Professional Documents

Culture Documents

SS Data

Uploaded by

robertino000 ratings0% found this document useful (0 votes)

15 views2 pagesStainless Steel Data Designation System for Stainless Steel (ISO 3506 1979) Composition Groups Identification of steel grades austenitic A1, A2, A4 50 70 80 Martensitic C1, C4 C3 50 70 80 Hardened Hardened Cold-HighSoft Soft Cold-Worked Soft and Worked Strength Tempered Ferritic F1 45 60 Stainless Steel properties Extract from DIN 267 Part 11 - Chemical Composition of austenitic chromium-nickels steels

Original Description:

Original Title

SS data

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStainless Steel Data Designation System for Stainless Steel (ISO 3506 1979) Composition Groups Identification of steel grades austenitic A1, A2, A4 50 70 80 Martensitic C1, C4 C3 50 70 80 Hardened Hardened Cold-HighSoft Soft Cold-Worked Soft and Worked Strength Tempered Ferritic F1 45 60 Stainless Steel properties Extract from DIN 267 Part 11 - Chemical Composition of austenitic chromium-nickels steels

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views2 pagesSS Data

Uploaded by

robertino00Stainless Steel Data Designation System for Stainless Steel (ISO 3506 1979) Composition Groups Identification of steel grades austenitic A1, A2, A4 50 70 80 Martensitic C1, C4 C3 50 70 80 Hardened Hardened Cold-HighSoft Soft Cold-Worked Soft and Worked Strength Tempered Ferritic F1 45 60 Stainless Steel properties Extract from DIN 267 Part 11 - Chemical Composition of austenitic chromium-nickels steels

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

Stainless Steel Data

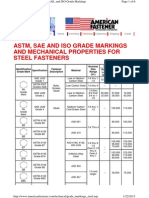

Designation System for Stainless Steel (ISO 3506 1979)

Composition Groups Identification of Steel Grades Property Class Austenitic A1, A2, A4 50 70 80 Martensitic C1, C4 C3 50 70 80 Hardened Hardened Cold- HighSoft Soft Cold-Worked Soft and and Worked Strength Tempered Tempered Ferritic F1 45 60

Stainless Steel Properties

Extract from DIN 267 Part 11 - Chemical Composition of austenitic chromium-nickels steels in % by weight Austenitic Material C Si Mn P S Cr Mo Ni Grade No. to AISI A1 303 0.12 1.0 2.0 0.20 0.15 to 0.35 17.0 to 19.0 0.6 8.0 to 10.0 A2 304 0.08 1.0 2.0 0.05 0.03 17.0 to 20.0 8.0 to 13.0 A4 316 0.08 1.0 2.0 0.05 0.03 16.0 to 18.5 2.0 to 3.0 10.0 to 14.4 Maximum values unless otherwise stated. Types A2 and A4 may contain up to a maximum of 4% copper. The selection of steel grades within a group is the prerogative of the manufacturer, unless the purchaser has specified particular steels to ISO or national standards.

Different grades of steel may be used as long as all physical and mechanical properties and the corresponding corrosion resistance of the finished product are achieved. Only when all these conditions are fulfilled may finished articles be marked in accordance with DIN 267 Part 11.

Mechanical Properties-Austenitic Grades

Bolts, Screws and Studs Property Grade Class A2 and A4 70 80 Tensile Strength Yield Stress Elongation AL Proof Load Stress Rm MPa Rp 0.2 Mpa Diameter Range Minimum Sp Mpa (N/mm2) minimum (N/mm2) minimum (N/mm2) minimum 700 450 0.4d 700 =<M20 800 600 0.3d 800 =<M20

You might also like

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarNo ratings yet

- Aços Comp Aços Inox Torques (A1, A2, A4)Document3 pagesAços Comp Aços Inox Torques (A1, A2, A4)Paulo Henrique NascimentoNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- ASME Specification For Fastener MaterialsDocument11 pagesASME Specification For Fastener MaterialsAnonymous IwqK1Nl100% (1)

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- MPAPS A-37 - Stainless-Heat Resistant Steels and Finish RequirementsDocument18 pagesMPAPS A-37 - Stainless-Heat Resistant Steels and Finish RequirementsPANKAJ CHAUHANNo ratings yet

- SS 316 & SS316LDocument3 pagesSS 316 & SS316LVijayakumar AtthuluriNo ratings yet

