0% found this document useful (0 votes)

524 views1 pageBasic Explanation & Schematic View - Injection Moulding Process

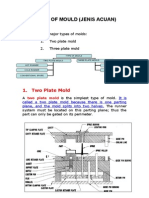

The injection moulding process involves 4 main stages: (1) plastic material is melted and injected into a closed metal mould tool under pressure, (2) the molten plastic cools and hardens inside the mould, (3) the tool is held closed under pressure until the plastic fully sets, (4) the tool then opens and the finished part is ejected to begin the next cycle. The process continuously melts, injects, cools and ejects plastic to form parts.

Uploaded by

NazriCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

524 views1 pageBasic Explanation & Schematic View - Injection Moulding Process

The injection moulding process involves 4 main stages: (1) plastic material is melted and injected into a closed metal mould tool under pressure, (2) the molten plastic cools and hardens inside the mould, (3) the tool is held closed under pressure until the plastic fully sets, (4) the tool then opens and the finished part is ejected to begin the next cycle. The process continuously melts, injects, cools and ejects plastic to form parts.

Uploaded by

NazriCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd