Professional Documents

Culture Documents

EssarSteel HR CR Brochure

Uploaded by

Anonymous D2GXdEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EssarSteel HR CR Brochure

Uploaded by

Anonymous D2GXdECopyright:

Available Formats

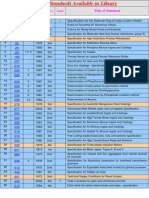

Some prominent grades that Essar specialises in:

Indian International

Hot Rolled Products Standards Standards

JIS G3131

Cold Rolling IS 11513 ASTM A569 Harnessing world-class technology

BS 1449

Deep Drawing IS 1079 JIS G 3132 4 -150 tonne DC Eectric Arc Furnaces - Clecim, France

ASTM A621 4 - 150 tonne Ladle Furnaces - Davy, United Kingdom

Corrosion Resistance IRSM 41 JIS G 3125 1- 150 tonne Vacuum Degasser - Standard Messo, Germany

ASTM A588 3 - Single Strand Slab Casting Machines - Mannesmann DemagAG, Germany

EN 10155 S

Hot Strip Mill Mechanicals - SMS Schloemann Siemag Engineering, USA

Boiler Quality IS 2002 JIS G 3103

Hot Strip Mill Electricals and Automation - General Electric, USA

ASTM 515 / 516

ASTM A537 2 Reheating Furnace - Stein Heurty, France Essar Steel Limited

Hot Skinpass Mill - Clecim, France

General Engg fabrication IS 5986 JIS 3101

IS 8500 EN 10025 3 Shearing Lines - Bronx, UK ; SMS, USA

IS 2062 ASTM A36, 53, 283

2 Slitting Lines - Bronx, UK

Pipes & tubes IS 10748 API Specification 6 Hi Reversible Cold rolling mill - Hitachi, Japan

IS 10748 SAE 1008

4 Hi Continous Tandom Mill - VAI Clecim, France

Automobile JIS G 3113 Auto Cut to length line - FIMI, ITALY

SAPH 310-340

QSTE 340-380 DMS Slitting cum recoiling line - DMS

EN 10149

LIR Inspection cum trimming line - LIR

Product Form - Coils, Plates, Sheets ¥ Thickness - 1.60-20 mm Batch Annealing furnace - LOI, Germany

¥ Width - 180-2000 mm ¥ Length - 2000-12000 mm

Skin pass mill for CR unit - VAI Clecim, France

Cold Rolled Products Skin pass mill for galvanizing line - BWG, Germany

Furnace for galvanising line - Selas, France

Commercial Quality IS 513 Gr O ASTM A-366

JIS SPCC Tension leveler for galvanising line - Herrvoss, USA

Drawing IS 513 Gr D BS CR - 4

ASTM A - 619

JIS SPCD

Deep Drawing IS 513 GR DD BS CR - 3

ASTM A - 620

JIS SPCD

Extra Deep Drawing IS 513 GR EDD CR - 2 / CR - 1

ASTM - 620 Marketing Head Office

JIS SPCEN Essar House, 11, K.K. Marg,

Super EDD IF IF

Mahalaxmi, Mumbai 400 034.

Toll Free : 1800 22 5105 (for MTNL and BSNL Subscriber)

Product Form - Coils, Sheets ¥ Thickness - 0.14-3.2 mm

¥ Width - 200-1625 mm ¥ Length - 600-4800 mm 6000 9595 (add Local STD code when dialing

from your mobile phone)

Galvanised Products

Email : steel@essar.com

Commercial Quality IS 277 Gr CQ / O BS 2989 Z1

Website : www.essarsteel.com

Drawing IS 277 Gr D ASTM CS - A, B, C

JIS 3302 SGCC

Deep Drawing IS 277 Gr DD ASTM FS - A, B

SMS

JIS 3302 SGCD 1

Steel to 53636

Extra Deep Drawing IS 277 Gr EDD ASTM DDS

JIS 3302 SGCD 2

Extra Deep Drawing IS 277 Gr EDD ASTM EDDS www.essarsteel.com

(Al Killed) JIS 3302 SGCD 3

Product Form - Coils, Sheets ¥ Thickness - 0.15-3.2 mm

¥ Width - 600-1370 mm ¥ Length - up to 4800 mm

Essar_6 Page Brochiour Outside_Close Size:11" x 8"_06/08/05_dtp8/cp

A Tradition of Excellence Quality that the World Approves

Integrating processes further downstream, the plant is equipped with some of the finest technologies.The complex houses a 1.3 MTPA

HRPO (Hot Rolled Pickled and Oiled) facility, 0.9 MTPA Cold Rolling and 0.5 MTPA Galvanising lines for catering to value-based customers. What makes Essar Steel the world’s preferred steel maker is the wide product range

Essar Steel is part of the Essar Group, a key player in several core sector

The state-of-the-art service centre includes India's only Hot Skin Pass mill of 1.2 MTPA capacity along with Shearing and Slitting lines that is completely customisable to unique customer needs along with flexible

industries such as Steel, Power, Shipping, Telecommunications, BPO, Oil and

capable of handling capacities of 0.6 MTPA and 0.4 MTPA respectively. Moreover, PT Essar Indonesia - Essar's 0.4 MTPA cold rolling and 0.15 delivery options.

Gas and Constructions. With an asset base of over Rs. 200 billion (US$ 4.4

MTPA galvanising facility in Jakarta - adds international muscle to Essar Steel. Essar Steel’s strong standing in domestic and international markets

billion) in businesses that are at the heart of the Indian economy, Essar is an

All the processes, from raw material acquisition to its downstream processes, come together in a perfectly synchronised, yet flexible is also due to its lofty quality standards. Ever the leader, Essar Steel

important contributor to the country's infrastructure.

integration that makes Essar Steel a low-cost and customer-focussed steel producer. With products ranging from hot rolled coils, plates and was the first integrated steel plant in the country to obtain the

Essar Steel - A Versatile Steel Producer prestigious ISO 9001 for all operations. In addition, it was the first

sheets to normalised, galvanised and shot blasted steel, Essar Steel truly sets the gold standard in steel.

Indian steel plant to achieve the ISO 14001 accreditation for

Essar Steel, the group’s flagship company, has emerged a fully-

Strategic Location Environmental Management System.

integrated steel major. With its robust chain of production and

From its location on the West Coast, about 260-kms north of Mumbai, Essar Steel has a Obviously, quality-driven processes would only create products that surpass

downstream processes, Essar Steel has raised itself above the rest –

major advantage with respect to the inward movement of raw materials and the outbound international quality standards as well. Certifications for its products include Lloyds

making 24 Carat Steel the benchmark of quality steel for its

movement of finished goods.The captive port – capable of handling 6 MTPA of cargo Register (UK) for exports, IRS (Indian Registrar of Shipping), DNV, ABS, TUV, BIS

customers.

annually – is loaded with facilities like sea-going floating cranes, articulated barges and other (Bureau of Indian Standards), OITC and IBR (Indian Boiler Regulation Act).

Essar Steel’s cutting-edge Midi Mill technology enables unmatched

versatility and greater flexibility in its processes, thus ensuring marine equipment.

The 24 Carat Edge

excellent product quality and a higher level of product customisation. A

The Technological Advantage To develop a unique identity and differentiate its products, Essar Steel launched

blend of sophisticated automation levels and an inspired workforce has

Essar Steel employs the world’s most advanced technology from the best equipment 24-Carat Steel, the first branded steel of its kind in India. 24 Carat Steel defines the

helped it emerge as one of the most productive and cost-efficient mills the

suppliers. Its many firsts include an indigenous Hot DRI charging system, the largest DC core properties of Essar Steel as well as the total offering from the company in

world over. All this while, being one of the most environment-friendly

electric-powered steel plant and India’s first Continuous Tandem Cold Mill (CTCM). terms of product quality, standards, delivery systems and customer service.

manufacturing facilities in the steel world.

Level II automation aided by one of the largest ERP installations in India by SAP and an 24 Carat Steel today finds application in diverse specialised and demanding

An Integrated Steel Giant industries – from general engineering to automotive and shipbuilding.

Integrated Marketing and Production System (IMPS) from UEC of USA make Essar Steel

Essar Steel’s dominion begins at its iron ore beneficiation plant in Bailadila, completely future-ready.

Chhattisgarh. Refining iron ore to its purest form for use at its steel mill, the

Answering the World's Need for Steel

iron ore slurry is transported along a 267km-long slurry pipeline – the 2nd

longest in the world – through very difficult terrain, to the pellet-making With technology that surpasses global benchmarks, Essar Steel produces grades that many Indian steel mills can only aspire to.The market

facility in Visakhapatnam. Here, Essar Steel’s 4 MTPA pelletisation leader in many niche segments in the domestic market, Essar Steel is one of the leading

plant (en-route to being augmented to 8 MTPA) produces iron ore suppliers for pipelines, automobile manufacturers, construction and other sophisticated

pellets for use at the steel complex.The pelletisation plant, situated industries, as it provides a competitively priced, yet superior quality, alternative to high-

at a natural all-weather port, facilitates low-cost transportation of grade imports.

