Professional Documents

Culture Documents

Properties of Different Manmade Fibre

Uploaded by

saikat550 ratings0% found this document useful (0 votes)

44 views2 pagesthis paper helps to differentiate among the various man made fibre

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentthis paper helps to differentiate among the various man made fibre

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views2 pagesProperties of Different Manmade Fibre

Uploaded by

saikat55this paper helps to differentiate among the various man made fibre

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

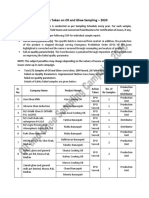

Properties of different manmade fibre

Properties Acetate Elastomeric Nylon Polyester Viscose

i. Polymer Secondary cellulose 85% segmented Polyhexa methylene diamine Polyethylene glycol Regenerated

acetate polyurethane and adipic acid terephthalate cellulose

ii. Dimension Short Long Short Short Short

iii. Approximate length 160 nm Un unavailable 90-140 nm 120-150nm 180nm

iv. Approximate thickness 2.3nm 0.7 nm 0.3 nm 0.6nm 0.8nm

v. Degree of

130 unavailable 50 to 80 115-140 175

polymerization

vi. Polymer system Very amorphous Extremely amorphous Very crystalline Extremely crystalline Very amorphous

vii. Amorphous region (%) 60 - 35-15 35-15 65-60

viii. Crystalline region (%) 40 - 65-85 65-85 35-40

ix. Tenacity Very weak Very weak Strong to very strong Strong to very strong Fair

x. Elastic plastic nature Plastic Extremely elastic Elastic More elastic than plastic Plastic

xi. Elongation and 2 5 10 15 20 5 10 20 50 2 5 10 15 20 2 4 5 8 10 2 3 10 15 20

corresponding

Elastic recovery (%) 94 73 39 27 23 100 100 100 95 100 98 90 82 75 97 95 87 89 77 82 52 40 34 30

xii. Moisture regain

percentage

At 65% RH 6.5-9.0 % 0.4-1.3% 4.0-4.5% 0.1-0.3% 12-14%

At 95% RH 13.0-16.0% Unavailable 6.0% 0.4% 25-30%

At 100% RH 18% 3.0% 8.0% 0.4% 45%

xiii. Thermal properties Extremely heat Extremely heat

Heat sensitive Heat sensitive Heat sensitive

sensitive sensitive

xiv. Melting point 260˚c 230˚c 250-260˚c 250-260˚c Does not melt

xv. Decomposition begin Un available Un available 315˚c Un available 270˚c

You might also like

- EndocrinologyDocument23 pagesEndocrinologysaikat55No ratings yet

- Trade PaymentsDocument29 pagesTrade Paymentssaikat55No ratings yet

- Winch Dyeing MachineDocument8 pagesWinch Dyeing MachineUsama KhanNo ratings yet

- Volumetric and Viscometric Study OfnDocument14 pagesVolumetric and Viscometric Study Ofnsaikat55No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Water Quality Index Determination of Malathalli LakeDocument16 pagesWater Quality Index Determination of Malathalli Lakeajay kumar hrNo ratings yet

- Course Guide Pe1 PDFDocument4 pagesCourse Guide Pe1 PDFrahskkNo ratings yet

- Coarse DispersionsDocument35 pagesCoarse Dispersionsraju narayana padala0% (1)

- Key ScientificDocument4 pagesKey ScientificGarrettNo ratings yet

- Operational Safety and Health Procedures, Practices and RegulationsDocument20 pagesOperational Safety and Health Procedures, Practices and RegulationsDionisa ErnacioNo ratings yet

- Blood DonationDocument19 pagesBlood DonationsuruthiNo ratings yet

- Astm B633Document5 pagesAstm B633nisha_khan100% (1)

- Action Taken On Oil and Ghee Sampling - 2020Document2 pagesAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiNo ratings yet

- Overall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Document6 pagesOverall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Ganapathi RajNo ratings yet

- Nodular Goiter Concept MapDocument5 pagesNodular Goiter Concept MapAllene PaderangaNo ratings yet

- Classification of Nanostructured Materials: June 2019Document44 pagesClassification of Nanostructured Materials: June 2019krishnaNo ratings yet

- Social Style InventoryDocument12 pagesSocial Style InventoryMaheshwari JaniNo ratings yet

- Kingdom of AnimaliaDocument6 pagesKingdom of AnimaliaBen ZerepNo ratings yet

- Constipation Treatment For Infants and ChildrenDocument2 pagesConstipation Treatment For Infants and Childrenapi-559575515No ratings yet

- Aluminium - Hull Structure in Naval ApplicationsDocument6 pagesAluminium - Hull Structure in Naval ApplicationsStefano CostaNo ratings yet

- 21A Solenoid Valves Series DatasheetDocument40 pages21A Solenoid Valves Series Datasheetportusan2000No ratings yet

- 8 Categories of Lipids: FunctionsDocument3 pages8 Categories of Lipids: FunctionsCaryl Alvarado SilangNo ratings yet

- NCR RepairDocument4 pagesNCR RepairPanruti S SathiyavendhanNo ratings yet

- (Engine International Air Pollution Prevention) : EIAPP CertificateDocument2 pages(Engine International Air Pollution Prevention) : EIAPP CertificateTan DatNo ratings yet

- Test On QuantifiersDocument1 pageTest On Quantifiersvassoula35No ratings yet

- Schedule NDocument3 pagesSchedule Nmittal kelaNo ratings yet

- Emerging Re-Emerging Infectious Disease 2022Document57 pagesEmerging Re-Emerging Infectious Disease 2022marioNo ratings yet

- Hospital - Data Collection & Literature StudyDocument42 pagesHospital - Data Collection & Literature StudyNagateja MallelaNo ratings yet

- DeMeo HERETIC'S NOTEBOOK: Emotions, Protocells, Ether-Drift and Cosmic Life Energy: With New Research Supporting Wilhelm ReichDocument6 pagesDeMeo HERETIC'S NOTEBOOK: Emotions, Protocells, Ether-Drift and Cosmic Life Energy: With New Research Supporting Wilhelm ReichOrgone Biophysical Research Lab50% (2)

- Metabolism of Carbohydrates and LipidsDocument7 pagesMetabolism of Carbohydrates and LipidsKhazel CasimiroNo ratings yet

- Ra Concrete Chipping 7514Document5 pagesRa Concrete Chipping 7514Charles DoriaNo ratings yet

- TCJ Series: TCJ Series - Standard and Low Profile - J-LeadDocument14 pagesTCJ Series: TCJ Series - Standard and Low Profile - J-LeadgpremkiranNo ratings yet

- Index Medicus PDFDocument284 pagesIndex Medicus PDFVania Sitorus100% (1)

- Hamraki Rag April 2010 IssueDocument20 pagesHamraki Rag April 2010 IssueHamraki RagNo ratings yet

- Form - Pelaporan B3Document16 pagesForm - Pelaporan B3sukma nugraNo ratings yet