Professional Documents

Culture Documents

Highlights of ISO 9001 2008 Changes Subodh Hegde

Highlights of ISO 9001 2008 Changes Subodh Hegde

Uploaded by

SUBODHHCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Highlights of ISO 9001 2008 Changes Subodh Hegde

Highlights of ISO 9001 2008 Changes Subodh Hegde

Uploaded by

SUBODHHCopyright:

Available Formats

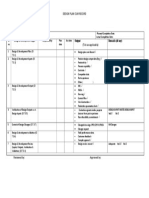

HIGHLIGHTS OF ISO 9001:2008 CHANGES

1. ISO 9001:2008 Version released in Nov 2008.

2. The Standard can be used for assessment of meeting organization’s capability to meet

customer, Statutory, regulatory requirements related to the product apart from

organizational requirements.

3. Purchase, Quality (Clause 4.1) : Control of outsourced processes (including Job work)

need to be elaborately detailed in the Quality Management system (QMS) including type

and extent of control:

a) Criteria for Selection, Evaluation of Supplier / service provider of outsourced

processes with related records such as supplier approval form, supplier evaluation

report.

b) Job-work Quality Plan

c) Inspection records of receipt of material after job work processing

d) Annual Maintenance Contract /Job work order

e) Service visit report of service provider

f) Visit report to job-worker

4. Documentation requirements-MR (Clause 4.2.1)- Multiple procedures /documents

can be combined into one and vice versa.

5. Document Control (Clause 4.2.3): External documents related to planning and

operation of QMS need to be determined.

6. Mgt Representative -MR (Clause 5.5.2)- Mgt Representative should be member of

organization’s own management.

7. Human resources –HR- (Clause 6.2.2)-Competency of personnel performing work

directly or indirectly affecting conformity to product requirements need to be identified.

Training should be provided to achieve the necessary competence.

8. Infrastructure –Admin (Clause 6.3)- Information systems-Computer controls

/Electronic data controls included.

9. Work environment-Admin (Clause 6.4)-Requirements made more elaborate such as

Temperature, noise, lighting, humidity controls.

10. Customer related processes-Marketing (Clause 7.2)- The post-delivery (Warranty,

etc) activities should be covered under contract review process.

11. Design-(Clause 7.3) - Design Review, Verification and Validation can be combined or

conducted separately as appropriate.

Packing requirements need to be considered during design output.

12. Identification and traceability-Production-(Clause 7.5.3)-Product identification

should be maintained throughout Production cycle.

13. Control of monitoring and measuring equipment-Calibration-(Clause 7.6)-

Computer software, if used for monitoring and measurement will be confirmed for ability

to satisfy intended application.

14. Customer Satisfaction-Marketing-(Clause 8.2.1)-Sources of customer feedback to

include Lost business analysis, customer appreciation, warranty claims, dealer reports,

customer data on product Quality.

15. Monitoring and measurement of product-Quality (Clause 8.2.4)-Records should

indicate person authorizing release of product for delivery to customer.

16. Corrective and preventive action-Clause 8.5.2, 8.5.3-Effectiveness of corrective

action and preventive action should be reviewed.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHHNo ratings yet

- Mould Trial ReportDocument5 pagesMould Trial ReportSUBODHH0% (1)

- Mobile Policy: When Sim + Mobile Allotted To EmployeeDocument5 pagesMobile Policy: When Sim + Mobile Allotted To EmployeeSUBODHHNo ratings yet

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHH0% (1)

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHH100% (1)

- Fta Checklist Group NV 7-6-09Document7 pagesFta Checklist Group NV 7-6-09initiative1972No ratings yet

- Part 1 - Unit 7 of 7 Procedures, Analysis, Conclusions, and DocumentationDocument14 pagesPart 1 - Unit 7 of 7 Procedures, Analysis, Conclusions, and DocumentationMuhammad Shahzad KhanNo ratings yet

- Art - Fashion Design Concepts and LessonDocument18 pagesArt - Fashion Design Concepts and LessonRalucaFlorentina100% (2)

- Process Change NoteDocument1 pageProcess Change NoteSUBODHHNo ratings yet

- 4M Change Management FormatDocument1 page4M Change Management FormatSUBODHH100% (2)

- Cs 403 Software Engineering Jun 2020Document3 pagesCs 403 Software Engineering Jun 2020Majid KhanNo ratings yet

- Designing Classroom Language Tests Chapter 3Document9 pagesDesigning Classroom Language Tests Chapter 3Yamith J. Fandiño100% (7)

- Iso 9001 Clause ChartDocument2 pagesIso 9001 Clause ChartSUBODHHNo ratings yet

- PMBOK (Project Management Body of Knowledge)Document8 pagesPMBOK (Project Management Body of Knowledge)Hari Purwadi0% (1)

- Macroergonomics For Manufacturing Systems - An Evaluation Approach PDFDocument235 pagesMacroergonomics For Manufacturing Systems - An Evaluation Approach PDFDario DorkoNo ratings yet

- Unit 17. ULC - Assignment - 17BMDocument7 pagesUnit 17. ULC - Assignment - 17BMSơn BadGuyNo ratings yet

- LABELS SmallDocument6 pagesLABELS SmallSUBODHHNo ratings yet

- Electric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderDocument7 pagesElectric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderSUBODHHNo ratings yet

- Performance Assessment and Review Admin and Accounts ManagersDocument3 pagesPerformance Assessment and Review Admin and Accounts ManagersSUBODHHNo ratings yet

- Performance Appraisal Managers-Performance LinkedDocument1 pagePerformance Appraisal Managers-Performance LinkedSUBODHHNo ratings yet

- Leave Application Form: SL CL Half Day LeaveDocument1 pageLeave Application Form: SL CL Half Day LeaveSUBODHHNo ratings yet

- Fire Response PlanDocument1 pageFire Response PlanSUBODHHNo ratings yet

- Leave Travel Allowance Claim LTADocument1 pageLeave Travel Allowance Claim LTASUBODHHNo ratings yet

- Performance Appraisal ManagersDocument1 pagePerformance Appraisal ManagersSUBODHHNo ratings yet

- Name of Company: Sub: Application For LeaveDocument2 pagesName of Company: Sub: Application For LeaveSUBODHHNo ratings yet

- Kaizen ReportDocument1 pageKaizen ReportSUBODHHNo ratings yet

- Customer Feedback SummaryDocument1 pageCustomer Feedback SummarySUBODHHNo ratings yet

- Enquiry Register Cum Job Tracker: Page No.Document1 pageEnquiry Register Cum Job Tracker: Page No.SUBODHHNo ratings yet

- Design Plan Cum Record: Output Remarks (If Any)Document1 pageDesign Plan Cum Record: Output Remarks (If Any)SUBODHHNo ratings yet

- Vision MissionDocument1 pageVision MissionSUBODHHNo ratings yet

- Manpower PlanningDocument7 pagesManpower PlanningSUBODHHNo ratings yet

- Evaluation of Neighbours, Friends & FamiliesDocument55 pagesEvaluation of Neighbours, Friends & FamiliesKevin Anthony OndunaNo ratings yet

- Call Fail CauseDocument16 pagesCall Fail CauseFirman FiversNo ratings yet

- Performance Appraisal - Orient ELECTRICALS (1) MansoorDocument71 pagesPerformance Appraisal - Orient ELECTRICALS (1) MansoorNisha AggarwalNo ratings yet

- Dr. Joshi AssignDocument14 pagesDr. Joshi Assignmrudula phuleNo ratings yet

- 8615 1Document15 pages8615 1Shaf Alam100% (1)

- Exam 1Document1 pageExam 1Marisza E. H.No ratings yet

- What Is The EFQM ModelDocument5 pagesWhat Is The EFQM ModelHeba HemdanNo ratings yet

- Evaluating Learning FactsheetDocument8 pagesEvaluating Learning FactsheetCristian IlincaNo ratings yet

- Lessons LearnedDocument8 pagesLessons LearnedHarryTendulkarNo ratings yet

- March 2017 (v2) MS - Paper 2 CIE Biology IGCSE PDFDocument3 pagesMarch 2017 (v2) MS - Paper 2 CIE Biology IGCSE PDFSELVAKUMAR SNo ratings yet

- Coleman Lew + Assoc. - Response To Director of Schools Search RFPDocument20 pagesColeman Lew + Assoc. - Response To Director of Schools Search RFPDan LehrNo ratings yet

- Slo Template - ShortDocument2 pagesSlo Template - Shortapi-255141801No ratings yet

- NCBSSH e FormDocument59 pagesNCBSSH e FormDaryll Anne LagtaponNo ratings yet

- BaguioDocument32 pagesBaguiomahallah4126No ratings yet

- Course Code: MTOE10 Course Title: Non Destructive Testing and Failure Analysis Number of Credits 3 Prerequisites (Course Code) : Nil Course Type: Oe Course Learning ObjectivesDocument1 pageCourse Code: MTOE10 Course Title: Non Destructive Testing and Failure Analysis Number of Credits 3 Prerequisites (Course Code) : Nil Course Type: Oe Course Learning ObjectivesNags DevaNo ratings yet

- Meter Centimeter 1Document2 pagesMeter Centimeter 1Vani Nathan50% (4)

- Course Outline PSYC 1070Document12 pagesCourse Outline PSYC 1070Ahmed ZeybNo ratings yet

- Food Technology PDFDocument28 pagesFood Technology PDFMin ChongNo ratings yet

- 0580 Mathematics: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of TeachersDocument4 pages0580 Mathematics: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of TeachersMustufa KhalilNo ratings yet

- 0610 BIOLOGY: MARK SCHEME For The May/June 2015 SeriesDocument2 pages0610 BIOLOGY: MARK SCHEME For The May/June 2015 Seriesmath magicNo ratings yet

- Table of Specification and Its Relevance in Educational Development AssessmentDocument17 pagesTable of Specification and Its Relevance in Educational Development AssessmentFikri Mosleh75% (4)

- E Street LightingDocument32 pagesE Street LightingHrushikesh DushiNo ratings yet