Professional Documents

Culture Documents

Elasticna Spojnica Litostroj

Uploaded by

Dudás Árpád0 ratings0% found this document useful (0 votes)

467 views8 pagesThe coupling is designed for torque transmissions and for connection between engines and apparatus. The shape and the flexibility of rubber packings allow angular dellection i.e. A determined axial displacement.

Original Description:

Original Title

Elasticna spojnica Litostroj

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe coupling is designed for torque transmissions and for connection between engines and apparatus. The shape and the flexibility of rubber packings allow angular dellection i.e. A determined axial displacement.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

467 views8 pagesElasticna Spojnica Litostroj

Uploaded by

Dudás ÁrpádThe coupling is designed for torque transmissions and for connection between engines and apparatus. The shape and the flexibility of rubber packings allow angular dellection i.e. A determined axial displacement.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

‘e-np-2.1,1973

ELEMENT!

ELEMENTS

ELASTICNE SKLOPKE

4 Elastiéna sklopka je namenjena 20 prenos vtiinegs momenta ter za po

verevo strojev in napray.

Polovici sklopk sta si po obliki in izvedbi razigni, Prednji del 1 slu2i 2a

prttditey sornikov, del 2 pa za vsaditev gumijastih viobkov.

in povezana 2 mozniki all zagozdami.

Oba dela sta nasajona na gr

Deli so popolnoma obdelan’ in dinamiéno izteditéeni, Za normalne po-

tgoje obretovanja 80 sklopke izdolane iz materiala CL, 20 (Modificrana

Tiina) mex ustreza hitrosti 36 m/sek za imenske prem

2a tedje obratovaine pogoje in vetje obodne hitrosti so sklonke izdelane

os i 7 iz eklene litine CL. 0600.

Pr cestovjenja al raesavjanu stroje ai gr poveben ost razr

ere saterdemontata sorikev 2 gumjasim vies. Zradh matetala

‘Qumnestage votke se sme elostiGna skionka uporabliat v sURer pro

Siar (raku) do temperature oka 70°C. v vlainem prosoru pa do

Qe core.

Obi gumjestoga vodka in elasténost doputtat Kotno elastinost

fdroma dolatan prem ob

Shtopla ni preautdana zo pronaianjonikakrénih sn sil ter jo lahko

Sporabmo za be cmt vtenja (avo, desno).

klopka mora bit ko pee vidajtena

FLEXIBLE COUPLINGS

‘The coupling is designed for torque transmissions and for connection

between engines and apparatus.

‘The coupling halves differ in shape and design, Part 1 is forward, serving

for fastening of bolts, and part 2 for insertion of rubber packings. Both

ports are helved on the shaft and connected with dowel pins or wedges.

Coupling parts are entirely machined and dynamically balanced. Coup

lings. designed for normal operation conditions, are made of material

CL. 20. (modified cast); max corresponds to the peripheral speed

[36 m/sec for rated diameters.

‘Couplings designed for heavier operation conditions and greater per

pheral speeds, are made of cast steel CL. 0600.

Its not necessary to mave the axis away when dismantling engines

fr shafts but only to screw out the bolts and the rubber packings. Due

to material used for rubber packings the floxible coupling may be used

lup to 70°C atmospheric temperature in dry conditions and up to 80°C

in wet conditions.

‘The shape and the flexibility of rubber packings allow angular deflection

ie a determined axial displacement.

‘The coupling is not designed to withstand any axial forces and may

be used for both ditections of rotation (sight, left).

‘The coupling has to be embedded close by the hub.

wr

evasTi¢Na skLorKa ES ELASTIONA SKLoPKA ESZ ——zavorni KoLut ZK

FLEXIBLE COUPLING FLEXIBLE COUPLING BRAKE DISC

JUS M.C1S15 JUS M.C1 56

PROSPERT - LEAFLET 644

LTOSTROD

NOSILNOST IN IZBOR ELASTICNE SKLOPKE

BEARING CAPACITY AND TYPE OF FLEXIBLE COUPLING

TABELA NOSILNOSTI

TABLE OF BEARING

CAPACITIES

ing Veiout phe ES — Si of coving ES

imi] 9 100 130 | 160 | 200.1 250° 290360 00.450" 60D 550 | 620 710. 850, 950]