- Stainless Steel Data - Fuller Metric Parts LTDDocument3 pagesStainless Steel Data - Fuller Metric Parts LTDchitopeNo ratings yet

- Astm A194Document3 pagesAstm A194poerwntiNo ratings yet

- Section2 04Document16 pagesSection2 04swainpiyush123No ratings yet

- Stainless Steel Data PDFDocument4 pagesStainless Steel Data PDFRobert SumińskiNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- BoltsDocument6 pagesBoltsJuragan IwalNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings Bolt SpecificationDocument8 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings Bolt Specificationamir_hossein858No ratings yet

- ASTM A320: GradesDocument1 pageASTM A320: Gradesmaryam KAHRIZINo ratings yet

- StainlessSteelData (GERPAAS)Document4 pagesStainlessSteelData (GERPAAS)ilovemould100% (1)

- Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceDocument4 pagesSeamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceAlejandro GonzálezNo ratings yet

- Stud Bolt Specification 2Document7 pagesStud Bolt Specification 2santoshblonkarNo ratings yet

- 3506 - 1e Stainless Screw StandardDocument26 pages3506 - 1e Stainless Screw StandardTuncay KAMAŞNo ratings yet

- Aisi 4140 En8 En19Document1 pageAisi 4140 En8 En19Jose KurianNo ratings yet

- Bolts & Nuts SpecificationDocument7 pagesBolts & Nuts Specificationpattanaik_munaNo ratings yet

- A2 Vs A4 Stainless Steel BoltsDocument3 pagesA2 Vs A4 Stainless Steel BoltsmamahsenNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- Astm A193 - Nuts and BoltsDocument5 pagesAstm A193 - Nuts and BoltsgarrybieberNo ratings yet

- A 635Document10 pagesA 635Gustavo Suarez100% (2)

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- Marcação Parafusos PDFDocument5 pagesMarcação Parafusos PDFpank7210100% (1)

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- UNS R30006 Steel GradesDocument3 pagesUNS R30006 Steel GradesRatnakar PatilNo ratings yet

- Kapitel 02 DINO Techn TeilDocument8 pagesKapitel 02 DINO Techn TeilBoulHich BoulHichNo ratings yet

- Astm 193Document2 pagesAstm 193Nilesh TadhaNo ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- Basic Rules For Stainless Steel SpecificationDocument9 pagesBasic Rules For Stainless Steel SpecificationmutemuNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- ASTM A194 - Portland BoltDocument3 pagesASTM A194 - Portland BoltJonathan DouglasNo ratings yet

- Mild Steel SpecificationDocument1 pageMild Steel SpecificationSteinol SolutionsNo ratings yet

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Document3 pagesFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsNo ratings yet

- G-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Document7 pagesG-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Prince Ali50% (2)

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersNabil RamehNo ratings yet

- EN 10152 Grade DC01Document3 pagesEN 10152 Grade DC01Vanesh KumarNo ratings yet

- Aisi 347 CaracteristicasDocument2 pagesAisi 347 CaracteristicasdcarunchioNo ratings yet

- minfm31548-DIN-17177 Grade St42.8Document2 pagesminfm31548-DIN-17177 Grade St42.8ravi guptaNo ratings yet

- Bolts and Nuts Stainless SteelDocument2 pagesBolts and Nuts Stainless SteelfedemochileroNo ratings yet

- Stainless Steel Data - Fuller Metric Parts LTDDocument4 pagesStainless Steel Data - Fuller Metric Parts LTDAmith sathyanarayan k rNo ratings yet

- Steel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Document2 pagesSteel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Akhi IsMailNo ratings yet

- Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDocument20 pagesElectric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingMohamad ShafeyNo ratings yet

- A 732 - A732M - 02 Equivalencia Ic AstmDocument8 pagesA 732 - A732M - 02 Equivalencia Ic AstmorivaldopenaNo ratings yet

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaNo ratings yet

- SAE L6, Steel Grades, Tool SteelDocument1 pageSAE L6, Steel Grades, Tool SteelMayur12345dt0% (1)

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryNo ratings yet

- A227A227M-06 (2011) Standard Specification For Steel Wire, Cold-Drawn For Mechanical SpringsDocument4 pagesA227A227M-06 (2011) Standard Specification For Steel Wire, Cold-Drawn For Mechanical Springstjt4779No ratings yet

- Final SS Specification 18 12 2020Document10 pagesFinal SS Specification 18 12 2020Amit NG AmitNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet