0% found this document useful (0 votes)

445 views2 pagesQuality Assurance SOP for Plastic Products

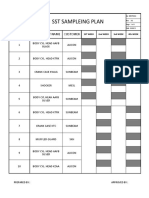

This document is a quality assurance standard operating procedure (SOP) from Vishal Plastic Industries for conducting an acceptable quality limit (AQL) test on a plastic product lot. The SOP details the 13 test parameters to check, including material, dimensions, packaging, and defects. It also specifies the sampling plan and defines critical, major and minor defects. The conclusion will either approve the lot for storage/shipping or treat it as "hold" if it fails specification.

Uploaded by

a_chrjCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

445 views2 pagesQuality Assurance SOP for Plastic Products

This document is a quality assurance standard operating procedure (SOP) from Vishal Plastic Industries for conducting an acceptable quality limit (AQL) test on a plastic product lot. The SOP details the 13 test parameters to check, including material, dimensions, packaging, and defects. It also specifies the sampling plan and defines critical, major and minor defects. The conclusion will either approve the lot for storage/shipping or treat it as "hold" if it fails specification.

Uploaded by

a_chrjCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd