Professional Documents

Culture Documents

KTM Foxi

Uploaded by

Kasper Lp0 ratings0% found this document useful (0 votes)

654 views78 pagesOriginal Title

KTM FOXI

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

654 views78 pagesKTM Foxi

Uploaded by

Kasper LpCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 78

FOR.

RAL 6 STAR ST MOP

with

GENERAL MOPED GO., ING.

: PERMA-LINED BLDG

; 50 OAK STREET

ae EAST RUTHERFORD. NJ. 07073

S TEL: (212) 564-3876

@BLL PARTS ORDERS SHOULD BE ORWARDED TO.

; =. ~ GENERAL MOPED co

ABO SEVENTH AVENUE -

NEW YORK, Nov. 10001

. USS AC

4

CONTENTS

Tech ical Data.

Part: List Frame Group....eeesseeee eee ee eee eeee ee eeees 239

Fron: Wheea| Assi

nibs Ly oe on sevens 23

Roar Wheel Assembly. ..ceeeeeeeee sees . 45

Fron’ Fork Assembly....ceeeeeeeeeeee . 6-7

Rear Shock & Swing APM. ..ssseeeeeeneeeeeeneeeeenees 8-9

Handle Bar & Cable... sceeeseee eee eee e eee eee e ee eeee eee TWO-TT

Fram: Assembly cecesseeecerssee eee eee e eter eee e eee eee e eee 12-13

Fuel Tank & Seatecsseeeeseese Tha 15,

16-17

18-19

Chain Cover, 20-21

Granl. & Pedhl Assembly.. + 22-23

MULE OF ASSPMDIY cee eee cece eee cece ete e eee enna ee BABS

Fron Fender 4 Rear Fonder..

Speer ometer| Assembly

Turn Signal Assembly.. 0.00... eee eee eee cece 26=27

Head Light Assembly... +2... .00eeeeeee cece teen eens sae BBA29

Tail Light Assembly. 30-51

Wire Harness & Electricity.. 32-95

Part List Engine Grou . Bh-h7

Cran: Case, Crank Shaft, Piston, Cylinder, Decompressor,

+ 34-35

CLUE Ne cece cee eee e eee ssee ee eenesteeeneeneeereneeeeeres 38899

Inta

Gear

Magn :to-Generator....cceee cece essen eeees serge 4o-ky

Peda. Shaft. steer eee eee e ee ee eee eeee 4a-43

Carbiretar. - seeeeneeeeee - 2 hbabs

Intaie Silencer.....- se teeeeeseneeneee - 46-67

Repa _r Tools & Mounting Jig.. semadtaccuwuresseskas 4B

Qwne: Tool Kit & Repair ToO1S........eeeeeee eee Ag

50-53

59-57

58-63

64-65

Dismintling The Engine. .

Working On Individual Parts..seesseeeeeeene

Rebuilding The Engine

Operitions After Engine Overhaul.

a

Tighteaing Toksion For All Nuts & Bolts 66

Assemtly Instructions. 67

Engine Startihg @ Preparation Instructions For Riding... 68

Adjustnent Pok Drive Che . 69

Brakes Adjusting. ....++ . 69

Mainteqance Of Battery. : 70

Essent Maiftenane

Troubl sshootL

Electrical Wifing....se.ees

Fran

Front Suspension

Rear Suspension

Brakss

Tire, Front & Rear

Wheel Base

Dime ision

Fuel Tank

Fuel Consumption

Net feight

Engi ve

Engite Starting

Engire Output

Comp-ession Rate

Exha ist

Ignition

Spar Plug

Transmission

Maxi num Speed

Maxi um Steeping

Head Light

Tail Light

Othe > Accessories

TECHNICAL DATA

Heavy-Gauge Sturdy Tubular Steel Frame

Heavy Duty Telescopic Hydraulic Shock

Absorber

i Swing Arm & Telescopic Hydraulic Shock

Absorber

Dual Drum Brakes/Hand & Foot Brakes

217" x 2.25"

Whe 1/8"

672"(L) x264" (W)xO"(H)

1.1 Gallon Capacity

170 Miles/Gallon

S4kB 119 Lys.

SACHS 505/1H, 2-Stroke Air-Couled Single

Cylinder ("505/1A is also available)

Pedal System

1.1 kw (1.5 PS) at 4000 1/min.

Bt

hqee

BOSCH Magneto-Generater,

Taillight 6V5W

BOSCH W 175 T 1(with SAE connecting nut}

Automatic Cluteh

20 MPH/1B, 25 MPH/1A

22°30"

SAE Certified

SAE Certified

SAE Certified Front 4 Rear Turn Signal

Assembly (Left & right), Rear Viow

Mirror, ete.

inlight 6v2aw

‘TABLE- 1 FRONT WHEEL ASSEMBLY

TABLE-1 FRONT WHEEL ASSEMBLY

SSS

REF NO. PART NO, QUANTITY DESCRIPTION

1 -1450-5q99 1 HUB ASSEMBLY (6. 7. 23. 25)

2 1150-5d08 1 BACKING PLATE ASSEMBLY (12-22, 24, 29,

33. 34. 36)

3 1150-5d97 1 HUB,RIM,SPOKE ASSEMBLY (1, 8, 26. 27. 28)

A 1150-5da6 1 SPACER L/M

5 1150-505 1 SPACER R/H

6 1150-sqo4 1 HUB

7 1150-5q93. 1 ‘COLLAR

B 1150-592 1 RIM 2.25%17

9 1150~5q91 1 TIRE 2.25x17

10 1150-5d90 1 TUBE 2.25x17

11 1150-5089 1 RIM STRAP 2.25%17

Oo 12 1150-3088 1 PANEL BRAKE

19 1450-5987. 2 BRAKE SHOE

1h 1150-5086 1 BRAKE CAM !

15 1150-5985 1 SPRING BRAKE SHOE

16 1130-5084 1 BRAKE ARM

17 1150-5083 1 PINION SPEEDOMETER

18 1150-5082 1 WASHER SPEEDOMETER PINION

19 1150-5084 1 GEAR SPEEDOMETER

20 -1150-Sda0 1 RECEIVER SPEEDOMETER

Ri 1150-scre 1 WASHER, GEAR BOX

220 1150-578 1 OIL SEAL, 39x47x5

2300 1150-5077 1 OIL SEAL, 17%32x6

zh 1150-5076 1 ‘OIL SEAL, 4.5x11x3.5

25 1150-5075 2 BEARING 6201

26 1950-sq74 16 OUTER SPOKE #12%176

27 1150-5073 16 INNER SPOKE 412x176

BB 1150-5472 3 NIPPLE

29° 1150-5d71 2 RUBBER PLUG

30. 1150-500 1 FRONT WHEEL ASSEMBLY (WITHOUT 1. 2. 3)

oO 31 6210-07)10 2 PLAIN WASHER 10mm

32 6180-0110 1 LOOK NUT 10:0

35 6160-03)05 1 NUT Siem

34 6190-4006 1 SCREW lix6

1

AXLE 10145,

36 6110-5022 1 HOLT 5x22 .

2 REAR WHEEL ASSEMBLY

TABLE-2

REF No.

REAR WHEEL ASSEMBLY

PAl QUANTITY SCRIPTION

———

1150-5499

2150~ 5498.

1150-5997

1150-5996

1150-5495

1150-5494

1150-5492

1150-5490

1150-5489

2150-5487

2150-5486

2150-5485

2150-5484

2150-5452

1150-5481

2150-5479

1150-5478

1150~ 5470

1150-5469

1150= 5468

1150-5467

2150-5400

1150-5491

1150-590

1150-5d89

1150-51

1150-51

1150-5

1150-5

1150-51

Reto

1150-50lr1

6220-11p6

6210-01p6

6180-0112

6160-01p8

6160-01b6

6160-01p5,

611 1=21p2

6110-8084

6110-50P2

noeee

Busan sse6

BuUssn Gann

HUB ASSEMBLY (5. 6. 28. 29)

BACKING PLATE ASSEMBLY (8.99. 45, 264 27

37. 4O)

COLLAR L/H

TENSION BRACKET

HUB

BRAKE CAM

CHAIN #415x 10%

SPRING (REAR BRAKE LEVER)

BRAKE ROD

BRAKE ARM

SPROCKET FINAL DRIVEN Lor

ADJUSTER DRIVE CHAIN

SNAP PIN

TONGUED WASHER

OUTER SPOKE #12%171

INNER SPOKE #12x171

JOINT, DRIVEN CHAIN

HUB, RIM, SPOKE, ASSEMBLY(1. 7. 18. 335

30.

REAR WHEEL ASSEMBLY (1, 2, 10. 20. 21)

TIRE 2.25x17

TUBE 2.25x17

RIM STRAP 2.25417

BRAKE SHOE

SPRING, BRAKE SHOE

OIL SEAL 17x32x6

BEARING 6201

NIPPLE

RUBBER PLUG

SPRING WASHER 6mm

PLAIN WASHER 6mm

LOCK NUT 12mm

NUT 8mm

NUT 6mm

NUT 5mm

AXLE 12x172

BOLT 8x34

BOLT 5x22

TABLE <3

FRONT FORK ASSEMBLY

PABLE~3 /unnenTiveak assem |

Sc

REF NO. PART NO, Quantity DESCRIPTION

1 1150-5899 1 FRONT FORK ASSEMBLY (WITHOUT 5-11. 28. 29.

32. 54. 55)

2 1150-585 2 BOLT, FRONT FORK

3 150-5895 1 NUT, STEERING HEAD STEM

4 150-589 1 PLAIN WASHER

5 150-5893 1 RACE, STEERING TOP CONE

6 150-5892 ' STEERING BALL TOP RACE

7 150-589)1 1 STEERING BALL BOTTOM RACE

8 150-389) NG STEERING BALL 3/16"

9 “oc Saeh 1 STEERING CONE BOTTOM RACE

10 150-58: 1 Lock

W 150-5887 2 KEY (SPECIFY CODE NUMBER)

12 130-5886 1 SPACER

3 150-586] 1 ‘TOP CROWN

vi 150-38: 1 BOTTOM CROWN

15 150-585) 1 LEG, ASSEMBLY L/H

130-588 1 LEG, ASSEMBLY R/i

16 150-588} 2 OTL RING

17 150-588} 2 INNER TUBE

i o-geab 2 BUST COVER

19 150-587 2 OTL SEAL

20 150-587 2 FORK NUT

21 150587] 2 GUIDE, FRONT FORK TUBE

22 1150-587 1 OUTER TUBE L/it

5150-586) 1 OUTER TUBE R/H

29 150-587} 2 STOPPER FRONT FORK SPRING

ah 150-587, 2 SPRING

25 150~587P a SET FRONT FORK TUBE

26 150-587, 2 HOOK

27 150-586) 2 WASHER

28 5150-5867 2 UPPER HOLDER, HANDLE BAR

29 5 150~586) 2 UNDER HOLDER, HANDLE BAR

30 50-5864 1 CaP NUT, STEERING STEN

31 €220-110) 2 SPRING WASHER 8am

32 € 210-0104 4 PLAIN MASHER Sma

34 £310-010 2 PLAIN WASHER Gma

ah 601 2 SCREW 6x10

35° € 110-805 u BOLT 8x55

36 €110-803 2 BOLT 8x30

37 € 110-601 2 POLT 6x10

LABLES4

REAR SHOCK & SWING ARM

TABLE-! REAR SHOCK & SWING ARM

REF NO, PART QUANTITY DESCRIPTION

1 1150-6p99 SWING ARM

2 BUSH

3 SHOCK ASSEMBLY

4 PLAIN WASHER

5 CHAIN PROTECTING RING

6 SPRING WASHER 10m

7 PLAIN WASHER 10mm

8 LOCK NUT 10mm

9 CAP NUT 10:

o NUP 10mm

AXLE 10x160

12 BOLT 10x40

TABLE-5,

HANDLE BAR & CABLE

em 8

16 8 fe wm 9

\Q

\

jhe

ao

go

ge

oO

HANDLE BAR & CABLE

TABLE-5

REF. NO. PART.|NO. QUANTITY DESCRIPTION

1 5150-6299 1 HANDLE BAR

2 150-6298 1 SWITCH L/W

3 4150-6297 1 SWITCH R/H

ho 2150-6296 1 CABLE, THROTTLE

5 1150-6294 1 ‘CABLE, FRONT BRAKE

6 4150-6295 1 ‘CABLE, CLUTCH

7 3150-6292 1 GRIP L/H

8 3150-6391 1 GRIP R/H

9 3150-6390 1 THROTTLE PIPE

10 4150-6387 1 LEVER L/w (cLurcH)

Nn 3150-6386 1 LEVER R/H (FRONT BRAKE)

12 150-6380 1 CABLE CHOKE

139 1150-6383 1 HACK VIEW MIRROR L/H

Th 4150-6382 1 HANDLE LEVER ASSEMBLY L/# (2.10, 16.18.21.26,

27.28.29. 50x3.35. 36.3722.)

15 4150-6481 1 HANDLE LEVER ASSEMBLY R/H (3.11.16.17.18.22.

23.24,25.30.91.92.93.38x3. 35.36.3753.

16 4150-6480 2 BUSH

17 4150-6279 1 ADJUSTER BOLT

18 1150-6278 2 ADJUSTER NUT

19 ar58-676 1 CABLE HEAD

20 1150-6275 4 TIE STRAP

2 2150-6274 1 ADJUSTER BOLT

22 4150-6272 1 SPRING WASHER

2300 4150-621 1 PLAIN WASHER

24 4150-6270 1 LEVER, CHOKE

25 4150-6259 1 BRACKET, CHOKE LEVER

26 4150-5089 1 DECAL START

27 3150-9088 1 DECAL HORN |

28 = 3150-p0R7 1 DECAL OFF of

29 3150-9086 1 DECAL LIGHTS

80 150-9085 1 DECAL CHOKE

31 3150-9084 1 DECAL Stop

32 3150-9085 1 DECAL ENGINE STOP

33 3150-9082 1 DECAL L. TURN. R.

34 820-1105 6 SPRING WASHER Sam

35 6160-0105 2 NUT 5mm

36 6130-5040 Fy SCREW 5x30

37 6130-5085 5 SOREW 5x25

FRAME ASSEMBLY

TABLE-6 FRAME ASSEMBLY

_—

REF NO, PART NO. QUANTITY DESCRIPTION

1 4150-6699 1 FRAME ASSEMBLY

2 3150-6667 1 MAIN STAND

5 1150-6666 1 SHAPT MAIN STAND

& 1150-6865 1 SPRING MAIN STAND

5 1150-6664 1 COTTER PIN 25x1

6 1150-6662 1 O RING

T 1150-6659 1 ‘GROMMET

8 1150-6656 1 TOOL SET (9-12. 15)

9 1150-6655 1 TOOL BAG

10 1150-6654 1 WRENCH SOCKET

1 1150-6659 1 DRIVER

12 1150-6652 1 END WRENCH 10x12

13 3150-6653 1 INFORMATION PLATE

1h 1150-6649 2 RIVET (3mm)

VS 1150-6648 1 END WRENCH 14x17

16 6220-1108 3 SPRING WASHER Smn

17 6820-1106 H SPRING WASHER Gum

18 6210-0110 1 PLAIN WASHER 10mm

i] 6210-0108 6 PLAIN WASHER 8mm

20 6210-0106 1 PLAIN WASHER 6mm

21 6160-0108 3 NUT 8mm

22 6120-6015, 1 SCREW 6x15,

25 6110-8070 3 BOLT 8x70

———————

FUEL TANK & SEAT

TABLE-7_ FUEL TANK & SEAT

—

REF NO. PART QUANTITY DESCRIPTION

1 4150-9999 1 DECAL, FUEL TANK L/H

4150-9098 1 DECAL, FUEL TANK R/H

2 1 DECAL, FUEL TANK

3 1 DECAL’ REMINDER

4 L SEAT ASSEMBLY

5 1 SUPDORTING, TUBE

6 BEND

T 1 FUEL TANK

8 1 FUEL TANK CAP

4g 1 FUEL ASS]

io “Bisa FBoF TRL HOSE

11 3150-7b95 2 CLEP PUEL HOSE

12 6220-1) 10 1 SPRING WASHER 10mm

Oo 43 6220-1106 2 SPRING AASHER 6mm

14 6210-01 10 z PLAIN WASHER 10m

ae) 6210-0108 2 PLAIN WASHER 8mm

16 6210-0706 2 PLAIN WASHER 6mm

VW 6160-0110 1 NUT 10am

18 6160-0706 1 NUT Gam

20 6111-0045, 1 BOLT 10x45

20 6110-6080 1 BOLT 6x80

ai 6110-6012 2 BOLT 6x12

TABLE-8 FRONT FENDER & REAR FENDER

~16-

TAULE-€ FRONT FENDER & REAR FENDER

—

REF NO. PART NO. QuaNnriry DESCRIPTION

1 2150-7899 1 FRONT FENDER ASSEMBLY (2. 3. 7x2 8x 2x2,

axe

2 2150-7898 1 FRONT FENDER

3 2150-7897 1 SUPPORTING BAR

4 2150-7896 1 REAR FENDER

3 2150-7895 2 RUBBER

6 6220-1108 4 SPRING WASHER Sma

7 6220-1106 10 SPRING WASHER 6mm

8B 6210-0106 16 PLAIN WASHER 6mm

9 6160-0106 6 NUT Gum

10 6110-8010 4 BOLT 8x10

110 6110-6015 4 BOLT 6x15

120 6110-6012 6 BOLT 6x12

oO

SPEEDOMETER ASSEMBLY

TABLE- 9

TABLE-9 . SPEEDOMETER ASSEMBLY

=

REF NO. PART

QUANTITY DESCRIPTION

1 1450-8ap9 ' SPEEDOMETER ASSEMBLY (WITHOUT 2)

2 1150-8097 1 CABLE SPEEDOMETER

3 -1150-80p6 ' WIRE HARNESS SPEEDOMETER

4 150-8095 2 Gromer:

5 1150-804 3 LAMP 6V 1.54

6 1150-8099 2 PLAIN WASHER

7 1150-80b2 i SPEEDOMETER

B 6220-116 2 SPRING WASHER 6mm

9 6160-0106 2 SUT Gam

TABLE~1 CHAIN COVER

—

BEF XO, PART NO. QUANTITY DESCRIPTION

1 4150-9097 DECAL CHAIN COVER L/H & R/H

2 hijo-9095 DECAL CHAIN COVER L/H

4150-9094 DECAL CHAIN COVER R/H

3 2150-7802 CHAIN COVER L/H

& 2150-7H91 CHAIN GOVER R/Ht

5 3150-7889 SCREW

TABLE=11 CRANK & PEDAL ASSEMBLY

TABLE-1 CRANK & PEDAL ASSEMBLY

REF NO. PART xt QUANTITY DESCRIPTH

1 2150-9299 1 CRANK L/W

2 1450-9298 1 PEDAL ASSEMBLY R/It

3 1150-9207 1 PEDAL ASSEMBLY L/H

2150-9286 1 GRANK R/i

2150-9295 2 COTTER

PLAIN WASHER Gam

NUT 6mm

6210-011

éigocotde

pamune & MUFFLER ASSEMBLY.

i

TABLE-12 MUFFLER ASSEMBLY

att lee RIRRRIIRIaeeeeenemmmmimeere emcee

REF No, PART (xo. Quaxtary DESCRIPTION

1 2150-7099 1 MUFFLER ASSEMBLY (2, 3, 4. 8. 10x2. 11,

ih)

2 2150-7098 MUFFLER BODY

3 sunspot EXHAUST PIPE

i a50-qoos REND

5 50-71099 ’ SUPPORTING ARM

6 — 2150-7}092 1 BEND

7 6220-1108 3 SPRING WASHER Sem

8 6220-1106 1 SPRING WASHER 6mm

9 6210-4108 1 PLAIN WASHER Sam

10 6210-0106 2 PLAIN WASHER Gmum

ti 6160-0106 : NUT 6mm

re 12 6110-8b25 1 BOLT 8x25

4 15 2 BOLT 8x15

hg 18 1 BOLT 6x18

TABLE~13 TURN SIGNAL ASSEMBLY

TABLE- 13 TURN SIGNAL ASSEMBLY

===

REF NO. PART ho. quantity DESCRIPTION

t g150-8P99 1 FRONT TURN SIGNAL ASSEMBLY L/1

3150-BR98 1 FRONT TURN SIGNAL ASSEMBLY R/E

2 3150-8297 1 REAR TURN SIGNAL ASSEMBLY 1/1

3150-8296 1 REAR TURN SIGNAL ASSEMBLY R/H

1150-8395 4 LOGK MASHER INTERNAL TOOTH 10mm

3150-8294 2 BRACKET BAR FRONT

150-8493 2 PRACKET BAR REAR

3150-8392 SOCKET

1150-8491 LAMP 6v BW

1150-8390 LENS

1150-8388 GASKET

150-8387 BULB SOCKET

6220-1}10 SPRING VASHER 10am

6220-1 }06 SPRING WASHER Gren

6220~-1]05 SPRING VASHER 5mm

6210-0110 PLAIN WASHER 10am

6210-0106 PLAIN WASHER 6mm

6160-01 10 2 NUT 10mm

17 6160-0406 4 NUT Gram

18 6130-5906 4 SCREW 5x6

19 6130-3423 5 SCREW 3x23

20 6110-6430 os BOLT 6x30

———

HEAD LIGHT ASSEMBLY

TABLES 1!

REF NO,

PARE

2150-84

1150-84

1150-84)

1150-88

1150-844

Coa ee

3150-84

3150-8

03a

2150-58

1150-845

oraus

2150-84

1150-8

6210-014

6160-010

6130-501

9

8

0

6

6120-60:

6111-00!

HEAD LIGHT ASSEMBLY

QUANTITY

2

z

2

2

1

senso

nee

DESCRIPTION

HEAD LIGHT ASSEMBLY (2-5. 10-12. 14.)

RIM HEAD Licht

SEALED BEAM GE 4667

MOUNTING SPRING

CASE

BRACKET A, HEAD LIGHT (6mm)

BRACKET B, HEAD LIGHT

ANBER REFLECTOR

REFLECTOR GASKET

RUBBER MEAD LIGHT

HARNESS ADAPTER

GASKET HEAD LIGHT

PLAIN WASHER 1Qmm

RUT 6am

SCREW 5x10

SCREW 6x 20

BOLT 10x20

TAIL LIGHT ASSEMBLY

QUANTITY DESCRIPTION

TALL LIGHT ASSEMBLY

TALL LIGHT BRACKET

BODY ASSEMBLY

BULB 6V 21/3¢P

GASKET

Lens

SPRING WASHER Siam

PLAIN VASHER 5mm

SCREW 5x15.

SCREW 4x50.

nem nm

-30-

32

TABLE-16 WIRE HARNESS & ELECTRICITY

es

HEF NO, PART NO, QUANTITY DESCRIPTION

1 150-8899 ' WIRE HARNESS ASSEMBLY

2 150-8858 1 BATTERY 6NUB-24

3 150-8897 ’ HORN

4 150-8896 1 FLASHER

5 150-8895 i RECTIFIER

6 5150-8894 1 BRAKE SWITCH ASSENALY

7 150-8892 1 FUSE 104

8 150-8890 1 BATTERY STRAP

9 $ 150-8888 1 SPaitk PLUG CAP

10 5150-8887 1 FOSE

11 1 150-8885. 1 EARTH WIRE A

12 150-8884 : EARTH ¥IRE B

43 1 1502888 1 CONNECTING WIRE

© ht az0-1106 2 SPRING WASHER 6muo

15 220-1105 2 SPRING WASHER Sum

16 216-0106 2 PLAIN WASHER Gam

17 ¢ 160-0106 2 NUT 6am

1B ¢ 160-0105 2 NUT. 5mm

19 € 410-6035 1 BOLT 635.

20 4110-6012 1 BOLT 6x12

TABLE-17 — CRANKCASE, CRANKSHAFT, PISTON, CYLINDER, DECOMPRESSOR, INTAKE PIPE

i

”

38

REF. NO, PART. NO AVA (AB DESCRIPTION

1 0287-140-000 1 rankease assty

287-140-003 1 Crankcase ass'y

* in connection with Pig. 42

and 49

2 O240-176-002 10 10 Pillister head screw M 6x70

3 o640-003-002 4% & Fillister head screw M 6x55

4 640-001-001 1 1 Fillister head screw M 6x22

5 240-058-101 4 4 Stud M 6x20

6 ogit-ike-002 4K Washer 6.2x12«1.5

7 0316-057-002 4 «Hexagon nut M 6

8 0640-027-000 4 4 Oval head screw M5 * 14

9 O277-117-000 1 1 Cover ass'y with

1x0250-131-000 gasket

1xO0240-140-107 screw M14x1

for oil level check

10 0250-155-200 1 1 Gasket

x = as required

298

TABLE- 17 CR

(CASE, CRANKSHAFT, PISTON, CYLINDER, DECOMPRESSOR, INTAKE PIPE

REP. 30, 9 PART. NO. 1A 1B DESCRIPTION

u 0230-107-000 1 1 Oi) seal 15%90x5.5

12 0246-008-003 1 1 Washer 25. 3x34x0.2 -

3 0232-120-001 2 Grooved ball bearing 6202 C3

DIN 625

ah 0246-009-001 1 Washer 15. 3x20%0.5

15 0288-114-000 i Crankshaft

16 0246-005-000 1 i Woodruff key 3x%.7

17 O232-157-001 4 1 Needle cage 12x15x19

18 0246-009-000 x = x Washer 15.320, page 9

19 0244-153-000 1 1 Washer 30x36.8%1.5

20 0230-106-000 1 1 O41 goal 15x35K7

21 0245-022-000 1 1 Spring washer for M 10xt

22 0942-072-100 4 1 Coller nut M 1x1

23 O24L=167-000 1 1 Cap

ay 0286-3978-005 1 1 Piston assty ¢ 33:5 } Ssh

0286-378-006 1 1 Piston ass'y ¢ 38.3) 53 mm

25 0216-003-105 1 1 Gudgeon pin

26 o245-000-000 2 2 Wire spring ring

27 0215-009-000 2 2 Piston ring 6 35.0

28 0215-a10-000 2 2 Piston ring ¢ 38.3

250-154-000 1 1 Gasket

29 0219-146-210 1 Cylinder

0213-146-215 1 Cylinder

30 0291-022-200 1 1 Decompressor

a 0291-021-000 1 1 Cable ass'y anote

with solder nipple | Seeds aa

No, 0291-020-000 length

32 o2g1-024—011 1 1 Outer casing

33 660-018-000 4 1 Protective cap

3h 0998-004-001 1 H Spark plug W 173 T 1 with

SAE connecting nut

35 0250-156-100 2 2 Gasket

36 211-152-000 1 1 Intermediate flange (not appli-

cable for cylinder with flange)

37 O267-114=201 1 1 Intake pipe

* o244-114-209 1 1 Intake pipe

38 ozkk-100-008 2 2 Washer 6.2x10x1

39 ogho-085-102 2 2 Hexagon head screw M 6x35

ho 960-136-000 1 1 Rubber grommet (1 hole)

“a 260-020-000 4 1 Rubber grommet (2 hole)

42 9251-121-000 6 6 Rubber mounting bush

4g o2b7-14h=100 3 3 Distance tube

4 244-168-000 7 1 Closing cap 6 13

as 1950-023-000 1 1 Sealing ring 10.5x1lx1

46 1726-080-100 1 1 Screw plug M 10x1

x = as required

=35-

TABLE-1

GEAR

—— ee

TABLE 1B GEAR

PART. NO. /1A /1 DESCRIPTION

1 0285-122-001 1 1 Mainshaft ass'y with layshaft,

39 bearing needles, bearing

ring and fixed gear

2 0244-006-000 x Washer 13.2x18, page >

3 0232-155-000 3 Bush

4 0245-121-000 1 1 Cirelip

5 9230-108-000 1 1 O41 seal 15x32x5.5

6 0236-105-101 1 1 Sprocket 11 teeth

oO 7 026-056-000 1 1 Washer

8 O642-005-101 4 1 Hexagon nut M 12x1

9 285-123-000 1 1 Gearshaft ass'y with fixed

gear

10 0247-105-000 1 + Bush 15,6%18%14.3

u 244-164-000 1 1 Closing cap ¢ 18

x = as required

CLUTCH

TABLE -19 CLUTCH

em

REF. 10. PART. NO. /1A /1B DESCREPTION

1 O640-107-100 1 1 Threaded pin M BxIxt4.5

z oz42-121-000 1 1 Hexagon nut M Sxt

3 O2Z48-150-200 1 1 Clutch Lever

4 O239-136-200 1 1 Torsion spring

5 o291-021-090 1 1 Cable assy quote

with solder nipple fraavaves

No. 0291-020-000 Length

6 0291-024-011 1 1 Outer casing

Co 7 0660-018-000 1 1 Protective cap

a o2k7-140-000 1 1 Bush 7.6x1221.2

9 1950-024-000 1 i Sealing ring

10 o240-181-102 1 1 Pillister head screw M 8x1

VW 0284-016-000 1 4 Pressure cup

12 0242-000-000 1 1 Hexagon nut M 10x1

3 0244-157-000 1 1 Washer

as O244-154-000 x x Washer 24.8%44 page 9

o24h- 154-003 1 Washer 248x401. 7

15, 0258-014-200 1 3 Internal plate 1.7mm thick

258-014-101 2 Tnternal plate 2.5mm thick

° 16 5-122-100 2 2 Spring washer

17 O258-015-000 2 2 External plate

18 oz58-012.000 4 1 Clutch hab

19 agk7-141-000 1 1 wings

20 O284-015-000 1 1 Centrifugal weight ass'y with

1 « 0299-137-100 tension

spring

at 0258-016 100 1 1 Clutch plate

22 ozkh-11z-000 2 2 Washer 11. 9x23x1

23 o284-014-000 1 1 Clutch case

ah 0292-192-101 1 1 Bush 11.7%16x16.5

x = as required

TABLE-20

MAGNETO-GENERATOR

“u@ : a 3

—_—

REP. No. PaRT| NO. © 1/A 1/B DESCRIPTION

1 1 ' Magne to-generater

6 vole 17 Watt only available

under Fig. 3 and §

4 0286-1]75-005- 1 1 Flywheel for

ROSCH:0212-112-019

02 12-122=006

4

5 O286-254-008 1 ' Armagure base plate ass'y

for BOSCH:0212-112-019

~40:

TABLE-2 9 MAGNETO-GENERATOR

REF. NC. PART, NO, fA 1/B DESCRIPTION

6 2865-003-000 1 1 Protective cap against rain

7 0965-133-001 1 1 Ignition cabloge

8 263-121-001 1 1 Insulating hose

9 1 1 Cancelled

10 0265-109-000 1 1 Protective cap against rain

W 0265-100-100 1 1 Spark plug connector, partly

suppressed

0960-116-900 1 ' Bush.

0288-091-000 Spark plug connector, 1

suppressed

vk o998-004-001 4 1 Spark plug W175 Ti with SAP

connecting nut

3 1 1 Armature base plate

for BOSCH:0212-112-006

6 165-008-000 1 1 Lubricating pad

17 Oghk-108-000 3° 3 Washer 4. 1x9x1.2

18 O240-106- 100 3 3 Oval head screw M lhctl

19 0265-052-003 1 1 Condenser

20 0265-G77-001 1 1 Connecting cable to condenser

2 983-106-000 1 1 Set of contact breakers

22 0240-066-009 1 1 Bearing pin

23 0283-107=000 1 1 Set of spares for contact

breakers

24 0299-059-009 1 1 Lighting cable quote

25 99-059-016 1 1 Rear light cable required

9299-059-021 Stop light cable length

26 83-009-000 1 1 Short-circuiting cable

27 265-074-000 2 Cable terminal

28 0260-020-000 1 1 Rubber grommet (2 hole)

29 0260=020-005 Rubber grommet (4 hole)

30 0265=159-001 Generating armature with 2

connections (lighting and

stop light ceili

for BOSCH:021

oa o2h7-106-001 Bush 4.3%8x7

32 0265-139-006 Rear light armature

for BOSCH: 02 12-122-006

a3 0246-025-000 Spring ring for M4

ae O240-122-000 Fillister head screw M 4x13

35 O265-113-003 1 1 Generating armature

for BOSCH!0212—112-019

36 02 000 2 2 Fillister head screw

37 0265-142-000 1 1 Ten n armature

for BOSCH:0212-112-019

O212-122-006

38 0-105-000 a Fillister head serew M 4x21

PEDAL SHAFT

TABLE-2

ee

TABLE: 21 PEDAL SHAFT

REF. PO. PART. NO. /1A. /1B DESCRIPT LON

1 O237=106-101 tt Pedal shaft

0285-121-000 1 1 Pedal shaft ass'y with

Fig. 6, 7 and &

2 o285-120-000 4 ot Driver bush assty with

washer brake Lever

3 250-165-000 10 Round sealing ring 19x2

& 0239-051-001 11 Brake spring

5 o252-007-201 +t Driver

6 oz34-106-001 tT Starting wheel

7 og4h-120-002 2 2 Washer 16.2x22x1

8 oghg-020-001 1 4 Cirelip

9 o2h7-149-000 1 1 Bush 16. 3¢2009 62

10 0250-164-000 2 2 Round seating ring 13x13

eee

TABLE=* CARBURETOR

——————SSSSeSeFSFSFSFSFSSSSFSFSFSFSSSFeFseF

CARBURETOR

——

REF. 0. PART. NO. 1A DESCRIPTION

' 281-124-005 1 Carburetor ass'y BING mark

85/12/101 (main jot 52,needle

position 11, needle jet 2,17)

0281-124-000 1 Carburetor ass'y BING mark

85/10/1601 (main jet 50,ne0cdle

position 11, needle jet 2,17)

2 0291-004-000 1 Cable

with solder nipple

No. 0291-003-000 ee teed

4 291-024-001 1 Outer casing, black f 784 h

o291-024-011 1 Outer casing, mgt

silver-coloured

4 0260-024-001 1 Protective cap

5 0261-143-000 1 1 Pipe bend ass'y with 2x hex=

agon nut anc adjusting screw

6 0261-144-000 1 1 Cover plate with fastening

screw

7 250-162-000 1 1 Gasket,

8 239-140-000 1 1 Slide spring

9 0244-109-000 1 1 Washer

° 261-018-000 1 1 Smal1 retaining plate

" 0261-006-003 1 Jet needle, 33 mm long

0261-006-004 1 Jet needle, 36 mm Long

12 0261-146-000 1 1 Throttle valve

0261-148=000 Throttle valve

13 ozh2-110-000 1 1 Cap nut

wh 0962-013-000 2 2 Sealing ring

15 0261-125-000 1 1 Hose connection

16 0281-109-000 1 1 Tickler ass'y with spring and

forelock

7 0962-066-000 1 1 Clamping screw

18 0962-065-000 1 1 Adjusting serew)for throttle

19 0962-065-000 1 1 Spring valve position

20 Carburetor bedy, only

available under Pigs]

2 0250-161-000 1 1 Gasket

Ba 0261-142-000 1 1 Needle jet 2.17

25 O247-145-000 1 Ring (in needle jet)

23 0961-151-000 1 1 Main jet (quote required size)

ah Available only under Fig.25

25 O281-125-000 1 1 Float ass'y with float needle

and pin

26 0261-145-000 1 ' Screening sleeve

27 o261- 1 ' Float chamber

0261-1 Float chamber

28 ozh5-023-000 2 2 Spring ring for M 4

29 0241-028-001 2 2 Fillister head screw

ES

INTAKE SILENCER

ABLE-23

REF. 10,

1

2

x

Bee

12

PM

+ NO,

0291-904-000

0291-02

0250-160-000

0225-007-100

0239-198-000

225-009-000

o244-160-000

2015-007-004

0225-011-000

9225-010-100

0225-008-005

0299-139-000

INTAKE SILENCER

SS

fia

/1B

DECRIPTION

Carburettor ass'y see Fig. 1/1

Cable

with solder nipple | quote

No. 0291-003-000. $ required

Outer casing, | Length

silver-coloured

Round sealing ring Wx1.5

Intake silencer housing

Pressure spring

Starting slide

Shim

Fillister head screw M 5x10

Filter holder

Micronic air filter, intake

16

Intake silencer cap

grey, intake ¢ 16

Stirrup

a7

REPAIR TOOLS AND MOUNTING JIG

18

8

a

46 -

Pert No.

0076 065 108

0077 083.000

0276 023 001

0278 072 005

0276 154.000

0976 135 100

0976 150 005

036 182 000

776 180 002

(276.181 000

0276019 101

0276 175 000

0276 170 000

‘O276 179 000

1476013 000

)476011 000

1440027 OOF

1476012 000

1447 099 000

1476014 002

0976081 000

‘0776 087 000

(0276 085 006

C76 088 005

lapel

‘Gudgeon pin extractor

Inset bush for gudgeen pin extractor

‘Gudgeon pin for piston

Protective slasve bar crankshaft (power

icko-off side)

Protecting cop, bors 10

park edvancé timing gau

Puller tor magnete ipeben M2615

Holding teal Yow clutch

Hook wrench

Pin sponnes, adjustable

Intermediate plo

Revolution count

Torque wyonch *

1476013 000

ing inner dia, 58 men (228°)

Bir grooved boil beoring

ve | spore parts for

Clampini

Poller shel

OWNER TOOL KIT

OWNER Took KIT

r 2 3 4

REPAIR TOOLS

§ 6

—

REF. TO. PART. NO. DESCRIPTION

1 1150-6648 Double end wreeh 14/17 mn

2 1150-6625 Double end wrench 10/12 mm

3 1150-6654 Wrench socket

4 1150-6654 Serew driver "4" & "="

5 115-6664 Wrench for stom cap nub

6 1150-6654 Stem nut locking wrench

=49—

DISMANTLING THE ENGINE

Remave the engine from the frome end clean it

thoroughly before dismantling,

Intoke silencer, carburettor and ialake pipe

Remove the lencer cop (1) and the micro:

nic oir fi frame,

Remove starter slide with contre! cable and prev

sure spring

Unierew carburettor and intake pipe (5). Remave

gasket or gaske!, intermediate flonge and gosket.

Unicrew the jntoke silencer housing (2) only in

ease of neces

Unscrew cover {3} with gorket

Drain the gearbox oil,

Movat the engine

Mount ine [lower part of eronkeoss up-

wards} with 7 hexagon hood screws [1] Mi 8 x 65

ond nuts fo the aouating jig

Cylinder

Unscrew the cylinder ond remove the cylinder

flonge gasket.

Note:

‘The cylinder con be rebored ones, ta be used

the corresponding piston [see Spore Ports, Lie)

When fit jinder oF 9 reconditioned

eylindiar with piston, the colour mock (red or white)

fon ihe piiton crown ond in the intake port of the

cylinder must be of the same colaur,

Fiston and cover

Rernove both wire circlips.

Puth out the gudgesr pin with gudgeon pin ex-

Tevtor ond ner oun (0

Remove the needle cage,

Pry ot the cover (2) or knock it off (use a sgrew-

iver).

Magneto flywheel

Ingert odjvstoble pin spanner, os illustrated, un-

screw the callar aut and cemave the spring washer.

Slip on Hing cop and pull the mognete

tywhael with puller (1

Stator plore

Remave the spark plug connector from the igni-

ion cable, Unscrew 3 cross: head screw (2) wth

woshers, remove the stolor plote ond the Wood:

raff hey (2

Sprocket

Apply the hook wrench [I] with its chain to the

sprocke!, as illustrated, unscrew the nut [2) ond

remove the special washer,

Pull off the sprocket.

Starting ad driving cites

Unhook the torsion spring ()

Unscrow the filster fread screw (4) with, sealing

fing, remove bush (9, chtdh lever (2, with come

tral cable} ond torsion spring,

Remove thrvst cup 5) with thrust pin

-51-

Baars 1

Wide 12

Hold the washer ()} with the halding tol. unsere

the nut (2),

Remove the washer (1), shims {4, Fig. 6), inner and

‘ovier plotes with sprang washers

Remove the clutch hub (I) (if need be, loosen it by

a slight blow).

Remove Woodrulf key, if existing (te be omiited

during rempunting}:

Remave the clutch case {2 with centrifugal wei

CAriing (ah cluich plate underneath it aad) the

check plate.

Remove bush [I] and check plate (2).

Note:

If the bush sticks; pull itoff together with the groo-

ttl beanng fakes endongag the eeosed

boll beoringsh

Spliting the erankease

idler head screws ond remove the

Crankshott ond gearbox

Remove pedal shaft (1), georshalt (2), cover plete

] moinghait [4) and exenkshoft (5)

Unierew the crankcose lower part fram the mount.

Bidttig 3

WORKING ON INDIVIDUAL PARTS

Exchange of crankshaft bearings

Pulling the greoved ball bearings

nd 6) and wosher

ball beonngs (3

shells (9), puller sleeve (7) and clamping ring (Bh

Installation dimensions of crankshaft

S775 mom (2.278 inh.

Thee #5 no need to mecaure the crankcase

Exomple:

Fitting dimension af crankshot!: $775 mm 2275"

Dimension of test and make sure turn signals work well. (Brightness)

11. 1» check if the free play of fr

nt and rear brake is proper

arg brake light ie bright enough.

12, bold cluch lever tightly with left hand and pedal by left

foot. Give the throttle grip @ slight inside turning with

right hand at the same time of pedalling. Engine then started.

Feplace clutch.

13. 1f engine itself is cool, choke lever should be grasped

together with clutch lever so that fuel mixture increasing

jor which is helpful for ensy 3

arting. Replace cheke lever

shen engine is warmed up.

Ce eiaeenneee en pee

Ad_ustment for Drive Chain

Th: tensiow which chain gets is correct when chain itself has

j= ‘em slack at the central point between two spreckets.

Ad lusting process: to loosen rear wheel axle nut, Turn adjuster

nu until Hoth testing mark and socket on adjuster get inte a

line.

Bri kes. Adjusting

Th: free play at the end of front brake lever should be 2-Jom.

In pect frdnt and rear brake every time before you drive the

bile. Adjiet adjuster bolt and nut, if necessary.

Check Spark |Plug 6

acces

Chick spa. 4 plug and if necessary clean carbon & contamination

ar‘und cap an? electrodes area with spark plug cleaner.

Spork gap is normally ©. 5mm-0.6mm.

If insulater is broken, replace a new one.

Drive Chain Lubrication

Th L cation of drive chain will be done depends on fact.

— ~69~

Maintena ice of Battery

1. To ;heck the level of battery electrolytic fluid often.

Fil, with distilled water until it reach the HI

MEST Level

if .ou find battery fluid a

wn below th

LOWEST level.

2, Usig @ gravimeter to test the apecifie qravity of battery

flud. If its spe gravity is less than 1.20 (20°C) ,

the battery should be charged.

3. If he bike will be stored for @ long time, it's suitable

to tismount the battery from the bike and charge once o

mon h.

Whe) the botcom gap of electric channel built up with white

dep sits thav indica

wf the battery will to be of no use.

Battery ( harge

ng efficiency: o.4AH

Cha: ge until the below items are proper.

a) i pecific gravity: 1.26-1.28 (20°C)

b) ‘oltage: 7¥-8¥

Cha ging time: 10-12 hours.

By refe ring the following time table, please have your bike a periodic inspection and

lubricat on so that it can be operated under better condition.

Month of Riding

Clean or adjuat spark plug

Ignit on timige adjust

Clean aiy clean

Adjus. and clean carburetor

Clean of] filter x |x |x

Chain adjusting & lubrication x|x}x] x x

Adjus front & rear brake x

Inspe t front 4 rear brake shoe

Check & adjust bearing ball ef handle

Blect: olytic fluid check x

After :irst 18 months riding, you say do the above umintenance

ow ix months.

T=

Ttem

Diffiieult or no

starting

Eng: ne sudden

ato) during

dei ing

Hare steering

Troubleshooting

Possible Cause

1. Spark plug or ignition system

a) Dirty spark plug Clean

b) Wet spark plug Clean

©) Poor terminal contact Ad just

d) Dirty breaker points Clean

e} Incorrect point gap Ad just

f) Incorrect ignition timing Adjust

g) Faulty ignition coil Replace

h) Condenser short circuit Replace

2. Ne fuel delivery

a) Puel tank vent is clogged

|b) fuel cock encumberred

¢) Fuel pipe clogged with dirt

Dirty spark plug

. Dirty breaker paints

Fuel pipe is clogged

Clogged carburetor fuel jets

Worn or bad steering ball Replace

bearing

Stoering ball race too Adjust to

standard

tightened tenuion

Low tire pressure Pump air

eo required

-72-—

Possible Cause

Brakes do not Brake show wern out Roplaca

2. Brake arm serration flectened | Replace

3. Brake cam vorn out Replace

Turi signal out|1. Turn signal switch

of crder 2) Poor contact of flasher relay | Replace

b) Flasher relay short circuit | Replace

¢) Incerreet wire connection Correct

d) Bad ground return for turn | Repair

signal iteelz. .

©) Battery fuse blown out Roget

2. Bulb

Replace

a) Filament blown out

b) Incarrect ‘voltage Replace

Morr can't work|1. Morn diphragm worn

2. Bad ground return of horn

Replace

Repair

button

3. Poor contact of wire Adjust

Correct

4. Incorrect adjustment

5. Hattery fuse blown out Reset

Head or 1. Bulb tungsten filament blown

light out of out

order 2. Poor contact of switch Repoir

* blown our Reset

Braks light aut |t. Fill

2. Brake switeh out of order Replace

©

Battery fuse blown out

{ Repl

Adjust

4. Poor contact of wire

“1+

E

lectrical, Wiring

ee

>

‘sii

You might also like

- Ηλεκτρονικές κάρτεςDocument4 pagesΗλεκτρονικές κάρτεςthriskeftikaNo ratings yet

- ΑΕΡΙΟΣΤΡΟΒΙΛΟΙDocument254 pagesΑΕΡΙΟΣΤΡΟΒΙΛΟΙEvagelos Mamios100% (1)

- ΣΤΑΥΡΟΣ ΜΑΡΤΙΟΣ 2011Document16 pagesΣΤΑΥΡΟΣ ΜΑΡΤΙΟΣ 2011orfeasfmNo ratings yet

- Promoting unity and orthodoxy in the Greek ChurchDocument4 pagesPromoting unity and orthodoxy in the Greek Churchdimitrios02No ratings yet

- M9Document89 pagesM9dds70100% (1)

- ΕΨΙΛΟΝ DelicatessenDocument11 pagesΕΨΙΛΟΝ DelicatessenElsa -V- Elsarand100% (1)

- I~TOPIA TOY EAAHNIKOY E8NOY2: A Concise History of the Greek PeopleDocument542 pagesI~TOPIA TOY EAAHNIKOY E8NOY2: A Concise History of the Greek Peopleartodys100% (2)

- AEK Athens - Slavia Prague 04.04.1968Document30 pagesAEK Athens - Slavia Prague 04.04.1968Klearchos KapoutsisNo ratings yet

- XAIRONEIADocument88 pagesXAIRONEIAgzapasNo ratings yet

- LeksilogioDocument61 pagesLeksilogiosonyak83100% (2)

- National Geographic 1900-11Document44 pagesNational Geographic 1900-11alkananiNo ratings yet

- Grimal Latino (A-V)Document70 pagesGrimal Latino (A-V)mens_reaNo ratings yet

- NietzscheDocument100 pagesNietzscheMary FilippakouNo ratings yet

- VostokDocument1 pageVostokTiberiu Cristian Papa100% (3)

- Yaesu FT-209 Operating ManualDocument39 pagesYaesu FT-209 Operating ManualYayok S. Anggoro100% (1)

- Sta Ixni Ton TheonDocument197 pagesSta Ixni Ton Theonanet140100% (1)

- Komiks 079 - To Fylaxto Toy AmoyndsenDocument52 pagesKomiks 079 - To Fylaxto Toy AmoyndsenParaskwvi laskouNo ratings yet

- Watch Battery Selection Guide: EnergizerDocument1 pageWatch Battery Selection Guide: Energizerjojo_221No ratings yet

- National Geographic - CyprusDocument50 pagesNational Geographic - Cyprusporfyra_100% (2)

- The Devil's Dictionary IllustratedDocument133 pagesThe Devil's Dictionary IllustratedAntri.AnNo ratings yet

- αυνανισμοςDocument50 pagesαυνανισμοςpaximaderosNo ratings yet

- Making Clocks - Industrial Chemistry & Manufacturing TechnologiesDocument4 pagesMaking Clocks - Industrial Chemistry & Manufacturing Technologieskifatazo0% (1)

- Price ListDocument25 pagesPrice ListVijay BarreyNo ratings yet

- ΚρουμπάχερDocument860 pagesΚρουμπάχερLinda Alexopoulou100% (1)

- Marx-Engels Germaniki Ideologia 1Document416 pagesMarx-Engels Germaniki Ideologia 1Despina DimitriadiNo ratings yet

- Khmer Fashion Magazine 2009Document56 pagesKhmer Fashion Magazine 2009Sophal HuotNo ratings yet

- Κωφός - 1992 - Η μυστική οργάνωση της ΈδεσσαςDocument26 pagesΚωφός - 1992 - Η μυστική οργάνωση της ΈδεσσαςMakedonas AkritasNo ratings yet

- Turkish Story PDFDocument5 pagesTurkish Story PDFfoodprinteuNo ratings yet

- National Geographic 1926-09Document196 pagesNational Geographic 1926-09alkananiNo ratings yet

- 586 Ellhnes Aei EsmenDocument136 pages586 Ellhnes Aei EsmenΤόνοι και Πνεύματα100% (1)

- Donald Rooum-WildcatDocument16 pagesDonald Rooum-WildcatucftaicNo ratings yet

- Dse at 27771112Document82 pagesDse at 27771112it-adminNo ratings yet

- Speedport Entry 2i Maintenance Management EN V 2 1 PDFDocument99 pagesSpeedport Entry 2i Maintenance Management EN V 2 1 PDFNELO2011No ratings yet

- Álftirnar Kvaka PDFDocument1 pageÁlftirnar Kvaka PDFArnór VilbergssonNo ratings yet

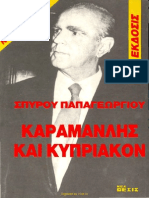

- @ Karamanlis CyprusDocument280 pages@ Karamanlis Cyprusχριστακης χαραλαμπουςNo ratings yet

- ORYKTOLOGIKA NEA-NEWS ON MINERALS, January-February 2016 Issue, Vol. 31, No 181Document28 pagesORYKTOLOGIKA NEA-NEWS ON MINERALS, January-February 2016 Issue, Vol. 31, No 181Dimitris G. MinatidisNo ratings yet

- Aung Gyi Letters To Ne Win in 1988 - 11 PagesDocument11 pagesAung Gyi Letters To Ne Win in 1988 - 11 PagesniknaymanNo ratings yet

- K D80KDocument141 pagesK D80Kmikevlah100% (1)

- Η ΑΧΡΗΜΑΤΗ ΣΥΝΑΛΛΑΓΗ ΤΗΣ ΝΕΑΣ ΕΠΟΧΗΣ ΤΟΥ ΑΝΤΙΧΡΙΣΤΟΥDocument8 pagesΗ ΑΧΡΗΜΑΤΗ ΣΥΝΑΛΛΑΓΗ ΤΗΣ ΝΕΑΣ ΕΠΟΧΗΣ ΤΟΥ ΑΝΤΙΧΡΙΣΤΟΥwestrock6448100% (2)

- Access To English - Getting On (OUP) (OCR)Document145 pagesAccess To English - Getting On (OUP) (OCR)Kemi AlonsoNo ratings yet

- Ειρηνοδικείο Αθηνών 902-2023Document9 pagesΕιρηνοδικείο Αθηνών 902-2023Λεωνίδας ΣτάμοςNo ratings yet

- Tahqeeq e Ahle HadeesDocument91 pagesTahqeeq e Ahle HadeesTariq Mehmood TariqNo ratings yet

- Ειρηνοδικείο Αθηνών 969-2023Document9 pagesΕιρηνοδικείο Αθηνών 969-2023Λεωνίδας ΣτάμοςNo ratings yet

- Wynne's 1755 Field Book - IndexDocument7 pagesWynne's 1755 Field Book - Indexjim6998No ratings yet

- Metamosxeyseis Orthodox Ecclesiastical ViewcDocument14 pagesMetamosxeyseis Orthodox Ecclesiastical ViewcHASSAN AL MASRINo ratings yet

- Isa Ibn Maryam (A.s)Document148 pagesIsa Ibn Maryam (A.s)Nasir AhmadNo ratings yet

- Land Rover Lucas Spare Parts - Series I (1957)Document16 pagesLand Rover Lucas Spare Parts - Series I (1957)Cesar Vacca100% (1)

- NOA Magazine - Origami de Christmas2Document97 pagesNOA Magazine - Origami de Christmas2Budsaya Tungjaidee100% (4)

- Air Forces International 013Document32 pagesAir Forces International 013José Fernandes Dos SantosNo ratings yet

- Scawaii 2010 02Document174 pagesScawaii 2010 02chaudeNo ratings yet

- Lover's Guide To PalmistryDocument47 pagesLover's Guide To Palmistryarsh2750% (1)

- Jarir Bookstore Flayer May 2011Document8 pagesJarir Bookstore Flayer May 2011Aqeela Ali Al-SuwaiketNo ratings yet

- Prospekt Wal-MartDocument12 pagesProspekt Wal-MarteoicoNo ratings yet

- Inventions, Researches and Writings of TeslaDocument324 pagesInventions, Researches and Writings of Teslaokowrygo100% (2)

- Paramount MTCDocument5 pagesParamount MTCLarson Dominic D SouzaNo ratings yet

- Gothic Lolita Bible 4Document100 pagesGothic Lolita Bible 4Zona Cosplay50% (2)

- Bead AccessoriesDocument83 pagesBead Accessoriesanyt77100% (5)

- Manual Tester Hansen FNDocument31 pagesManual Tester Hansen FNpwargentina100% (4)

- Psycho Social Occupational Therapy - A Clinical Practice by Elizabeth Cara - Anne MacRaeDocument78 pagesPsycho Social Occupational Therapy - A Clinical Practice by Elizabeth Cara - Anne MacRaeVAHIDKHEIRKHAHNo ratings yet