In the international market, Essar Steel is positioned alongside prime European and Superior production processes, world-class technology and a committed workforce

the raw material to Essar Steel’s complex at Hazira.

Japanese steel producers. Little surprise then, that Essar Steel is the largest exporter of flat has helped Essar Steel develop value-added steel and placed the

This port-based complex houses the world’s largest Hot Briquetted

products from India. Moreover, Essar Steel is a leading supplier of API grade steel in the world for pipelines in the oil & gas sector, having company in the league of a select few world-class steel

Iron (HBI) plant of 3.4 million tonnes per annum (MTPA) capacity

helped create pipelines that stretch 8500kms across 5 continents. manufacturers - thus casting the 24 Carat promise in concrete.

that feeds a state-of-the-art steel mill which has a capacity of 3 MTPA.

Essar_6 Page Brochiour Inside_Close Size:11" x 8"_06/08/05_dtp8/cp

Some prominent grades that Essar specialises in:

Indian International

Hot Rolled Products Standards Standards

JIS G3131

Cold Rolling IS 11513 ASTM A569 Harnessing world-class technology

BS 1449

Deep Drawing IS 1079 JIS G 3132 4 -150 tonne DC Eectric Arc Furnaces - Clecim, France

ASTM A621 4 - 150 tonne Ladle Furnaces - Davy, United Kingdom

Corrosion Resistance IRSM 41 JIS G 3125 1- 150 tonne Vacuum Degasser - Standard Messo, Germany

ASTM A588 3 - Single Strand Slab Casting Machines - Mannesmann DemagAG, Germany

EN 10155 S

Hot Strip Mill Mechanicals - SMS Schloemann Siemag Engineering, USA

Boiler Quality IS 2002 JIS G 3103

Hot Strip Mill Electricals and Automation - General Electric, USA

ASTM 515 / 516

ASTM A537 2 Reheating Furnace - Stein Heurty, France Essar Steel Limited

Hot Skinpass Mill - Clecim, France

General Engg fabrication IS 5986 JIS 3101

IS 8500 EN 10025 3 Shearing Lines - Bronx, UK ; SMS, USA

IS 2062 ASTM A36, 53, 283

2 Slitting Lines - Bronx, UK

Pipes & tubes IS 10748 API Specification 6 Hi Reversible Cold rolling mill - Hitachi, Japan

IS 10748 SAE 1008

4 Hi Continous Tandom Mill - VAI Clecim, France

Automobile JIS G 3113 Auto Cut to length line - FIMI, ITALY

SAPH 310-340

QSTE 340-380 DMS Slitting cum recoiling line - DMS

EN 10149

LIR Inspection cum trimming line - LIR

Product Form - Coils, Plates, Sheets ¥ Thickness - 1.60-20 mm Batch Annealing furnace - LOI, Germany

¥ Width - 180-2000 mm ¥ Length - 2000-12000 mm

Skin pass mill for CR unit - VAI Clecim, France

Cold Rolled Products Skin pass mill for galvanizing line - BWG, Germany

Furnace for galvanising line - Selas, France

Commercial Quality IS 513 Gr O ASTM A-366

JIS SPCC Tension leveler for galvanising line - Herrvoss, USA

Drawing IS 513 Gr D BS CR - 4

ASTM A - 619

JIS SPCD

Deep Drawing IS 513 GR DD BS CR - 3

ASTM A - 620

JIS SPCD

Extra Deep Drawing IS 513 GR EDD CR - 2 / CR - 1

ASTM - 620 Marketing Head Office

JIS SPCEN Essar House, 11, K.K. Marg,

Super EDD IF IF

Mahalaxmi, Mumbai 400 034.

Toll Free : 1800 22 5105 (for MTNL and BSNL Subscriber)

Product Form - Coils, Sheets ¥ Thickness - 0.14-3.2 mm

¥ Width - 200-1625 mm ¥ Length - 600-4800 mm 6000 9595 (add Local STD code when dialing

from your mobile phone)

Galvanised Products

Email : steel@essar.com

Commercial Quality IS 277 Gr CQ / O BS 2989 Z1

Website : www.essarsteel.com

Drawing IS 277 Gr D ASTM CS - A, B, C

JIS 3302 SGCC

Deep Drawing IS 277 Gr DD ASTM FS - A, B

SMS

JIS 3302 SGCD 1

Steel to 53636

Extra Deep Drawing IS 277 Gr EDD ASTM DDS

JIS 3302 SGCD 2

Extra Deep Drawing IS 277 Gr EDD ASTM EDDS www.essarsteel.com

(Al Killed) JIS 3302 SGCD 3

Product Form - Coils, Sheets ¥ Thickness - 0.15-3.2 mm

¥ Width - 600-1370 mm ¥ Length - up to 4800 mm

Essar_6 Page Brochiour Outside_Close Size:11" x 8"_06/08/05_dtp8/cp

A Tradition of Excellence Quality that the World Approves

Integrating processes further downstream, the plant is equipped with some of the finest technologies.The complex houses a 1.3 MTPA

HRPO (Hot Rolled Pickled and Oiled) facility, 0.9 MTPA Cold Rolling and 0.5 MTPA Galvanising lines for catering to value-based customers. What makes Essar Steel the world’s preferred steel maker is the wide product range

Essar Steel is part of the Essar Group, a key player in several core sector

The state-of-the-art service centre includes India's only Hot Skin Pass mill of 1.2 MTPA capacity along with Shearing and Slitting lines that is completely customisable to unique customer needs along with flexible

industries such as Steel, Power, Shipping, Telecommunications, BPO, Oil and

capable of handling capacities of 0.6 MTPA and 0.4 MTPA respectively. Moreover, PT Essar Indonesia - Essar's 0.4 MTPA cold rolling and 0.15 delivery options.

Gas and Constructions. With an asset base of over Rs. 200 billion (US$ 4.4

MTPA galvanising facility in Jakarta - adds international muscle to Essar Steel. Essar Steel’s strong standing in domestic and international markets

billion) in businesses that are at the heart of the Indian economy, Essar is an

All the processes, from raw material acquisition to its downstream processes, come together in a perfectly synchronised, yet flexible is also due to its lofty quality standards. Ever the leader, Essar Steel

important contributor to the country's infrastructure.

integration that makes Essar Steel a low-cost and customer-focussed steel producer. With products ranging from hot rolled coils, plates and was the first integrated steel plant in the country to obtain the

Essar Steel - A Versatile Steel Producer prestigious ISO 9001 for all operations. In addition, it was the first

sheets to normalised, galvanised and shot blasted steel, Essar Steel truly sets the gold standard in steel.

Indian steel plant to achieve the ISO 14001 accreditation for

Essar Steel, the group’s flagship company, has emerged a fully-

Strategic Location Environmental Management System.

integrated steel major. With its robust chain of production and

From its location on the West Coast, about 260-kms north of Mumbai, Essar Steel has a Obviously, quality-driven processes would only create products that surpass

downstream processes, Essar Steel has raised itself above the rest –

major advantage with respect to the inward movement of raw materials and the outbound international quality standards as well. Certifications for its products include Lloyds

making 24 Carat Steel the benchmark of quality steel for its

movement of finished goods.The captive port – capable of handling 6 MTPA of cargo Register (UK) for exports, IRS (Indian Registrar of Shipping), DNV, ABS, TUV, BIS

customers.

annually – is loaded with facilities like sea-going floating cranes, articulated barges and other (Bureau of Indian Standards), OITC and IBR (Indian Boiler Regulation Act).

Essar Steel’s cutting-edge Midi Mill technology enables unmatched

versatility and greater flexibility in its processes, thus ensuring marine equipment.

The 24 Carat Edge

excellent product quality and a higher level of product customisation. A

The Technological Advantage To develop a unique identity and differentiate its products, Essar Steel launched

blend of sophisticated automation levels and an inspired workforce has

Essar Steel employs the world’s most advanced technology from the best equipment 24-Carat Steel, the first branded steel of its kind in India. 24 Carat Steel defines the

helped it emerge as one of the most productive and cost-efficient mills the

suppliers. Its many firsts include an indigenous Hot DRI charging system, the largest DC core properties of Essar Steel as well as the total offering from the company in

world over. All this while, being one of the most environment-friendly

electric-powered steel plant and India’s first Continuous Tandem Cold Mill (CTCM). terms of product quality, standards, delivery systems and customer service.

manufacturing facilities in the steel world.

Level II automation aided by one of the largest ERP installations in India by SAP and an 24 Carat Steel today finds application in diverse specialised and demanding

An Integrated Steel Giant industries – from general engineering to automotive and shipbuilding.

Integrated Marketing and Production System (IMPS) from UEC of USA make Essar Steel

Essar Steel’s dominion begins at its iron ore beneficiation plant in Bailadila, completely future-ready.

Chhattisgarh. Refining iron ore to its purest form for use at its steel mill, the

Answering the World's Need for Steel

iron ore slurry is transported along a 267km-long slurry pipeline – the 2nd

longest in the world – through very difficult terrain, to the pellet-making With technology that surpasses global benchmarks, Essar Steel produces grades that many Indian steel mills can only aspire to.The market

facility in Visakhapatnam. Here, Essar Steel’s 4 MTPA pelletisation leader in many niche segments in the domestic market, Essar Steel is one of the leading

plant (en-route to being augmented to 8 MTPA) produces iron ore suppliers for pipelines, automobile manufacturers, construction and other sophisticated

pellets for use at the steel complex.The pelletisation plant, situated industries, as it provides a competitively priced, yet superior quality, alternative to high-

at a natural all-weather port, facilitates low-cost transportation of grade imports.

In the international market, Essar Steel is positioned alongside prime European and Superior production processes, world-class technology and a committed workforce

the raw material to Essar Steel’s complex at Hazira.

Japanese steel producers. Little surprise then, that Essar Steel is the largest exporter of flat has helped Essar Steel develop value-added steel and placed the

This port-based complex houses the world’s largest Hot Briquetted

products from India. Moreover, Essar Steel is a leading supplier of API grade steel in the world for pipelines in the oil & gas sector, having company in the league of a select few world-class steel

Iron (HBI) plant of 3.4 million tonnes per annum (MTPA) capacity

helped create pipelines that stretch 8500kms across 5 continents. manufacturers - thus casting the 24 Carat promise in concrete.

that feeds a state-of-the-art steel mill which has a capacity of 3 MTPA.

Essar_6 Page Brochiour Inside_Close Size:11" x 8"_06/08/05_dtp8/cp

Some prominent grades that Essar specialises in:

Indian International

Hot Rolled Products Standards Standards

JIS G3131

Cold Rolling IS 11513 ASTM A569 Harnessing world-class technology

BS 1449

Deep Drawing IS 1079 JIS G 3132 4 -150 tonne DC Eectric Arc Furnaces - Clecim, France

ASTM A621 4 - 150 tonne Ladle Furnaces - Davy, United Kingdom

Corrosion Resistance IRSM 41 JIS G 3125 1- 150 tonne Vacuum Degasser - Standard Messo, Germany

ASTM A588 3 - Single Strand Slab Casting Machines - Mannesmann DemagAG, Germany

EN 10155 S

Hot Strip Mill Mechanicals - SMS Schloemann Siemag Engineering, USA

Boiler Quality IS 2002 JIS G 3103

Hot Strip Mill Electricals and Automation - General Electric, USA

ASTM 515 / 516

ASTM A537 2 Reheating Furnace - Stein Heurty, France Essar Steel Limited

Hot Skinpass Mill - Clecim, France

General Engg fabrication IS 5986 JIS 3101

IS 8500 EN 10025 3 Shearing Lines - Bronx, UK ; SMS, USA

IS 2062 ASTM A36, 53, 283

2 Slitting Lines - Bronx, UK

Pipes & tubes IS 10748 API Specification 6 Hi Reversible Cold rolling mill - Hitachi, Japan

IS 10748 SAE 1008

4 Hi Continous Tandom Mill - VAI Clecim, France

Automobile JIS G 3113 Auto Cut to length line - FIMI, ITALY

SAPH 310-340

QSTE 340-380 DMS Slitting cum recoiling line - DMS

EN 10149

LIR Inspection cum trimming line - LIR

Product Form - Coils, Plates, Sheets ¥ Thickness - 1.60-20 mm Batch Annealing furnace - LOI, Germany

¥ Width - 180-2000 mm ¥ Length - 2000-12000 mm

Skin pass mill for CR unit - VAI Clecim, France

Cold Rolled Products Skin pass mill for galvanizing line - BWG, Germany

Furnace for galvanising line - Selas, France

Commercial Quality IS 513 Gr O ASTM A-366

JIS SPCC Tension leveler for galvanising line - Herrvoss, USA

Drawing IS 513 Gr D BS CR - 4

ASTM A - 619

JIS SPCD

Deep Drawing IS 513 GR DD BS CR - 3

ASTM A - 620

JIS SPCD

Extra Deep Drawing IS 513 GR EDD CR - 2 / CR - 1

ASTM - 620 Marketing Head Office

JIS SPCEN Essar House, 11, K.K. Marg,

Super EDD IF IF

Mahalaxmi, Mumbai 400 034.

Toll Free : 1800 22 5105 (for MTNL and BSNL Subscriber)

Product Form - Coils, Sheets ¥ Thickness - 0.14-3.2 mm

¥ Width - 200-1625 mm ¥ Length - 600-4800 mm 6000 9595 (add Local STD code when dialing

from your mobile phone)

Galvanised Products

Email : steel@essar.com

Commercial Quality IS 277 Gr CQ / O BS 2989 Z1

Website : www.essarsteel.com

Drawing IS 277 Gr D ASTM CS - A, B, C

JIS 3302 SGCC

Deep Drawing IS 277 Gr DD ASTM FS - A, B

SMS

JIS 3302 SGCD 1

Steel to 53636

Extra Deep Drawing IS 277 Gr EDD ASTM DDS

JIS 3302 SGCD 2

Extra Deep Drawing IS 277 Gr EDD ASTM EDDS www.essarsteel.com

(Al Killed) JIS 3302 SGCD 3

Product Form - Coils, Sheets ¥ Thickness - 0.15-3.2 mm

¥ Width - 600-1370 mm ¥ Length - up to 4800 mm

Essar_6 Page Brochiour Outside_Close Size:11" x 8"_06/08/05_dtp8/cp

A Tradition of Excellence Quality that the World Approves

Integrating processes further downstream, the plant is equipped with some of the finest technologies.The complex houses a 1.3 MTPA

HRPO (Hot Rolled Pickled and Oiled) facility, 0.9 MTPA Cold Rolling and 0.5 MTPA Galvanising lines for catering to value-based customers. What makes Essar Steel the world’s preferred steel maker is the wide product range

Essar Steel is part of the Essar Group, a key player in several core sector

The state-of-the-art service centre includes India's only Hot Skin Pass mill of 1.2 MTPA capacity along with Shearing and Slitting lines that is completely customisable to unique customer needs along with flexible

industries such as Steel, Power, Shipping, Telecommunications, BPO, Oil and

capable of handling capacities of 0.6 MTPA and 0.4 MTPA respectively. Moreover, PT Essar Indonesia - Essar's 0.4 MTPA cold rolling and 0.15 delivery options.

Gas and Constructions. With an asset base of over Rs. 200 billion (US$ 4.4

MTPA galvanising facility in Jakarta - adds international muscle to Essar Steel. Essar Steel’s strong standing in domestic and international markets

billion) in businesses that are at the heart of the Indian economy, Essar is an

All the processes, from raw material acquisition to its downstream processes, come together in a perfectly synchronised, yet flexible is also due to its lofty quality standards. Ever the leader, Essar Steel

important contributor to the country's infrastructure.

integration that makes Essar Steel a low-cost and customer-focussed steel producer. With products ranging from hot rolled coils, plates and was the first integrated steel plant in the country to obtain the

Essar Steel - A Versatile Steel Producer prestigious ISO 9001 for all operations. In addition, it was the first

sheets to normalised, galvanised and shot blasted steel, Essar Steel truly sets the gold standard in steel.

Indian steel plant to achieve the ISO 14001 accreditation for

Essar Steel, the group’s flagship company, has emerged a fully-

Strategic Location Environmental Management System.

integrated steel major. With its robust chain of production and

From its location on the West Coast, about 260-kms north of Mumbai, Essar Steel has a Obviously, quality-driven processes would only create products that surpass

downstream processes, Essar Steel has raised itself above the rest –

major advantage with respect to the inward movement of raw materials and the outbound international quality standards as well. Certifications for its products include Lloyds

making 24 Carat Steel the benchmark of quality steel for its

movement of finished goods.The captive port – capable of handling 6 MTPA of cargo Register (UK) for exports, IRS (Indian Registrar of Shipping), DNV, ABS, TUV, BIS

customers.

annually – is loaded with facilities like sea-going floating cranes, articulated barges and other (Bureau of Indian Standards), OITC and IBR (Indian Boiler Regulation Act).

Essar Steel’s cutting-edge Midi Mill technology enables unmatched

versatility and greater flexibility in its processes, thus ensuring marine equipment.

