Professional Documents

Culture Documents

A 915

A 915

Uploaded by

gustavofx210 ratings0% found this document useful (0 votes)

11 views8 pagescompresor

Original Title

a915

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcompresor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views8 pagesA 915

A 915

Uploaded by

gustavofx21compresor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

A915

Installation Instructions

FLEX I/O

Spring Clamp Terminal Base

(Cat. No. 1794-TB3S)

Component Identification

Female flexbus connector

Terminal base unit

Male flexbus connector

Keyswitch ~ Setto the position required for the installed module

input/output terminal strip for connecting inputfoutput

Terminal strip for inputloutput commons

[Terminal stip forpowerconnecions = =SSSCSC~S~S

Locking tab

10 [Moduelockingiatch SSS~—~S

1

=|

TI

|

“6 _[ Mounting holes for panel mounting

~e |

TI

“ef

oI

‘over plug for male flexbus connector

FLEX 0 is a trademark of Allen-Bradley Co. Ine. Publication 1794-5.42 - June 1996

2 FLEX /0 Spring Clamp Terminal Base

European Union Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union or EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards. in

whole or in part, documented in a technical construction file:

© EN 50081-2

EMC - Generic Emission Standard, Part 2 - Industrial Environment

© EN 50082-2

EMC - Generic Immunity Standard, Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 6131-2 Programmable

Controllers, Part 2 ~ Equipment Requirements and Tests.

For specific information required by EN 6131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications

© Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

© Guidelines for Handling Lithium Batteries, publication AG-5.4

© Automation Systems Catalog, publication B11

Publication 1794-5,42 - June1996

FLEX I]O Spring Clamp Terminal Base 3

Mounting on a DIN Rail

ATTENTION: Do not remove or replace a terminal base unit

when power is applied. Interruption of the flexbus can result in

unintended operation or machine motion.

1.

uw

3

Remove the cover plug (if used) in the male connector of the unit to

which you are connecting this terminal base unit

Check to make sure that the 16 pins in the male connector on the

adjacent device are straight and in line so that the mating female

connector on this terminal base unit will mate correctly.

Position the terminal base on the 35 x 7.5mm DIN rail A (A-B pt. no.

199-DR1; 4627-3; EN 50022) at a slight angle with hook B on the

left side of the terminal base hooked into the right side of the unit on

the left.

Make certain that the female flexbus connector C is fully retracted

into the base unit.

Rotate the terminal base onto the DIN rail with the top of the rail

hooked under the lip on the rear of the terminal base. Use caution to

make sure that the female flexbus connector does not strike any of

the pins in the mating male connector.

Publication 1794-5.42 - June 1996

FLEX |/O Spring Clamp Terminal Base

6. Press the terminal base down onto the DIN rail until flush. The

locking tab D snaps into position and locks the terminal base to the

DIN rail.

7. If the terminal base does not lock in place, use a screwdriver or

similar device to move the locking tab down, press the terminal base

flush with the DIN rail and release the locking tab to lock the base in

place,

8. Gently push the female flexbus connector C into the adjacent

terminal base or adapter male connector to complete the flexbus

connections

9. For specific wiring information, refer to the installation instructions

for the module you are installing in this terminal base unit.

10. Repeat the above steps to install the next terminal base.

Wiring

ote ass e7eomnwiuwis | RowA

161710 1920 21 22 maa4 25 28 27 28 290 31223] AoWB

395 96 97 98 09 40 412 49 4 45.48 47 48-49 5051] RoW

Label placed at top of wiring area,

To connect wiring, insert a blade-type screwdriver with a blade width of

0.100-0.120in, (2.54~-3.0Smm) into the slot above the selected wiring port

and lift up. Insert the wire while holding the screwdriver up. Release the

upward screwdriver pressure to secure the wire.

Publication 1794-5.42 - June1996

FLEX UO Spring Clamp Terminal Base

ATTENTION: Total current draw through the terminal base unit

is limited to 10A. Separate power connections may be necessary.

Daisy-chaining

2avec Note: All modules must be analog modules for this configuration,

‘Wiring when total current draw is less than 108

Individual

| ar | ones,

24V de

24 door

120V ae

Note: Use this configuration if using any

ade “noisy’ de discrete YO modules in your system,

‘Thermocouple Modu wig Separate am cre wg,

Wiring when total current draw is greater than 108

Combination

Note: Alfmodules powered by the sare power supply

rust be analog modules for this confguaion,

Total current draw through any base unit must not be greater than 10A

Publication 179¢-5.42 - June 1996

FLEX 1/0 Spring Clamp Terminal Base

6

{4 s2as6op 1¢1) 9 s20,60p g po2oxe ou snus

4e0 ne ungua amyerodwi, Suyesedg = 9

40) suojsuawup ayoy 6

‘Arana hprewpxoudde yes nig aunoag

(a69 x mvs x Hye (069 x Mv6 x Hes) (69 x Meg x Hz8)

| aN te. GLX EX HEE arexMee x Hee,

f ‘ealnee! | zaLveut avi

_ _ (g9)

r os ve >|

— I

=| (ea)

__ 7 ¥e

eo 8 (08)

.

mammals

eo

ee | (siajouN)

lv | seyou

Publication 1794-542 - June1996

FLEX /O Spring Clamp Terminal Base

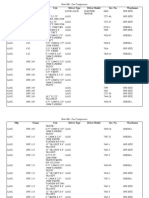

1794-TB3S Specifications

Number of Terminals

Terminal Type

Dimensions (with module installed

in base)

Inches

(Milimeters)

Current Capacity

Voltage Rating

Isolation Voltage

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Shock Operating

Non-operating

Vibration

Conductors Wire Size

Category

‘Agency Certification

(when product or packaging is

marked)

Trow of 16

2rows of 18

Spring-type clamp - To open, insert bladed

screwdriver (0,100-0.120in/2.54-3, 05mm wide) into

slot and lift up.

3.7HxX3.7Wx27D

(94H x 94W x 69D}

10A maximum

192V ac maximum

‘Channe-to-channel isolation determined by

inserted module

Oto 55°C (32 to 131°F}

40 to 85°C (-40 to 185°F]

'5to 95% noncondensing

30 g peak acceleration, 11(+1)ms pulse width

50 g peak acceleration, 11(t)ms pulse width

Tested 5 g @ 10-500Hz per IEC 68-2-6

12 gauge (4mm?) stranded maximum

64 neh (1.2mm insulation masimum

2

+ CSAcerified

+ CSA Class I, Division 2,

Groups A, B, C, D certified

+ ULiisted

‘CE marked forall applicable directives

1 You use this conductor category information for planning conductor routing

as described in the system level installation maral

Publication 1794-5,42 ~ June 1996

FLEX I]O Spring Clamp Terminal Base

@ Rockwell Automation

Allen-Bradley

With major offices Wo, SS

World Headquarters, Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204 USA

Tel (1) 414 982-2000 Fax: (1) 414 982-4444

Publication 1794-5.42 - June 1996 PN955124-35

Cane 196 Aan Base Carpe. Patesin USA

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Force Feed Lubricator Pump: PrimingDocument2 pagesForce Feed Lubricator Pump: Priminggustavofx21No ratings yet

- Woodward Mechanical TG Governor PDFDocument52 pagesWoodward Mechanical TG Governor PDFgustavofx21No ratings yet

- Proflo Jr. No-Flow SwitchDocument3 pagesProflo Jr. No-Flow Switchgustavofx21No ratings yet

- Rino KK - Gas CompressorsDocument20 pagesRino KK - Gas Compressorsgustavofx21No ratings yet

- CATERPILLAR 3516 TA Parts 1 PrelubricadoraDocument2 pagesCATERPILLAR 3516 TA Parts 1 Prelubricadoragustavofx21No ratings yet

- Demo 24x3ringDocument20 pagesDemo 24x3ringgustavofx21No ratings yet

- Recommended Maintenance Intervals For Continuous Duty Reciprocating CompressorsDocument7 pagesRecommended Maintenance Intervals For Continuous Duty Reciprocating Compressorsgustavofx21No ratings yet

- Ariel-Er-105 1 1Document9 pagesAriel-Er-105 1 1gustavofx21No ratings yet

- Cómo Probar Un ReléDocument15 pagesCómo Probar Un Relégustavofx21No ratings yet

- Diagramas Electricos VHP ESMDocument12 pagesDiagramas Electricos VHP ESMgustavofx21100% (1)

- U 134Document2 pagesU 134gustavofx21No ratings yet

- Psu 2 PDFDocument2 pagesPsu 2 PDFgustavofx21No ratings yet

- P 172Document2 pagesP 172gustavofx21No ratings yet

- P 172Document2 pagesP 172gustavofx21No ratings yet

- York Centrifugal M PamphletDocument8 pagesYork Centrifugal M Pamphletgustavofx21No ratings yet

- H 276Document46 pagesH 276gustavofx21No ratings yet

- HG 12 SeriesDocument2 pagesHG 12 Seriesgustavofx21No ratings yet