Nauvna mot (W] — Rao copii 17

vo, | osssae eae] oh] a) SS SS

Ha) aes [89° GI ats 8) B18 | 8

18] Goer 8h, BA Ge i) 8) 8B a8

PLE OH oda | 88e BB) 8 BR

1g | o0ss)o1s | 925 | ose! 22) 59. 79. 100/130

1S | Sa9e 848 | 83° | o58) BS B19) 18

Bo | 8868 O48 | Bas | Se Be 8 Ute

a] O48 Sa" 357 | BF B58 woo Ho 188

25 [orss|o28 [oa | ae | 78 130. 199. 200

BY Oie 852 B45 | tas Bl) Bue 8 Be

Hs] ory os gar | 13 ae | $5 143 Me Jen

80°] 823 8 865 | V5 S| 138, 193) 398. $80

4g Jo25 [a4 075 | 20] 25 | 140, 200 299

TEHNICNI PODATKI Bp faze oe Zz, Tr | 185 220 | 300.

POTREBNI ZA 1Z60R [ey ge O58 de & | 178 Ho) 3

ELASTICNE SKLOPKE 20 | oe Se ee

11 [ozs (oes 115) 29 top | 220 215 220

Mot N w [kW] 7 | oa woH M9 | 249 $30 S50,

Veto nv Coir) [ete Se 14 | 1 | 39, 389. $0

rae 8 8s me 48 | Bb 3

Odgonski stro, 190 | 0.50 18 4 350 | 300) 490 900.

Faktor dinamiérih obreme i yas 9° 48 | ds $55 | 323, 33, 988

La epee ty Bee i | 3e0| 820, Jeo

i for 33 2s | 88 300 | 83,830. oo8

wo Joss 15 25 | es | 220 | g00| 700 1000

/88 oR 388 | #o| Bo son

Mepis ie de 383 | O83) Boo 185

TECHNICAL DATA Ep yo 39 8 283 | Sao seen 3300

REQUIRED: 250 135 [23 | 4 to_|te | 39 | 5a 71 170 | 480 250 350| 780/100 1550

OF FLEXIBLE CO we pis 3° 58°) |B a Ne ae So | Big ee

OF FLEXIBLE COUPLING =| 235 [32 [37 BB tas | 29 | 88 | 2 088 31538300 | saa | 1280 toes 80

Capacity N in (kW) +

aso J2s 14, 48 38829, [70 [ios 120 | amp | azo ss0 | sso | 1400 2000 2000

‘Speed nin [r.p.m) 500 28 [45 #8 20 | 425 | 76 [115 150 | 350 350 600 710 | 1850 2200 3000 |

Driving engine Ee ee

Die anie SB Pbs $8 8 BGS [88 TS | aaa | Ste eke | So 1200 3000 3000

Factor of dynamic stresses no Jae las 1s | 20 | as hoo hes (210 [ago |so0 | 210 1000 2200 2150 aaoo

refi G2 We RS Re A Be so SS 2s 1008. 3599 555 seo

Mets fe PAR A hh Ste Gio 1185 Zap aetp Stoy —

Soo fs? 28 18338 do 3 (fed | 25s | G85 Sto Heo Geoo soon

100 56 19 16 | 40 65 [155 [230 | 280 | 80 | 710 1000 1500 3000,

sae JES 19 18 SF HSS RSH SR ask AaB Aas Soy SS

fa [82 Hf 38 $3 (AM aso Sao Gea | on 4380 2

ease JSS 33 SSS RD 8D 888 BRT? S{S:=|=

soo Js is 22 | 5 100 [250 [79 [99.100 —}-|-l-]-

W188 HB BG fi MR se = = -

soso fas 18 a3 183 (BBR [tg =

eso fio? as ar 3 de |B 888 |S é =

200 fias a2 [40 [100 [160 foo | — | hex =f=l=l=

sico f° ze 8 18 18 88 |= |= |= |=

aio fe a (ts ssf y= |= = | =lE}=]=

foo fa 8) Gees || 2 |s/eje|= 5

age ie fe [= |= |= |= l= [ElEl=z aE

Stoo fo gs = = |= |2 |= |- =

see |= = |= f= ft = -

jas fio Sea = =|t

ES : = =|=/=|=

PRIMER:

Inbor elastiéne sklopke 2a pogon mlina cementa, med eloktitnim moteriom in zobnigkim prenosnikom.

N=220kW, n=950min!, pog.stroj — el, motor, odg. stro] — mlin cements, f=1,5.

Ni=N-f —Ni=230-1,5=345, izberemo sklopko E5-400.

EXAMPLE

Selection of @ flexible coupling, placed between the

N=230kW,

Ny

lecttic motor and the gear transmission, for the cement mill drive

15.

150 r.pem, Driving engine — electric motor, Driven engine — cement mill,

sf N,=230-1.5=345, the coupling ES-400 is chosen,

FAKTOR DINAMICNIH OBREMENITEV

FACTOR OF DYNAMIC STRESSES

ODGONSK! STROJ — DRIVEN ENGINE

POGONSKI STAI

ENAKOMEREN POGON — ZELO MAJHEN ZAGONSKI

MOMENT

UNIFORM OPERATION — VERY SMALL ACCELERATION

Transmisiie, adprti zobni8ki prenosi. generator, ventilator, cen.

tefagaine éxpalke.

Transmissions, open gear transmissions, generators, fans, centr

fugal pumps...

ENAKOMEREN POGON — MAJHEN ZAGONSKI MOMENT

UNIFORM OPERATION — SMALL ACCELERATION,

Elevator), ventilator), transporter tekstini stroj, orodni stro

Elevators fans, conveyors textile mils, machine tools

NEENAKOMEREN POGON — SREDNJI ZAGONSKI

MOMENT

NONUNIFORM OPERATION — MEDIUM ACCELERATION

Viti, dvigala, brusiini stoi. vitlve peei. stioji za obdelave lesa,

Aranspertni trakovi, sine Skatjo, olovator

Winches, hoisting devices, grinding machines, rotary kilns, wood

working machines, belt convayors, machine scissors, elevators.

NEENAKOMEREN POGON — SREDN4JI ZAGONSKI

MOMENT, UDARCI

NONUNIFORM OPERATION — MEDIUM ACCELERATION,

SHOCKS

Osebna dvigala, mlini 22 cement, metalci comenta, centrifuge,

drobilnice, sto} za abdelavo kovin

Passenger lifts, coment mille, coment stireets, hydroextractors:

breaking machines, metal working machines.

NEENAKOMEREN POGON — VELIK ZAGONSKI MOMENT.

MOeNI UDaRC!

NONUNIFORM OPERATION — GREAT ACCELERATION

HEAVY SHOCKS

Stiskalnice, kovake stiskalnice, batne txpalke 2 2amasnjaki. ko-

vvatka Kladiva, pogonsk: mehanizmi za bagre, valjarski stoji 20

Svinec, min cementa (na krogle), udaeni mini

Presses, forging presses. piston pumps with fiywhesls, forge

hamme's, dredger driving mechanisms, lead rolling mis, ball

cement mil hammer mill

NEENAKOMEREN POGON — VELIK ZAGONSKIMOMENT,

ZELO MOCNI UDARCI

NONUNIFORM OPERATION — GREAT ACCELERATION, |

VERY HEAVY SHOCKS

Varlnk aareaati, valjarski strait 2a gum, batni Kompresoni batne|

Grpalke, siskalnice 22 opeko, vallarski siroji za jeklo, stvojt za}

sekanje lesa

Welding generators, rubber toling mills, piston compressors

piston pumps, brick prosses, ste! rolling mills, woodcutting ma

chines

ee ie

éé@@é@é é@

\V posameznih primerih je faktor dinamiénin obremenite ofe lahko tudi vedji, kot je predviden,

The factor of dynamic stresses“ may in special cases excoed the rated value.

TEHNICNI PODATKI — DIMENZIJE

TECHNICAL DATA — DIMENSIONS.

Elastigna sklopka ES Elastitna sklooka ESZ

Flexible coupling ES Flexible coupling ESZ

TEHNICNI PODATKI

TECHNICAL DATA

Yee = ioe | | Nt vet ma 2

SHE Meiact sa PEER) wg Sea] | Sita) | Scan

5 eee 0° oesan'numwer wend ZK Nominal 60" Deon inter Wowi GO* Desi’ mumbor

al an soe cen ene

i cu

am kom 1.200600 komt [L.20 9600

focesz 526 7600 none a1a07 ar9000

Jocesz, 9 a0 oo1s orm ot

ores 16 $300 0007 07a, oa

(027 313087 s1a016 5

oss 088) 17 10

126 | Oost 6 | 6500

veo | sors 30 | 430

200 | 00205, 20 | 3400

2500030 | 32 2800

315 | ape 63 | 2150

003 a1s189 Sian

os tsi) aes

Joss 404300 «0.182074. caa| 18

27) 089) 018 20

I

_

28) v2! 14a 10

| 18

Joes 63400 ons) 078 cal

43 i

Joass 180 | 2700 120 076 0080

Jo2s0 225 2380 255 077) 008 _ 60

Joes | z0s_| 1900 6 07a) 007120

Joss 670 | 1700, 118 79, 00m _175,

074 050/ or

za ont on

yea

tse 188

35) 188) 146 00

400 028 | 1251700

soo | 0289 | 250 1380 18147

Jo72 700 1500 205 080, 009) 20

j10s 1000 1350| 300 | 081 10 320

431400 1200/ 605 082 on 410

310 50001100 110, 08a, 12.625,

jsa8 4250 s80 1965 | ont 013, 80

tre, 280

tsa) 40) a0

(6000 2003705 | 088 O14) 1250

'a000 700 6355 obs O18 1680

4a

1. MoE N (AW), vray m (min)

2. Vetlaji nous ustrexajo obodni hivost! 36 m/sek, 24 pramer D in material CL. 20 (modi

Itine CL. 0600 je dopustna obodna hitost do 56 misek,

3. Sklopke na zalogi so izdelane za najmanjSi 4, dj v toleranci H7 brez utora 2a moznik

4. Stovilka risbe je Stevilka sestavnega naérta TP dokumentacije (TP ~ tipski proizvod.)

irana ltina), 2a iavedbo iz jekla ali iz jeklene

sa

Zavorni kolut 2K

POSEBNE |ZVEDBE

SPECIAL DESIGNS

Lahke invedba

Light design

Heavy design

Brake ise ZK

Proklopna iavedba YVarnostna iavedba

Se SIONS ‘Changeable design Safety design

Toe ering |

es D D om ]o Ll & h bh b c b by e

Vette

0 mew T

1 1) 00 | 138 so va [ie

1 40 20— 40) 130 152 | 152 90 2

2-50 25-56, two | 200 a0 ww | 137 wo | 7m) | 2 | |

25-00 32-7) 200 | 250100 | 115 | 212 | 217 | 20 | eo | 06 2 | 3 | as oo

30-70 38-80 250 | 315 120140 zea | ao | 120 | 120 0 § | 66 | 70) BO

3590 60-100, 290 400160 | 170 | sz | 1 | wo os | | 70 | ep

50-100, ss-110| 360 | — | 170 | 190 | ot | — | — | 4 | | | |

e110 66-126] 400) 500 190 220 | 35 | 408 m1 | 5 | ow | m0

69-125 0-140] 450 — 22080 | ats) 190, 5% | 110

80-140, 90-160| so 620250) 28085 | IS 20 | 0s) mo | 0

go-160 100-170 | 60 | 710 280 | 300 | 535 | 360 wo | 265 | sa oo | 110

fio iso rr0te0| exo | — 900 | a20 | smo | — ao | — 8) #0 wo) ¥0

40-200 40-200/ 10 — ano | ano | 2a so | — 8 | wo | wo) 10 |

ee ee so 8 td) nao 70

fvo—2sa 190-260] 960 | — 480) ago | man | ao | — | 8 0 | 40170

1. Output N (KW), speed n (1-p.m).

2. Speed finax corresponds to the peripheral speed 36micec, diameter D and to the material CL. 20. The peripheral speed up 10

‘56 misec is allowed for designs of stoel or cast steel CL. 0600.

3. Couplings in stock ate dasigned for minimum d, d,, within allowance H7, without notch for the dowel pin,

44. The design number is the number of drawing included in TP: document

jon (TP = standard product).

MERE ZA MOZNIK IN ZAGOZDO

DIMENSIONS FOR DOWEL PIN AND WEDGE

Bene ond 72 [17 [22] 90) 58 GE] 110 [190 160) 190, B00, TaD) 26D

Shar wz 20/8] a4 26 110 [130150 [170 209/ 230260 700

Dongipn | Simeon 2) 20) a2 )90 | 40 46

doe | van Hoon h 910 tt s4[ ts [18 20 | 22) 25| 26| a2 2

‘Younk — Bowe pin w 55/62/68 a7| 99114 129 l138 1531 17/193. 196

Zineuda —Woat” | odsopek — Deviion | +01 +02 +08

0 [> Jo|o|o Jo jojo > Jo) 0/0 o ojo|o ololo

foznk— Dowel pin t\22 20 3 |aa|s2 a0 |39|42 (47/66, s4| 6231 39. 87 99 114 129) 128