The 24 Carat Edge

excellent product quality and a higher level of product customisation. A

The Technological Advantage To develop a unique identity and differentiate its products, Essar Steel launched

blend of sophisticated automation levels and an inspired workforce has

Essar Steel employs the world’s most advanced technology from the best equipment 24-Carat Steel, the first branded steel of its kind in India. 24 Carat Steel defines the

helped it emerge as one of the most productive and cost-efficient mills the

suppliers. Its many firsts include an indigenous Hot DRI charging system, the largest DC core properties of Essar Steel as well as the total offering from the company in

world over. All this while, being one of the most environment-friendly

electric-powered steel plant and India’s first Continuous Tandem Cold Mill (CTCM). terms of product quality, standards, delivery systems and customer service.

manufacturing facilities in the steel world.

Level II automation aided by one of the largest ERP installations in India by SAP and an 24 Carat Steel today finds application in diverse specialised and demanding

An Integrated Steel Giant industries – from general engineering to automotive and shipbuilding.

Integrated Marketing and Production System (IMPS) from UEC of USA make Essar Steel

Essar Steel’s dominion begins at its iron ore beneficiation plant in Bailadila, completely future-ready.

Chhattisgarh. Refining iron ore to its purest form for use at its steel mill, the

Answering the World's Need for Steel

iron ore slurry is transported along a 267km-long slurry pipeline – the 2nd

longest in the world – through very difficult terrain, to the pellet-making With technology that surpasses global benchmarks, Essar Steel produces grades that many Indian steel mills can only aspire to.The market

facility in Visakhapatnam. Here, Essar Steel’s 4 MTPA pelletisation leader in many niche segments in the domestic market, Essar Steel is one of the leading

plant (en-route to being augmented to 8 MTPA) produces iron ore suppliers for pipelines, automobile manufacturers, construction and other sophisticated

pellets for use at the steel complex.The pelletisation plant, situated industries, as it provides a competitively priced, yet superior quality, alternative to high-

at a natural all-weather port, facilitates low-cost transportation of grade imports.

In the international market, Essar Steel is positioned alongside prime European and Superior production processes, world-class technology and a committed workforce

the raw material to Essar Steel’s complex at Hazira.

Japanese steel producers. Little surprise then, that Essar Steel is the largest exporter of flat has helped Essar Steel develop value-added steel and placed the

This port-based complex houses the world’s largest Hot Briquetted

products from India. Moreover, Essar Steel is a leading supplier of API grade steel in the world for pipelines in the oil & gas sector, having company in the league of a select few world-class steel

Iron (HBI) plant of 3.4 million tonnes per annum (MTPA) capacity

helped create pipelines that stretch 8500kms across 5 continents. manufacturers - thus casting the 24 Carat promise in concrete.

that feeds a state-of-the-art steel mill which has a capacity of 3 MTPA.

Essar_6 Page Brochiour Inside_Close Size:11" x 8"_06/08/05_dtp8/cp

Some prominent grades that Essar specialises in:

Indian International

Hot Rolled Products Standards Standards

JIS G3131

Cold Rolling IS 11513 ASTM A569 Harnessing world-class technology

BS 1449

Deep Drawing IS 1079 JIS G 3132 4 -150 tonne DC Eectric Arc Furnaces - Clecim, France

ASTM A621 4 - 150 tonne Ladle Furnaces - Davy, United Kingdom

Corrosion Resistance IRSM 41 JIS G 3125 1- 150 tonne Vacuum Degasser - Standard Messo, Germany

ASTM A588 3 - Single Strand Slab Casting Machines - Mannesmann DemagAG, Germany

EN 10155 S

Hot Strip Mill Mechanicals - SMS Schloemann Siemag Engineering, USA

Boiler Quality IS 2002 JIS G 3103

Hot Strip Mill Electricals and Automation - General Electric, USA

ASTM 515 / 516

ASTM A537 2 Reheating Furnace - Stein Heurty, France Essar Steel Limited

Hot Skinpass Mill - Clecim, France

General Engg fabrication IS 5986 JIS 3101

IS 8500 EN 10025 3 Shearing Lines - Bronx, UK ; SMS, USA

IS 2062 ASTM A36, 53, 283

2 Slitting Lines - Bronx, UK

Pipes & tubes IS 10748 API Specification 6 Hi Reversible Cold rolling mill - Hitachi, Japan

IS 10748 SAE 1008

4 Hi Continous Tandom Mill - VAI Clecim, France

Automobile JIS G 3113 Auto Cut to length line - FIMI, ITALY

SAPH 310-340

QSTE 340-380 DMS Slitting cum recoiling line - DMS

EN 10149

LIR Inspection cum trimming line - LIR

Product Form - Coils, Plates, Sheets ¥ Thickness - 1.60-20 mm Batch Annealing furnace - LOI, Germany

¥ Width - 180-2000 mm ¥ Length - 2000-12000 mm

Skin pass mill for CR unit - VAI Clecim, France

Cold Rolled Products Skin pass mill for galvanizing line - BWG, Germany

Furnace for galvanising line - Selas, France

Commercial Quality IS 513 Gr O ASTM A-366

JIS SPCC Tension leveler for galvanising line - Herrvoss, USA

Drawing IS 513 Gr D BS CR - 4

ASTM A - 619

JIS SPCD

Deep Drawing IS 513 GR DD BS CR - 3

ASTM A - 620

JIS SPCD

Extra Deep Drawing IS 513 GR EDD CR - 2 / CR - 1

ASTM - 620 Marketing Head Office

JIS SPCEN Essar House, 11, K.K. Marg,

Super EDD IF IF

Mahalaxmi, Mumbai 400 034.

Toll Free : 1800 22 5105 (for MTNL and BSNL Subscriber)

Product Form - Coils, Sheets ¥ Thickness - 0.14-3.2 mm

¥ Width - 200-1625 mm ¥ Length - 600-4800 mm 6000 9595 (add Local STD code when dialing

from your mobile phone)

Galvanised Products

Email : steel@essar.com

Commercial Quality IS 277 Gr CQ / O BS 2989 Z1

Website : www.essarsteel.com

Drawing IS 277 Gr D ASTM CS - A, B, C

JIS 3302 SGCC

Deep Drawing IS 277 Gr DD ASTM FS - A, B

SMS

JIS 3302 SGCD 1

Steel to 53636

Extra Deep Drawing IS 277 Gr EDD ASTM DDS

JIS 3302 SGCD 2

Extra Deep Drawing IS 277 Gr EDD ASTM EDDS www.essarsteel.com

(Al Killed) JIS 3302 SGCD 3

Product Form - Coils, Sheets ¥ Thickness - 0.15-3.2 mm

¥ Width - 600-1370 mm ¥ Length - up to 4800 mm

Essar_6 Page Brochiour Outside_Close Size:11" x 8"_06/08/05_dtp8/cp

A Tradition of Excellence Quality that the World Approves

Integrating processes further downstream, the plant is equipped with some of the finest technologies.The complex houses a 1.3 MTPA

HRPO (Hot Rolled Pickled and Oiled) facility, 0.9 MTPA Cold Rolling and 0.5 MTPA Galvanising lines for catering to value-based customers. What makes Essar Steel the world’s preferred steel maker is the wide product range

Essar Steel is part of the Essar Group, a key player in several core sector

The state-of-the-art service centre includes India's only Hot Skin Pass mill of 1.2 MTPA capacity along with Shearing and Slitting lines that is completely customisable to unique customer needs along with flexible

industries such as Steel, Power, Shipping, Telecommunications, BPO, Oil and

capable of handling capacities of 0.6 MTPA and 0.4 MTPA respectively. Moreover, PT Essar Indonesia - Essar's 0.4 MTPA cold rolling and 0.15 delivery options.

Gas and Constructions. With an asset base of over Rs. 200 billion (US$ 4.4

MTPA galvanising facility in Jakarta - adds international muscle to Essar Steel. Essar Steel’s strong standing in domestic and international markets

billion) in businesses that are at the heart of the Indian economy, Essar is an

All the processes, from raw material acquisition to its downstream processes, come together in a perfectly synchronised, yet flexible is also due to its lofty quality standards. Ever the leader, Essar Steel

important contributor to the country's infrastructure.

integration that makes Essar Steel a low-cost and customer-focussed steel producer. With products ranging from hot rolled coils, plates and was the first integrated steel plant in the country to obtain the

Essar Steel - A Versatile Steel Producer prestigious ISO 9001 for all operations. In addition, it was the first

sheets to normalised, galvanised and shot blasted steel, Essar Steel truly sets the gold standard in steel.

Indian steel plant to achieve the ISO 14001 accreditation for

Essar Steel, the group’s flagship company, has emerged a fully-

Strategic Location Environmental Management System.

integrated steel major. With its robust chain of production and

From its location on the West Coast, about 260-kms north of Mumbai, Essar Steel has a Obviously, quality-driven processes would only create products that surpass

downstream processes, Essar Steel has raised itself above the rest –

major advantage with respect to the inward movement of raw materials and the outbound international quality standards as well. Certifications for its products include Lloyds

making 24 Carat Steel the benchmark of quality steel for its

movement of finished goods.The captive port – capable of handling 6 MTPA of cargo Register (UK) for exports, IRS (Indian Registrar of Shipping), DNV, ABS, TUV, BIS

customers.

annually – is loaded with facilities like sea-going floating cranes, articulated barges and other (Bureau of Indian Standards), OITC and IBR (Indian Boiler Regulation Act).

Essar Steel’s cutting-edge Midi Mill technology enables unmatched

versatility and greater flexibility in its processes, thus ensuring marine equipment.

The 24 Carat Edge

excellent product quality and a higher level of product customisation. A

The Technological Advantage To develop a unique identity and differentiate its products, Essar Steel launched

blend of sophisticated automation levels and an inspired workforce has

Essar Steel employs the world’s most advanced technology from the best equipment 24-Carat Steel, the first branded steel of its kind in India. 24 Carat Steel defines the

helped it emerge as one of the most productive and cost-efficient mills the

suppliers. Its many firsts include an indigenous Hot DRI charging system, the largest DC core properties of Essar Steel as well as the total offering from the company in

world over. All this while, being one of the most environment-friendly

electric-powered steel plant and India’s first Continuous Tandem Cold Mill (CTCM). terms of product quality, standards, delivery systems and customer service.

manufacturing facilities in the steel world.

Level II automation aided by one of the largest ERP installations in India by SAP and an 24 Carat Steel today finds application in diverse specialised and demanding

An Integrated Steel Giant industries – from general engineering to automotive and shipbuilding.

Integrated Marketing and Production System (IMPS) from UEC of USA make Essar Steel

Essar Steel’s dominion begins at its iron ore beneficiation plant in Bailadila, completely future-ready.

Chhattisgarh. Refining iron ore to its purest form for use at its steel mill, the

Answering the World's Need for Steel

iron ore slurry is transported along a 267km-long slurry pipeline – the 2nd

longest in the world – through very difficult terrain, to the pellet-making With technology that surpasses global benchmarks, Essar Steel produces grades that many Indian steel mills can only aspire to.The market

facility in Visakhapatnam. Here, Essar Steel’s 4 MTPA pelletisation leader in many niche segments in the domestic market, Essar Steel is one of the leading

plant (en-route to being augmented to 8 MTPA) produces iron ore suppliers for pipelines, automobile manufacturers, construction and other sophisticated

pellets for use at the steel complex.The pelletisation plant, situated industries, as it provides a competitively priced, yet superior quality, alternative to high-

at a natural all-weather port, facilitates low-cost transportation of grade imports.

In the international market, Essar Steel is positioned alongside prime European and Superior production processes, world-class technology and a committed workforce

the raw material to Essar Steel’s complex at Hazira.

Japanese steel producers. Little surprise then, that Essar Steel is the largest exporter of flat has helped Essar Steel develop value-added steel and placed the

This port-based complex houses the world’s largest Hot Briquetted

products from India. Moreover, Essar Steel is a leading supplier of API grade steel in the world for pipelines in the oil & gas sector, having company in the league of a select few world-class steel

Iron (HBI) plant of 3.4 million tonnes per annum (MTPA) capacity

helped create pipelines that stretch 8500kms across 5 continents. manufacturers - thus casting the 24 Carat promise in concrete.

that feeds a state-of-the-art steel mill which has a capacity of 3 MTPA.

Essar_6 Page Brochiour Inside_Close Size:11" x 8"_06/08/05_dtp8/cp

Some prominent grades that Essar specialises in:

Indian International

Hot Rolled Products Standards Standards

JIS G3131

Cold Rolling IS 11513 ASTM A569 Harnessing world-class technology

BS 1449

Deep Drawing IS 1079 JIS G 3132 4 -150 tonne DC Eectric Arc Furnaces - Clecim, France

ASTM A621 4 - 150 tonne Ladle Furnaces - Davy, United Kingdom

Corrosion Resistance IRSM 41 JIS G 3125 1- 150 tonne Vacuum Degasser - Standard Messo, Germany

ASTM A588 3 - Single Strand Slab Casting Machines - Mannesmann DemagAG, Germany

EN 10155 S

Hot Strip Mill Mechanicals - SMS Schloemann Siemag Engineering, USA

Boiler Quality IS 2002 JIS G 3103

Hot Strip Mill Electricals and Automation - General Electric, USA

ASTM 515 / 516

ASTM A537 2 Reheating Furnace - Stein Heurty, France Essar Steel Limited

Hot Skinpass Mill - Clecim, France

General Engg fabrication IS 5986 JIS 3101

IS 8500 EN 10025 3 Shearing Lines - Bronx, UK ; SMS, USA

IS 2062 ASTM A36, 53, 283

2 Slitting Lines - Bronx, UK

Pipes & tubes IS 10748 API Specification 6 Hi Reversible Cold rolling mill - Hitachi, Japan

IS 10748 SAE 1008

4 Hi Continous Tandom Mill - VAI Clecim, France

Automobile JIS G 3113 Auto Cut to length line - FIMI, ITALY

SAPH 310-340

QSTE 340-380 DMS Slitting cum recoiling line - DMS

EN 10149

LIR Inspection cum trimming line - LIR

Product Form - Coils, Plates, Sheets ¥ Thickness - 1.60-20 mm Batch Annealing furnace - LOI, Germany

¥ Width - 180-2000 mm ¥ Length - 2000-12000 mm

Skin pass mill for CR unit - VAI Clecim, France

Cold Rolled Products Skin pass mill for galvanizing line - BWG, Germany

Furnace for galvanising line - Selas, France

Commercial Quality IS 513 Gr O ASTM A-366

JIS SPCC Tension leveler for galvanising line - Herrvoss, USA

Drawing IS 513 Gr D BS CR - 4

ASTM A - 619

JIS SPCD

Deep Drawing IS 513 GR DD BS CR - 3

ASTM A - 620

JIS SPCD

Extra Deep Drawing IS 513 GR EDD CR - 2 / CR - 1

ASTM - 620 Marketing Head Office

JIS SPCEN Essar House, 11, K.K. Marg,

Super EDD IF IF

Mahalaxmi, Mumbai 400 034.

Toll Free : 1800 22 5105 (for MTNL and BSNL Subscriber)

Product Form - Coils, Sheets ¥ Thickness - 0.14-3.2 mm

¥ Width - 200-1625 mm ¥ Length - 600-4800 mm 6000 9595 (add Local STD code when dialing

from your mobile phone)

Galvanised Products

Email : steel@essar.com

Commercial Quality IS 277 Gr CQ / O BS 2989 Z1

Website : www.essarsteel.com

Drawing IS 277 Gr D ASTM CS - A, B, C

JIS 3302 SGCC

Deep Drawing IS 277 Gr DD ASTM FS - A, B

SMS

JIS 3302 SGCD 1

Steel to 53636

Extra Deep Drawing IS 277 Gr EDD ASTM DDS

JIS 3302 SGCD 2

Extra Deep Drawing IS 277 Gr EDD ASTM EDDS www.essarsteel.com

(Al Killed) JIS 3302 SGCD 3

Product Form - Coils, Sheets ¥ Thickness - 0.15-3.2 mm

¥ Width - 600-1370 mm ¥ Length - up to 4800 mm

Essar_6 Page Brochiour Outside_Close Size:11" x 8"_06/08/05_dtp8/cp

A Tradition of Excellence Quality that the World Approves

Integrating processes further downstream, the plant is equipped with some of the finest technologies.The complex houses a 1.3 MTPA

HRPO (Hot Rolled Pickled and Oiled) facility, 0.9 MTPA Cold Rolling and 0.5 MTPA Galvanising lines for catering to value-based customers. What makes Essar Steel the world’s preferred steel maker is the wide product range

Essar Steel is part of the Essar Group, a key player in several core sector

The state-of-the-art service centre includes India's only Hot Skin Pass mill of 1.2 MTPA capacity along with Shearing and Slitting lines that is completely customisable to unique customer needs along with flexible

industries such as Steel, Power, Shipping, Telecommunications, BPO, Oil and

capable of handling capacities of 0.6 MTPA and 0.4 MTPA respectively. Moreover, PT Essar Indonesia - Essar's 0.4 MTPA cold rolling and 0.15 delivery options.

Gas and Constructions. With an asset base of over Rs. 200 billion (US$ 4.4

MTPA galvanising facility in Jakarta - adds international muscle to Essar Steel. Essar Steel’s strong standing in domestic and international markets

billion) in businesses that are at the heart of the Indian economy, Essar is an

All the processes, from raw material acquisition to its downstream processes, come together in a perfectly synchronised, yet flexible is also due to its lofty quality standards. Ever the leader, Essar Steel

important contributor to the country's infrastructure.

integration that makes Essar Steel a low-cost and customer-focussed steel producer. With products ranging from hot rolled coils, plates and was the first integrated steel plant in the country to obtain the

Essar Steel - A Versatile Steel Producer prestigious ISO 9001 for all operations. In addition, it was the first

sheets to normalised, galvanised and shot blasted steel, Essar Steel truly sets the gold standard in steel.

Indian steel plant to achieve the ISO 14001 accreditation for

Essar Steel, the group’s flagship company, has emerged a fully-

Strategic Location Environmental Management System.

integrated steel major. With its robust chain of production and

From its location on the West Coast, about 260-kms north of Mumbai, Essar Steel has a Obviously, quality-driven processes would only create products that surpass

downstream processes, Essar Steel has raised itself above the rest –

major advantage with respect to the inward movement of raw materials and the outbound international quality standards as well. Certifications for its products include Lloyds

making 24 Carat Steel the benchmark of quality steel for its

movement of finished goods.The captive port – capable of handling 6 MTPA of cargo Register (UK) for exports, IRS (Indian Registrar of Shipping), DNV, ABS, TUV, BIS

customers.

annually – is loaded with facilities like sea-going floating cranes, articulated barges and other (Bureau of Indian Standards), OITC and IBR (Indian Boiler Regulation Act).

Essar Steel’s cutting-edge Midi Mill technology enables unmatched

versatility and greater flexibility in its processes, thus ensuring marine equipment.

The 24 Carat Edge

excellent product quality and a higher level of product customisation. A

The Technological Advantage To develop a unique identity and differentiate its products, Essar Steel launched

blend of sophisticated automation levels and an inspired workforce has

Essar Steel employs the world’s most advanced technology from the best equipment 24-Carat Steel, the first branded steel of its kind in India. 24 Carat Steel defines the

helped it emerge as one of the most productive and cost-efficient mills the

suppliers. Its many firsts include an indigenous Hot DRI charging system, the largest DC core properties of Essar Steel as well as the total offering from the company in

world over. All this while, being one of the most environment-friendly

electric-powered steel plant and India’s first Continuous Tandem Cold Mill (CTCM). terms of product quality, standards, delivery systems and customer service.

manufacturing facilities in the steel world.

Level II automation aided by one of the largest ERP installations in India by SAP and an 24 Carat Steel today finds application in diverse specialised and demanding

An Integrated Steel Giant industries – from general engineering to automotive and shipbuilding.

Integrated Marketing and Production System (IMPS) from UEC of USA make Essar Steel

Essar Steel’s dominion begins at its iron ore beneficiation plant in Bailadila, completely future-ready.

Chhattisgarh. Refining iron ore to its purest form for use at its steel mill, the

Answering the World's Need for Steel

iron ore slurry is transported along a 267km-long slurry pipeline – the 2nd

longest in the world – through very difficult terrain, to the pellet-making With technology that surpasses global benchmarks, Essar Steel produces grades that many Indian steel mills can only aspire to.The market

facility in Visakhapatnam. Here, Essar Steel’s 4 MTPA pelletisation leader in many niche segments in the domestic market, Essar Steel is one of the leading

plant (en-route to being augmented to 8 MTPA) produces iron ore suppliers for pipelines, automobile manufacturers, construction and other sophisticated

pellets for use at the steel complex.The pelletisation plant, situated industries, as it provides a competitively priced, yet superior quality, alternative to high-

at a natural all-weather port, facilitates low-cost transportation of grade imports.

In the international market, Essar Steel is positioned alongside prime European and Superior production processes, world-class technology and a committed workforce

the raw material to Essar Steel’s complex at Hazira.

Japanese steel producers. Little surprise then, that Essar Steel is the largest exporter of flat has helped Essar Steel develop value-added steel and placed the

This port-based complex houses the world’s largest Hot Briquetted

products from India. Moreover, Essar Steel is a leading supplier of API grade steel in the world for pipelines in the oil & gas sector, having company in the league of a select few world-class steel

Iron (HBI) plant of 3.4 million tonnes per annum (MTPA) capacity

helped create pipelines that stretch 8500kms across 5 continents. manufacturers - thus casting the 24 Carat promise in concrete.

that feeds a state-of-the-art steel mill which has a capacity of 3 MTPA.

Essar_6 Page Brochiour Inside_Close Size:11" x 8"_06/08/05_dtp8/cp

Some prominent grades that Essar specialises in:

Indian International

Hot Rolled Products Standards Standards

JIS G3131

Cold Rolling IS 11513 ASTM A569 Harnessing world-class technology

BS 1449

Deep Drawing IS 1079 JIS G 3132 4 -150 tonne DC Eectric Arc Furnaces - Clecim, France

ASTM A621 4 - 150 tonne Ladle Furnaces - Davy, United Kingdom

Corrosion Resistance IRSM 41 JIS G 3125 1- 150 tonne Vacuum Degasser - Standard Messo, Germany

ASTM A588 3 - Single Strand Slab Casting Machines - Mannesmann DemagAG, Germany

EN 10155 S

Hot Strip Mill Mechanicals - SMS Schloemann Siemag Engineering, USA

Boiler Quality IS 2002 JIS G 3103

Hot Strip Mill Electricals and Automation - General Electric, USA

ASTM 515 / 516

ASTM A537 2 Reheating Furnace - Stein Heurty, France Essar Steel Limited

Hot Skinpass Mill - Clecim, France

General Engg fabrication IS 5986 JIS 3101

IS 8500 EN 10025 3 Shearing Lines - Bronx, UK ; SMS, USA

IS 2062 ASTM A36, 53, 283

2 Slitting Lines - Bronx, UK

Pipes & tubes IS 10748 API Specification 6 Hi Reversible Cold rolling mill - Hitachi, Japan

IS 10748 SAE 1008

4 Hi Continous Tandom Mill - VAI Clecim, France

Automobile JIS G 3113 Auto Cut to length line - FIMI, ITALY

SAPH 310-340

QSTE 340-380 DMS Slitting cum recoiling line - DMS

EN 10149

LIR Inspection cum trimming line - LIR

Product Form - Coils, Plates, Sheets ¥ Thickness - 1.60-20 mm Batch Annealing furnace - LOI, Germany

¥ Width - 180-2000 mm ¥ Length - 2000-12000 mm

Skin pass mill for CR unit - VAI Clecim, France

Cold Rolled Products Skin pass mill for galvanizing line - BWG, Germany

Furnace for galvanising line - Selas, France

Commercial Quality IS 513 Gr O ASTM A-366

JIS SPCC Tension leveler for galvanising line - Herrvoss, USA

Drawing IS 513 Gr D BS CR - 4

ASTM A - 619

JIS SPCD

Deep Drawing IS 513 GR DD BS CR - 3

ASTM A - 620

JIS SPCD

Extra Deep Drawing IS 513 GR EDD CR - 2 / CR - 1

ASTM - 620 Marketing Head Office

JIS SPCEN Essar House, 11, K.K. Marg,

Super EDD IF IF

Mahalaxmi, Mumbai 400 034.

Toll Free : 1800 22 5105 (for MTNL and BSNL Subscriber)

Product Form - Coils, Sheets ¥ Thickness - 0.14-3.2 mm

¥ Width - 200-1625 mm ¥ Length - 600-4800 mm 6000 9595 (add Local STD code when dialing

from your mobile phone)

Galvanised Products

Email : steel@essar.com

Commercial Quality IS 277 Gr CQ / O BS 2989 Z1

Website : www.essarsteel.com

Drawing IS 277 Gr D ASTM CS - A, B, C

JIS 3302 SGCC

Deep Drawing IS 277 Gr DD ASTM FS - A, B

SMS

JIS 3302 SGCD 1

Steel to 53636

Extra Deep Drawing IS 277 Gr EDD ASTM DDS

JIS 3302 SGCD 2

Extra Deep Drawing IS 277 Gr EDD ASTM EDDS www.essarsteel.com

(Al Killed) JIS 3302 SGCD 3

Product Form - Coils, Sheets ¥ Thickness - 0.15-3.2 mm

¥ Width - 600-1370 mm ¥ Length - up to 4800 mm

Essar_6 Page Brochiour Outside_Close Size:11" x 8"_06/08/05_dtp8/cp

A Tradition of Excellence Quality that the World Approves

Integrating processes further downstream, the plant is equipped with some of the finest technologies.The complex houses a 1.3 MTPA

HRPO (Hot Rolled Pickled and Oiled) facility, 0.9 MTPA Cold Rolling and 0.5 MTPA Galvanising lines for catering to value-based customers. What makes Essar Steel the world’s preferred steel maker is the wide product range

Essar Steel is part of the Essar Group, a key player in several core sector

The state-of-the-art service centre includes India's only Hot Skin Pass mill of 1.2 MTPA capacity along with Shearing and Slitting lines that is completely customisable to unique customer needs along with flexible

industries such as Steel, Power, Shipping, Telecommunications, BPO, Oil and

capable of handling capacities of 0.6 MTPA and 0.4 MTPA respectively. Moreover, PT Essar Indonesia - Essar's 0.4 MTPA cold rolling and 0.15 delivery options.

Gas and Constructions. With an asset base of over Rs. 200 billion (US$ 4.4

MTPA galvanising facility in Jakarta - adds international muscle to Essar Steel. Essar Steel’s strong standing in domestic and international markets

billion) in businesses that are at the heart of the Indian economy, Essar is an

All the processes, from raw material acquisition to its downstream processes, come together in a perfectly synchronised, yet flexible is also due to its lofty quality standards. Ever the leader, Essar Steel

important contributor to the country's infrastructure.

integration that makes Essar Steel a low-cost and customer-focussed steel producer. With products ranging from hot rolled coils, plates and was the first integrated steel plant in the country to obtain the

Essar Steel - A Versatile Steel Producer prestigious ISO 9001 for all operations. In addition, it was the first

sheets to normalised, galvanised and shot blasted steel, Essar Steel truly sets the gold standard in steel.

Indian steel plant to achieve the ISO 14001 accreditation for

Essar Steel, the group’s flagship company, has emerged a fully-

Strategic Location Environmental Management System.

integrated steel major. With its robust chain of production and

From its location on the West Coast, about 260-kms north of Mumbai, Essar Steel has a Obviously, quality-driven processes would only create products that surpass

downstream processes, Essar Steel has raised itself above the rest –

major advantage with respect to the inward movement of raw materials and the outbound international quality standards as well. Certifications for its products include Lloyds

making 24 Carat Steel the benchmark of quality steel for its

movement of finished goods.The captive port – capable of handling 6 MTPA of cargo Register (UK) for exports, IRS (Indian Registrar of Shipping), DNV, ABS, TUV, BIS

customers.

annually – is loaded with facilities like sea-going floating cranes, articulated barges and other (Bureau of Indian Standards), OITC and IBR (Indian Boiler Regulation Act).

Essar Steel’s cutting-edge Midi Mill technology enables unmatched

versatility and greater flexibility in its processes, thus ensuring marine equipment.

The 24 Carat Edge

excellent product quality and a higher level of product customisation. A

The Technological Advantage To develop a unique identity and differentiate its products, Essar Steel launched

blend of sophisticated automation levels and an inspired workforce has

Essar Steel employs the world’s most advanced technology from the best equipment 24-Carat Steel, the first branded steel of its kind in India. 24 Carat Steel defines the

helped it emerge as one of the most productive and cost-efficient mills the

suppliers. Its many firsts include an indigenous Hot DRI charging system, the largest DC core properties of Essar Steel as well as the total offering from the company in

world over. All this while, being one of the most environment-friendly

electric-powered steel plant and India’s first Continuous Tandem Cold Mill (CTCM). terms of product quality, standards, delivery systems and customer service.

manufacturing facilities in the steel world.

Level II automation aided by one of the largest ERP installations in India by SAP and an 24 Carat Steel today finds application in diverse specialised and demanding

An Integrated Steel Giant industries – from general engineering to automotive and shipbuilding.

Integrated Marketing and Production System (IMPS) from UEC of USA make Essar Steel

Essar Steel’s dominion begins at its iron ore beneficiation plant in Bailadila, completely future-ready.

Chhattisgarh. Refining iron ore to its purest form for use at its steel mill, the

Answering the World's Need for Steel

iron ore slurry is transported along a 267km-long slurry pipeline – the 2nd

longest in the world – through very difficult terrain, to the pellet-making With technology that surpasses global benchmarks, Essar Steel produces grades that many Indian steel mills can only aspire to.The market

facility in Visakhapatnam. Here, Essar Steel’s 4 MTPA pelletisation leader in many niche segments in the domestic market, Essar Steel is one of the leading

plant (en-route to being augmented to 8 MTPA) produces iron ore suppliers for pipelines, automobile manufacturers, construction and other sophisticated

pellets for use at the steel complex.The pelletisation plant, situated industries, as it provides a competitively priced, yet superior quality, alternative to high-

at a natural all-weather port, facilitates low-cost transportation of grade imports.

In the international market, Essar Steel is positioned alongside prime European and Superior production processes, world-class technology and a committed workforce

the raw material to Essar Steel’s complex at Hazira.

Japanese steel producers. Little surprise then, that Essar Steel is the largest exporter of flat has helped Essar Steel develop value-added steel and placed the

This port-based complex houses the world’s largest Hot Briquetted

products from India. Moreover, Essar Steel is a leading supplier of API grade steel in the world for pipelines in the oil & gas sector, having company in the league of a select few world-class steel

Iron (HBI) plant of 3.4 million tonnes per annum (MTPA) capacity

helped create pipelines that stretch 8500kms across 5 continents. manufacturers - thus casting the 24 Carat promise in concrete.

that feeds a state-of-the-art steel mill which has a capacity of 3 MTPA.

Essar_6 Page Brochiour Inside_Close Size:11" x 8"_06/08/05_dtp8/cp

You might also like

- Steel Service CentresDocument20 pagesSteel Service Centresabhinavjha7No ratings yet

- Total Market Scenario & Building Customer Satisfaction: A Project Report OnDocument68 pagesTotal Market Scenario & Building Customer Satisfaction: A Project Report Onarpitji24No ratings yet

- Bushan Power Steel PipeDocument16 pagesBushan Power Steel PipeKarthikeyan VisvakNo ratings yet

- Vendor MatrixDocument165 pagesVendor MatrixDeepak MendirattaNo ratings yet

- Vivek Final Project 2010Document75 pagesVivek Final Project 2010vkr1811No ratings yet

- Company AnalysisDocument9 pagesCompany AnalysisNaveen KumarNo ratings yet

- BMCT 5 Market Surey SteelDocument25 pagesBMCT 5 Market Surey SteelAastha ShrivastavaNo ratings yet

- Met Trade India LTD, Gandhidham: Colour Code For Aluminium AlloysDocument4 pagesMet Trade India LTD, Gandhidham: Colour Code For Aluminium AlloysSachinNo ratings yet

- Prime User List Gear TesterDocument31 pagesPrime User List Gear TesterPramod PatilNo ratings yet

- RDSO Vendor1Document169 pagesRDSO Vendor1adarshietk100% (1)

- Tata Steel AnalysisDocument25 pagesTata Steel AnalysisIsha SahuNo ratings yet

- Vendor Directory 16.01.2017Document80 pagesVendor Directory 16.01.2017Abhishek MishraNo ratings yet

- 3rd Marketing Analytics Summit - 2019 - PSR PDFDocument22 pages3rd Marketing Analytics Summit - 2019 - PSR PDFharsheenNo ratings yet

- ShineDocument31 pagesShineRajesh LenkaNo ratings yet

- List of Refineries & Petroleum / LPG Projects: Year Name of Project ClientDocument5 pagesList of Refineries & Petroleum / LPG Projects: Year Name of Project ClientSach KanhuNo ratings yet

- BEC Fertilizers, MilanDocument34 pagesBEC Fertilizers, Milandaiya2daiyaNo ratings yet

- Dross ReportDocument29 pagesDross ReportGaurav BehuneNo ratings yet

- 09 Profile of CompaniesDocument70 pages09 Profile of CompaniesSumit0% (2)

- Bolting Material Chemical &..Document6 pagesBolting Material Chemical &..arief setiawanNo ratings yet

- 100 Case CompetitionsDocument2 pages100 Case CompetitionsRohan BarmanNo ratings yet

- JSW Steel IndustryDocument37 pagesJSW Steel IndustrySri Ganesh ComputersNo ratings yet

- JSW Galvanised BrochureDocument14 pagesJSW Galvanised BrochurejeffyNo ratings yet

- Erw Steel Pipe PDFDocument2 pagesErw Steel Pipe PDFDeborahNo ratings yet

- Company Profile Amman Steel CroproationDocument8 pagesCompany Profile Amman Steel CroproationeshuNo ratings yet

- Introduction Letter - 3.4.21Document2 pagesIntroduction Letter - 3.4.21Gunjan PatelNo ratings yet

- Is 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsDocument10 pagesIs 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsNadeem KhanNo ratings yet

- Scanned Indian Standards ListDocument30 pagesScanned Indian Standards ListJignesh TrivediNo ratings yet

- Organogram of LNTDocument8 pagesOrganogram of LNTSiddhartha BoraNo ratings yet

- School ListDocument6 pagesSchool ListBhuvi CreationsNo ratings yet

- 25 Innovative ClustersDocument11 pages25 Innovative Clustersaeioums43910% (1)

- Distribution Channels of Vardhman SteelsDocument95 pagesDistribution Channels of Vardhman SteelsVainy GoelNo ratings yet

- Fundoo DataDocument22 pagesFundoo DataAnonymous qBU1JYFCoWNo ratings yet

- Material Handling India PDFDocument7 pagesMaterial Handling India PDFsangeeth_7No ratings yet

- Essar Chequered PlateDocument2 pagesEssar Chequered PlateSandeep NarayananNo ratings yet

- Quality InspectionDocument17 pagesQuality InspectionDeepakPandeyNo ratings yet

- TMT Steel Bar IndustryDocument68 pagesTMT Steel Bar IndustryRohitMishraNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- Steel Industry in IndiaDocument8 pagesSteel Industry in IndiaakashNo ratings yet

- Rajkot Forging Industries GujaratDocument20 pagesRajkot Forging Industries GujaratTarun ShankarNo ratings yet

- FastenersDocument3 pagesFastenersHeena AsharNo ratings yet

- Wire Rod Mailable PDFDocument11 pagesWire Rod Mailable PDFVenu PrasadNo ratings yet

- India Warehousing Market Report 2023 10258Document112 pagesIndia Warehousing Market Report 2023 10258shaji deloitteNo ratings yet

- Indian Cities and TownsDocument82 pagesIndian Cities and TownsJan Mohammed100% (1)

- SailDocument79 pagesSailAshish Sinha0% (1)

- Job Consultant ListDocument11 pagesJob Consultant ListNimit MalhotraNo ratings yet

- Fastener Manufacturers in IndiaDocument8 pagesFastener Manufacturers in IndiaKaloti IndiaNo ratings yet

- Consultant ListDocument17 pagesConsultant ListBruce AmigoNo ratings yet

- ApprovedVendorList Civil 15-05-2018Document61 pagesApprovedVendorList Civil 15-05-2018deputy executive engineerNo ratings yet

- Log Book For RollingDocument10 pagesLog Book For Rollingpatrik710No ratings yet

- Corporate BrochureDocument86 pagesCorporate BrochureNikhil JainNo ratings yet

- Mahindra and Mahindra Annual Report 2017 2018 PDFDocument359 pagesMahindra and Mahindra Annual Report 2017 2018 PDFShikhar DudejaNo ratings yet

- Welding Wire 25.10.4.LDocument2 pagesWelding Wire 25.10.4.LisupmanNo ratings yet

- Template - Comparison ChartsDocument10 pagesTemplate - Comparison ChartsgroovyoemNo ratings yet

- Report On Working Capital MGT of JSPLDocument43 pagesReport On Working Capital MGT of JSPLharshal_gupta100% (3)

- Iron and Steel Industry Analysis - IndiaDocument58 pagesIron and Steel Industry Analysis - Indiaprachi_jain_2667% (3)

- Essar Steel Galvanised BrochureDocument9 pagesEssar Steel Galvanised BrochureSukanya Sen DuttaNo ratings yet

- Essar Steel Plate Brochure 20101001Document38 pagesEssar Steel Plate Brochure 20101001kmbkrisNo ratings yet

- Essar Steel Pipes BrochureDocument13 pagesEssar Steel Pipes Brochureyaduvanshi1No ratings yet

- Brochure PSMDocument19 pagesBrochure PSMsirajuddin khowajaNo ratings yet

- Bhushan SteelDocument76 pagesBhushan SteelRajiv KalraNo ratings yet

- Construction and Mining Equipment Business in IndiaDocument12 pagesConstruction and Mining Equipment Business in Indianeettiyath1No ratings yet

- Indonesia EnvTech Export Plan 2013Document26 pagesIndonesia EnvTech Export Plan 2013neettiyath1No ratings yet

- NITI AyogDocument31 pagesNITI Ayogneettiyath1No ratings yet

- Affiliated Colleges ListDocument53 pagesAffiliated Colleges Listneettiyath1No ratings yet

- Hindalco Full Annual Report 2015 16Document2 pagesHindalco Full Annual Report 2015 16neettiyath1No ratings yet

- Hindalco Full Annual Report 2015 16Document200 pagesHindalco Full Annual Report 2015 16neettiyath1No ratings yet

- Tender 16 M032Document29 pagesTender 16 M032neettiyath1No ratings yet

- Qatar Real Estate 112007Document50 pagesQatar Real Estate 112007neettiyath1No ratings yet

- Final Supermax PrintDocument42 pagesFinal Supermax Printneettiyath1100% (1)

- GAILDocument26 pagesGAILneettiyath1No ratings yet

- PL Engineering Corporate PresentationDocument53 pagesPL Engineering Corporate Presentationneettiyath1100% (1)

- Siemens: Upgrade To BuyDocument18 pagesSiemens: Upgrade To BuyChander LaljaniNo ratings yet

- A Study On Customer Satisfaction of Honda Activa Among Customers in Changanacherry TalukDocument55 pagesA Study On Customer Satisfaction of Honda Activa Among Customers in Changanacherry TalukgunNo ratings yet

- Cars - A CelebrationDocument580 pagesCars - A Celebrationkcshieh100% (5)

- Dip JaipurDocument20 pagesDip JaipurPramesh KhatanaNo ratings yet

- Non Aero Revenue - MBA ProjectDocument68 pagesNon Aero Revenue - MBA ProjectSuresh Kumar100% (2)

- Study Perception Motor Cars KottakkalDocument59 pagesStudy Perception Motor Cars KottakkalShaNo ratings yet

- Railway Interiors2013Document108 pagesRailway Interiors2013christian_campean100% (1)

- Bajaj Auto Rural MarketingDocument17 pagesBajaj Auto Rural MarketingKunal Agarwal100% (1)

- Brosur CAT 320D-2Document2 pagesBrosur CAT 320D-2Wildan Kurnia100% (4)

- Hyatt General JBPDocument4 pagesHyatt General JBPDouglas ArandaNo ratings yet

- Iet Report Pavithra NewDocument80 pagesIet Report Pavithra NewPriyaNo ratings yet

- Axh1140 - Uk - Ed02 - Agri PlusDocument312 pagesAxh1140 - Uk - Ed02 - Agri PlusMauricio Plaza SalinasNo ratings yet

- BMW KeysDocument6 pagesBMW KeysFuckYou100% (1)

- Steering SystemDocument37 pagesSteering SystemSandeep Magapu100% (1)

- US Dollar Store Consumer BehaviourDocument10 pagesUS Dollar Store Consumer BehaviourTryden Royce D'SouzaNo ratings yet

- Resqjack 2016Document40 pagesResqjack 2016Sebastián DankerNo ratings yet

- Euskron Profile ENGDocument14 pagesEuskron Profile ENGEuskron Cutting ToolsNo ratings yet

- Automotive Industry - Indian Scenario: IndiaDocument2 pagesAutomotive Industry - Indian Scenario: IndiawilbertNo ratings yet

- Schaeffer Product Range enDocument52 pagesSchaeffer Product Range enDragos Manole0% (1)

- Rhino CranesDocument21 pagesRhino CranesecocadecNo ratings yet

- GAIKINDO - Mr. Kukuh KUMARA - The Future of Indonesia's Auto PDFDocument13 pagesGAIKINDO - Mr. Kukuh KUMARA - The Future of Indonesia's Auto PDFPirhot NababanNo ratings yet

- Parking PDFDocument3 pagesParking PDFAr Ajith KumarNo ratings yet

- RA Series PDFDocument9 pagesRA Series PDFCreuza Barbosa100% (1)

- Company Profile of Maruti SuzukiDocument10 pagesCompany Profile of Maruti SuzukiDave ChaudharyNo ratings yet

- Toyota Innova Crysta BrochureDocument4 pagesToyota Innova Crysta BrochureSushubhNo ratings yet

- Resume AjithDocument6 pagesResume AjithniranjanvengadNo ratings yet

- What Is Toyota Financial ServicesDocument3 pagesWhat Is Toyota Financial ServicesSaurabh TyagiNo ratings yet

- S BX Cone CrusherDocument4 pagesS BX Cone CrusherLuis Miguel Añasco CorimayhuaNo ratings yet

- Taj Lands End MumbaiDocument26 pagesTaj Lands End Mumbaifrankfcf100% (1)

- Mahindra and MahindraDocument16 pagesMahindra and MahindraBhavuk Kabra100% (1)