesProcess Presentation Shell and Tube Heat Exchanger GalfarKishore Sakhile100% (1)

- Hoja de Datos API-674Document5 pagesHoja de Datos API-674texwan_No ratings yet

- APNEA-J-DSH-0002 Rev. 1Document3 pagesAPNEA-J-DSH-0002 Rev. 1Michelle MartinezNo ratings yet

- Control ValveDocument1 pageControl ValveAjay TiwariNo ratings yet

- Pipe Specification Doniambo: Max MaxDocument3 pagesPipe Specification Doniambo: Max MaxHMMSPNo ratings yet

- Indirect Fired HeaterDocument3 pagesIndirect Fired Heatermatteo2009No ratings yet

- Thermal Design Calculation Procedure (Rev 00)Document24 pagesThermal Design Calculation Procedure (Rev 00)mkfe2005No ratings yet

- Heat Exchanger Spec SheetDocument1 pageHeat Exchanger Spec SheetAnnabellee ChuaNo ratings yet

- Gas Conditioning System Specification Sheet: Process InformationDocument3 pagesGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHNo ratings yet

- 2749 - Carrier 30 GH 095Document16 pages2749 - Carrier 30 GH 095Mohammad Amer100% (2)

- LG Therma V MonoblocDocument47 pagesLG Therma V MonoblocMuhidin KozicaNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocument9 pagesInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairNo ratings yet

- Spring-Supported Thrust BearingsDocument4 pagesSpring-Supported Thrust BearingsZoebairNo ratings yet

- Structures and Mechanisms ClassificationsDocument1 pageStructures and Mechanisms ClassificationsminakirolosNo ratings yet

- Installation and Operating Procedures: Manual Grease InterceptorsDocument8 pagesInstallation and Operating Procedures: Manual Grease InterceptorsZoebairNo ratings yet

- Datasheet TurbineDocument2 pagesDatasheet TurbineZoebairNo ratings yet

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Document1 page8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairNo ratings yet

- Indigenous ManufacturersDocument6 pagesIndigenous ManufacturersZoebairNo ratings yet

- Pennsylvania: Lehigh University'Document5 pagesPennsylvania: Lehigh University'ZoebairNo ratings yet

- Construction Specification 71-Water Control Gates: Instructions For UseDocument2 pagesConstruction Specification 71-Water Control Gates: Instructions For UseZoebairNo ratings yet

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocument7 pagesCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairNo ratings yet

- Hy 25 ValvesDocument3 pagesHy 25 ValvesZoebairNo ratings yet

- DAMS CFD ModellingDocument2 pagesDAMS CFD ModellingZoebairNo ratings yet