‘dstopek— Devin on “ea on

© e/a[olejo|o|o o|o|o

dager tne | ao[ae| as sa| 6s] do] 32) 30 100 1181 1158

Opa = Bavinion +02 +08

DOLZINA — LENGTH

= 7 bone CH] WO] oO] ton [eo ras [vad | 00] eo

Betton 20 410 140160 140 200 220 [aso 1200 315 [385400 400 [400 | 200-1 $00

Dente 12] 16 20] 25] 32 149 143 (59/55 [63 170 00] sv] 100 10 Tas ToT —

ie core Pas 6 [70 [soli fan'en” 190 bon 220 00 200 (705 965 400 doo sco 1400 | — dg

1. Odstopek na firino utora v pest je 2a trdnispoj P8, 20 chlepri 1. Deviations of hub notch width, for steady joint P9, for loose

$00) J8. joint J3.

2. Odstopek na firino v pasta za zagazdo 010. 2. Deviations of hub noteh width for wedge 010.

3. Vina she predsteviia navi del zagozde, prav tako mera t, 3. Height representing the highest Dert of the wedge, value ty

naj del ttora the highest part of the notch.

So

ay

NY

6a

Moznik Zagorda

Bowel pin US M.C2.060 Weago JUS M.C2.020

MERE ZA VGRADNJO »SGu OBROCA

DIMENSIONS FOR INSTALLATION OF “SG RING

Pana geai Nad Over [woe] w] os | Be HO ao Tee

Shatter oto so {se 65 75) 65

| *|>

Lo 10 [922 [34

@[e[t0|s0

De a |e

ho

16

12

Le laa! aol a6 se | so |

prostrezati osne sile in

v navpitni teal.

ASG" ting is placed

SSkica vgradnje

Sketch of installation

Varovanje sklopke na osi ali gredi 2 »SGx obrofem uporabliame takrat, ko. moramo

Zelimo sklopko zaverovati proti osnim pomikem, toda vedno Ze

between the coupling and the axle or the shaft 10 secure the

coupling against the forces acting on the axle and against axial movements, but

always in the vertical position.

Mere v mm

Dimensions in mm

SKLOPNI ELEMENT — SESTAVNI DELI

COUPLING ELEMENT — COMPONENT PARTS

‘Sklopni element :

Coupling element

PREGLED ELEMENTOV

REVIEW OF ELEMENTS,

ovstng

US M.c2.090

Steiabe Tass

300325

130/160

13006

Mio, 75 ‘13067

m6 120

11 118 99

Mag 259 245 185 60 12070

wus 6.60020

de /da| Rh | Tote

wos

+—

29 19 14) 80 2 0.001

on we 003

20 78 50.200 115 ott

STEVILO SKLOPNIH ELEMENTOV ZA

NUMBER OF COUPLING ELEMENTS

SKLOPKO

FOR THE COUPLING

ES

Esz

100 | 190 | 160 | 200

|

— | res | 160 | 200 280

Savio kara

Reiter ces

318 | 400

72

PRI PONUDBI ALI NAROCILU NAVESTI SLEDECE

PODATKE

Oznsko al ivedbo sklopke — zavornoga koluta

Ivrtino za del tin del 2

Utor za maznik, zagozdo

Pogonski in odgonski stroj

Moe (kW)

Veta n (mint)

Po potrebi, 2a posabne invedbe, skico all nagrt

3. Temperatura okolia

2a ES2 — in 2K zavorni moment

WHEN INQUIRING OR ORDERING, CITE THE

FOLLOWING DATA

« Mark or dosign of coupling — brake dise

9 Driling d for part + and part 2

5: Narches for dowel pin or wedge

Driving and driven engine.

Output (kW)

Speed (rpm)

Other requirements, for spacial designs, designs or drawings

Atmosphere temperature.

. Torque for ESZ— and ZK — couplings

VGRADNJA IN MONTAZA

INSTALLATION AND ASSEMBLY

DOVOLJENE NAPAKE PRI MONTAZI

ALLOWED DEVIATIONS AT ASSEMBLY

as Site of causing

bas 290-560

560-980 2

POTREBNO ORODJE ZA MONTAZO

REQUIRED ASSEMBLY TOOLS JUS 95.055 US K.95.053

Vaunwnon ES] 2 100, wo] ww too) aso m0] avo] sco] oso 600 om | emo, io emo 0

Tovmeszy” esz | 125 | 150 | 200 260 15 400 | soo | eo =) =

Zev huts — Gop ot key

LUTOSTROJ LJUBLJANA « TELEFON 66.012 + TELEPRINTER 31-100 » POSTM PREDAL: 308

EL TPO BOR

TTELERRONe

[EKONOM. PROF. LITOSTROJA » DESIGN PAHOR, LITOSTROJ + NATISNILA TISKARNA LJUDSKE PRAVICE V LJUBLJANI 8

x0

You might also like

- NPT, Nps & - ThreadsDocument3 pagesNPT, Nps & - ThreadsklashincoviskyNo ratings yet

- Ba12318 en GTW 1040Document37 pagesBa12318 en GTW 1040Jose Antonio Aguilaniedo BistuerNo ratings yet

- Wheel Model 6 CatalogDocument40 pagesWheel Model 6 CatalogHernan LopezNo ratings yet

- Pipe ThreadsDocument2 pagesPipe Threadsehab2003yeNo ratings yet

- National Pipe Thread Chart OPT P PDFDocument1 pageNational Pipe Thread Chart OPT P PDFRoselio MayoNo ratings yet

- Din 1480 2005Document6 pagesDin 1480 2005PacoNo ratings yet

- Round Washers SN 808: July 2000Document1 pageRound Washers SN 808: July 2000Maurício Duarte de AndradeNo ratings yet

- Parts list for industrial gearbox assemblyDocument4 pagesParts list for industrial gearbox assemblyrestu yanuar salamNo ratings yet

- Prirubnice I Prirubnički SetoviDocument26 pagesPrirubnice I Prirubnički SetovisinisamaticNo ratings yet

- NPT Pipe Thread Sizes and TapersDocument1 pageNPT Pipe Thread Sizes and TapersRajesh J BharadwajNo ratings yet

- Bearing SU004Document8 pagesBearing SU004Rashid AliNo ratings yet

- Filter Bound CatalogDocument248 pagesFilter Bound CatalogDenis JimenezNo ratings yet

- SENTRON LV36 Complete English 2014Document284 pagesSENTRON LV36 Complete English 2014charlonNo ratings yet

- PBL Series K CatalougeDocument117 pagesPBL Series K CatalougeankitkanujiyaNo ratings yet

- 100 R137 AD6 RS ProductData en DEDocument1 page100 R137 AD6 RS ProductData en DEJielyn San MiguelNo ratings yet

- NavojiDocument193 pagesNavojianon_419810527No ratings yet

- Parallel Key Calculation According To DIN 6892Document21 pagesParallel Key Calculation According To DIN 6892zahirshah1436923No ratings yet

- АрилјеМетал CatalogDocument10 pagesАрилјеМетал CatalogAnonymous DjWqKpZ1No ratings yet

- HVATACDocument2 pagesHVATACHrvatski strelicarski savezNo ratings yet

- Synchronous Belt Drives - Automotive PulleysDocument14 pagesSynchronous Belt Drives - Automotive Pulleystv-locNo ratings yet

- ISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsDocument4 pagesISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsViswanathan SrkNo ratings yet

- Section Q: Splined Hubs, Drive KitsDocument8 pagesSection Q: Splined Hubs, Drive KitshaggNo ratings yet

- Ansi B1 20 3 17Document1 pageAnsi B1 20 3 17Kristian Raphael BVNo ratings yet

- Is 4009.1981 Grease NippleDocument9 pagesIs 4009.1981 Grease NippleBhuvanessh RcNo ratings yet

- Root fillet failure analysis of spline shaftDocument34 pagesRoot fillet failure analysis of spline shaftKishore MylavarapuNo ratings yet

- Fenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyDocument3 pagesFenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyPankaj Pandey100% (1)

- Metric DIN Hydraulic Fittings and Threads Chart & DimensionsDocument3 pagesMetric DIN Hydraulic Fittings and Threads Chart & DimensionsTiago SucupiraNo ratings yet

- High-tensile steel wire braid hydraulic hosesDocument1 pageHigh-tensile steel wire braid hydraulic hosesANANPE1976No ratings yet

- Honing Machine Actuated by ServomotorDocument45 pagesHoning Machine Actuated by ServomotorNissan PatelNo ratings yet

- Hardened steel pins and weightsDocument1 pageHardened steel pins and weightsSachin JawaleNo ratings yet

- Aerospace Standard: Hose Assembly, Polytetrafluoroethylene, Metallic Reinforced, 3000 Psi, 400 °F, Heavyweight, HydraulicDocument5 pagesAerospace Standard: Hose Assembly, Polytetrafluoroethylene, Metallic Reinforced, 3000 Psi, 400 °F, Heavyweight, HydraulicRangaNo ratings yet

- KAT-A 2014-EA RIKO-EA Edition11 04-12-2012 ENDocument7 pagesKAT-A 2014-EA RIKO-EA Edition11 04-12-2012 ENpalanaruvaNo ratings yet

- ISO Metric Coarse Thread and Tapping Drill Size ChartDocument9 pagesISO Metric Coarse Thread and Tapping Drill Size Charthisaj4uNo ratings yet

- Durbal Bearings CatalogDocument36 pagesDurbal Bearings Cataloga042050% (1)

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- Thread Standard BSPDocument7 pagesThread Standard BSPĐạt TrầnNo ratings yet

- As 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionDocument6 pagesAs 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionSAI Global - APACNo ratings yet

- White Paper DIN FittingsDocument7 pagesWhite Paper DIN FittingsSiddhant JoglekarNo ratings yet

- SKF Erp 2014Document92 pagesSKF Erp 2014Telimo ChauhanNo ratings yet

- Sibre Crane Wheel SystemsDocument13 pagesSibre Crane Wheel SystemsZehNo ratings yet

- STI 463 ModelDocument1 pageSTI 463 Modelਗਗਨ ਜੋਤNo ratings yet

- Joh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290Document6 pagesJoh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290vuthanhNo ratings yet

- SN756 2005-02 eDocument4 pagesSN756 2005-02 eChristopher Lloyd100% (1)

- Equalent Material GradesDocument16 pagesEqualent Material GradesLesle GpNo ratings yet

- Kat A 1331 Lug Cerex300 L Wasser en 03 12Document6 pagesKat A 1331 Lug Cerex300 L Wasser en 03 12Sathishkumar DhamodaranNo ratings yet

- Complete Range of PTFE Fittings For Smooth Bore & Convoluted HoseDocument7 pagesComplete Range of PTFE Fittings For Smooth Bore & Convoluted HoseRasheshNo ratings yet

- Sist en 13104 2009 A2 2014Document12 pagesSist en 13104 2009 A2 2014Юрий КостенкоNo ratings yet

- 20 INV SPL. 2.50 MOD 20 PA 22F01113 HB IND. 55x50x MM (PART - ModelDocument1 page20 INV SPL. 2.50 MOD 20 PA 22F01113 HB IND. 55x50x MM (PART - Modelhb IndustriesNo ratings yet

- WFA Hose FittingsDocument0 pagesWFA Hose Fittingsedhy_03No ratings yet

- 1DIN 6921-10.9 Hex Flange Bo.Document2 pages1DIN 6921-10.9 Hex Flange Bo.Sunil BaliNo ratings yet

- 4 Inch Stub CycloneDocument2 pages4 Inch Stub CycloneTobias De Somer100% (1)

- Metalarm HH-10 Control UnitsDocument6 pagesMetalarm HH-10 Control UnitsDanielSantosNo ratings yet

- Calculation of Gear Dimensions - KHK Gears PDFDocument25 pagesCalculation of Gear Dimensions - KHK Gears PDFlawlawNo ratings yet

- Sae J343-2010 PDFDocument9 pagesSae J343-2010 PDFRavichandran DNo ratings yet

- Oring PDFDocument225 pagesOring PDFmartin.rubenNo ratings yet

- 2010 Catalogue AndertonDocument47 pages2010 Catalogue Andertonaiyubi2100% (1)

- Method For Combining Valves With Symmetric and Asymmetric Cylinders For Hydraulic Systems PDFDocument15 pagesMethod For Combining Valves With Symmetric and Asymmetric Cylinders For Hydraulic Systems PDFRichard De Medeiros CastroNo ratings yet

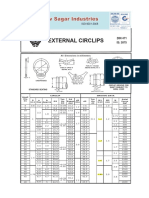

- External CirclipDocument2 pagesExternal CirclipDivyang MistryNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet